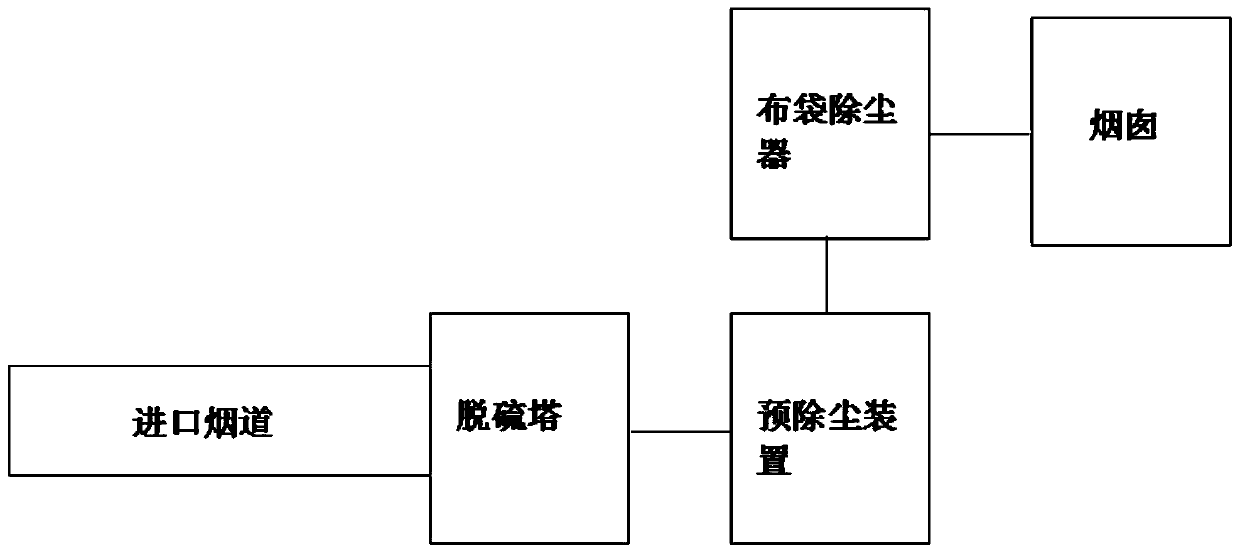

Fluidized bed semi-drying desulfurization system and method

A desulfurization system and fluidized bed technology, applied in the field of fluidized bed semi-dry desulfurization systems, can solve the problems of unfavorable pre-dust removal device dust removal efficiency, poor pre-dust removal device dust removal performance, etc., and achieve enhanced dust removal effect and better operation performance. Best, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

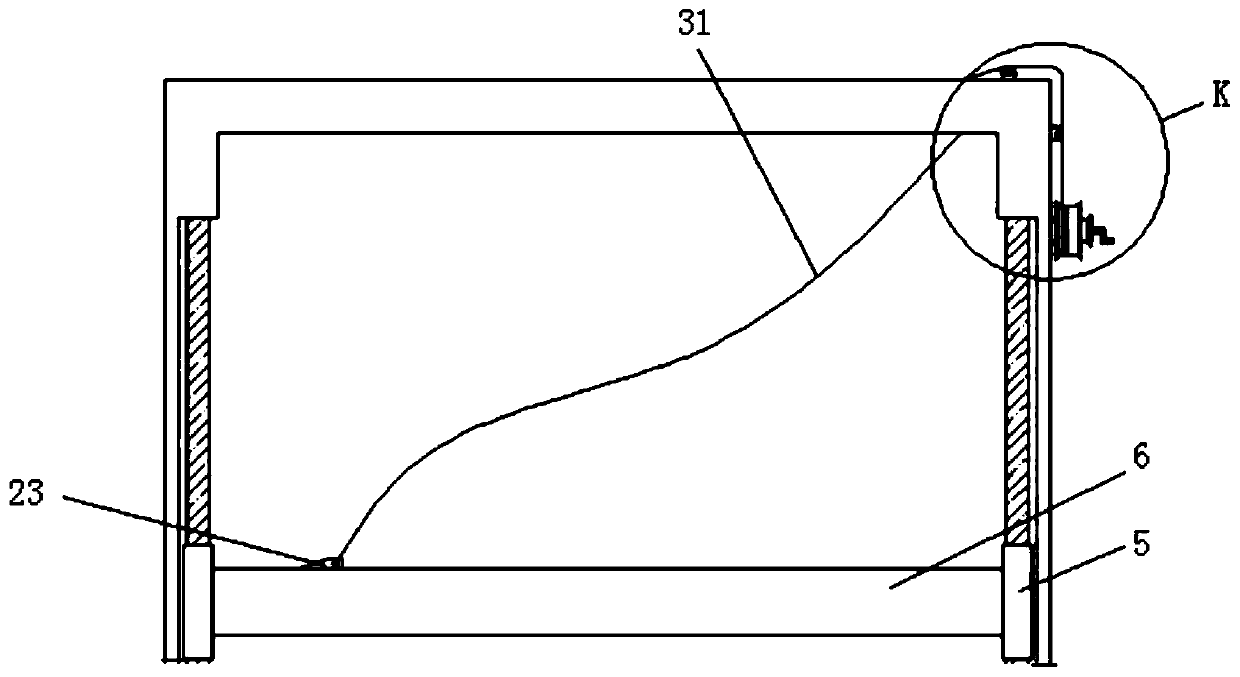

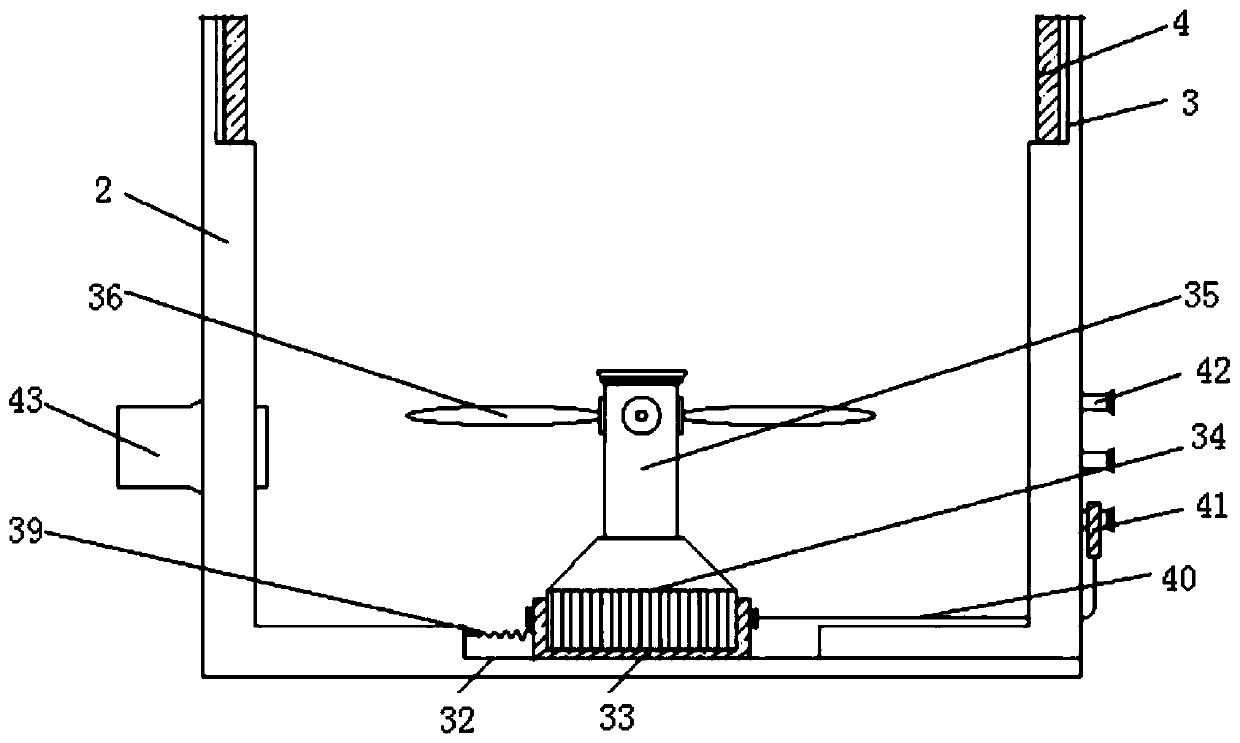

[0037] Such as Figure 1-Figure 6As shown, the fluidized bed semi-dry desulfurization system includes a pre-dust removal device connected with a desulfurization tower and a bag filter; the pre-dust removal device includes a hollow shell 2, and both sides of the inner surface of the hollow shell 2 are Guide rails 3 are provided, the number of the guide rails 3 is a pair, and the vertical center line of the hollow shell 2 is used as a mirror image line to mirror the distribution between the other pair of guide rails 3, and the inner surface of the guide rails 3 Both the upper end and the lower end are fixedly connected with the guide column 4 by welding, and the upper end of the guide column 4 is provided with a ring-shaped guide plate 5, and the other pair of guide plates 5 are fixedly connected with a disc-shaped disc-shaped body. 6. The upper end of the disc-shaped body 6 is sequentially provided with an insertion port 22, a cylindrical opening 7 and a cuboid opening 8 from o...

Embodiment 2

[0039] Fluidized bed semi-dry desulfurization system, including a pre-dust removal device connected with a desulfurization tower and a bag filter; the pre-dust removal device includes a hollow shell 2, and guide rails are provided on both sides of the inner surface of the hollow shell 2 3. The number of the guide rails 3 is a pair, and the other pair of guide rails 3 are distributed in a mirror image with the vertical center line of the hollow shell 2 serving as a mirror line. The upper and lower ends of the inner surface of the guide rails 3 All are fixedly connected with the guide column 4 by welding, the upper sleeve of the guide column 4 is provided with a ring-shaped guide plate 5, and the other pair of guide plates 5 are fixedly connected with a disc-shaped disc-shaped body 6, so The upper end of the disc-shaped body 6 is sequentially provided with an insertion port 22 , a cylindrical opening 7 and a cuboid opening 8 from one side to the other. The cylindrical opening 7 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com