Movable oil drum label silk-screen printing device

A screen printing device and mobile technology, which is applied in screen printing machines, printing machines, printing machines, etc., can solve the problems of difficult cleaning of silk screen labels and high technical requirements for workers, and achieve the effect of convenient use, low technical requirements, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

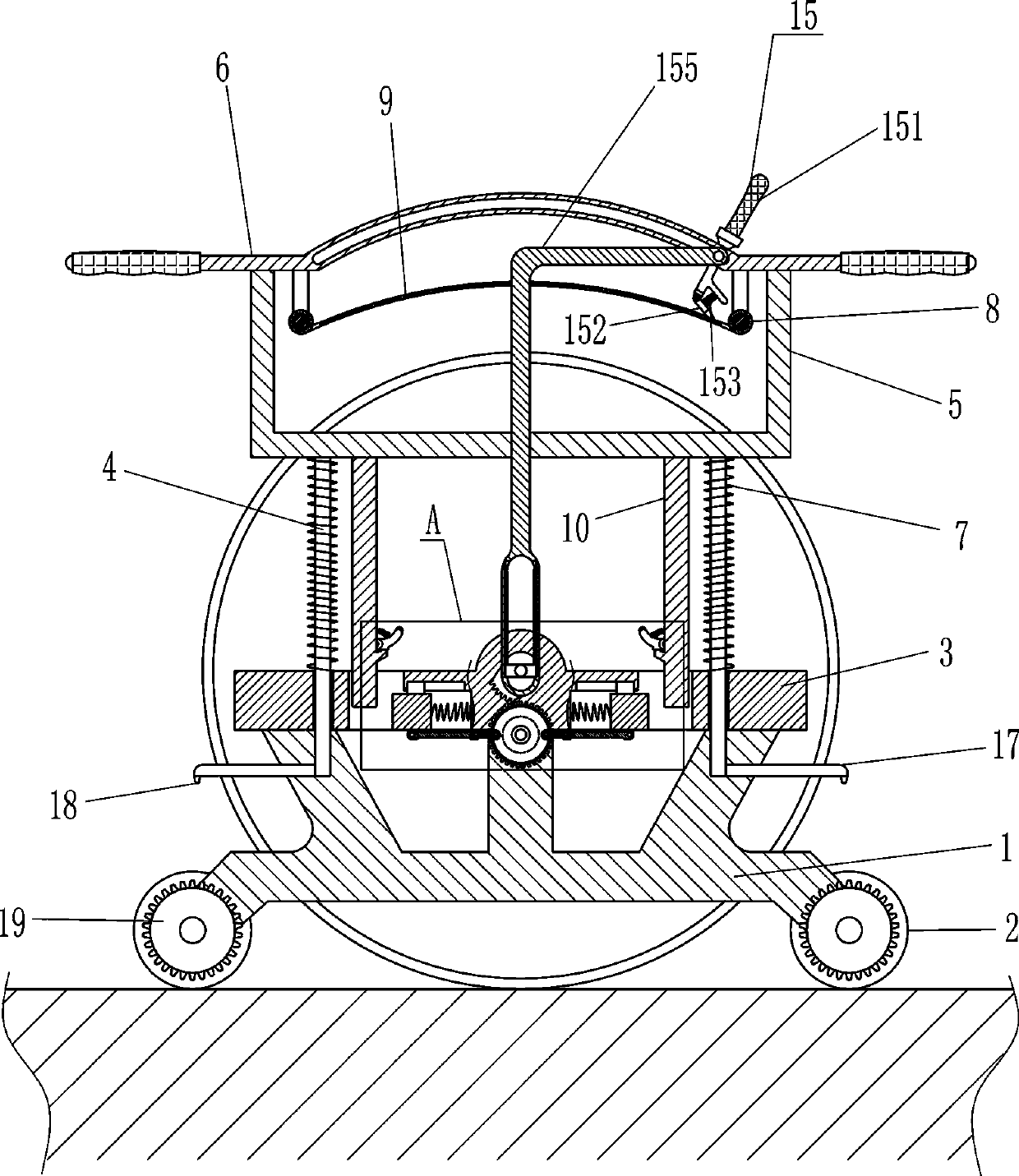

[0017] Such as Figure 1-2 As shown, a movable oil drum label screen printing device includes a connecting frame 1, a walking wheel 2, a mounting plate 3, a guide rod 4 and a mounting frame 5, the bottom of the connecting frame 1 is rotatably provided with a traveling wheel 2, and the connecting frame 1 There is a mounting plate 3 on the top, the mounting plate 3 is set horizontally, through holes are opened on the left and right sides of the mounting plate 3, guide rods 4 are slidingly provided on both sides of the mounting plate 3, and the two through holes are located on both sides Between the guide rods 4, a mounting frame 5 is arranged between the tops of the two guide rods 4, the mounting frame 5 is U-shaped, and also includes an arc-shaped guide plate 6, an elastic member 7, a fixed rod 8, an arc-shaped silk screen printing plate 9, Connecting rod 10, clamping rod 11, first spring 12, slide block 13, second spring 14 and stamp assembly 15, mounting frame 5 tops are prov...

Embodiment 2

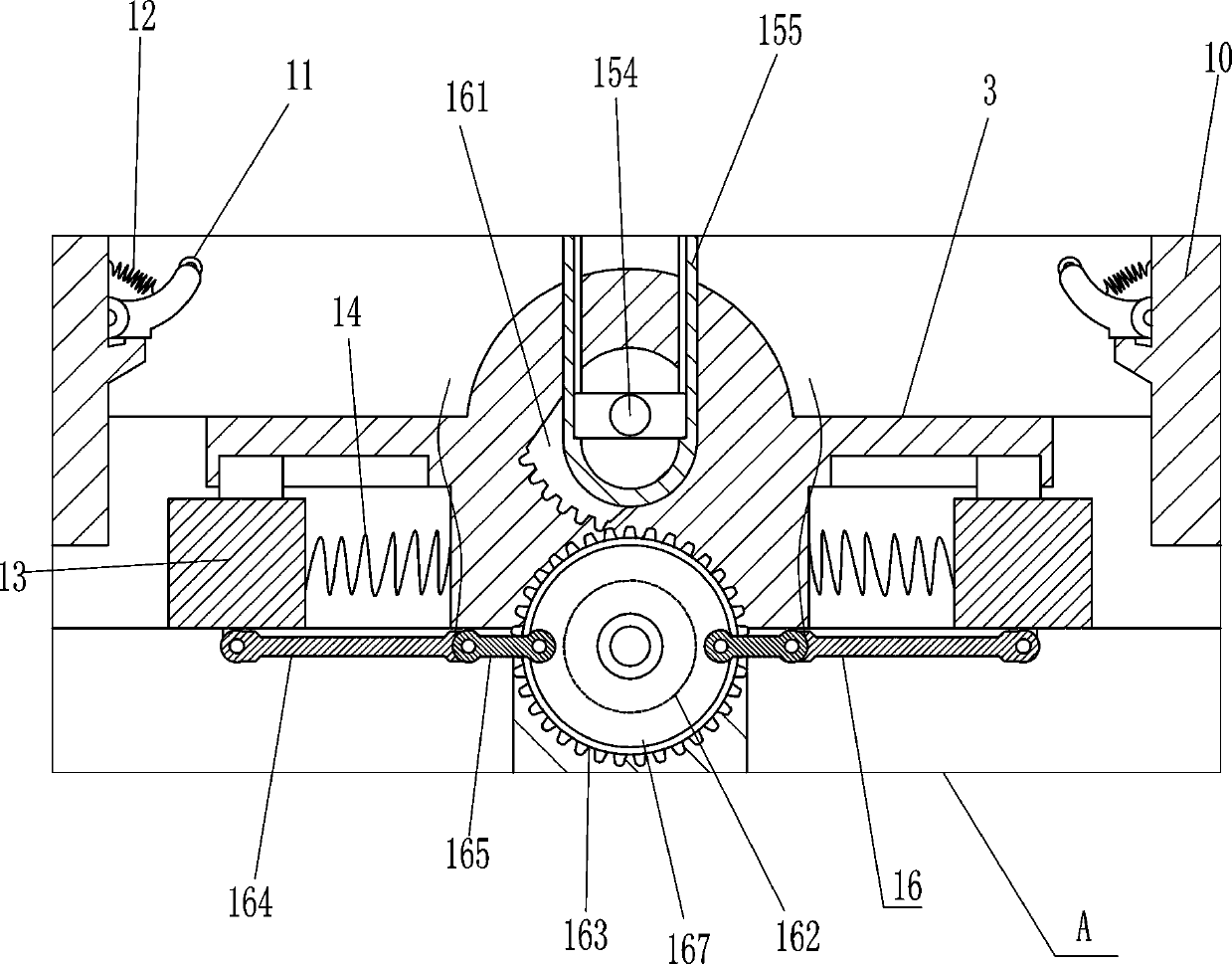

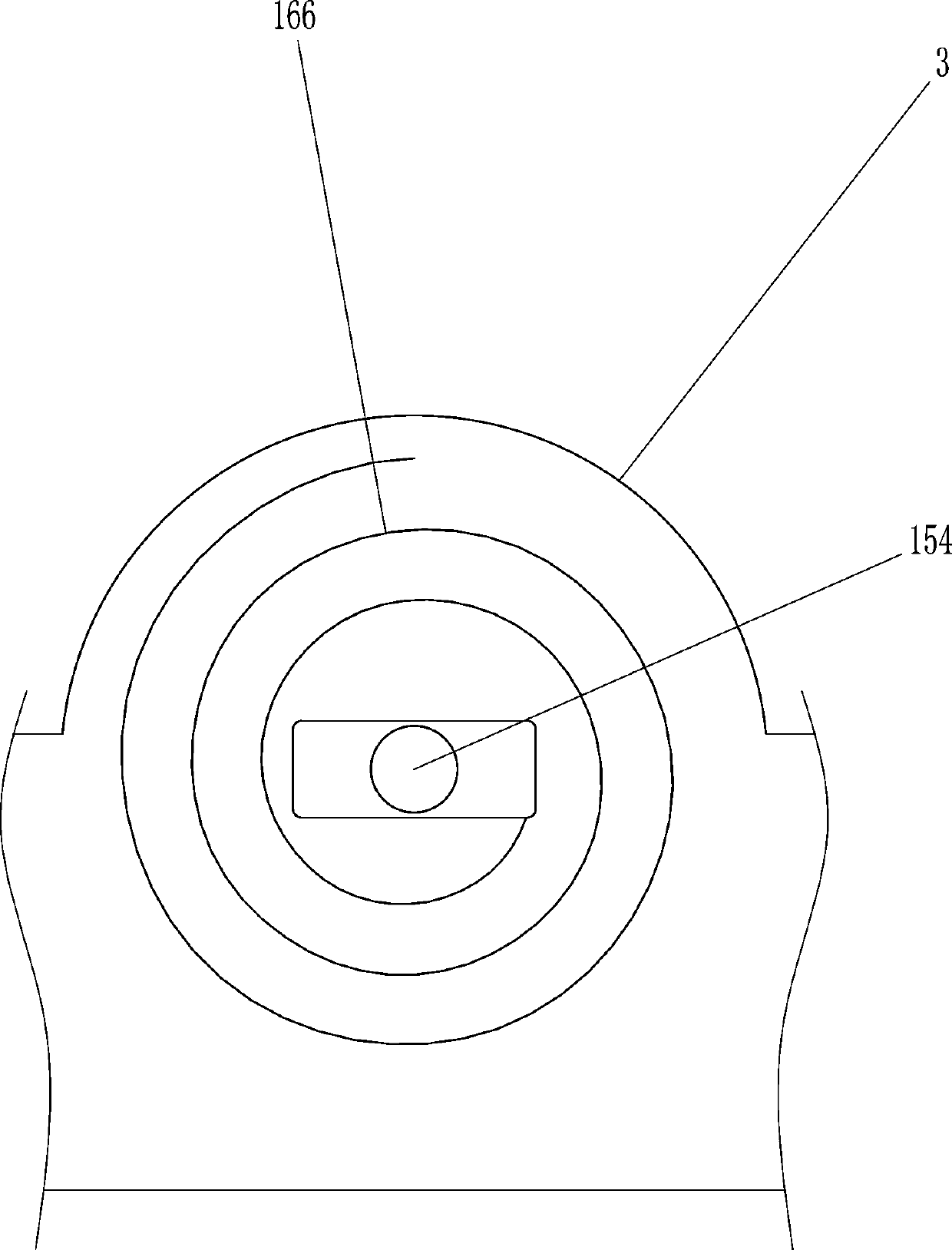

[0022] Such as Figure 2-3 As shown, an automatic reset assembly 16 is also included, and the automatic reset assembly 16 includes a sector gear 161, a one-way clutch 162, a first gear 163, a first connecting rod 164, a second connecting rod 165, a scroll spring 166 and a turntable 167 , the middle part of the rotating shaft 154 is provided with a sector gear 161, the sector gear 161 is connected with the rotating shaft 154 through an interference connection, the upper middle of the connecting frame 1 is provided with a rotating rod, and the rotating rod is located directly below the sector gear 161, and the rotating rod passes through The way the bearing seat is connected is connected with the connecting frame 1, the middle part of the rotating rod is provided with a one-way clutch 162, the one-way clutch 162 is provided with a first gear 163, the first gear 163 meshes with the sector gear 161, and the front end of the rotating rod is provided with a turntable 167, the eccent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com