New energy automobile motor stator enameled wire paint remover

A technology for new energy vehicles and motor stators, which is applied in motor generator connectors, vehicle connectors, circuit/collector parts, etc. To the hands of the staff and other problems, to achieve the effect of high work efficiency and prevent rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

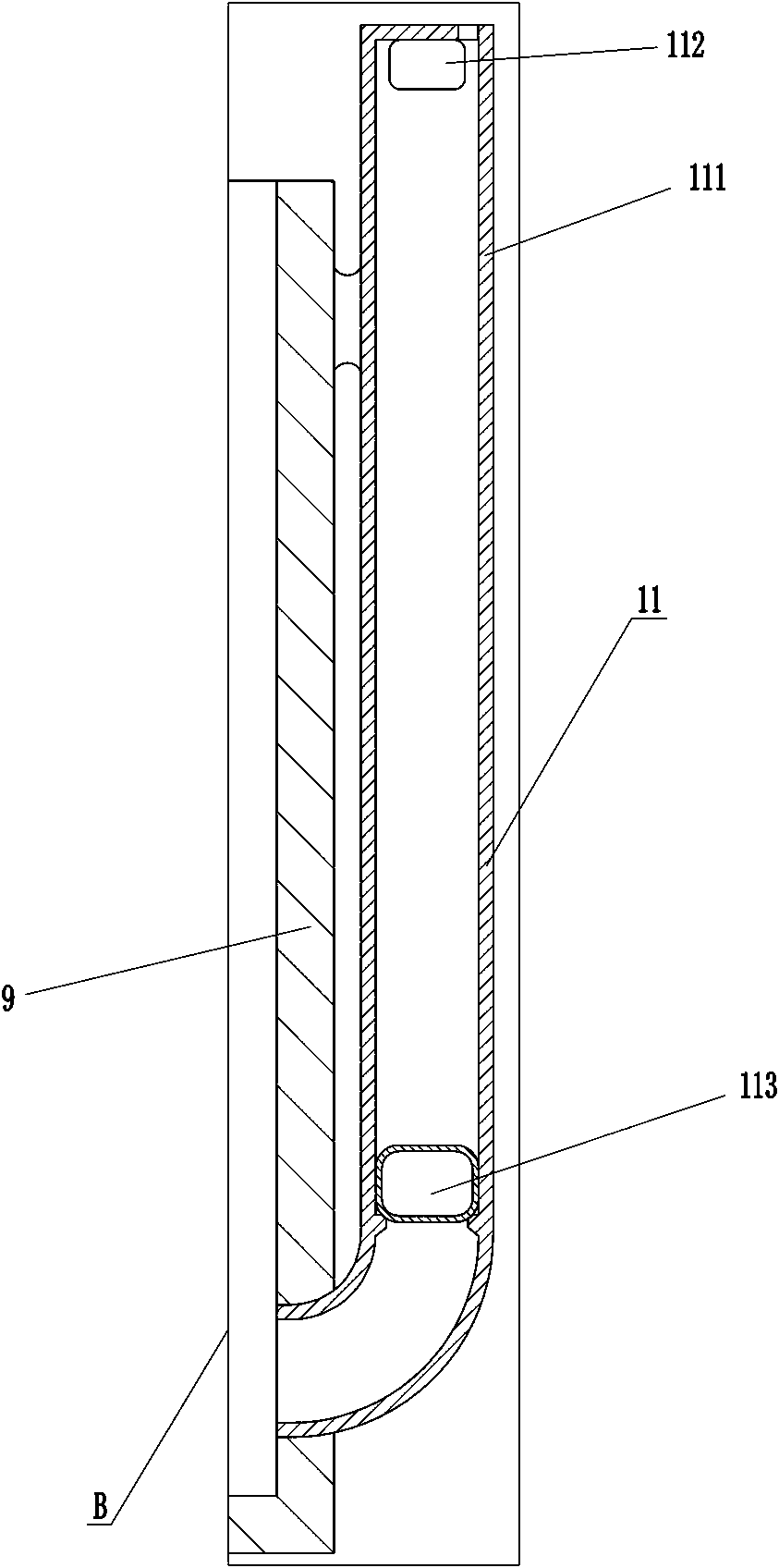

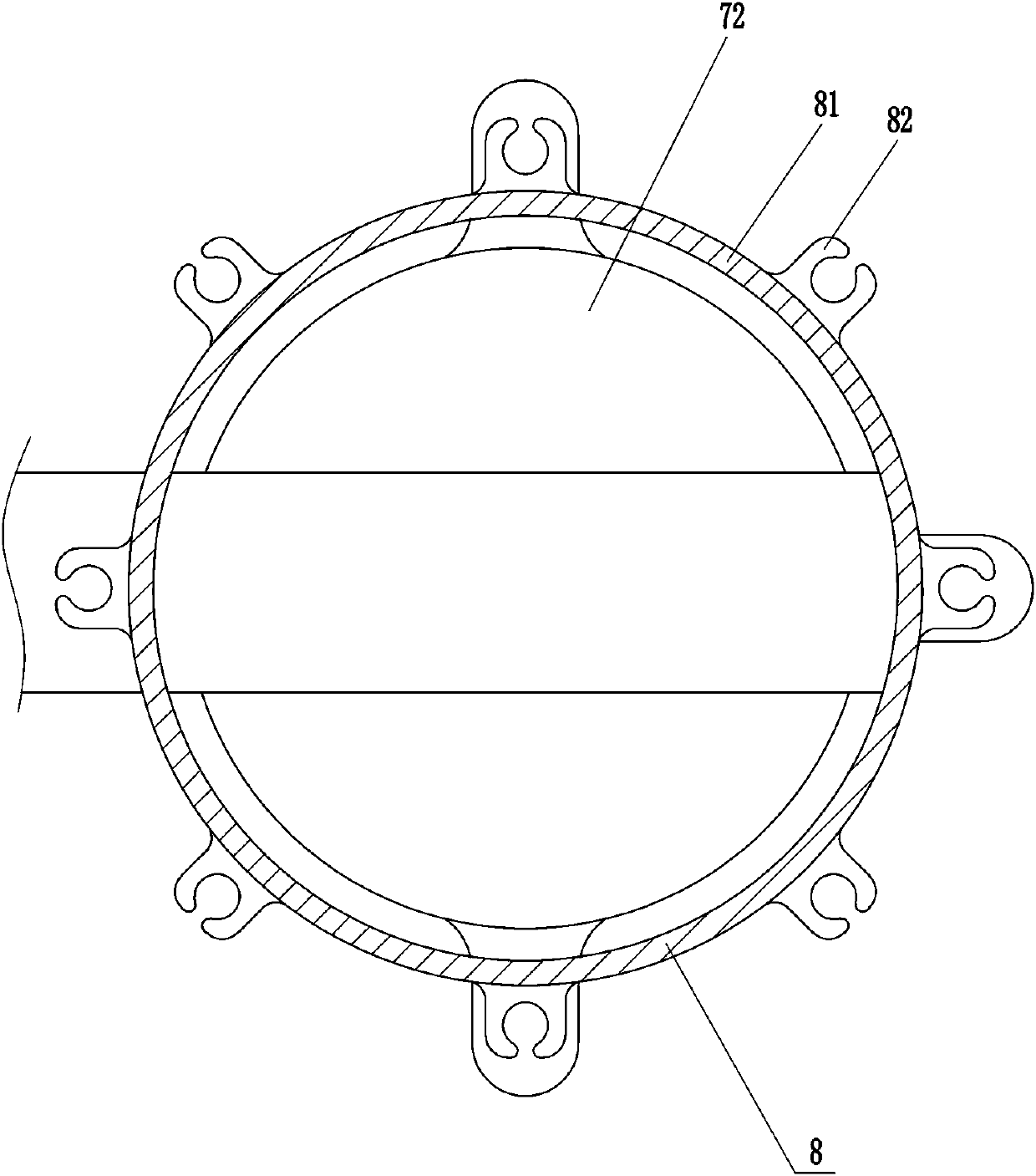

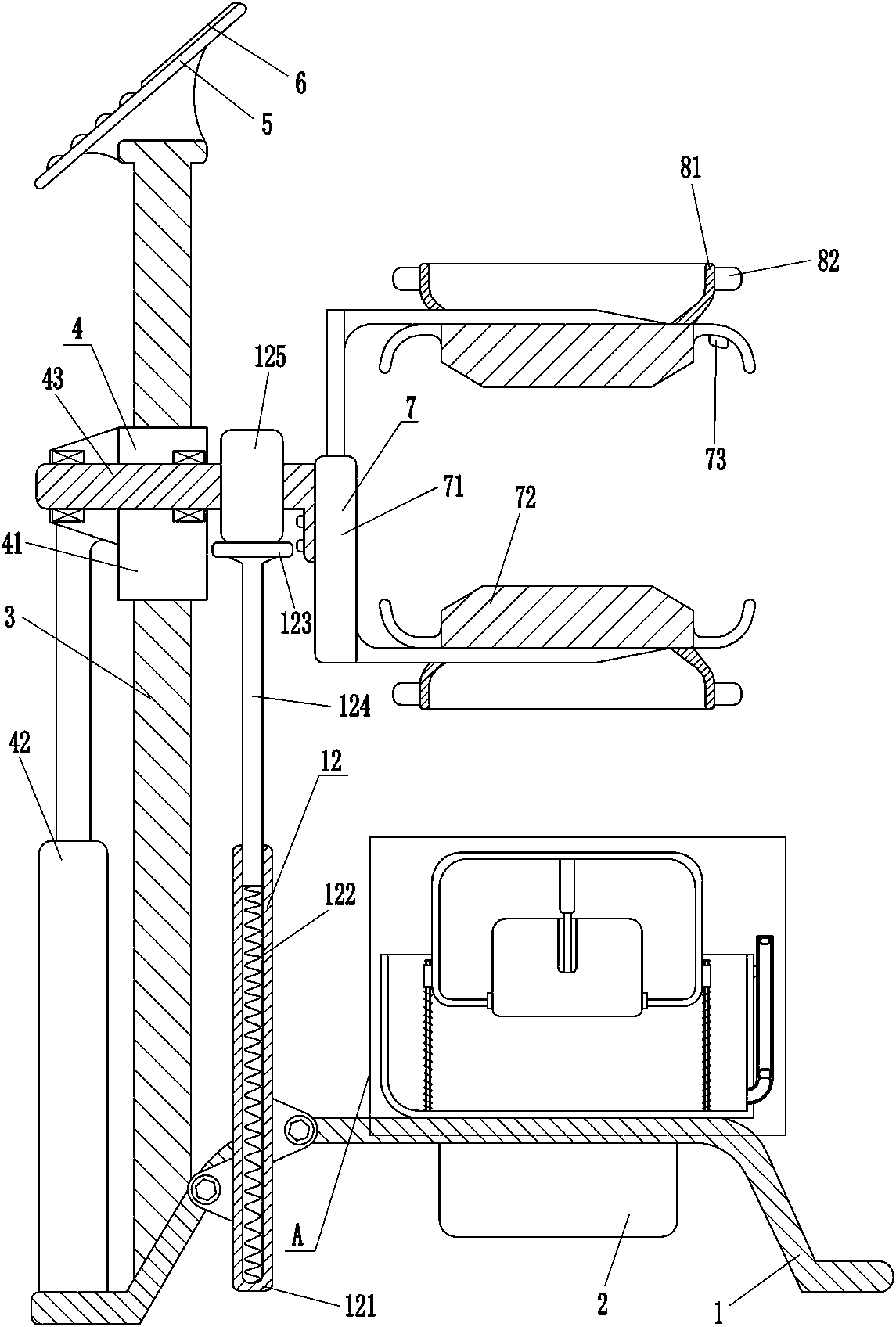

[0025] A new energy automobile motor stator enameled wire paint remover, such as figure 1 As shown, it includes a base 1, a pillar 3, a lifting mechanism 4, a clamping mechanism 7, a fixing mechanism 8, and a frame body 9. The left side of the top of the base 1 is fixed with a pillar 3, and the base 1 is connected to the pillar 3 by bolts. , the pillar 3 is provided with a lifting mechanism 4, the lifting mechanism 4 is used to drive the motor stator to move up and down, the lifting mechanism 4 is provided with a clamping mechanism 7, the clamping mechanism 7 is used to clamp the motor stator, and the clamping mechanism 7 is provided with There is a fixing mechanism 8, which is used to fix the terminal of the enameled wire, and a frame body 9 is arranged on the right side of the top of the base 1.

[0026] Such as figure 1 , Figure 5 with Image 6 Shown, also include control module, LCD display screen 6, setting key, plus one key, minus one key and confirmation key, LCD di...

Embodiment 2

[0035] On the basis of Example 1, such as image 3 As shown, a liquid level adjustment mechanism 10 is also included, and the liquid level adjustment mechanism 10 includes a slide bar 101, a first spring 102, a sliding sleeve 103, a box body 104, a filling block 105 and a third electric push rod 106, and the frame body 9 Slide bars 101 that play a guiding role are installed on the left and right sides of the inner bottom, and each slide bar 101 is slidably provided with a sliding sleeve 103, and a first spring 102 is connected between the sliding sleeve 103 and the inner bottom of the frame body 9. A spring 102 is wound on the sliding rod 101, and the box body 104 is connected between the sliding sleeves 103 on the left and right sides. The third electric push rod 106 is installed on the top of the box body 104, and the third electric push rod 106 is connected by bolts. Connected with the box body 104 , the bottom end of the third electric push rod 106 is connected with a fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com