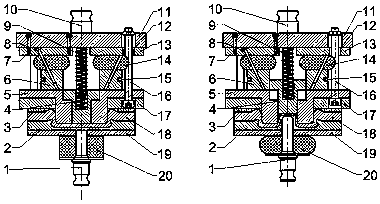

Bidirectional internal lock pressure riveting connecting device

A technology of riveting connection and locking pressure, which is applied in the field of two-way internal locking pressure riveting connection device, which can solve the problems of low efficiency, cumbersome process, and large protrusion height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

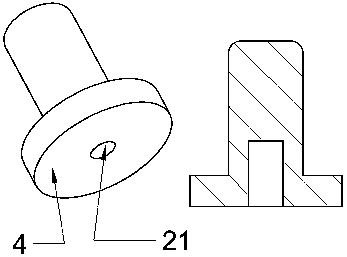

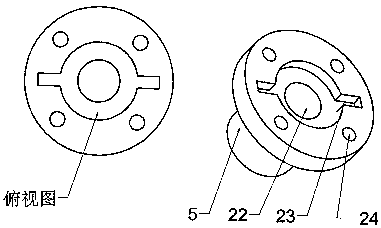

[0012] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any transformation made based on the teaching of the present invention falls within the protection scope of the present invention.

[0013] Working process of the present invention:

[0014] The first stage of a clinch joint is the formation of a flat point rivet joint. At the beginning of the riveting process, the backing ring (3) just touches the plate II (18), and other structures are at the initial position, and the riveting device basically has no pressure on the plate at this time. When the first die (1) is at the initial position, it is at the same horizontal position as the fixed plate (19), the elastic rubber II (20) is not compressed, and the first die (1) and the fixed plate (19) act as a flat Flat anvil structure connected by point pressure riveting. Under the action of the power device, the mold hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com