Device for solving intaglio printing UV varnishing nonuniformity

A gravure printing and uniform technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of uneven UV coating of gravure printing, affecting product quality and production efficiency, and generating bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

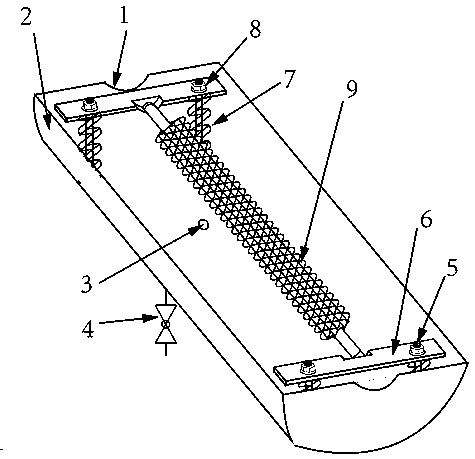

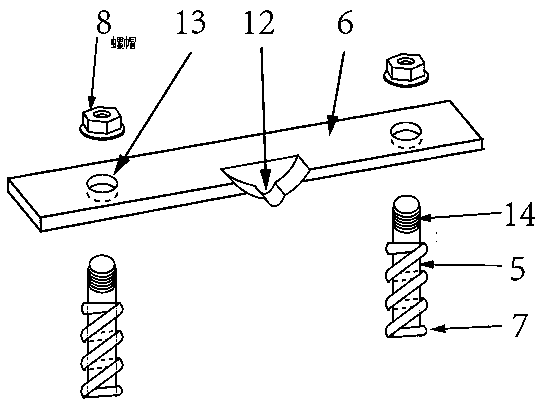

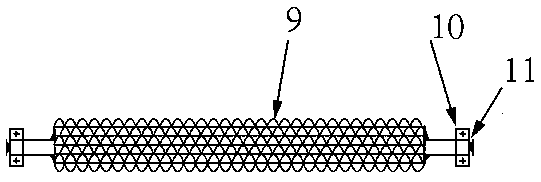

[0019] The technical solution will be described below as an embodiment in conjunction with the accompanying drawings.

[0020] 1 is the semicircular opening at the two ends of the ink tank, which is used to install and fix the printing plate bearing seat; 2 is the newly made ink tank; 3 is the ink return hole at the bottom of the ink tank 2, which is used to return the ink to the ink tank for circulation ; 4 is a stainless steel ball valve, which is connected with the ink return hole 3, and is used to adjust the size of the ink return; 5 is a stainless steel cylinder, which is welded on the bottom of the ink tank 2, and is used for the installation and fixing of the spring 7 and the stainless steel block 6; A stainless steel block with a thickness of 5 mm is used for mounting and fixing the ink transfer roller 9; 7 is an equidistant compression spring, which is used to push up the stainless steel block 6, and simultaneously press the ink transfer roller 9 against the printing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com