Chair frame

A chair frame and seat back frame technology, applied in chairs, reclining chairs, home appliances, etc., can solve the problems of human fatigue, large backrest, and incompatibility with stress conditions, and achieve the effect of stable and reliable operation and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

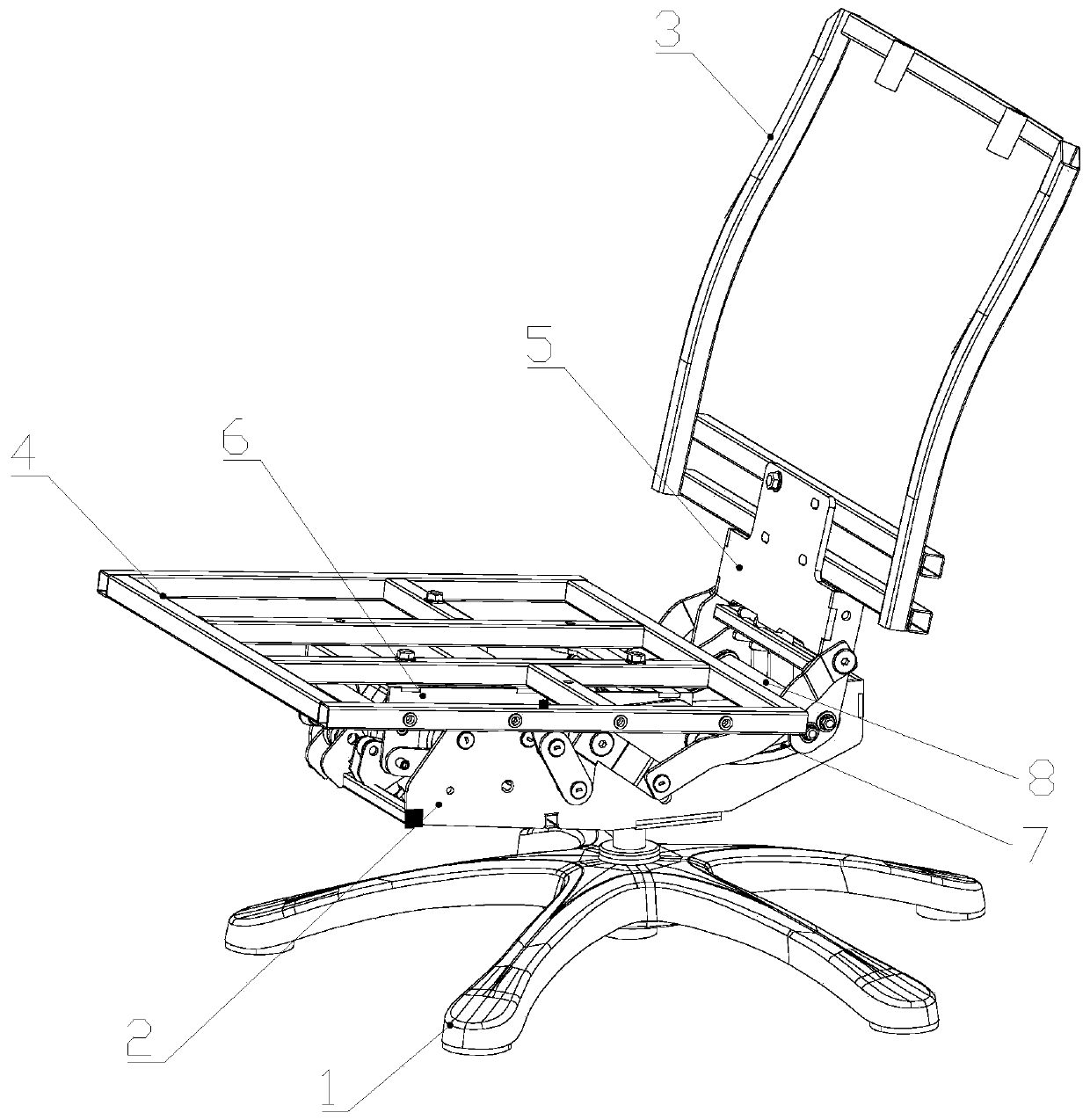

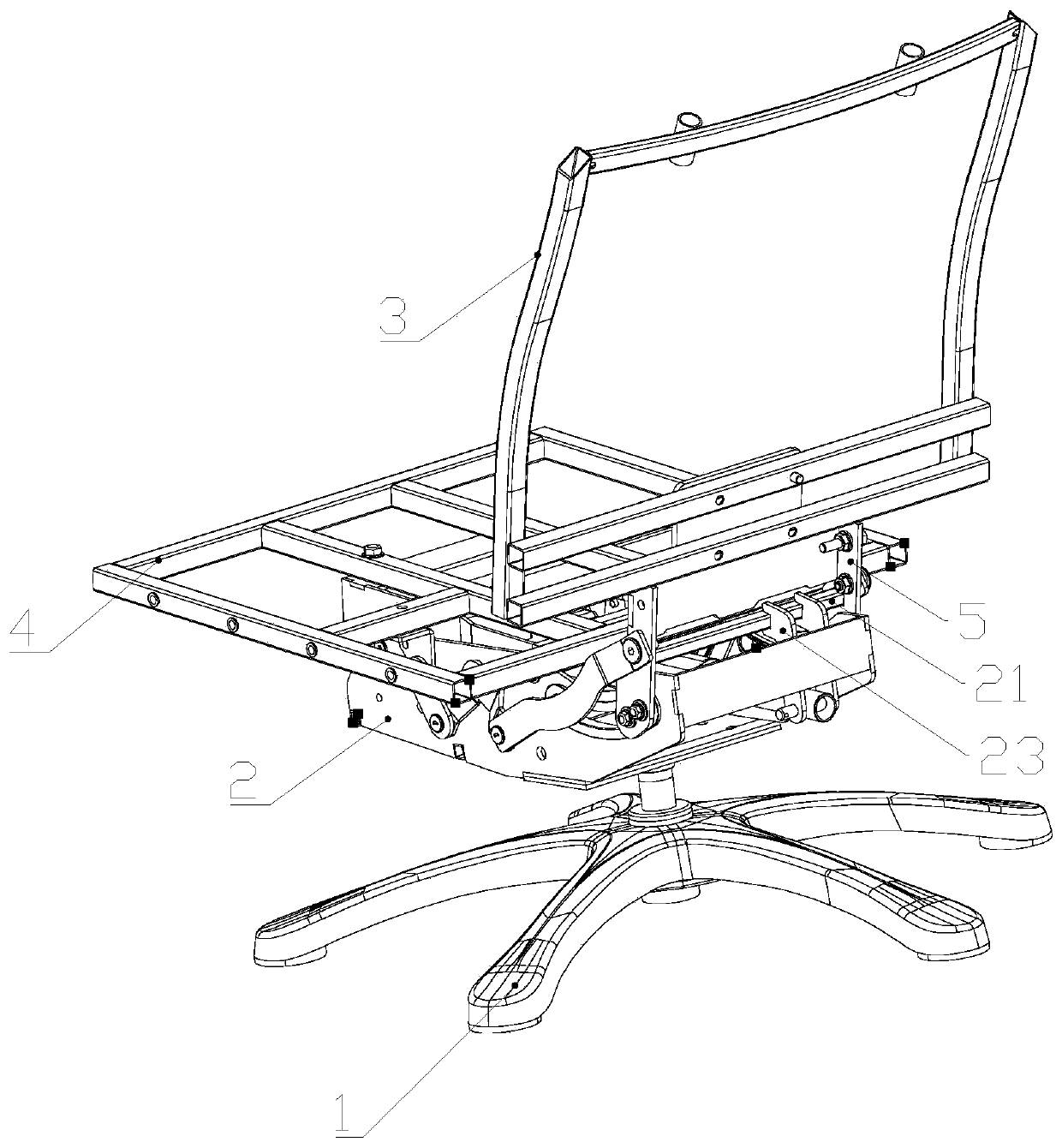

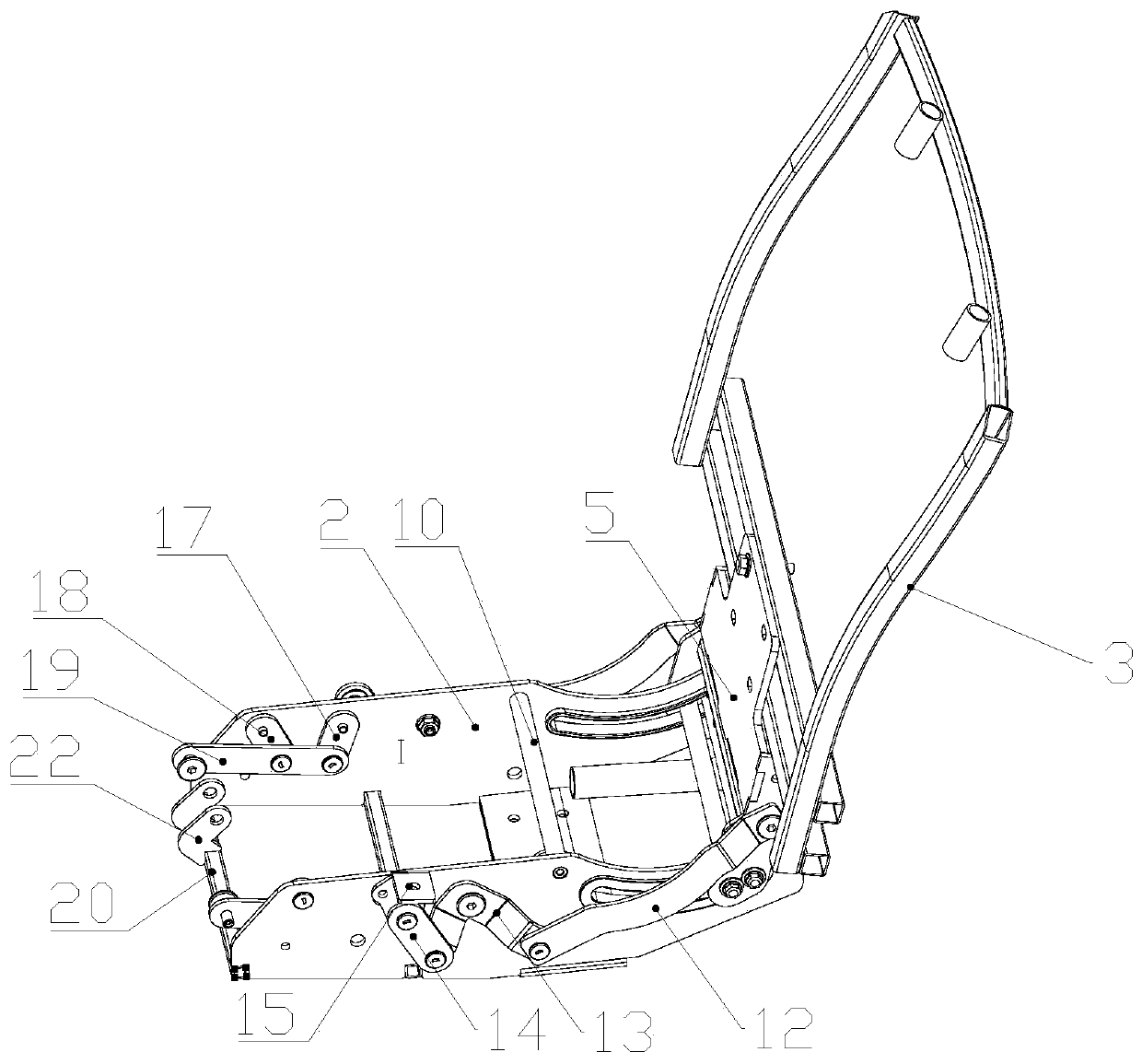

[0045] Such as Figure 1-4 As shown, a chair frame includes a foot 1, a fixed seat 2, a chair back frame 3, a seat frame 4, a first linkage frame 5 and a second linkage frame 6, wherein the fixed seat 2 is fixedly connected to the foot 1 , the first linkage frame 5 is fixedly connected or integrally formed with the bottom of the seat back frame 3 and is rotatably installed on the fixed seat 2; the second linkage frame 6 is fixedly connected or integrally formed with the bottom surface of the seat frame 4 and is movably installed on the fixed on seat 2; also includes:

[0046] There are two sets of first connecting rod 12 mechanisms on the left and right, and the first connecting rod 12 mechanisms are installed on the fixed seat 2, the first linkage frame 5 and the second linkage frame 6, and include the first linkage 12, the second linkage hinged in turn. Rod 13 and the third connecting rod 14, the top of the first connecting rod 12 is rotatably installed on the first linkage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com