Motor control method and washing machine

A technology for motor control and washing machine, which is applied to the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of washing machine drum throwing, large motor load fluctuation, asynchronous rotation speed of motor adapter and washing drum, etc. The effect of prolonging the service life and preventing the dumping of the bucket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

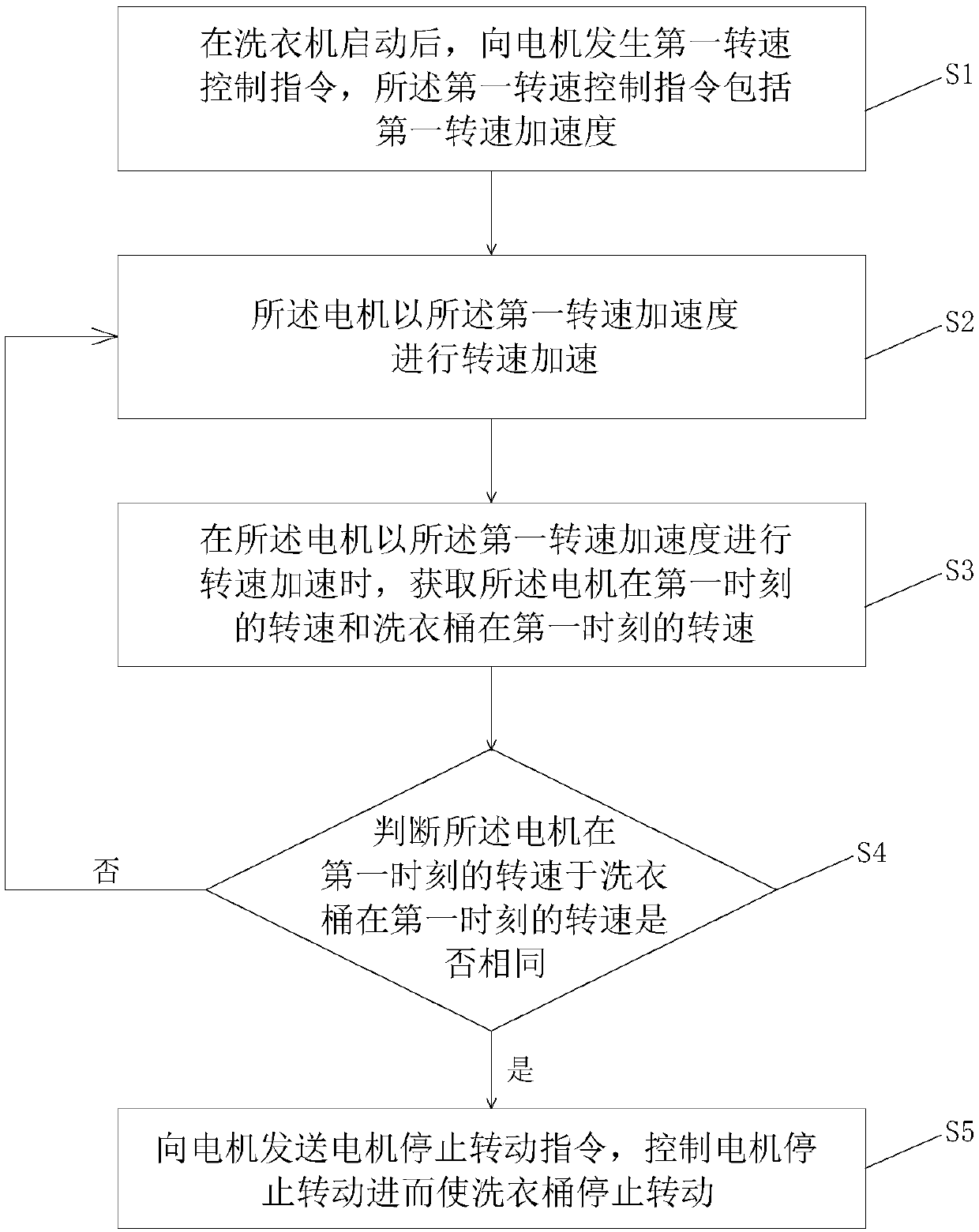

[0021] Such as figure 1 As shown, a motor control method according to an embodiment of the present invention includes the following steps:

[0022] S1: After the washing machine is started, a first rotational speed control command is sent to the motor, and the first rotational speed control command includes a first rotational speed acceleration;

[0023] S2: The motor accelerates at the first speed acceleration;

[0024] S3: When the motor is accelerating at the first speed acceleration, acquire the speed of the motor at the first moment and the speed of the washing tub at the first moment;

[0025] S4: judging whether the rotation speed of the motor at the first moment is the same as the rotation speed of the washing tub at the first moment;

[0026] If so, the washing machine continues to run at the first rotational speed acceleration;

[0027] If not, go to the next step;

[0028] S5: Sending a motor stop rotation instruction to the motor, controlling the motor to stop ...

Embodiment 2

[0031] An embodiment of the present invention provides a washing machine, which includes a washing tub; a motor; a memory; a processor; and a computer program;

[0032] Wherein, the computer program is stored in the memory, and is configured to execute the motor control method described in Embodiment 1 by the processor, so as to control the motor to accelerate the speed.

Embodiment 3

[0034] An embodiment of the present invention provides a storage medium readable by an electronic device, the storage medium readable by an electronic device may store a program, and when the program is run on the electronic device, the electronic device executes the method described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com