Motor control method and washing machine

A technology for washing machines and washing tubs, which is applied in the field of washing machines, and can solve the problems of washing machine spinning, large motor load fluctuations, and out-of-synchronization speed between motor adapters and washing tubs, etc., so as to prolong the service life and prevent buckets from being thrown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

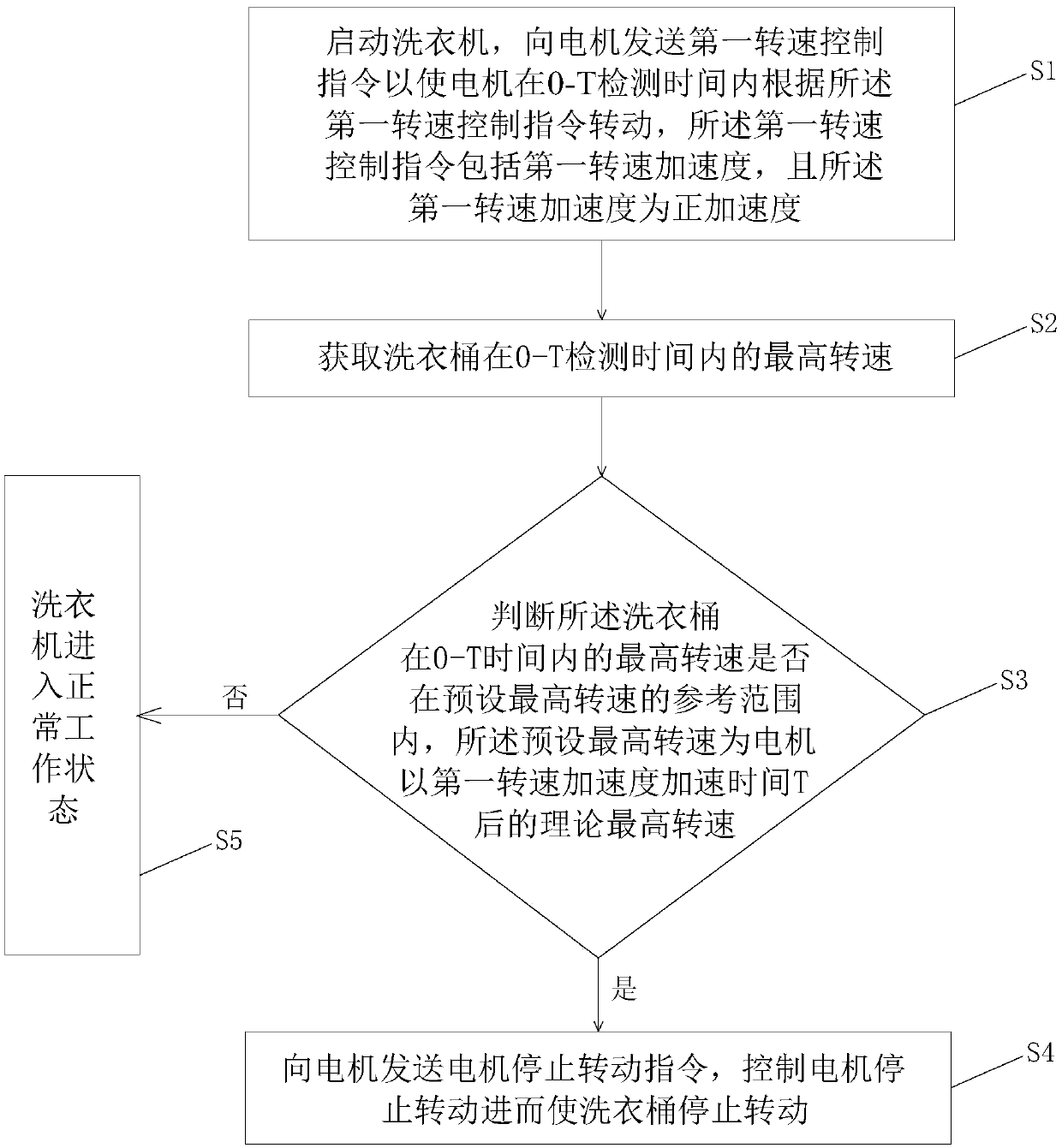

[0022] like figure 1 As shown, a motor control method according to an embodiment of the present invention includes the following steps:

[0023] S1: Start the washing machine, send a first rotational speed control command to the motor so that the motor rotates according to the first rotational speed control command within the 0-T detection time, the first rotational speed control command includes a first rotational speed acceleration, and the first rotational speed control command - speed acceleration is positive acceleration;

[0024] S2: Obtain the highest rotational speed of the washing tub within the 0-T detection time;

[0025] S3: judging whether the maximum rotation speed of the washing tub within the time period of 0-T is within the reference range of the preset maximum rotation speed, the preset maximum rotation speed is the theoretical maximum rotation speed after the motor accelerates at the first rotation speed for a time T;

[0026] If not, execute step S4;

[...

Embodiment 2

[0032] An embodiment of the present invention provides a washing machine, which includes a washing tub; a motor; a memory; a processor; and a computer program;

[0033] Wherein, the computer program is stored in the memory, and is configured to execute the motor control method described in Embodiment 1 by the processor, so as to control the motor to accelerate the speed.

Embodiment 3

[0035] An embodiment of the present invention provides a storage medium readable by an electronic device, the storage medium readable by an electronic device may store a program, and when the program is run on the electronic device, the electronic device executes the method described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com