Straightening machine and copper-chromium-zirconium alloy contact line production process

A production process and technology of a straightening machine, applied in the field of straightening machine and copper-chromium-zirconium alloy contact wire production technology, can solve the problems of uneven contact wire and influence on drawing, so as to reduce accuracy, prevent engineering errors, and reduce raw materials Equipped with effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings.

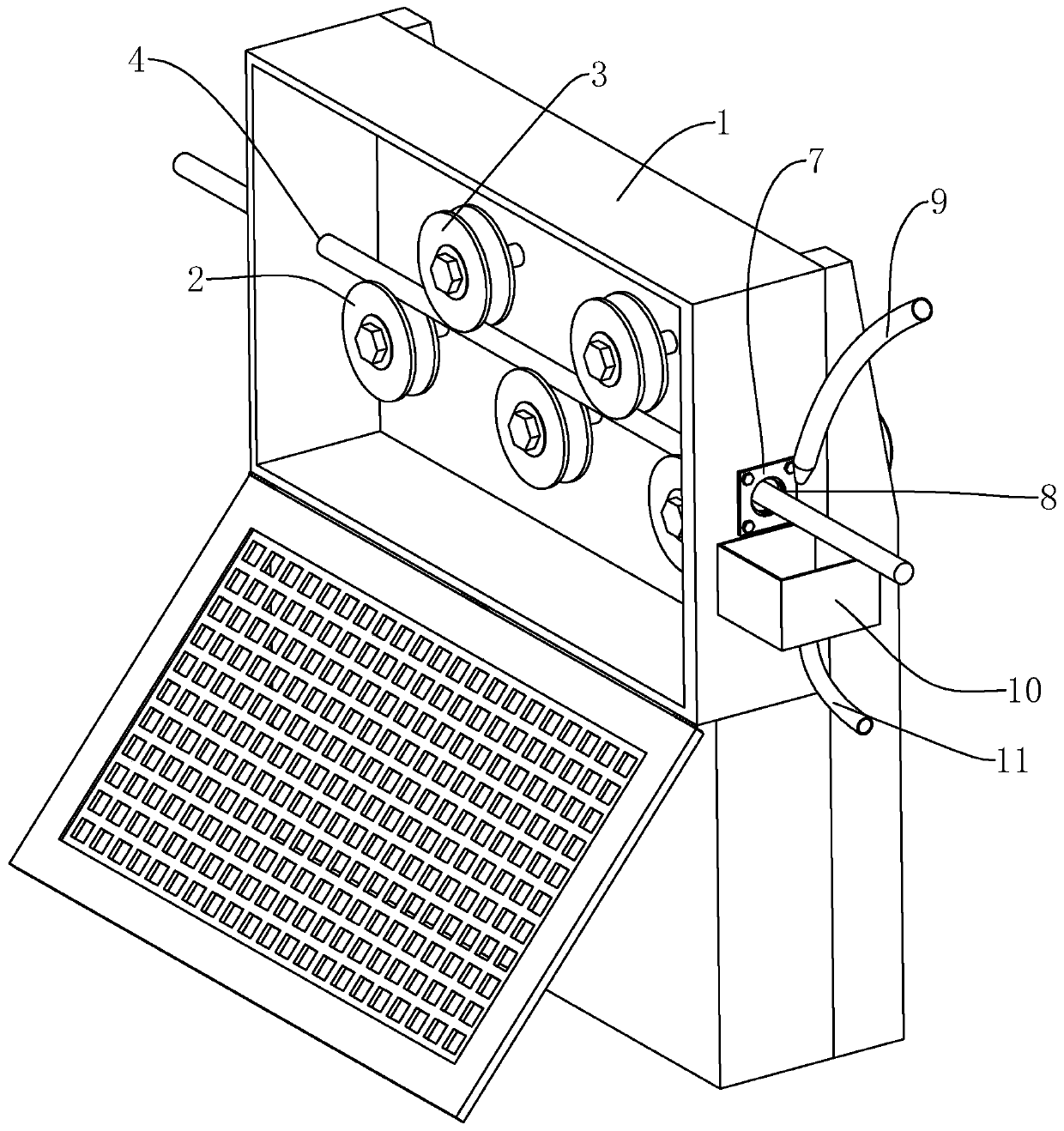

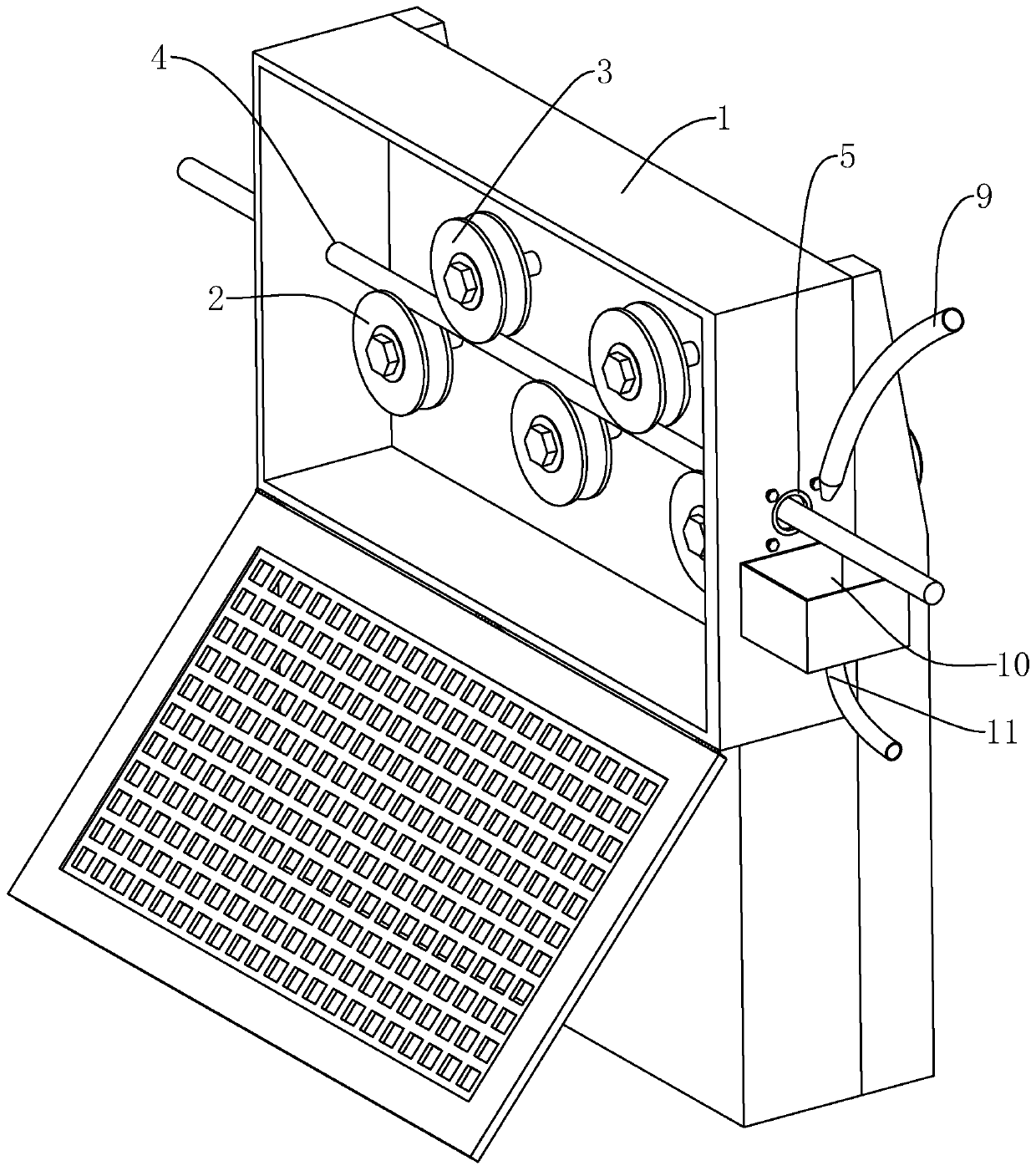

[0057] refer to figure 1 , figure 2, is a kind of straightening machine disclosed by the present invention, comprising a cabinet 1, a plurality of driving wheel groups and a plurality of driving wheels 3 arranged in the cabinet 1, one side of the cabinet 1 is hinged with a cabinet 1 door, and a plurality of driven wheels 2 are arranged side by side Setting, a plurality of driving wheels 3 are also arranged side by side. The driving wheel 3 is arranged on the upper side of the driven wheel 2, and the driving wheel 3 and the driven wheel 2 are alternately arranged; the two sides of the chassis 1 are respectively provided with perforations 4 for the casting rod to pass through, and the driving wheel 3 and the driven wheel 2 touch each other. When the straightening machine straightens the casting rod, the casting rod enters the cabinet 1 through the hole 4 on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap