An improved ramie peeling device

An improved, hemp-stripping technology, which is used in textiles and papermaking, fiber mechanical separation, mechanical treatment, etc., can solve the problems that the ramie fiber is easily broken by the stripping board, the noise is large, and the pressing force is difficult to adjust to the same level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

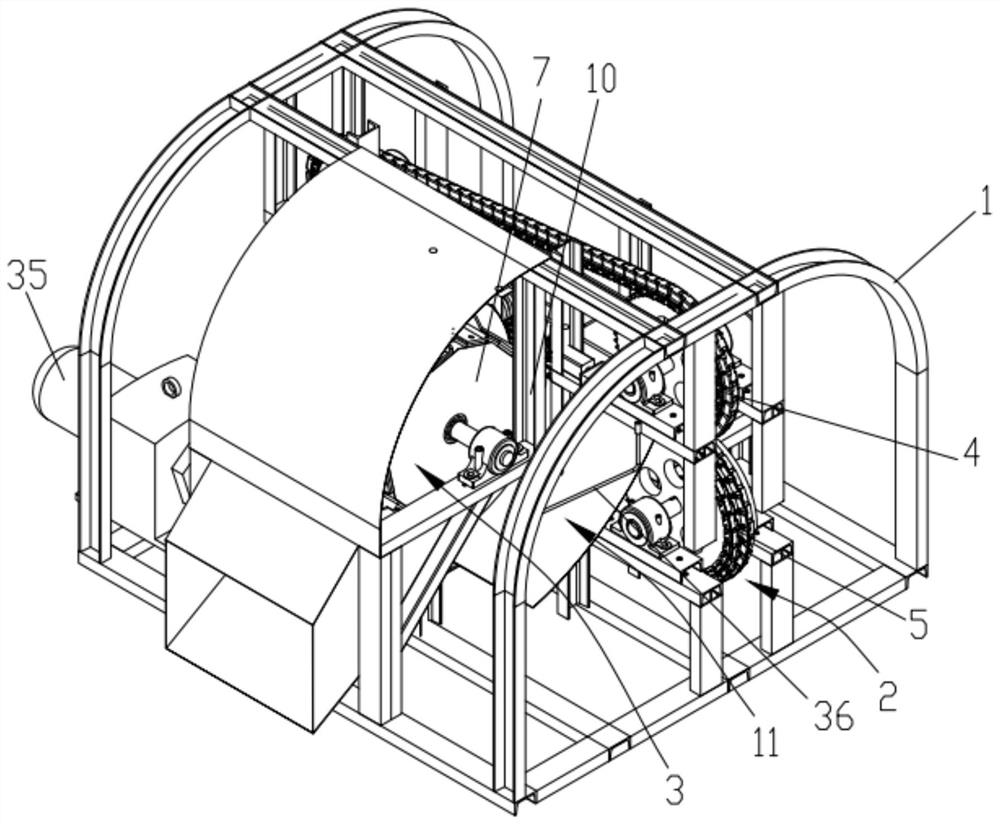

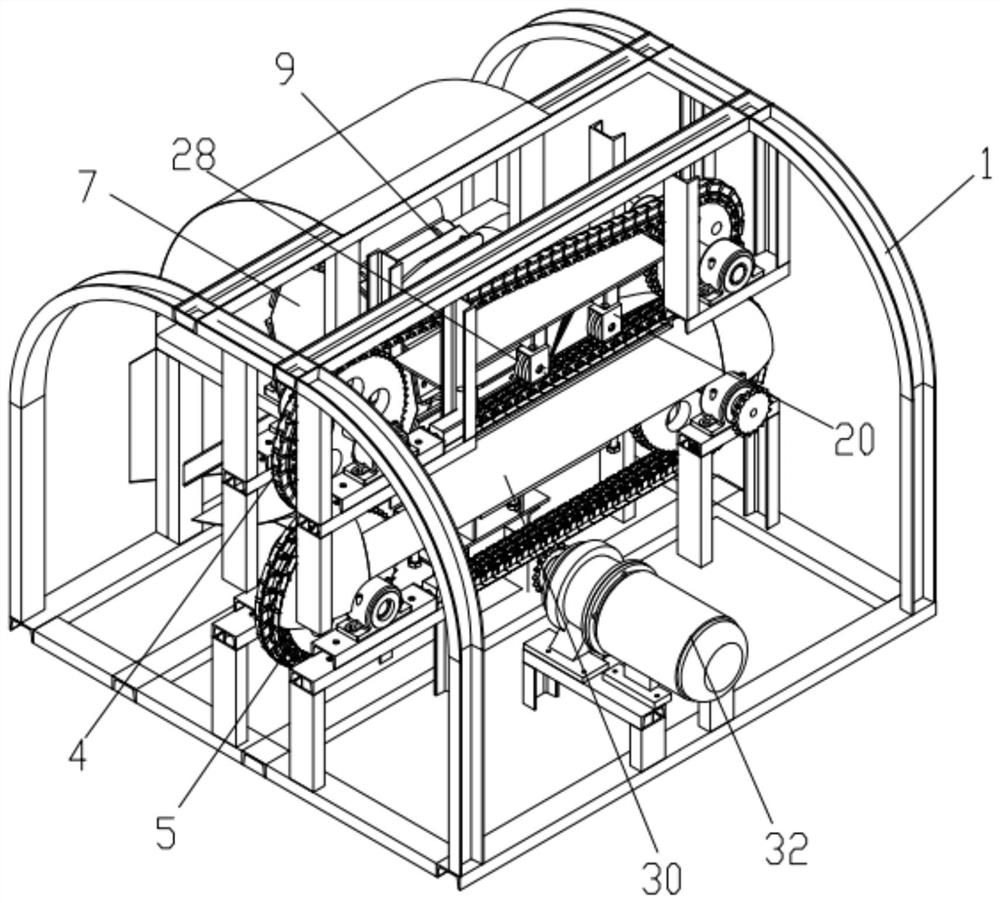

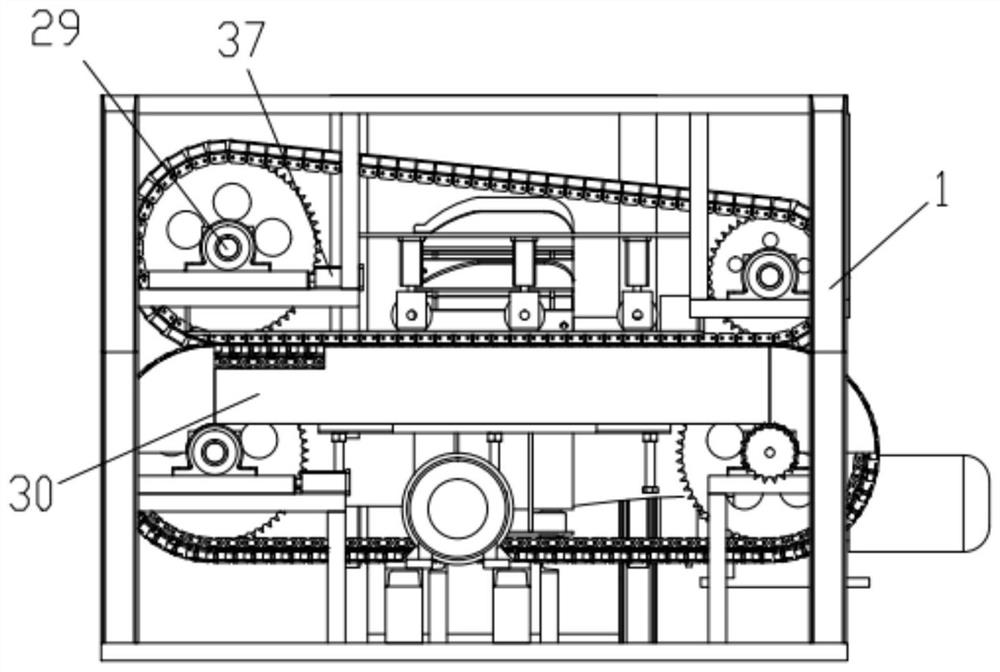

[0037] Such as Figure 1-8As shown, the present invention discloses an improved ramie stripping device, comprising a frame 1 and a ramie clamping and conveying device 2 and a stripping mechanism 3 installed on the frame 1, and the ramie clamping and conveying device 2 includes from the upper and lower sides Cooperate with each other to clamp and convey the clamping conveying chain of ramie. The clamping conveying chain includes the upper clamping conveying chain 4 and the lower clamping conveying chain 5. Both the clamping conveying chains are meshed with sprockets 6. Through the upper clamping conveying chain 4 and the lower clamping conveyer chain 5 clamp one end of the ramie to be stripped, and the stripping mechanism 3 includes the stripping cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com