A roller oblique reverse pull type ramie conveying stripping machine

A hemp stripping machine and back-pulling technology, which is applied in mechanical processing, fiber mechanical separation, textiles and papermaking, etc., can solve the problems of high labor intensity, noise, dust hazards, and easy breaking of ramie fibers by stripping hemp boards. Achieve the effects of reducing the probability of safety accidents, reducing operators, and improving the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

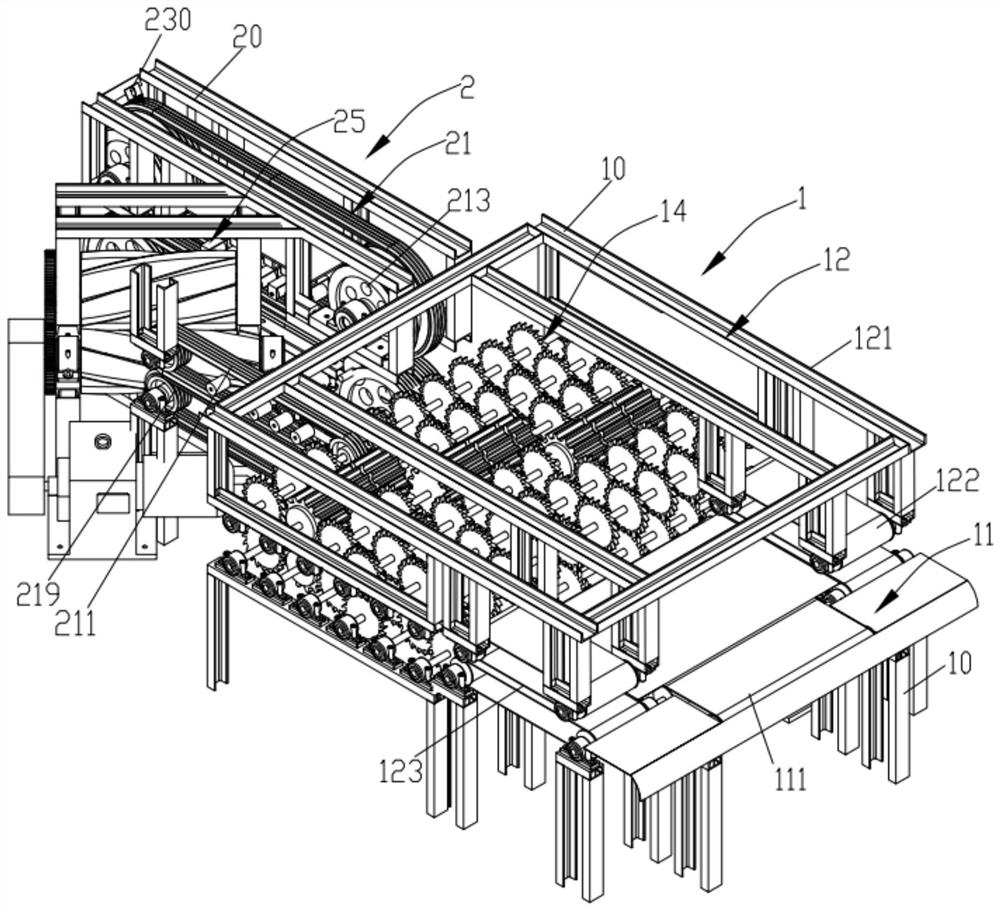

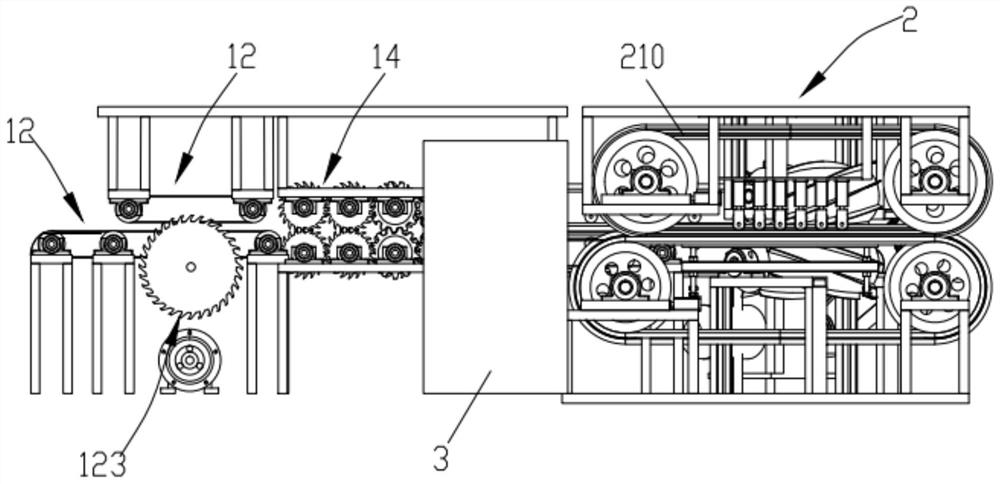

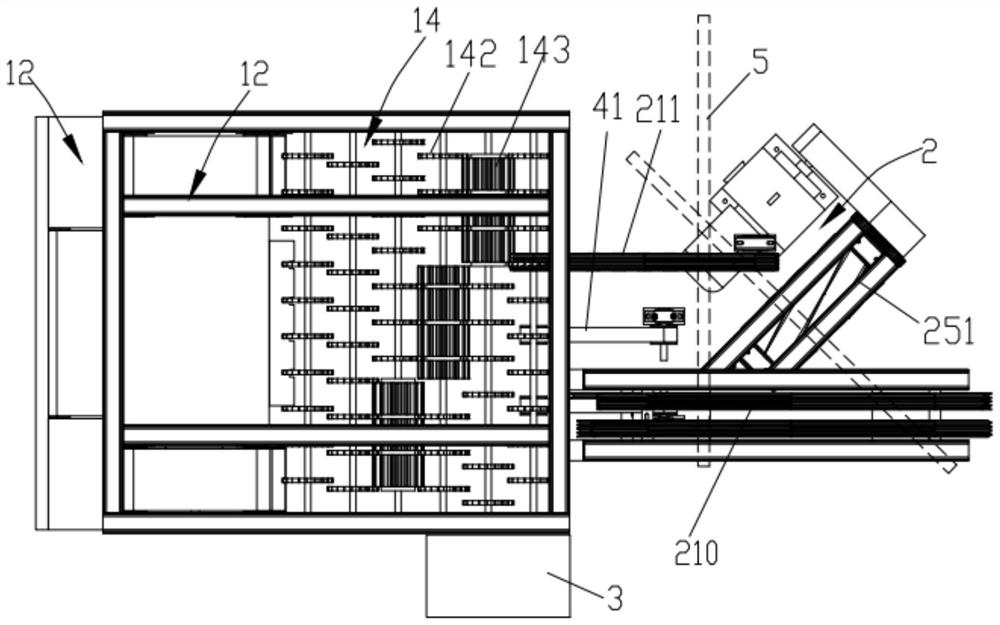

[0057] Such as Figure 1-9 As shown, the present invention discloses a ramie conveying and stripping machine with oblique rollers, including an electric control cabinet 3 and a ramie conveyor 1 and a front stripping machine 2 electrically connected to the electric control cabinet 3, through which the ramie conveyor 1 Realize the pretreatment of ramie such as uniform cutting, flaxing, rolling and clamping and conveying, through the clamping of the front stripping machine 2 and the stripping of the stalks other than the clamping part of the ramie, the front stripping machine 2 includes the front Ramie clamping conveying device 21 and front stripping hemp mechanism 25, preceding stripping hemp mechanism 25 comprises the front stripping hemp roller 251 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com