Robot for wall spraying and cleaning

A technology of robots and working robots, applied in building maintenance, construction, building construction, etc., can solve problems such as high risk, difficult installation of fixed rails, and difficulty in recruiting workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

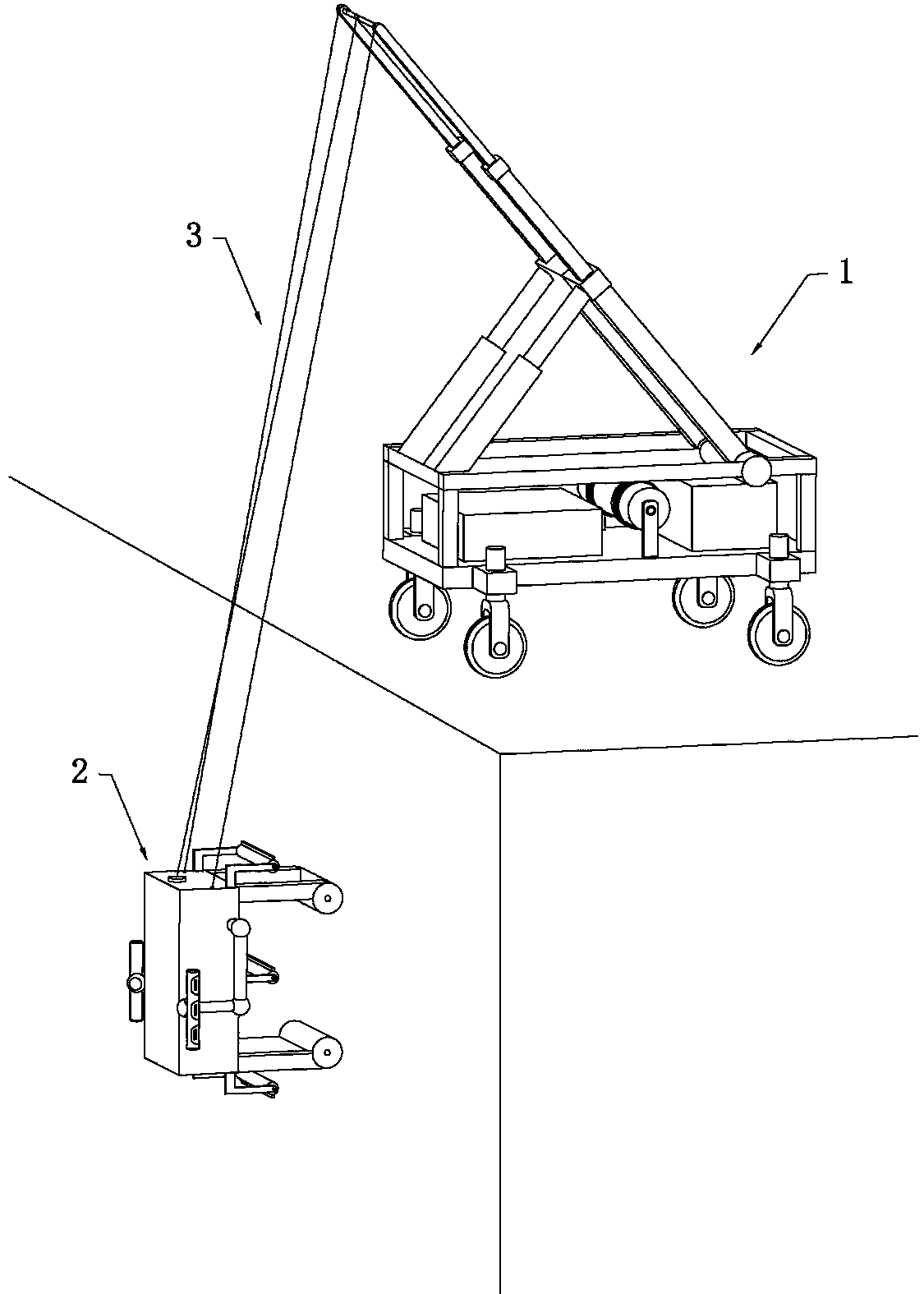

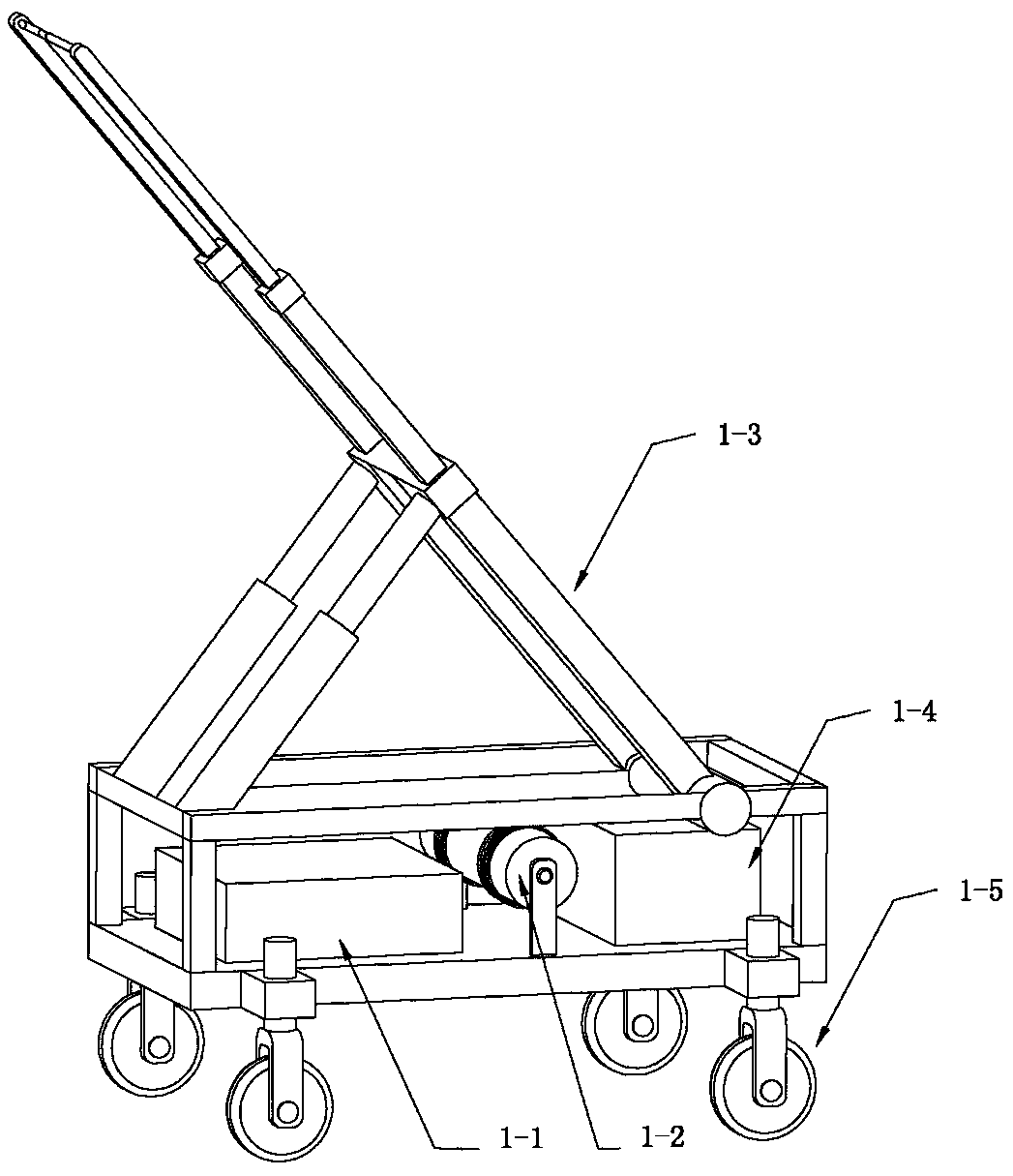

[0011] In order to facilitate the understanding of the technical features of the present invention, the present invention will be further elaborated below with reference to the accompanying drawings and in conjunction with specific embodiments, please refer to Figure 1 to Figure 3 , the robot is composed of a base control robot 1 and a working robot 2 connected by a cable and a feeding pipe 3 .

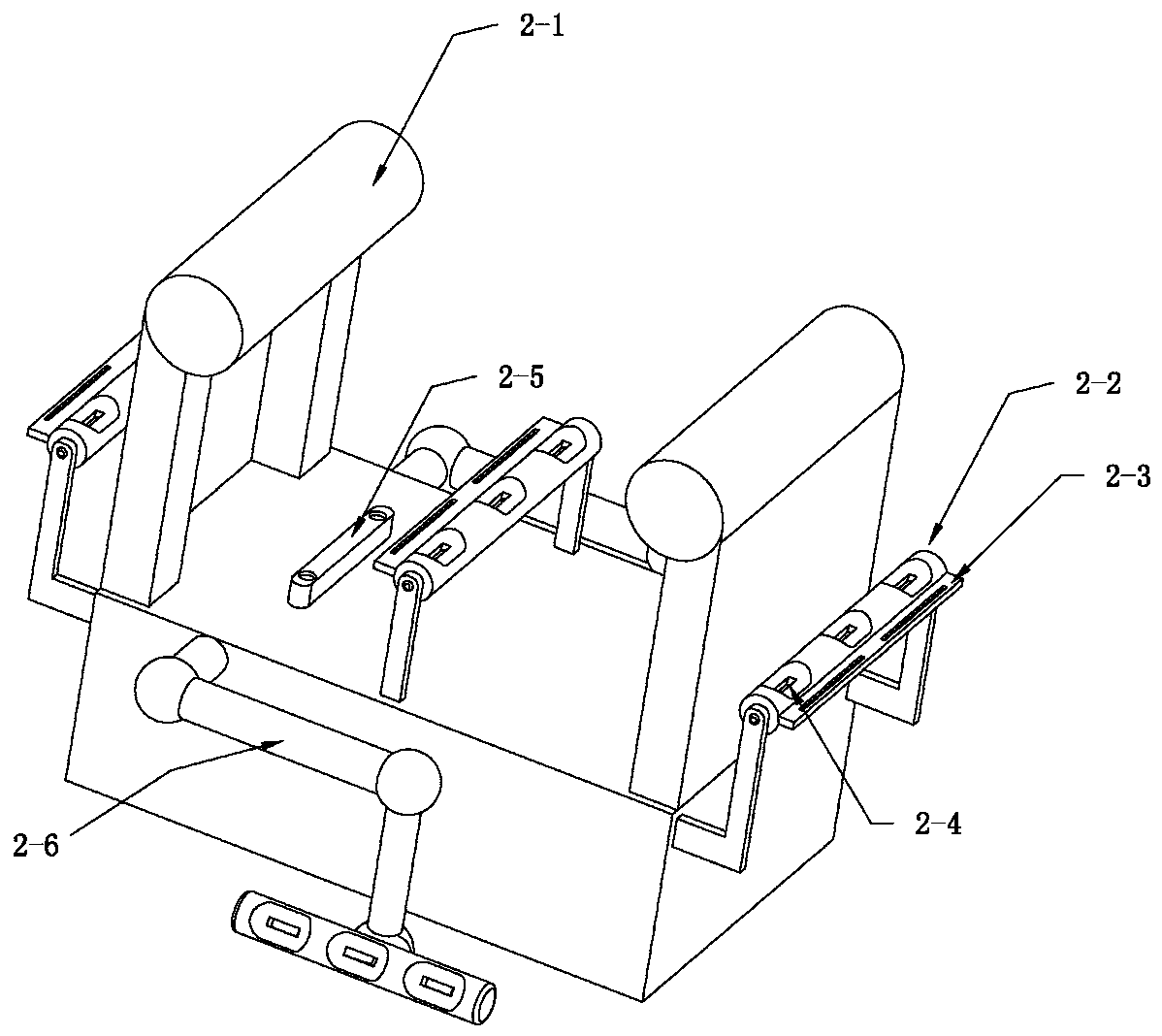

[0012] During the construction work, the base control robot 1 located on the roof is driven by the controller 1-1, and the hoist 1-2 controls the cable and the feeding pipe 3 through the hoisting bracket 1-3, and connects the hoisting operation on the end of the cable 3. robot 2, and control the material storage box 1-4 of the robot 1 from the base to deliver the spraying material to the working robot 2, and the working robot 2 on the wall construction uses the sensor installed on the spraying roller 2-2 and the machine vision detector 2- 3. After detecting and feeding back the condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com