Fallen bottle removing method and fallen bottle removing device

A technology of rejecting device and bottle pouring, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of high installation and operation cost, complicated structure of bottle pouring rejecting device, inconvenient maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

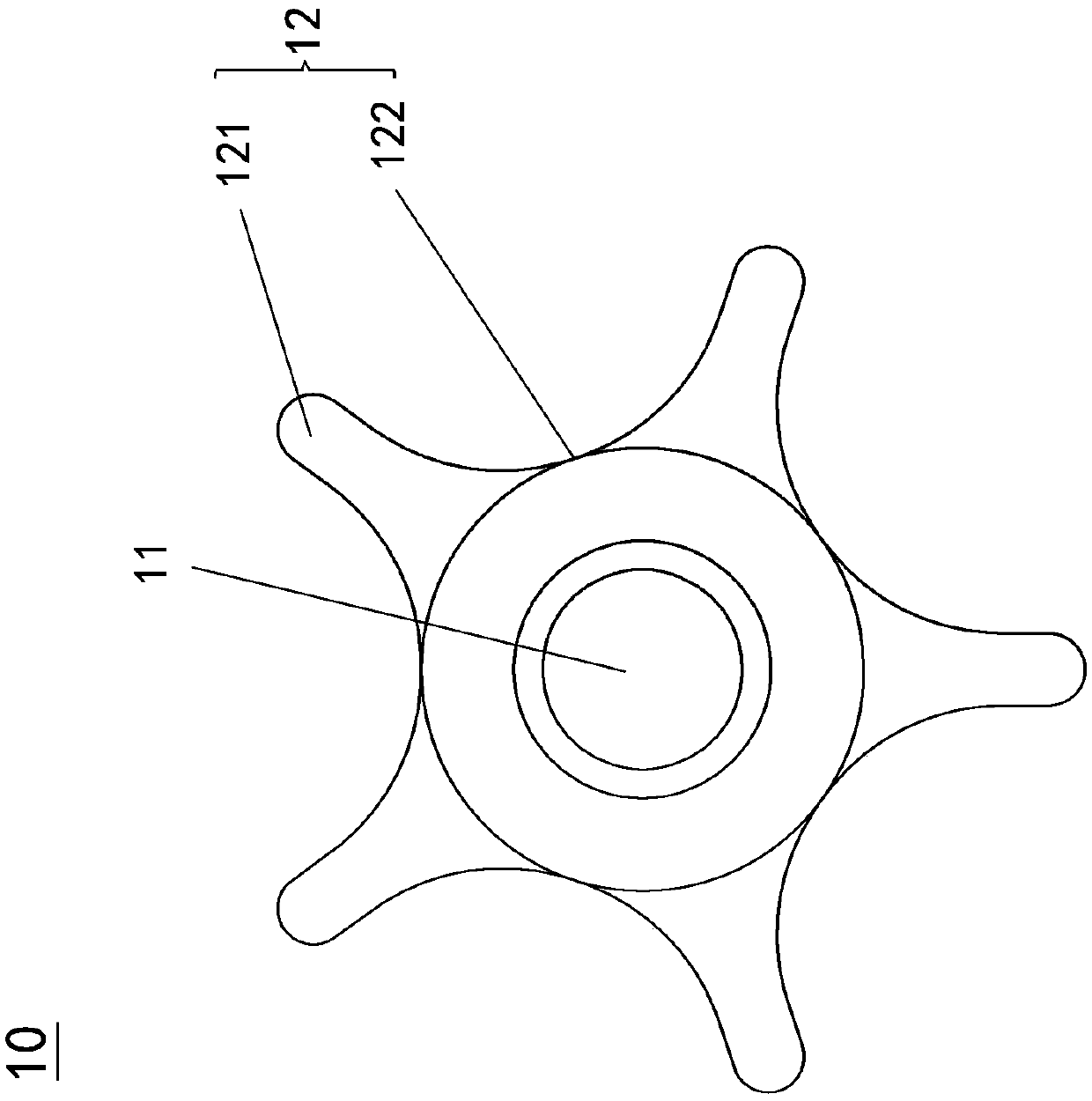

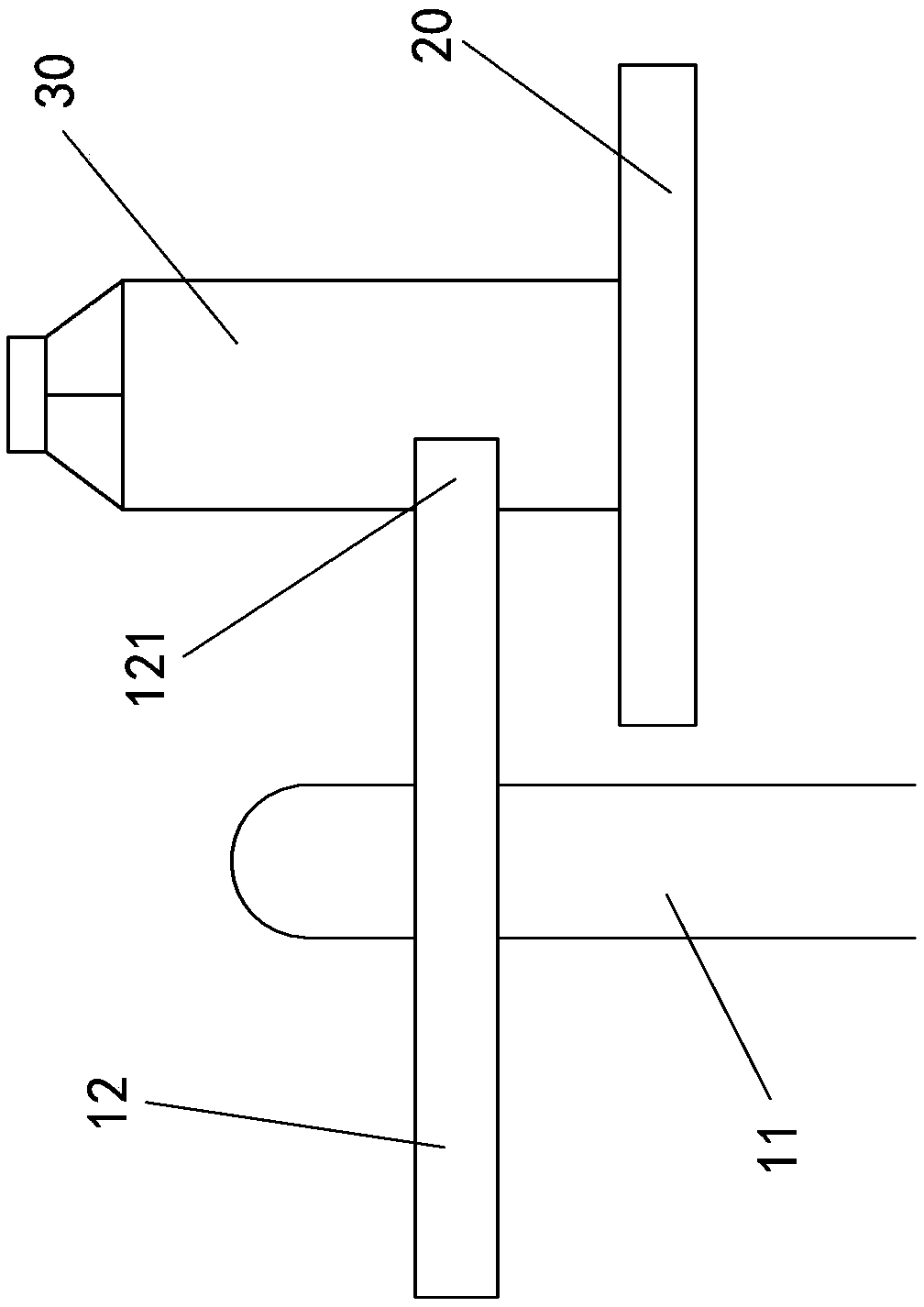

[0021] Hereinafter, the inverted bottle rejecting method and the inverted bottle rejecting device of the present invention will be described in detail with reference to the accompanying drawings. It should be noted that the drawings referred to in the following descriptions schematically show the embodiments, so the dimensions, intervals, positional relationships, etc. of the components may be exaggerated, or the illustration of a part of the components may be omitted. .

[0022] The idea of the present invention is to replace the existing method of "electric eye detection + cylinder rejection", and use a mechanical method to remove the inverted bottle products on the conveying chain.

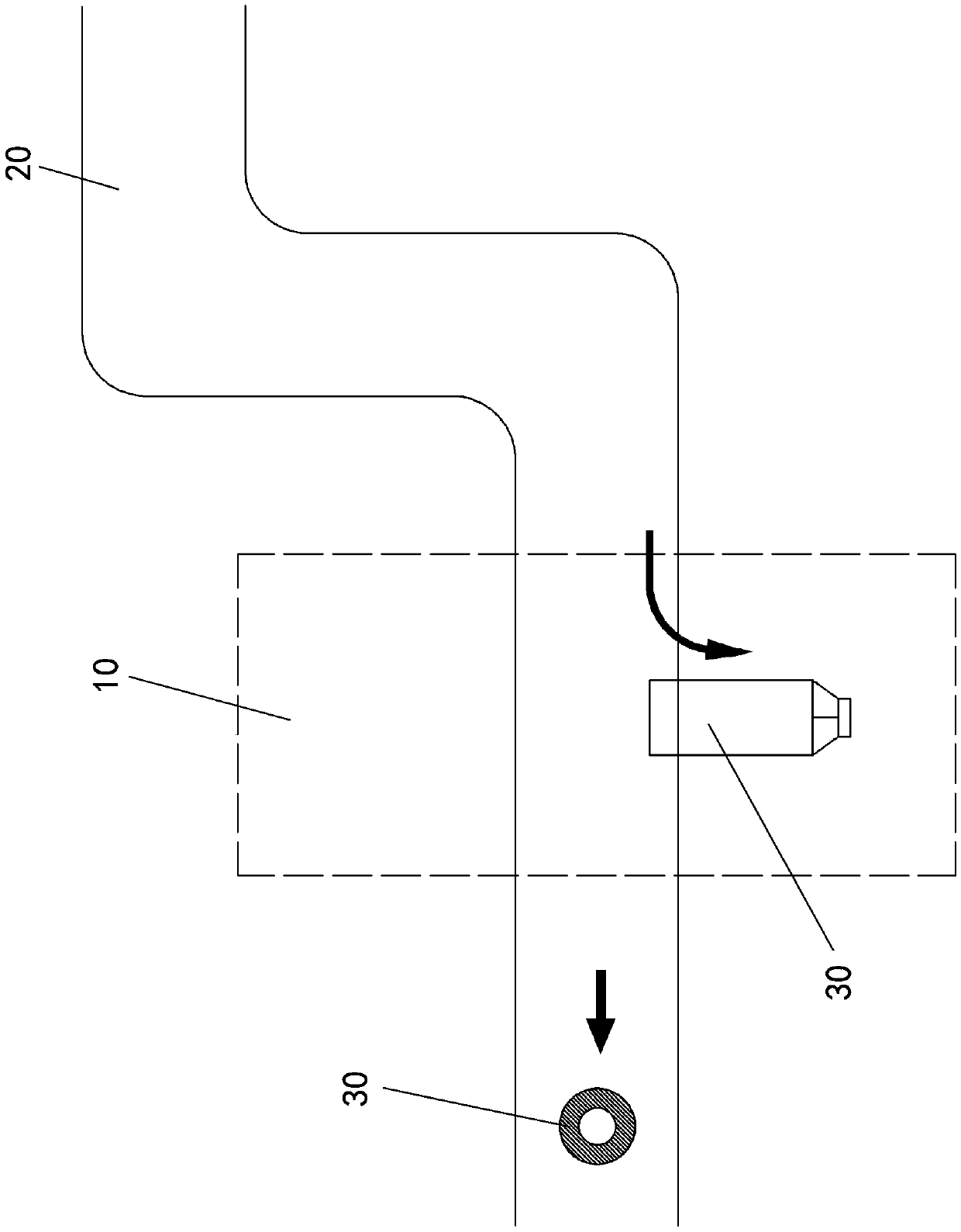

[0023] figure 1 It is a schematic diagram showing the inverted bottle rejecting method of the present invention. by figure 1 In the schematically shown inverted bottle rejecting method, the inverted bottle product is removed from the conveying chain 20 of the bottled product 30 by mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com