Reinforcement cage binding device

A steel cage and driving device technology, applied to wire netting, household appliances, and other household appliances, can solve the problems of low binding efficiency of steel cages, and achieve the effects of high binding efficiency, improved stability, and improved beats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

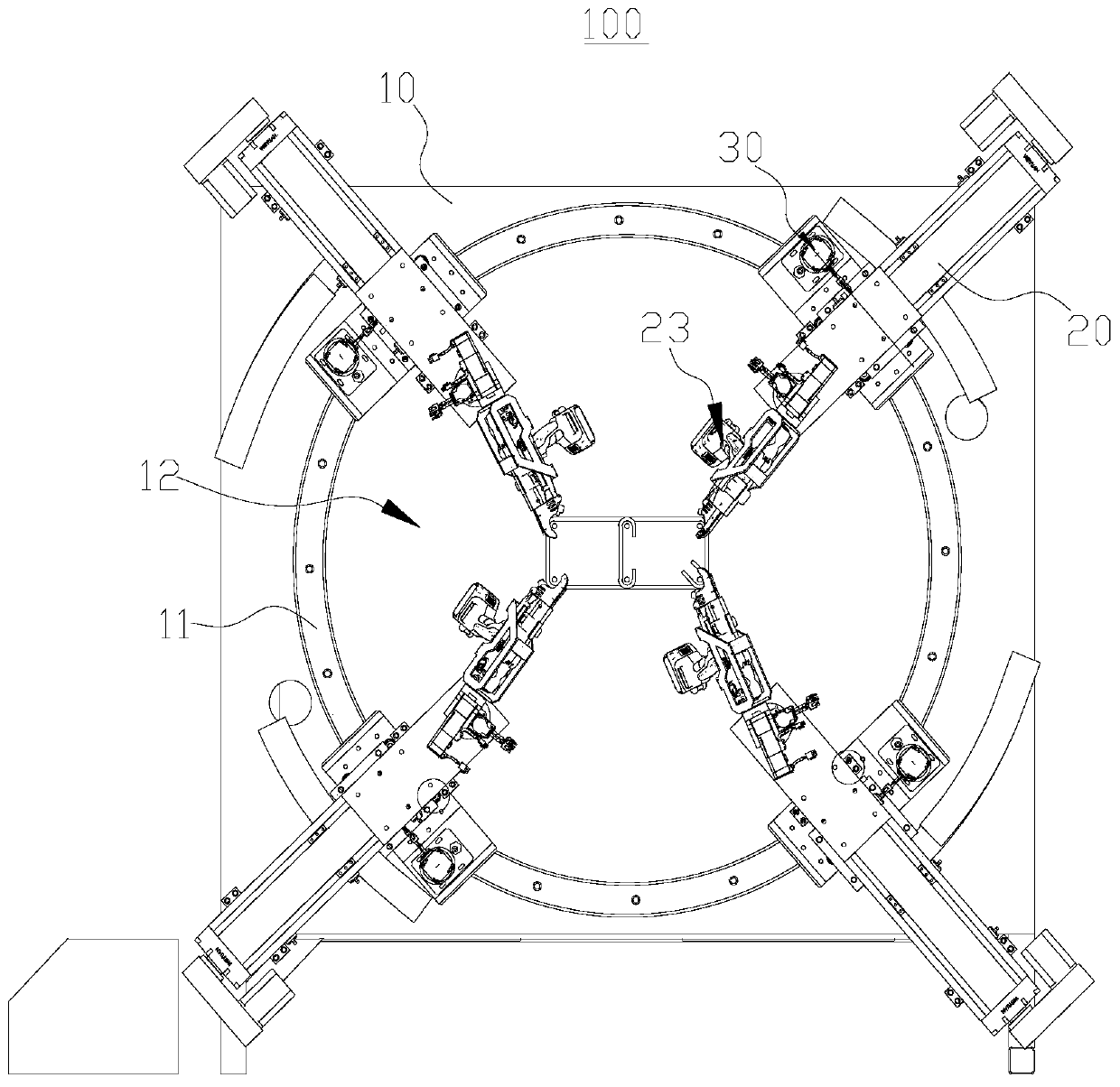

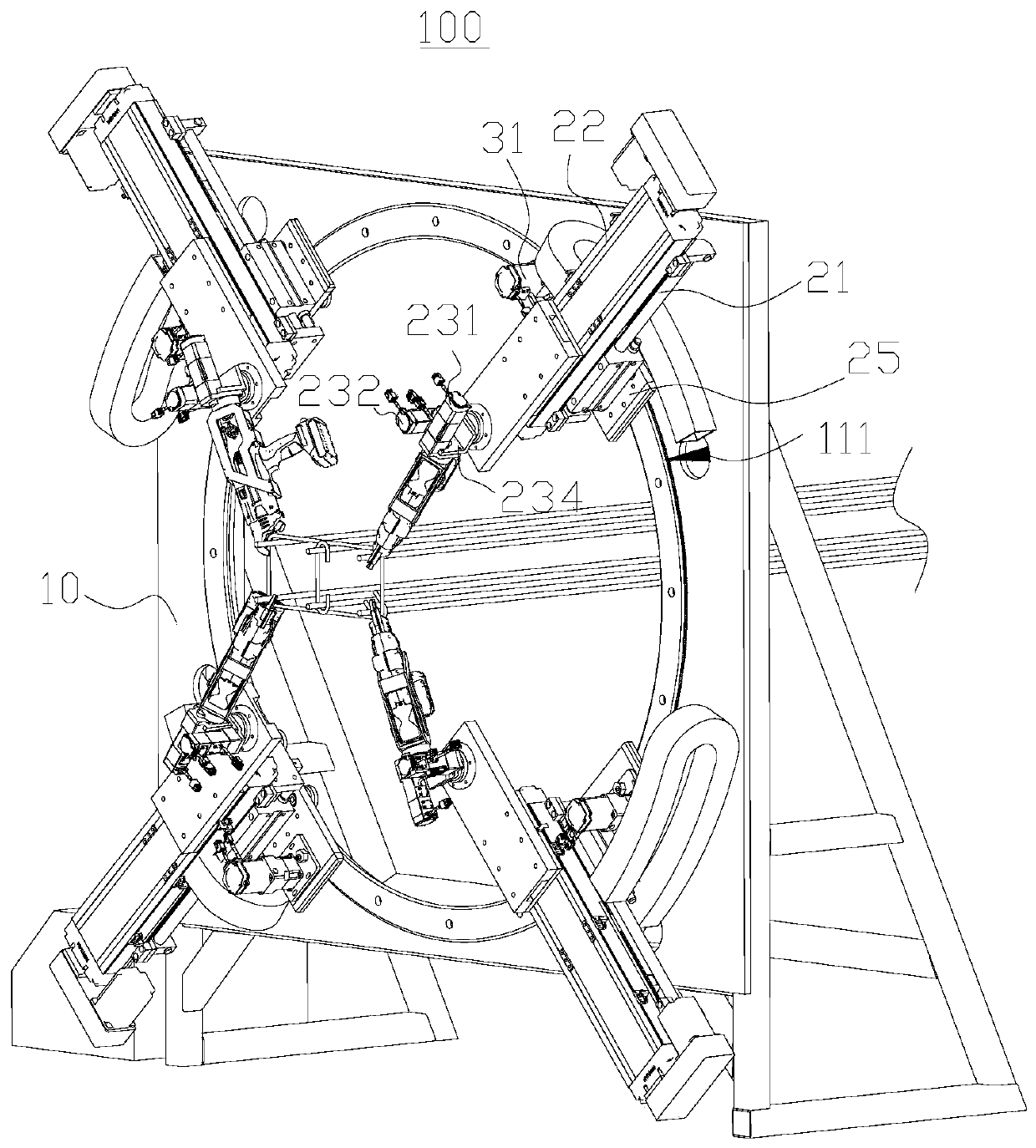

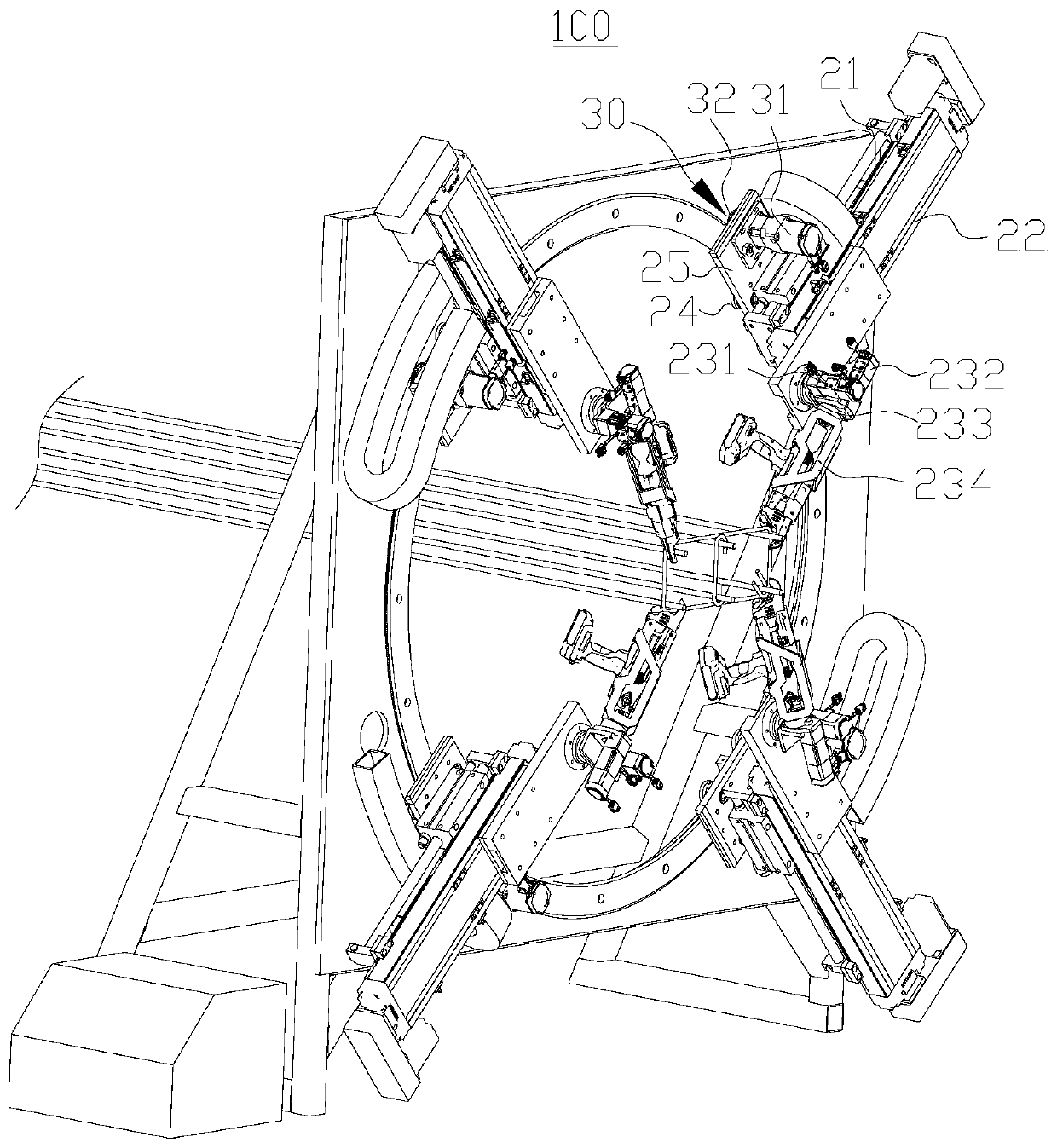

[0038] Such as Figure 1 ~ Figure 3 As shown, the embodiment of the present application provides a steel cage binding device 100, and the steel cage binding device 100 includes a frame 10, at least one binding unit 20 and a driving device. Each binding unit 20 is used for binding the reinforcement cage, and the frame 10 is provided with an annular track 11, which defines an installation space 12 for inserting the reinforcement cage. The driving device drives the binding unit to move along the circular track, so that the binding unit can bind different binding positions of the steel cage, so that the steel cage binding device has more application scenarios and a wider application range.

[0039]In this embodiment, the steel cage binding device 100 includes a plurality of binding units, and the driving device includes a plurality of driving units 30 , and each driving unit 30 is used to drive a binding unit 20 to move along the circular track 11 . Each binding unit 20 is movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com