Systems and methods for providing force vector compensated fan nozzles

A fan-shaped, arc-shaped technology used in the removal of contaminants from materials and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

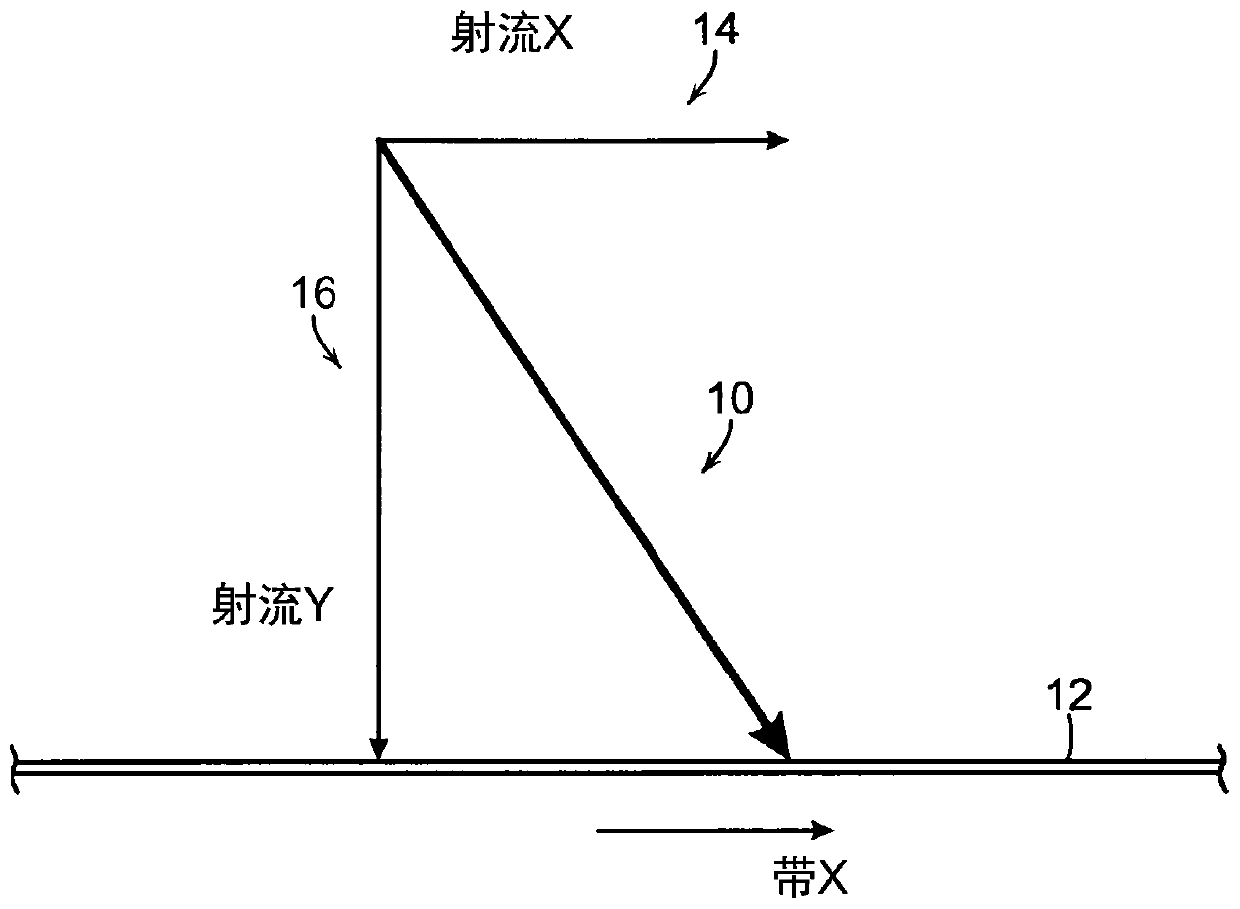

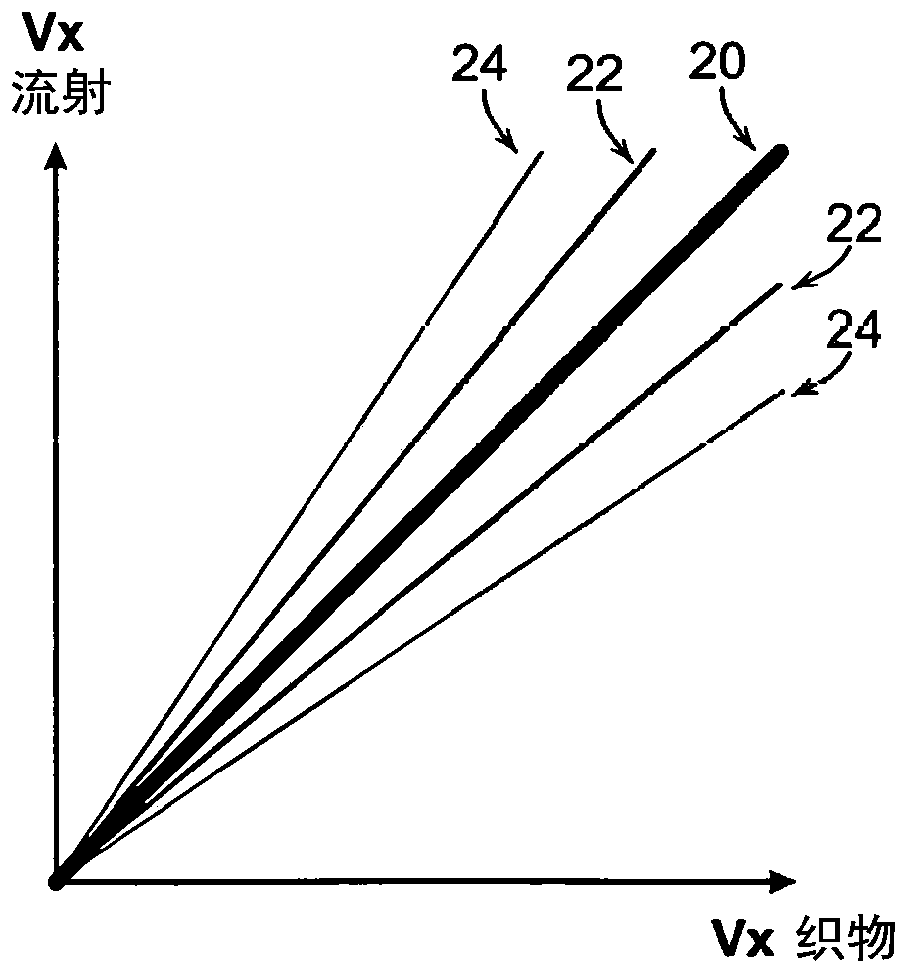

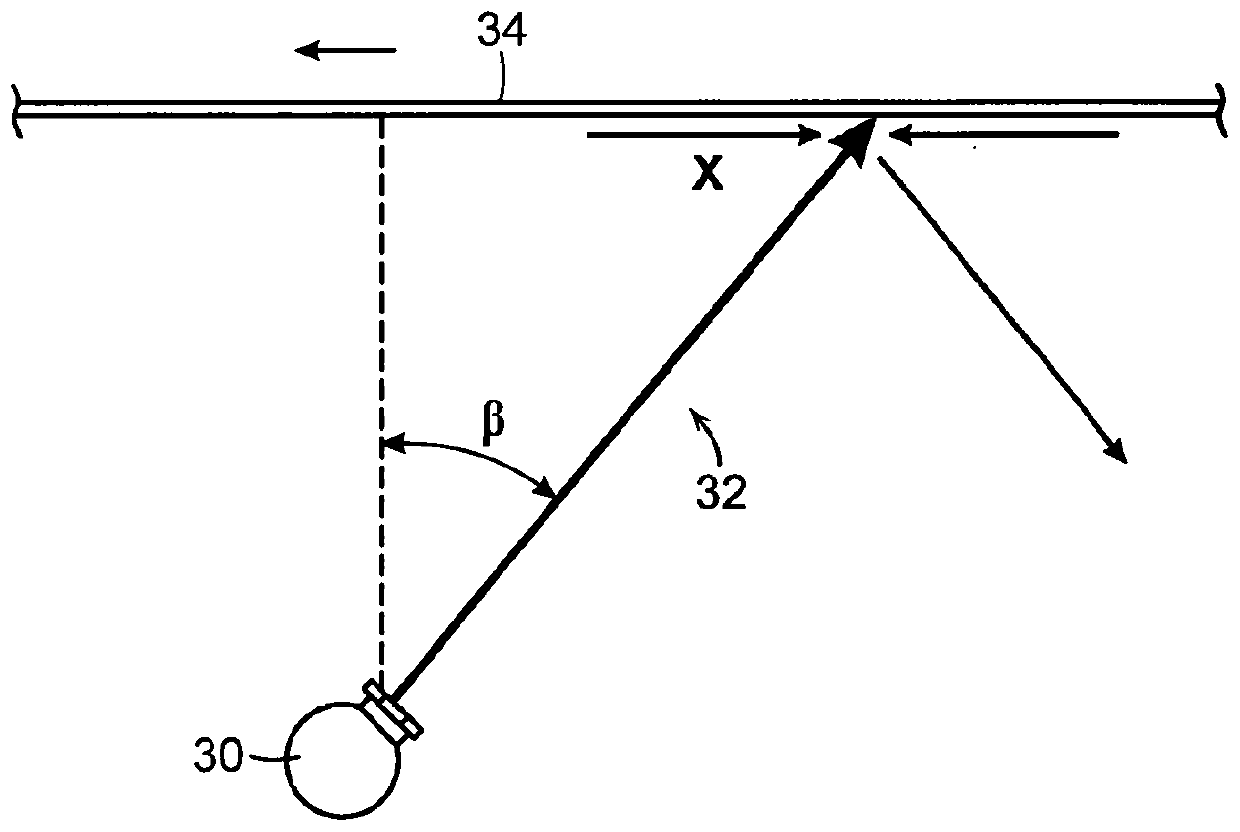

[0018] The geometry of the sprinkler / belt interaction is typically constructed in such a way as to provide the most efficient force vector intersection angle to provide the desired decontamination function. For penetration cleaning (pushing material through the belt), the system is typically set up so that the water spray X velocity vector value equals the belt X velocity value so that the Y force vector pushes the contaminant through the belt. The above content is in figure 1 , which shows a force vector 10 applied to the moving belt 12 , wherein the force vector 10 includes an X-direction component as shown in 14 and a Y-direction component as shown in 16 . Arrangements through penetration are generally well suited for jet nozzles because the impingement is essentially a single point per nozzle and only two axes are needed to determine the optimum impingement angle. The above content is in figure 2 , which shows at 20 that the force vector is maximized when the jet veloci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com