A costal cartilage slicer

A rib cartilage and slicer technology, applied in metal processing and other directions, can solve the problems of indeterminate thickness, cutting, and different slice thicknesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

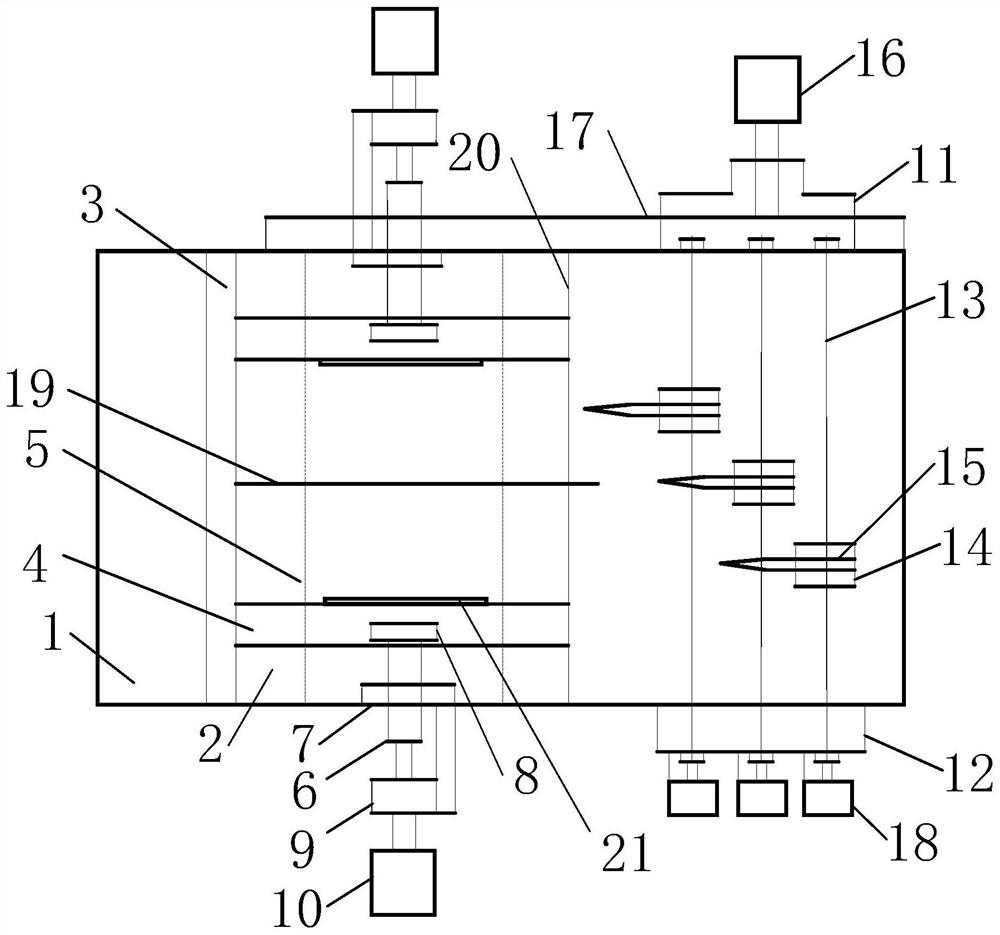

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

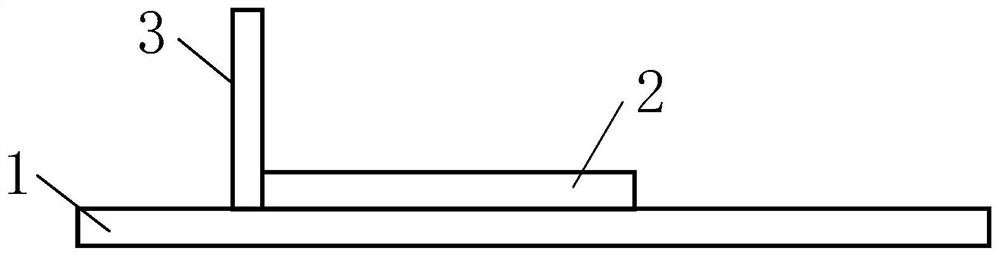

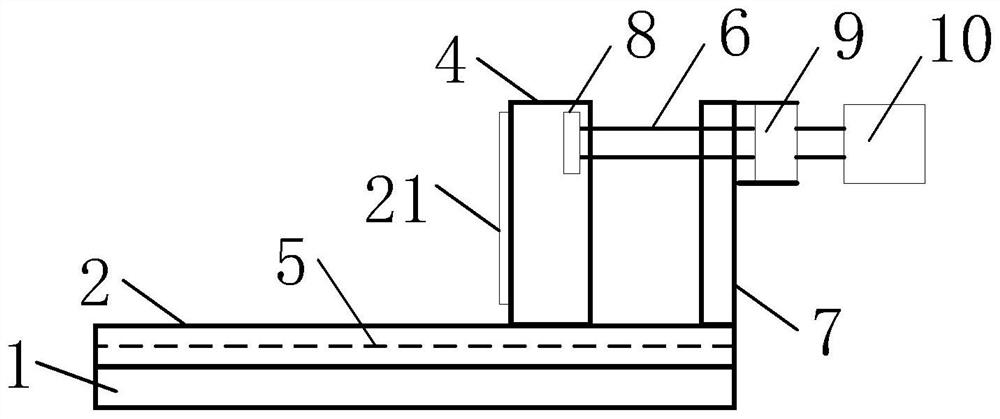

[0025] A costal cartilage slicer, comprising:

[0026] Base plate 1, costal cartilage fixed base plate 2 fixed on base plate 1, blade position baffle plate 3 is fixed on the vertical side of costal cartilage fixed base plate 2, adjustable baffle plate 4 is set on the horizontal two sides respectively, blade position baffle plate 3 and adjustable baffle plate The plates 4 are perpendicular to each other, and a position adjustment screw 6 is provided on the outside of the adjustable baffle 4. The middle part of the position adjustment screw 6 is engaged with the limit fixing block 7, and one end is engaged in the adjustable baffle 4 through the limit plate 8, and the position The adjusting screw 6 is fixedly connected to the drive shaft of the servo motor 9, the housing of the servo motor 9 is fixed on the limit fixing block 7 through the fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com