A cavitation load-reducing rod structure for underwater vehicles

A technology for underwater vehicles and aircraft, applied in the direction of hull, ship construction, hull design, etc., can solve the problems of aircraft shell rupture, damage to the internal structure of the aircraft, failure of the aircraft to enter the water, etc., to reduce the wetted area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will now be further described in conjunction with the embodiments and accompanying drawings:

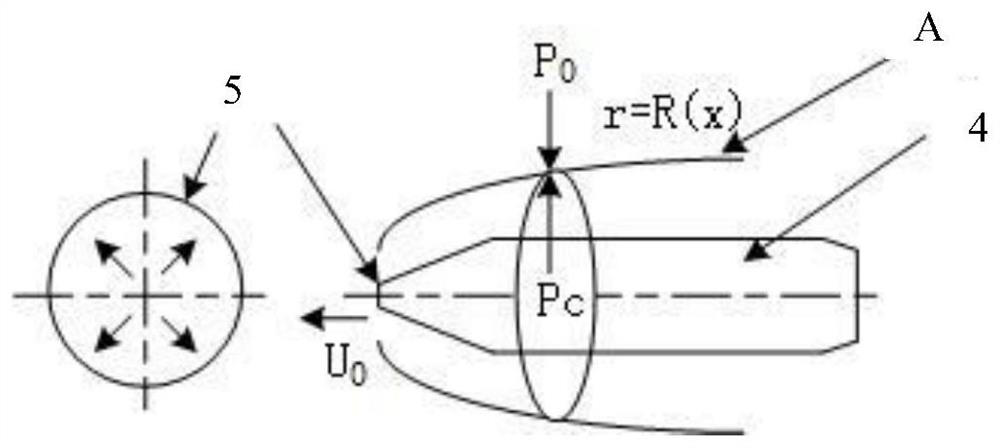

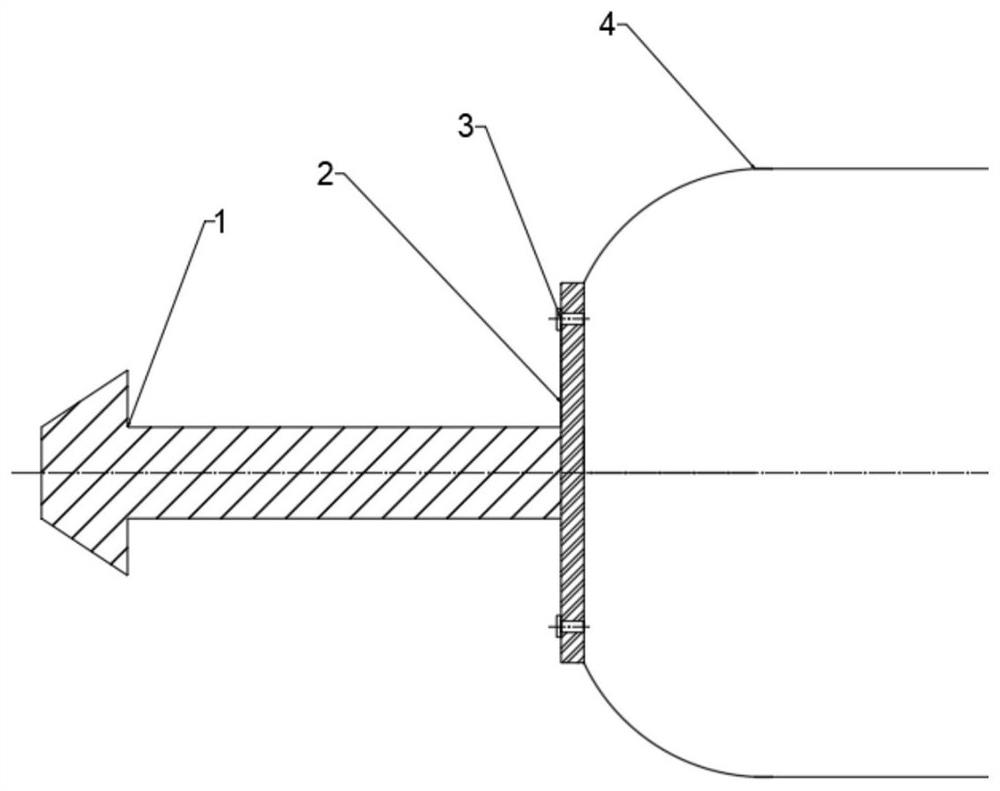

[0024] When the vehicle enters the water at a certain speed, under the action of the head cavitation, the surrounding water pressure P 0 There is a pressure drop process, when it drops to the internal pressure P of the cavity c When Δp=p 0 -p c , the vacuoles form agglomerates. Once this dynamic process reaches an equilibrium point, that is, the pressure values of the two are equal, at this time r=R(x) r is the radius of the vacuoles, and x is the radial length of the vacuoles, satisfying Cavitation Continuity Boundary Condition: When the boundary is in a steady state, a natural supercavitation that is stable and smooth and envelops the entire projectile (except the head cavitation is in a wet state) is formed.

[0025] The water entry speed of the aircraft targeted by the present invention is relatively large, so the natural cavitation device can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com