Safety valve

A safety valve and valve sleeve technology, which is applied in the field of safety valves, can solve the problems of increasing the overall volume, increasing the use cost and the complexity of installation, and achieves the effects of compact size, simple structure and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

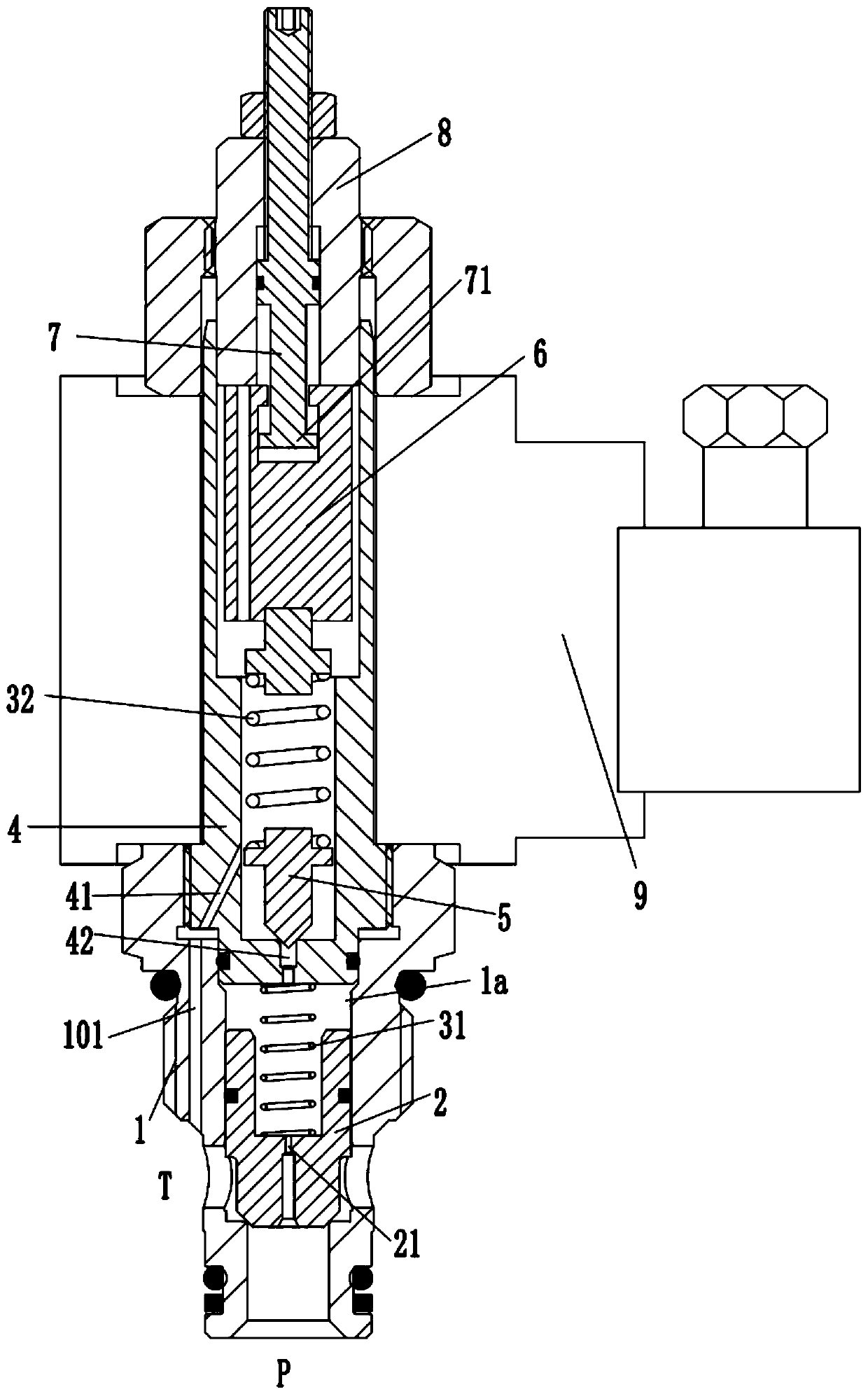

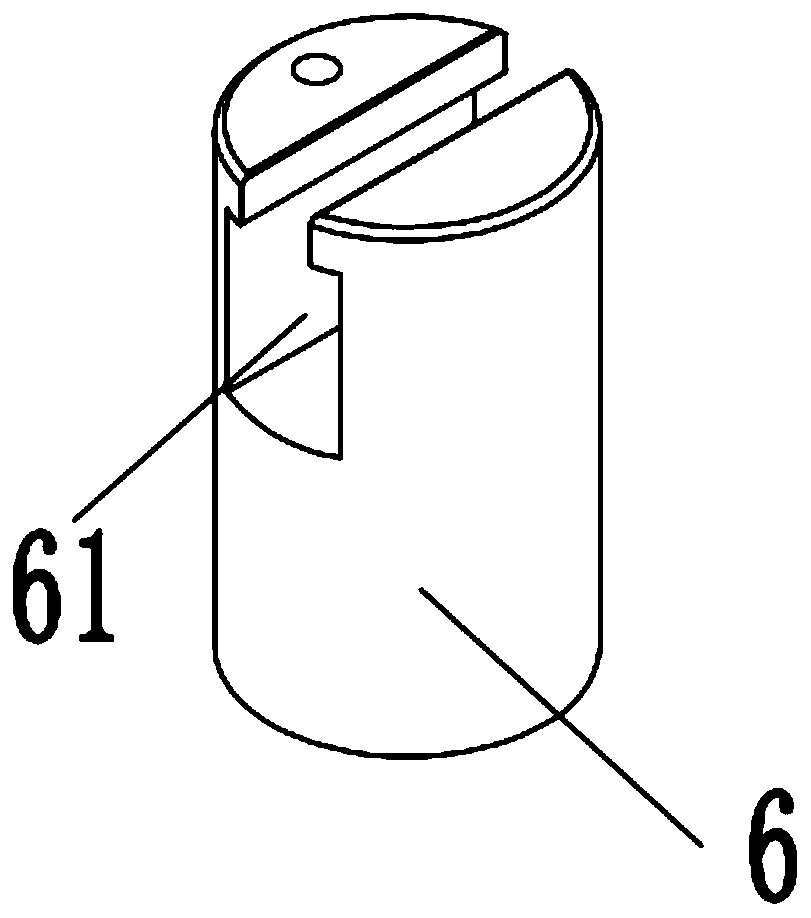

[0015] see Figure 1-2 As shown, a safety valve includes a valve sleeve 1, the valve sleeve 1 is provided with a valve hole with an upper end opening, the valve sleeve 1 is provided with a through hole at the bottom of the valve hole, and the lower end of the through hole is P The side of the valve sleeve is provided with a T port connected to the valve hole. The valve core 2 for controlling the on-off of the through hole is slidably connected in the valve hole, and the upper opening of the valve hole is fixedly installed with a magnetic sleeve. 4. In the valve hole, a control cavity 1a is formed between the valve core 2 and the magnetic sleeve 4; the magnetic sleeve 4 is provided with a magnetic sleeve through hole penetrating in the axial direction, and the magnetic sleeve through hole is formed by From top to bottom, it includes a sliding hole, a mounting hole and a pilot valve port. The mounting hole communicates with the T port through the communication channel provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com