Plastic oscillator standing wave test system and test method

A test system and vibrator technology, which is applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems that the standing wave ratio of plastic vibrators cannot be monitored in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

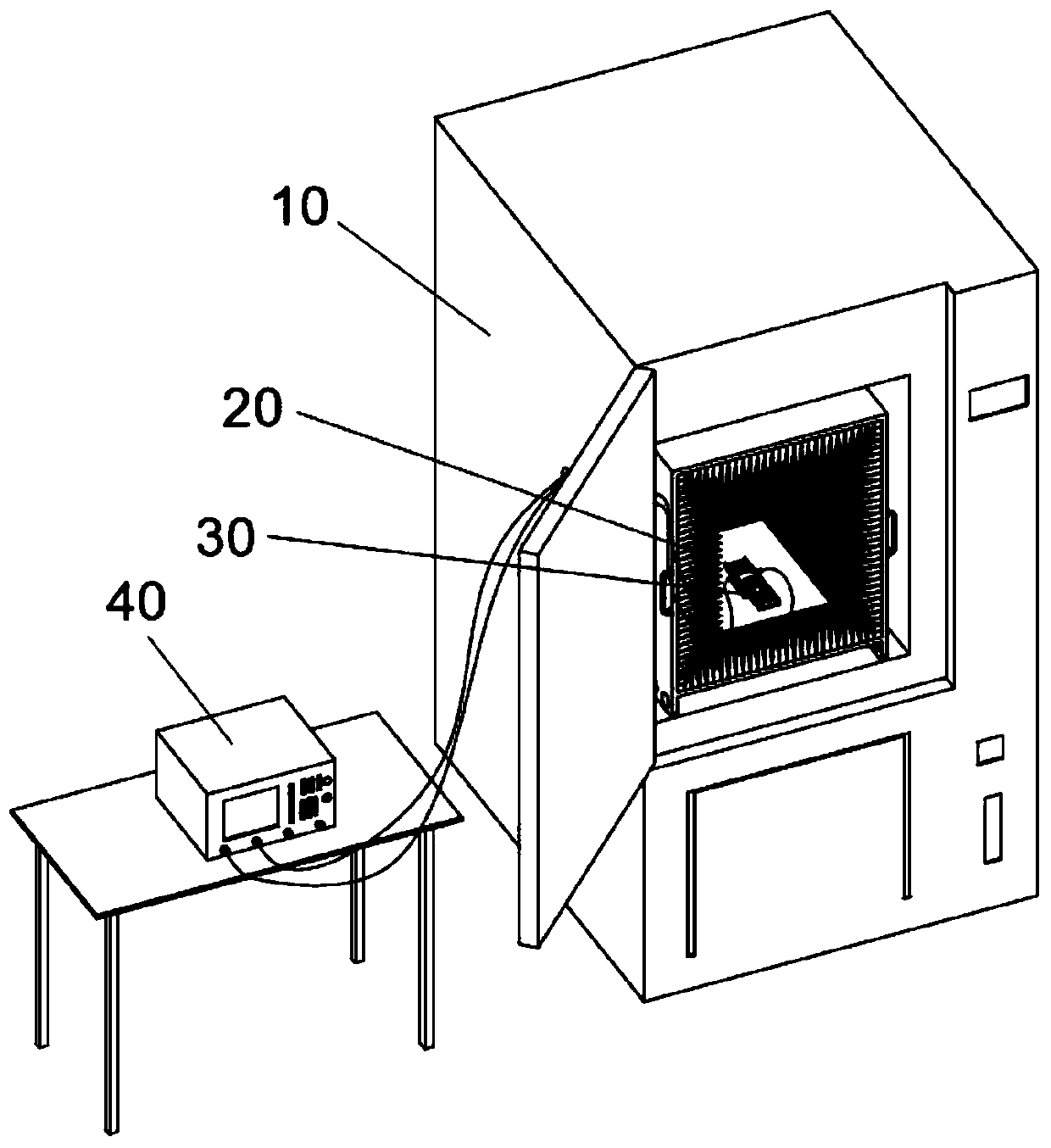

[0035] Example 1 Plastic vibrator standing wave test system

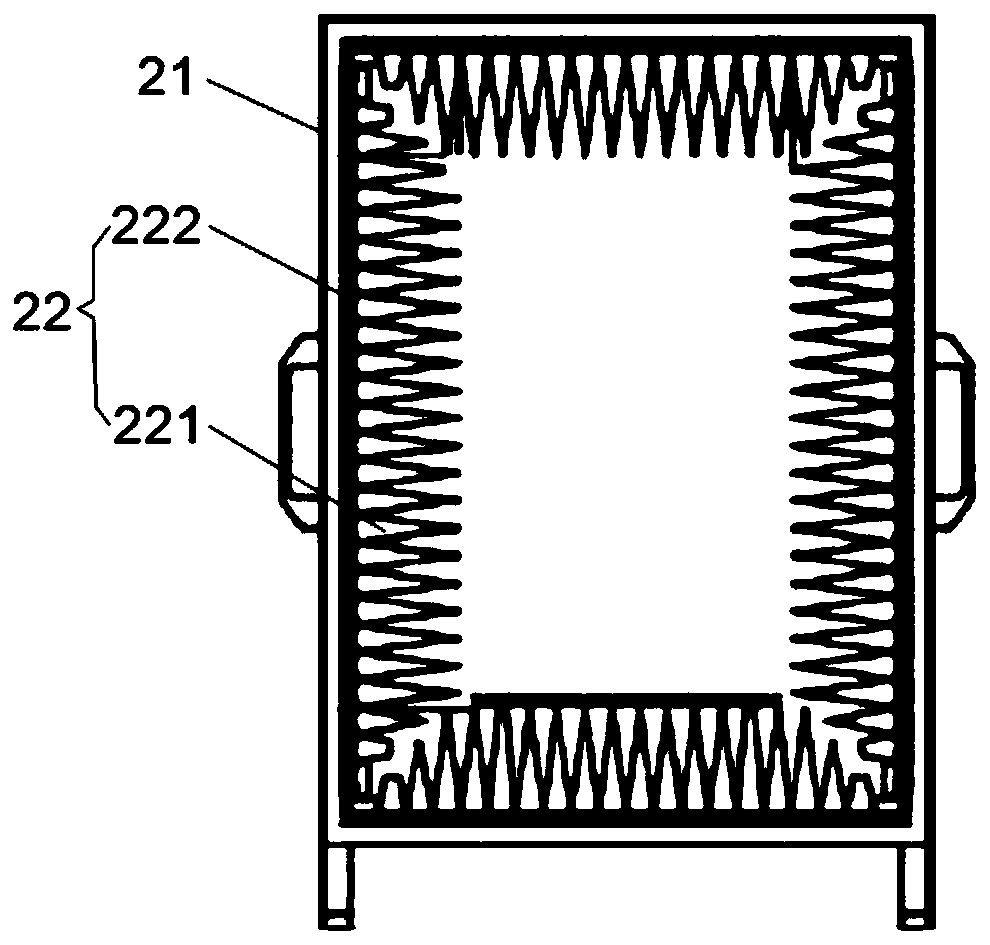

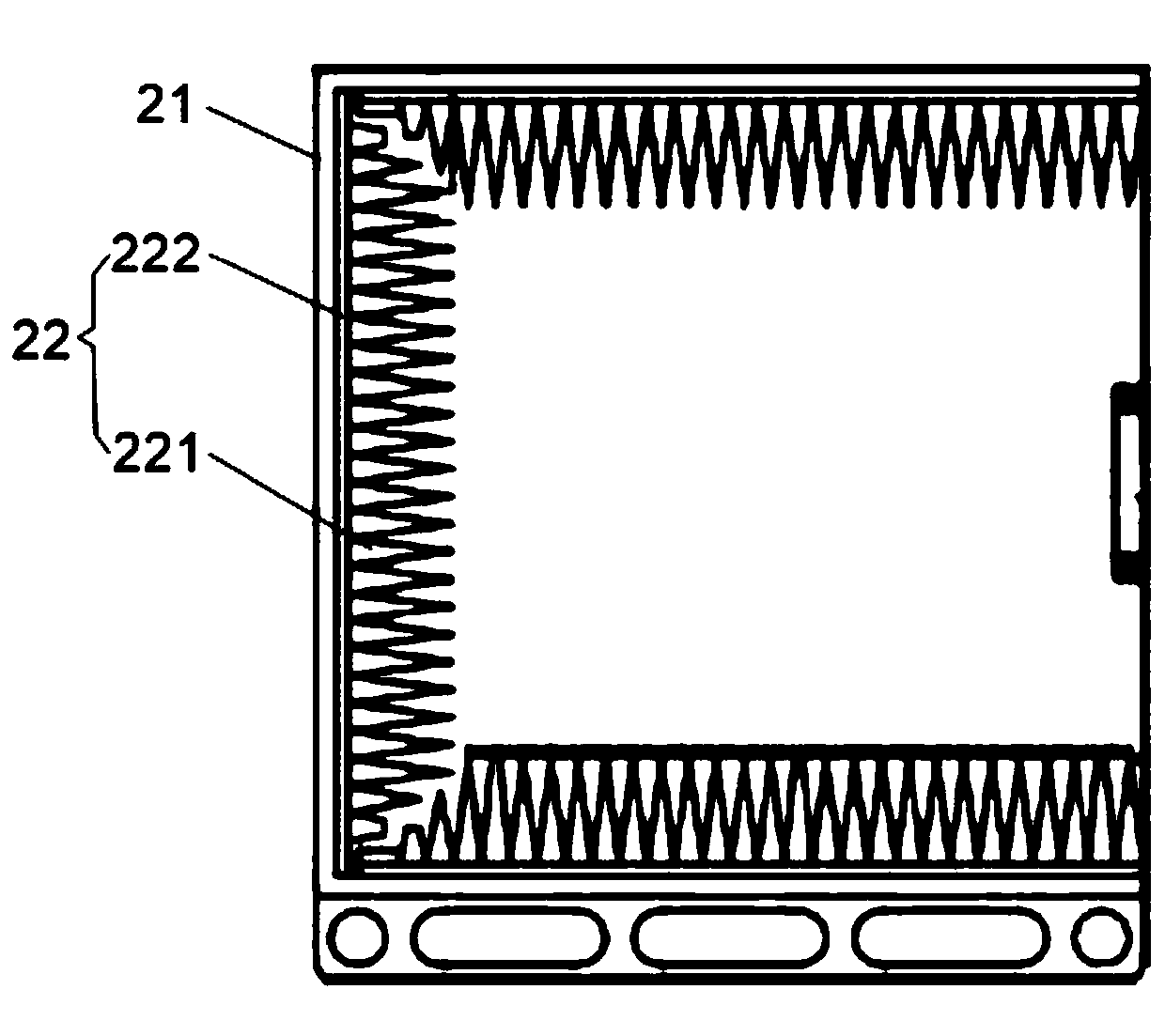

[0036] The embodiment of the present invention proposes a plastic vibrator standing wave test system, which can be used for plastic vibrator standing wave testing in high and low temperature environments, including a high and low temperature test box 10, a microwave shielding dark box 20, a test tool 30 and a network analyzer 40; The high and low temperature test chamber 10 has an inner cavity capable of accommodating the microwave shielding dark box 20 for accommodating the microwave shielding dark box 20; the microwave shielding dark box 20 is used for accommodating the testing tool 30 and the plastic vibrator M to be tested; The plastic vibrator M to be tested is placed on the test tool 30 for standing wave testing; the network analyzer 40 is used to record standing wave test data.

[0037] The high and low temperature test box 10 is preferably a high and low temperature test box 10 capable of withstanding a weight of...

Embodiment 2

[0055] Example 2 Plastic vibrator standing wave test method

[0056] The embodiment of the present invention also provides a method for performing a standing wave test on a plastic vibrator by using the plastic vibrator standing wave test system, which includes the following steps:

[0057] S1. Place the microwave shielding dark box 20 in the high and low temperature test box 10 so that the distance between the outer wall of the microwave shielding dark box 20 and the inner wall of the high and low temperature test box 10 is not less than 50mm to ensure a good internal circulation during heat exchange;

[0058] S2. Electrically connect the network analyzer 40 and the SMA connector 331 on the test tool 30;

[0059] S3. Place the plastic vibrator M to be tested on the test tool 30, so that the feed pin M1 on the plastic vibrator M to be tested contacts the probe fixed on the impedance matching circuit board 33 of the test tool 30, so that the two are electrically connected;

[0060] S4. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com