Raw material crushing device for medicine production

A technology for raw material pulverization and pharmaceutical production, applied in grain processing and other directions, can solve problems such as affecting the extraction of medicinal material particles, incomplete pulverization of medicinal materials, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

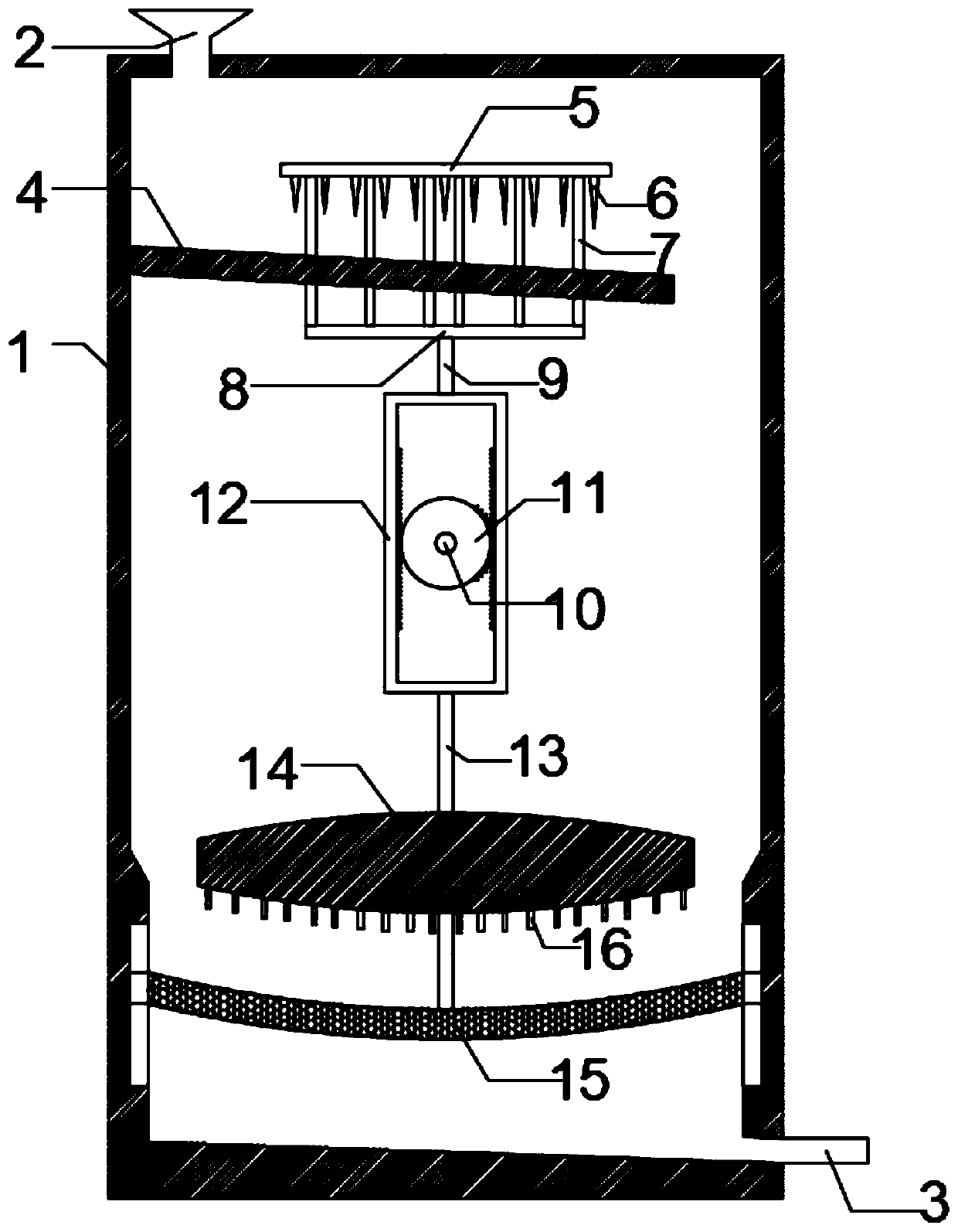

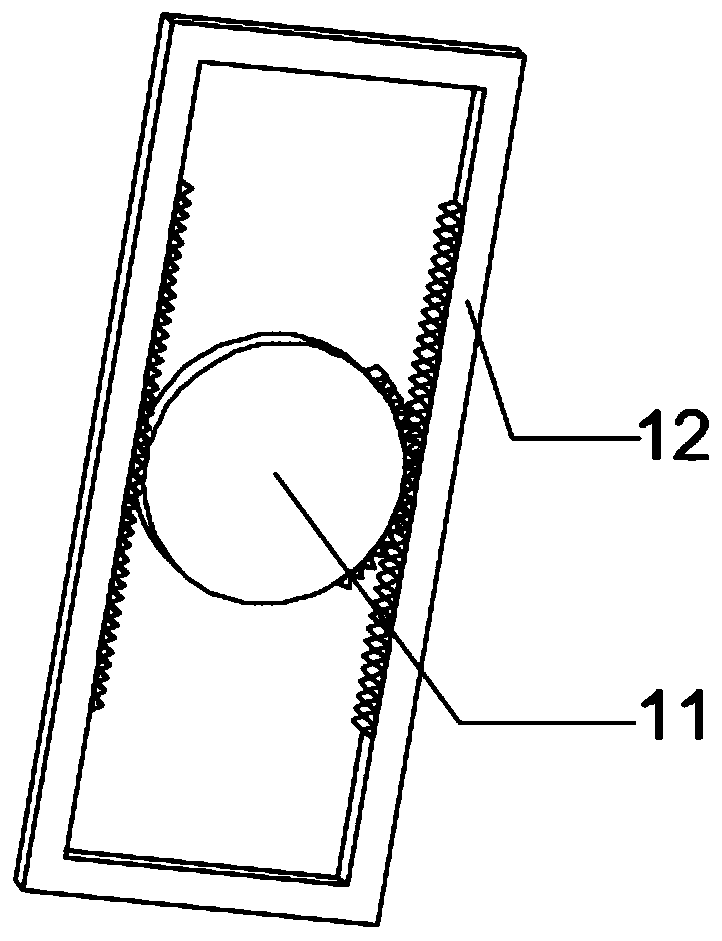

[0019] see Figure 1-2 , this embodiment provides a raw material crushing device for pharmaceutical production, comprising a device housing 1, a feed port 2 and a discharge port 3; the upper and lower ends of the device housing 1 are respectively provided with a feed port 2 and a feed port A discharge port 3 for discharging; also includes a chopping mechanism; the chopping mechanism includes a fixed chopping plate 4, a chopping horizontal plate 5, a chopping blade 6, a chopping slide bar 7, and a chopping cross bar 8 And the upper connecting rod 9; the left end and the front and rear ends of the fixed chopping plate 4 are fitted and fixed on the inner wall of the device shell 1, and there is a gap between the right end of the fixed chopping plate 4 and the inner wall of the device shell 1; the fixed The chopping plate 4 is arranged obliquely, and its right end is located at the lowest side; the top of the fixed chopping plate 4 is provided with a chopping horizontal plate 5; t...

Embodiment 2

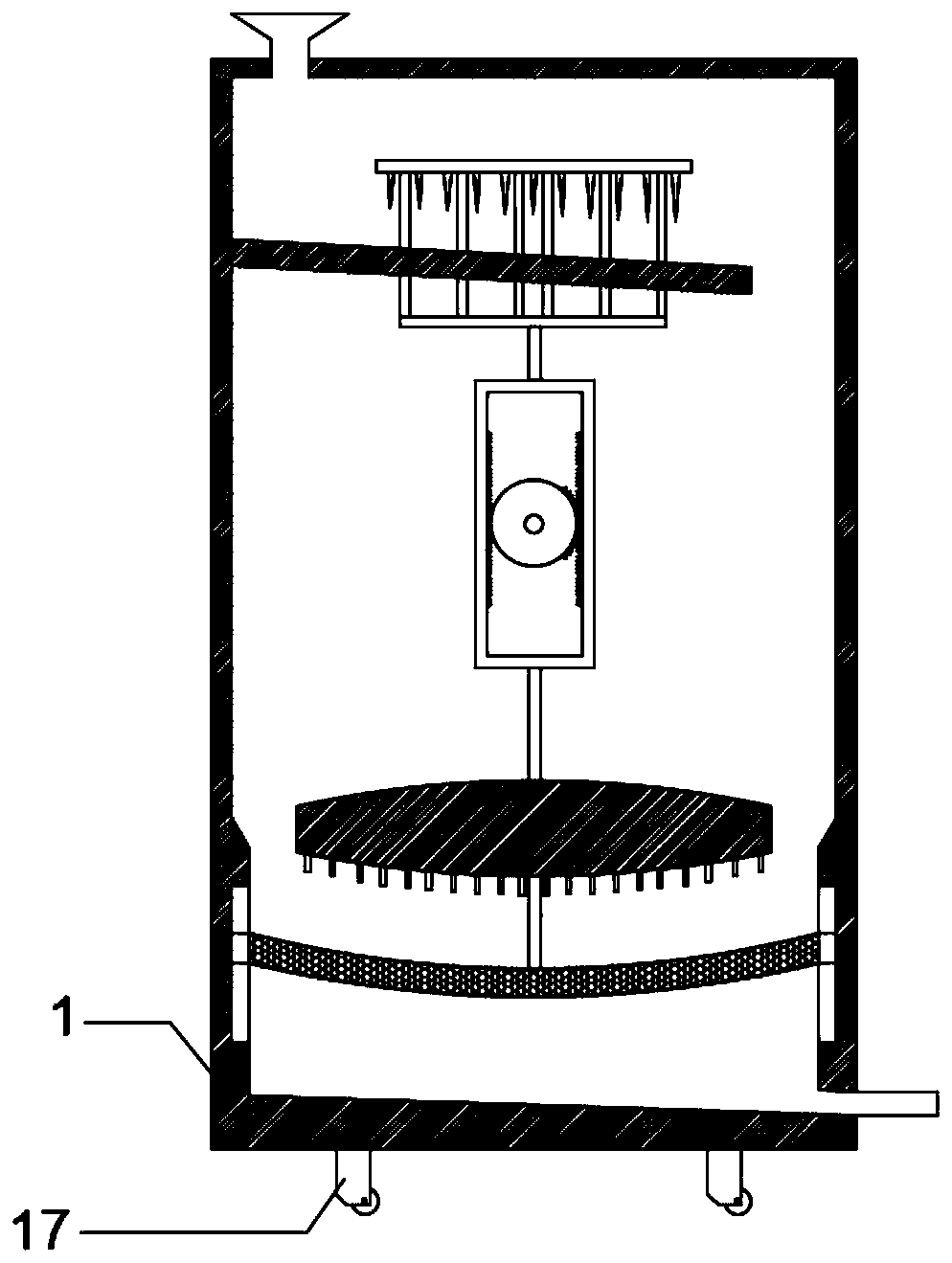

[0026] see image 3 , this embodiment is further improved on the basis of Embodiment 1, the improvement is: in order to facilitate the discharge of the crushed raw materials, the bottom of the inner wall of the device shell 1 is set to be inclined, and the discharge port 3 is located at its lowest side.

[0027] In order to facilitate the movement of the device, the bottom of the device housing 1 is equidistantly provided with a plurality of wheels 17 for easy movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com