Torque control method in mode switching process of hybrid electric vehicle

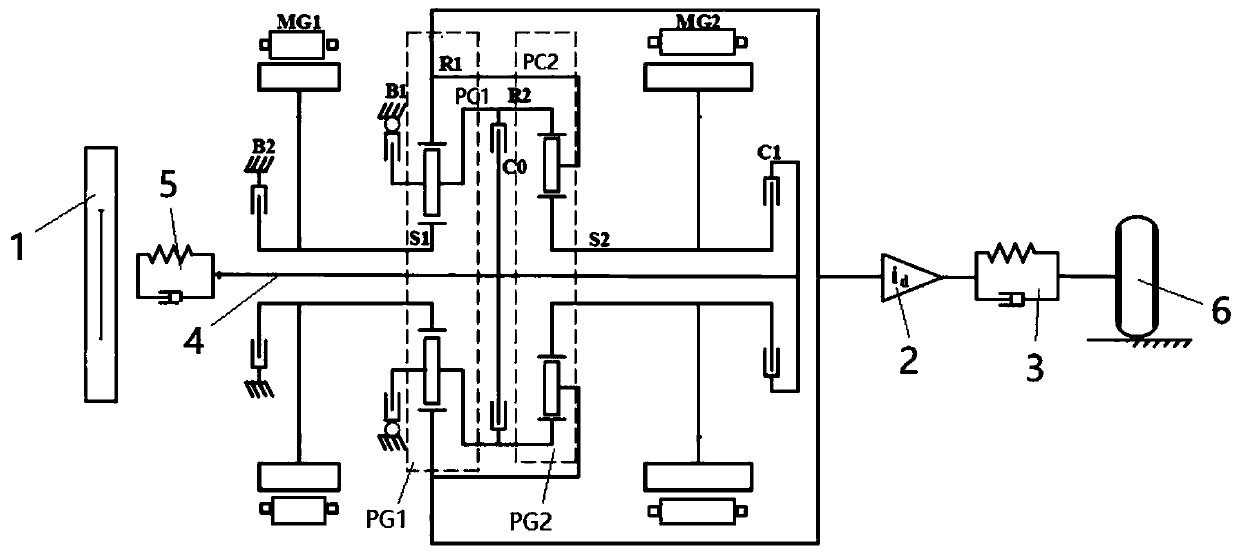

A hybrid electric vehicle, mode switching technology, applied in hybrid electric vehicles, motor vehicles, power plants, etc., can solve problems such as torsional vibration, lever attitude can not effectively adjust the optimal operating point of the engine, output torque deviates from the driver's power demand, etc. , to achieve efficient distribution, accurate demand torque, and avoid response deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

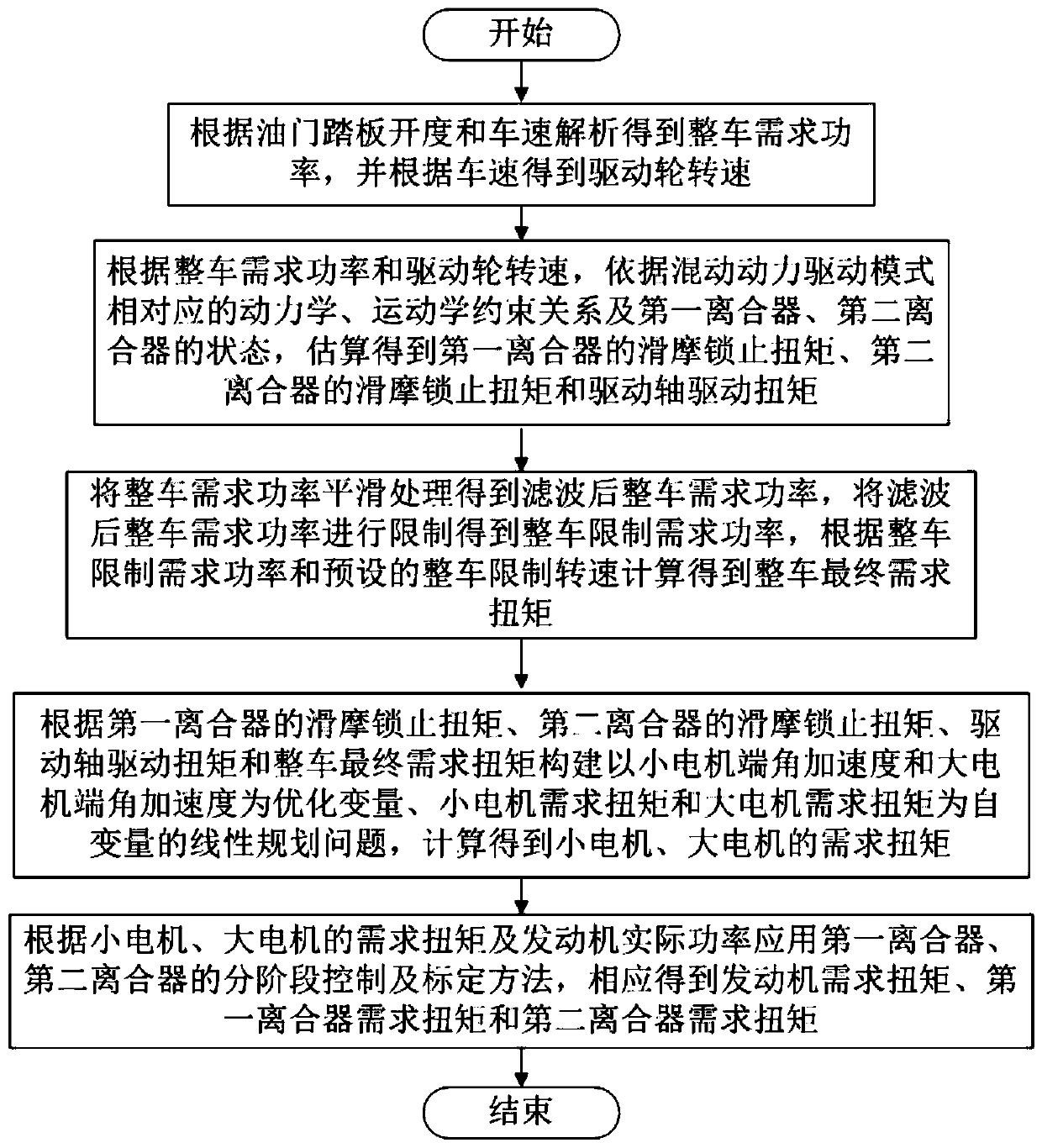

[0033] A torque control method during mode switching of a hybrid electric vehicle, the control flow chart of which is as follows figure 2 As shown, when the vehicle switches between any two hybrid drive modes, follow the steps below:

[0034] The S1 driver model obtains the required power of the vehicle according to the accelerator pedal opening and vehicle speed analysis, and obtains the driving wheel speed according to the vehicle speed;

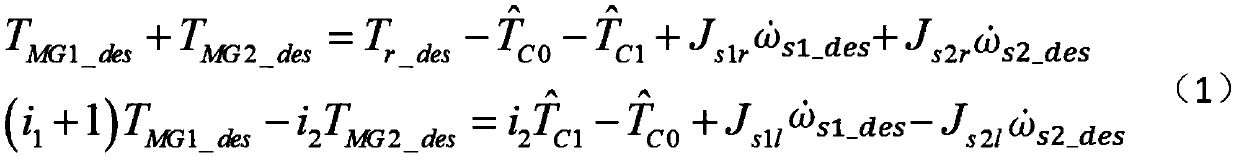

[0035] S2 According to the required power of the vehicle and the rotational speed of the driving wheels obtained in step S1, according to the dynamics and kinematics constraints corresponding to the hybrid drive mode and the states of the first clutch and the second clutch, the observer method is used to estimate and obtain the first The slipping lock-up torque of the clutch, the slipping lock-up torque of the second clutch, and the drive shaft drive torque; wherein, the observer method includes an input observer method, a reduced-order obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com