Snap-in braid and preparation method thereof

A webbing and buttonhole technology, which is applied in fasteners, applications, clothing, etc., can solve the problems of reduced adhesion and buckle performance of accessories, wear off, fluffing of the rough surface, etc., and achieve long-term stable performance, increased recognition, and improved life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

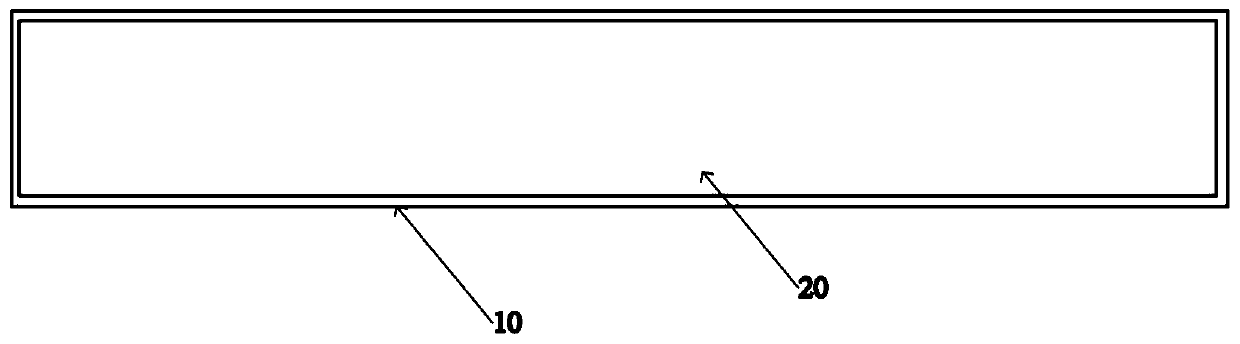

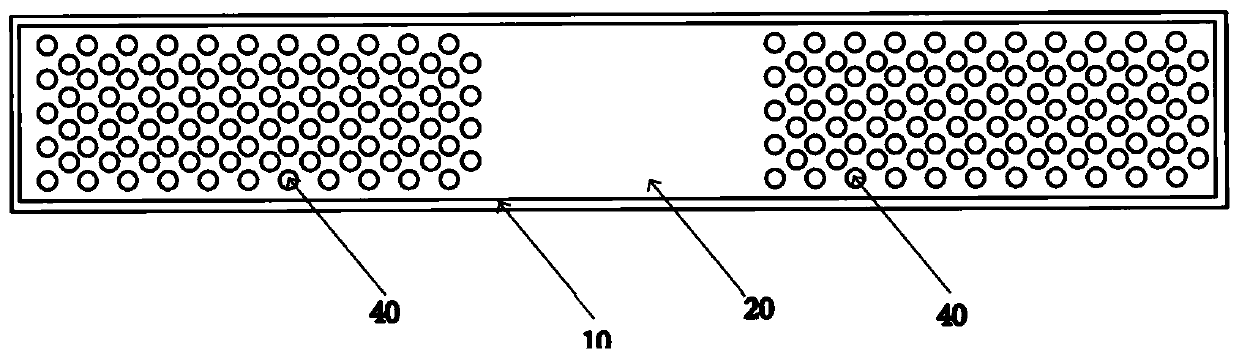

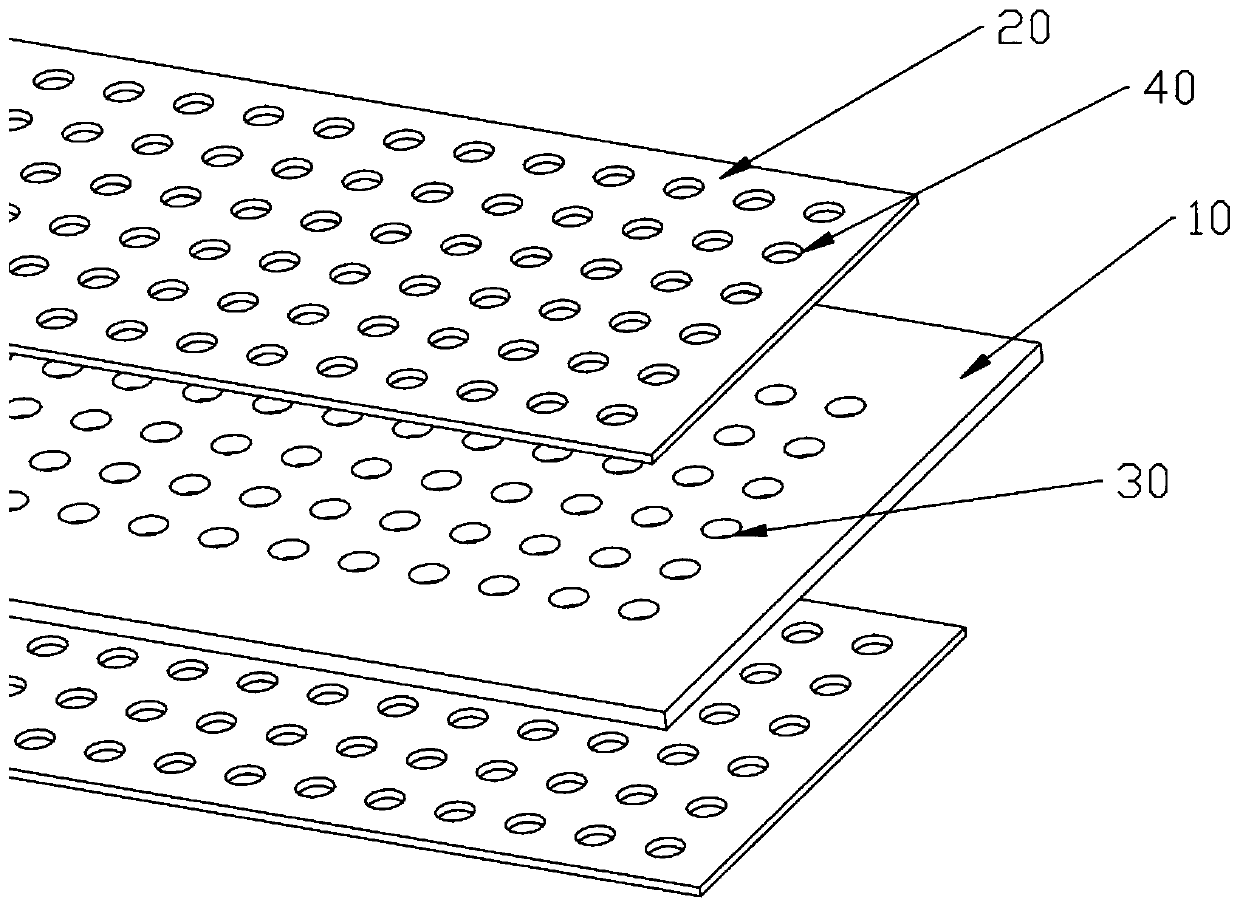

[0037] Examples such as Figure 1 to Figure 10 As shown, the buckle type webbing and its preparation method are provided with a webbing 10 and a bottom webbing 80, the webbing 10 is laser perforated and has a number of round holes 30, and the bottom web 80 is injection-molded with a shading reinforcement structure 60 at one time. With mushroom heads 70.

[0038] A reflective film 20 is hot-pressed on the webbing 10, and a number of buckle holes 40 are perforated by laser in the reflective film 20. The snap holes 40 are arranged correspondingly to the round holes 30, and the reflective film can prevent the webbing from falling apart.

[0039] The reflective film 20 has a thickness of 0.05-0.3mm.

[0040] The hasp holes 40 are arranged in a rectangular array, and the size of the holes is 1mm-3mm.

[0041] The mushroom head 70 is located above the shading reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com