Driving and transmission device based on ceramic rubber rollers for material conveying device

A technology of conveying equipment and rubber rollers, which is applied in the field of driving devices, can solve problems such as poor structure, inability to realize quick disassembly and assembly, and inability to realize quick disassembly of clean structures, etc., to achieve the effect of improving convenience and quick and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

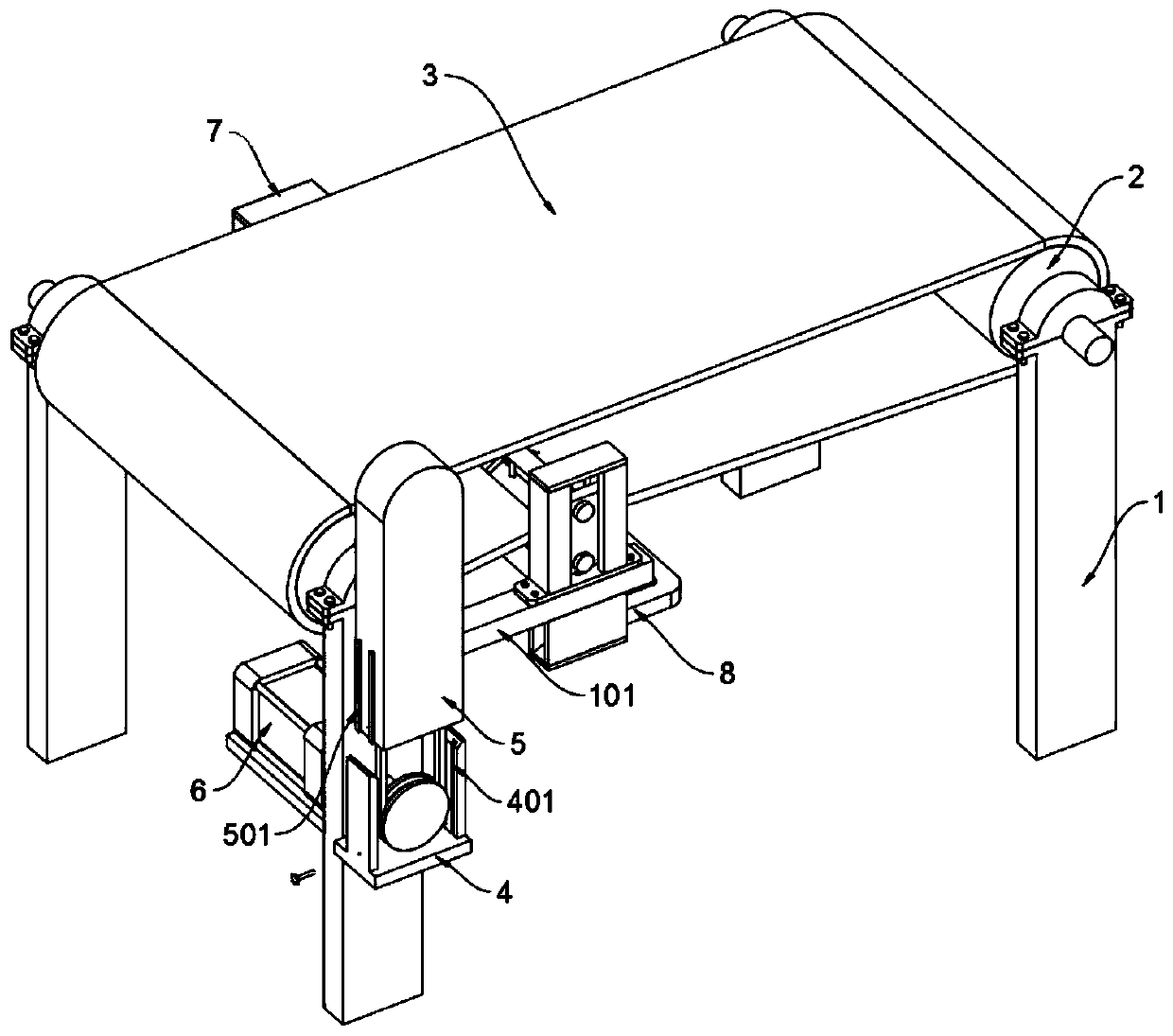

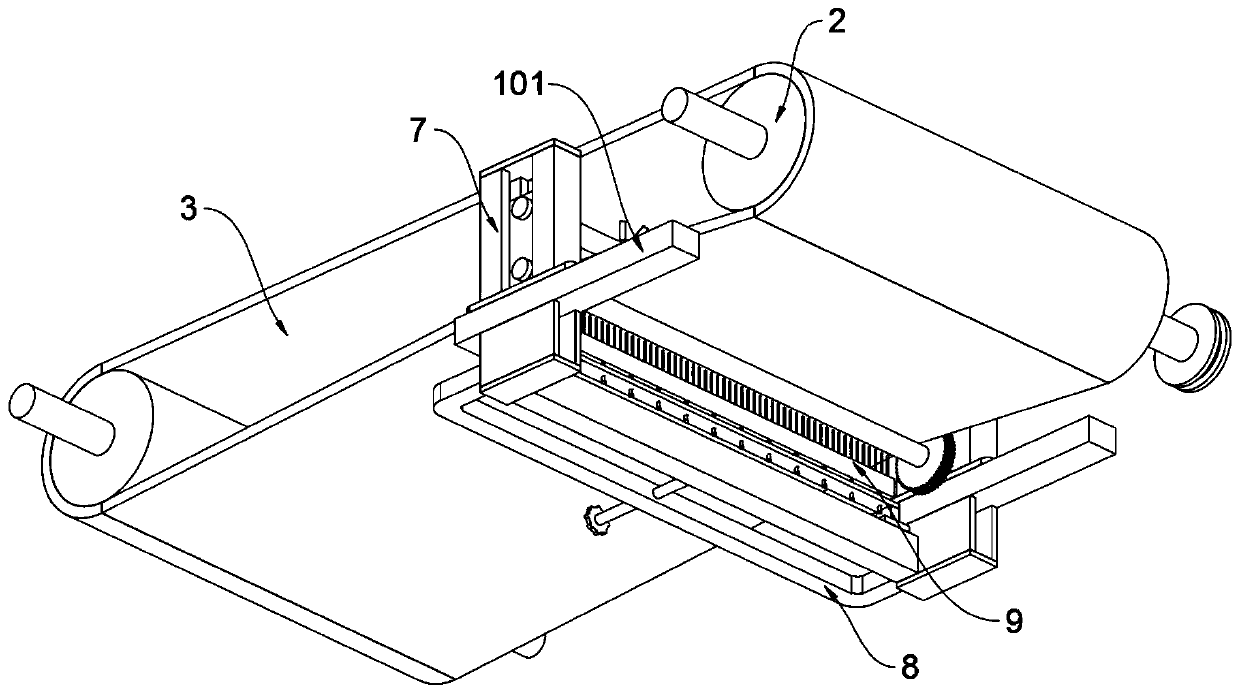

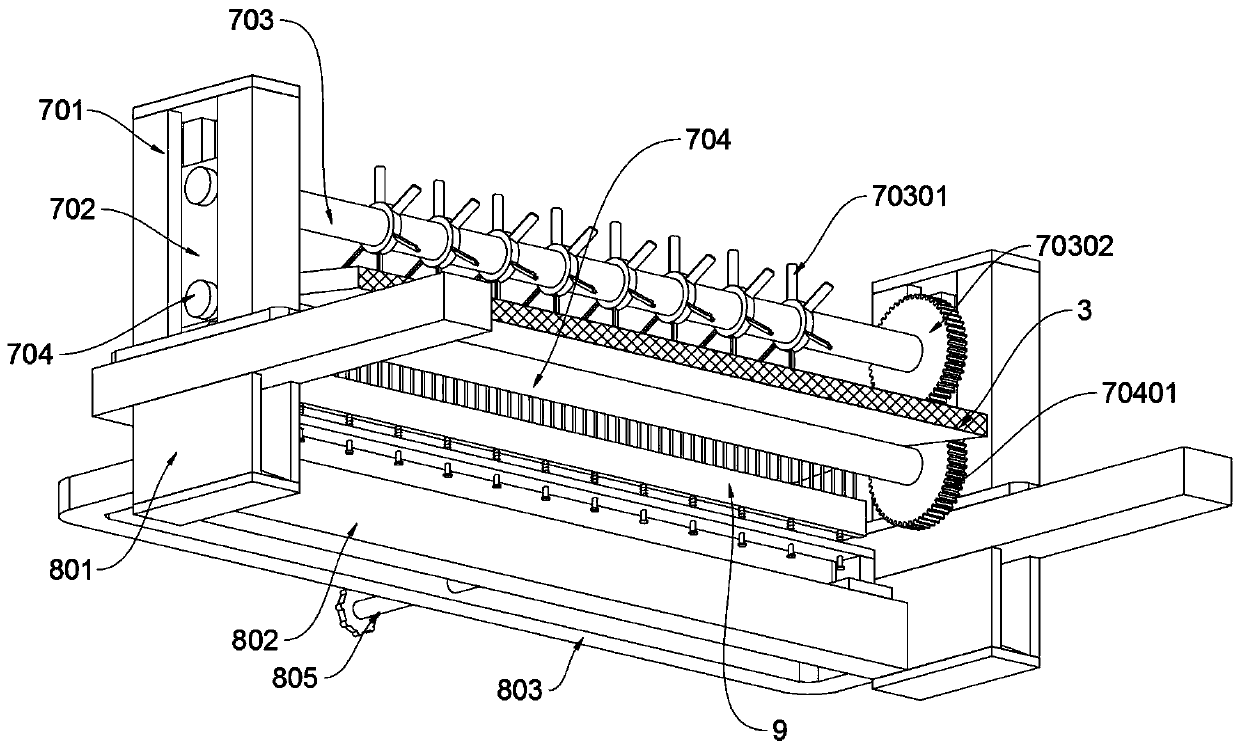

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides a driving and transmission device based on a ceramic rubber roller for material conveying equipment, including a support leg 1; two rollers 2 are installed on the support leg 1, and a conveyor belt 3 is connected to the roller 2, and the support leg 1 is welded with a Arm 101; the motor fixing seat 4 is welded on the supporting leg 1, and the motor fixing seat 4 is fixed with a protective cover 5 by bolts, and the supporting leg 1 is connected with a servo motor 6 by bolts; the supporting leg 1 is welded with a tensioning structure 7, and the adjustment structure 8 is welded on the supporting leg 1; refer to as figure 1 and Figure 4 , the tensioning structure 7 includes a sliding seat A701, a sliding block 702, a rotating shaft A703, a fan blade 70301, a gear A70302, a rotating shaft B704 and a gear B70401, there are two sliding seats A701, and the two sliding seats A701 are weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com