Water-wave-proof open-type self-ventilation main generator installed under vehicle and used for internal combustion motor car

A main generator, open type technology, used in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve problems such as the impact of motor insulation performance, and achieve good ventilation and cooling effects and large volume power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

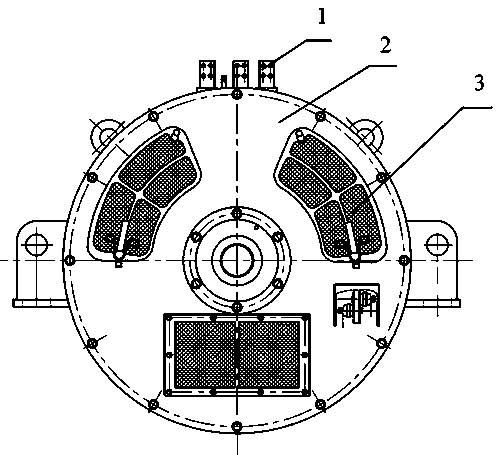

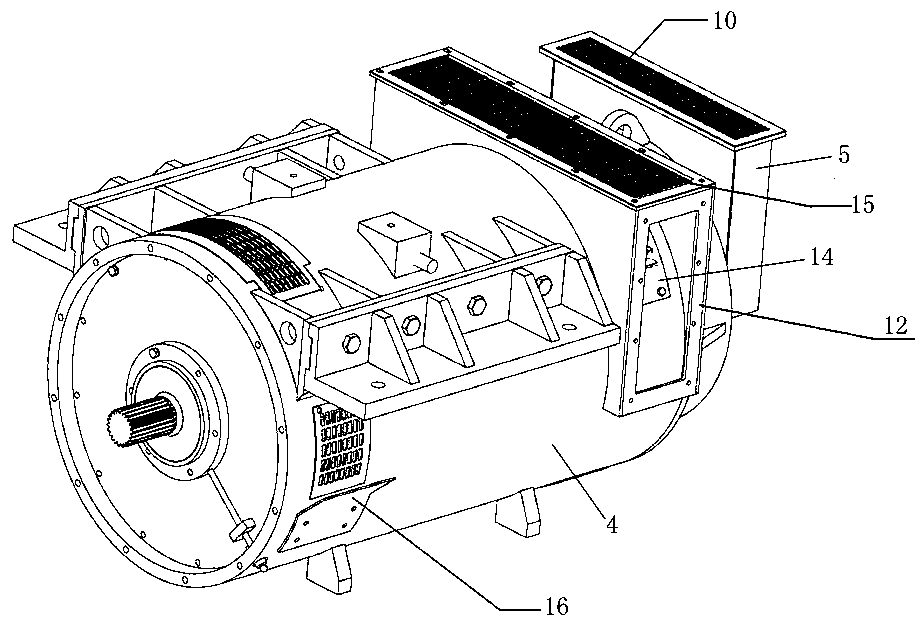

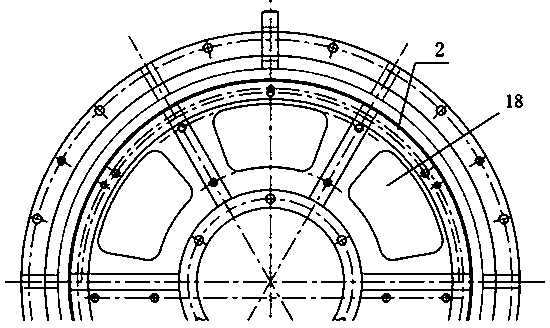

[0021] Install the waterproof wave-opening self-ventilating main generator of the internal combustion motor vehicle under the car, including a base 4, on which a non-drive end cover 2 with a first air inlet 18 is opened; Air duct 5, the bottom of air guiding tube 5 is sealed, and the opening at the top is upward. On the side opposite to the outer end face of the non-driving end cover 2 of the air guiding tube 5, there is a first air inlet opening on the non-driving end cover 2. The air intake window 6 facing the 18 positions. In this way, by setting the air guide tube, the axial air intake is transferred to the radial air intake above the motor to reduce the entry of water waves. Further, a first drainage hole 7 is opened at the bottom of the air guide tube 5 to discharge a small amount of accumulated water splashed into the air guide tube. The first air inlet 18 on the non-drive end cover 2 is opened above the horizontal center line of the non-drive end cover 2, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com