A building floor thickness detector

A technology of thickness detection and thickness measurement, which is applied in the field of construction, can solve the problems of measurement data error fluctuation, movement deviation, etc., and achieve the effect that it is not easy to deviate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] as attached figure 1 to attach Figure 5 Shown:

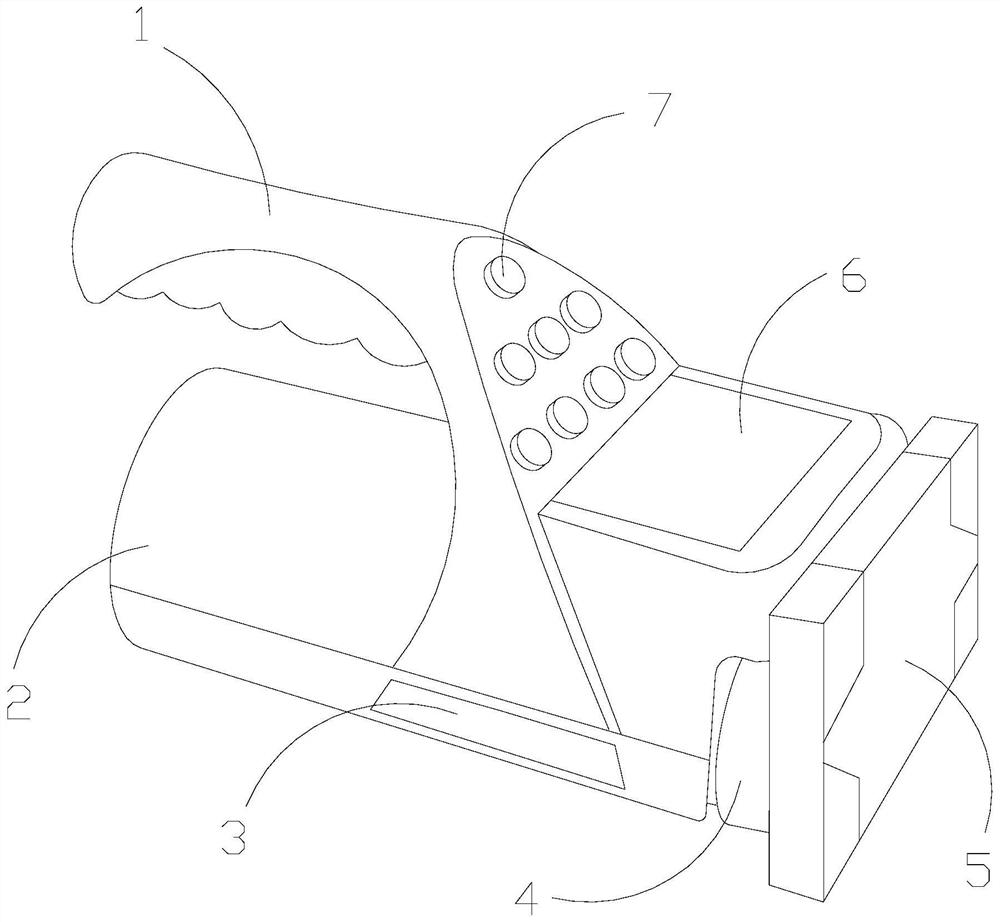

[0031] The invention provides a building floor thickness detector, the structure of which includes a handle 1, a power supply casing 2, a blockage bar 3, a receiving plate 4, a thickness measurement extension device 5, a display 6, and a control button 7. The handle 1 and the power supply The casing 2 is fixedly connected together, the blockage bar 3 is embedded and installed on the side of the power supply casing 2, the handle 1 is fixedly connected with the display 6, the receiving tray 4 is installed on the right side of the display 6, and the control The key 7 is embedded on the hand 1, and the receiving plate 4 is attached to the thickness measurement and abduction device 5 .

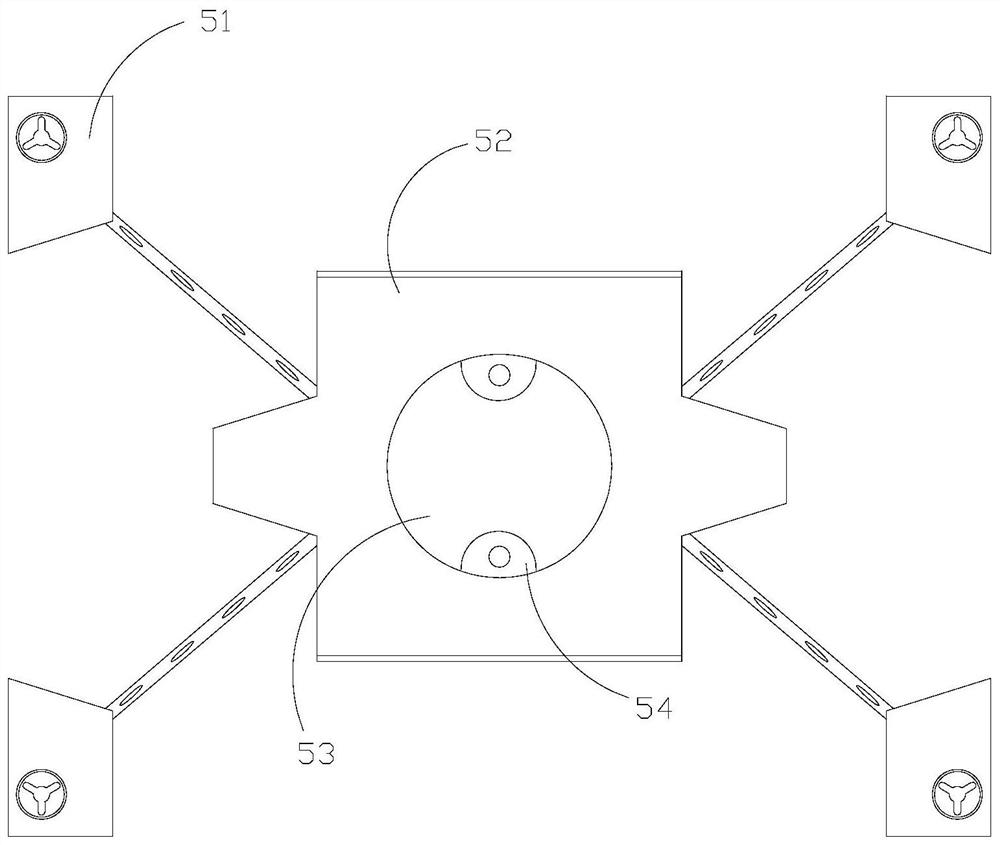

[0032] The thickness measurement outreach device 5 includes a spreading mechanism 51, a main sticking plate 52, a middle sticking plate 53, and a buckle piece 54. There are four spreading mechanisms 51 installed at the four corners of the ...

Embodiment 2

[0038] as attached Figure 6 to attach Figure 8 Shown:

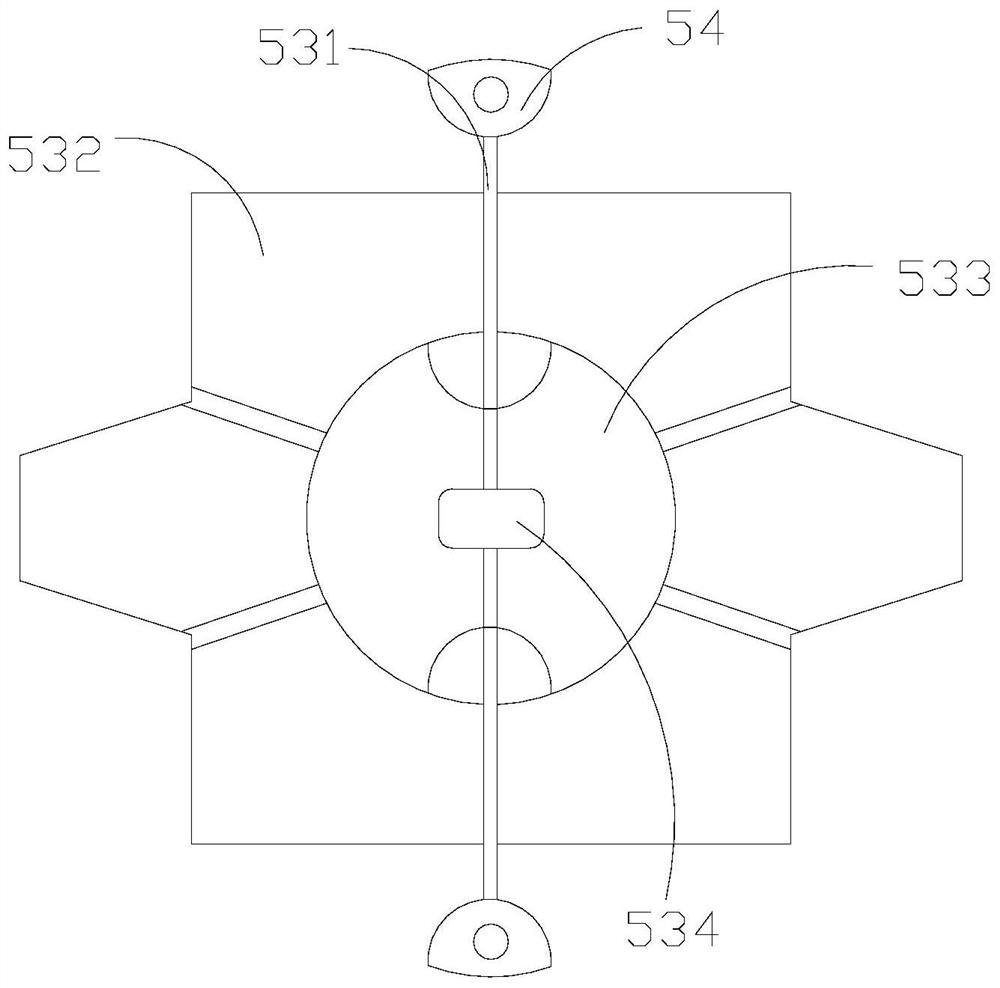

[0039] The present invention provides a building floor thickness detector. The extension mechanism 51 includes a clamping mechanism 511, a rotating disk 512, an inner rotating shaft 513, a display piece 514, and a stretching mechanism 515. The clamping mechanism 511 is embedded in the rotary On the disc 512, the inner rotating shaft 513 is installed on the rotating disc 512 by embedding, the spreading sheet 514 is fixedly connected with the inner rotating shaft 513, and the extending and pulling mechanism 515 is arranged on the right side of the spreading sheet 514 and fixed Installed on the surface, there are four extension mechanisms 51 that can be simultaneously deployed in four directions through the connection of the extension and pull mechanism 515, and are fixed by hooks to keep them in a stable state at the target point.

[0040] Wherein, the clamping mechanism 511 includes an elastic bar q1, a film q2, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com