Storage box for storing binding wires and preparation method of storage box

A realization method and storage box technology, applied in packaging, tool storage devices, manufacturing tools, etc., can solve problems such as waste, increased labor intensity of steel workers, inconvenient picking and placing of wires, etc., to achieve simple and convenient storage, easy to carry, The effect of convenient and continuous access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

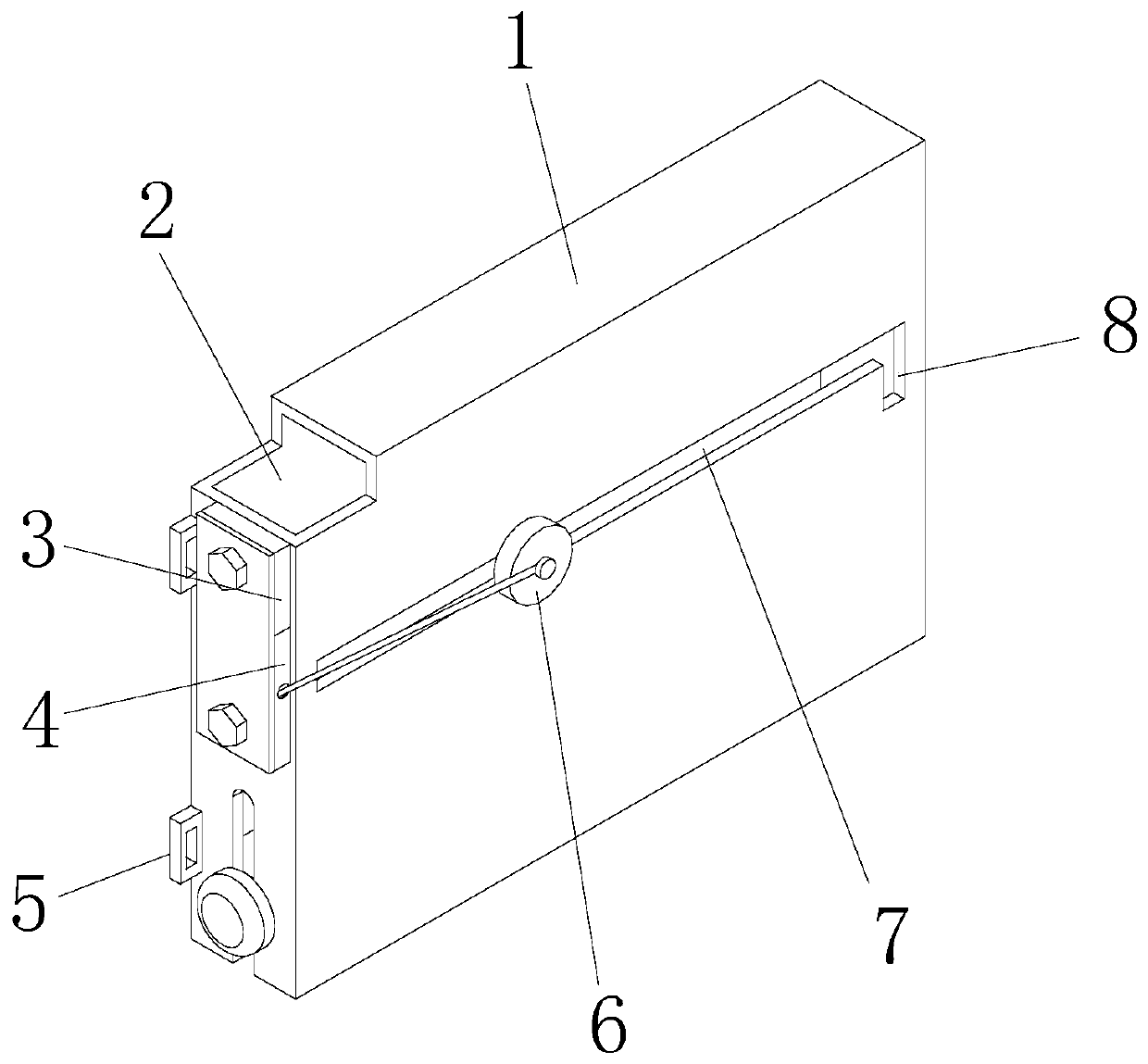

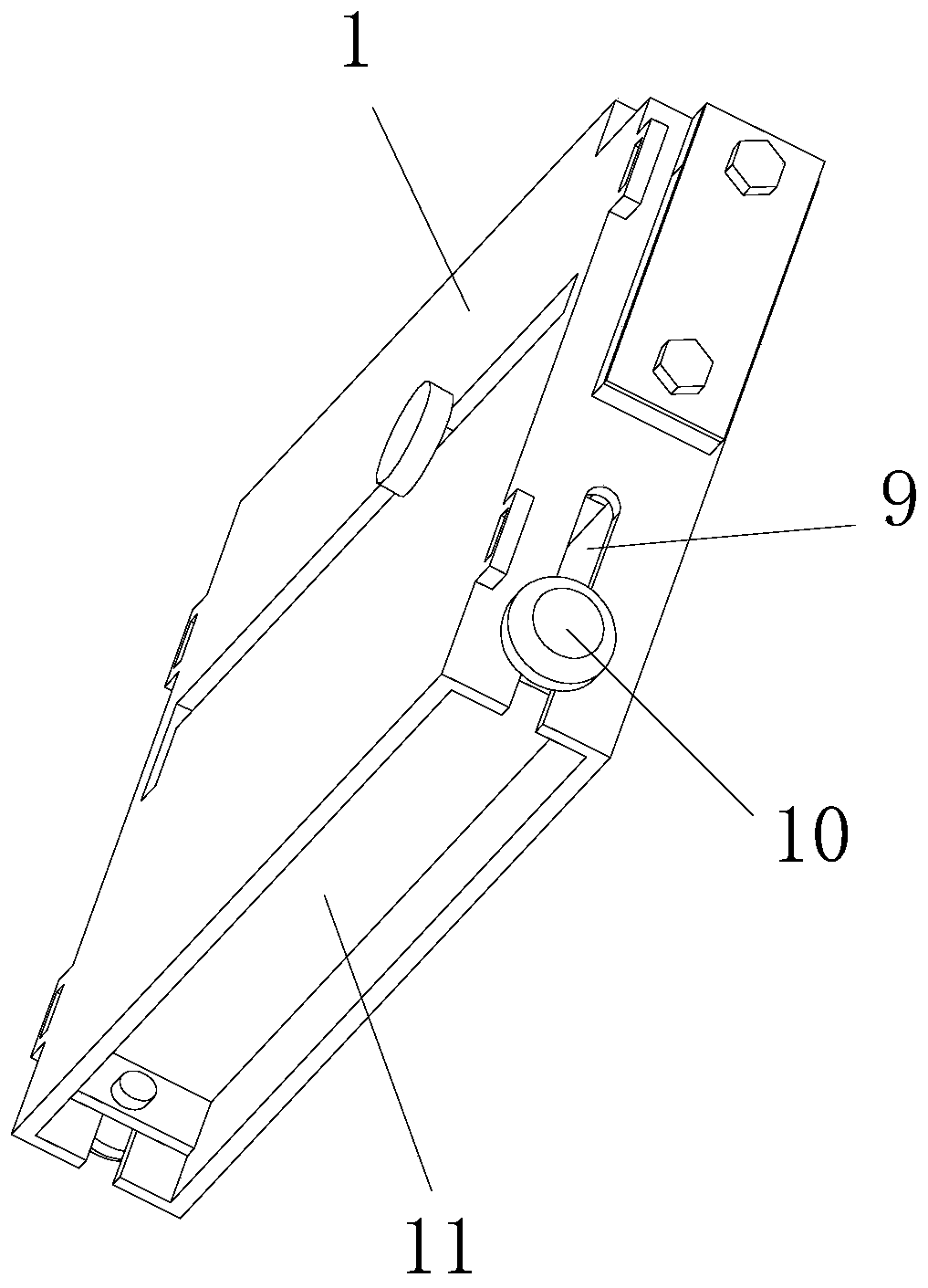

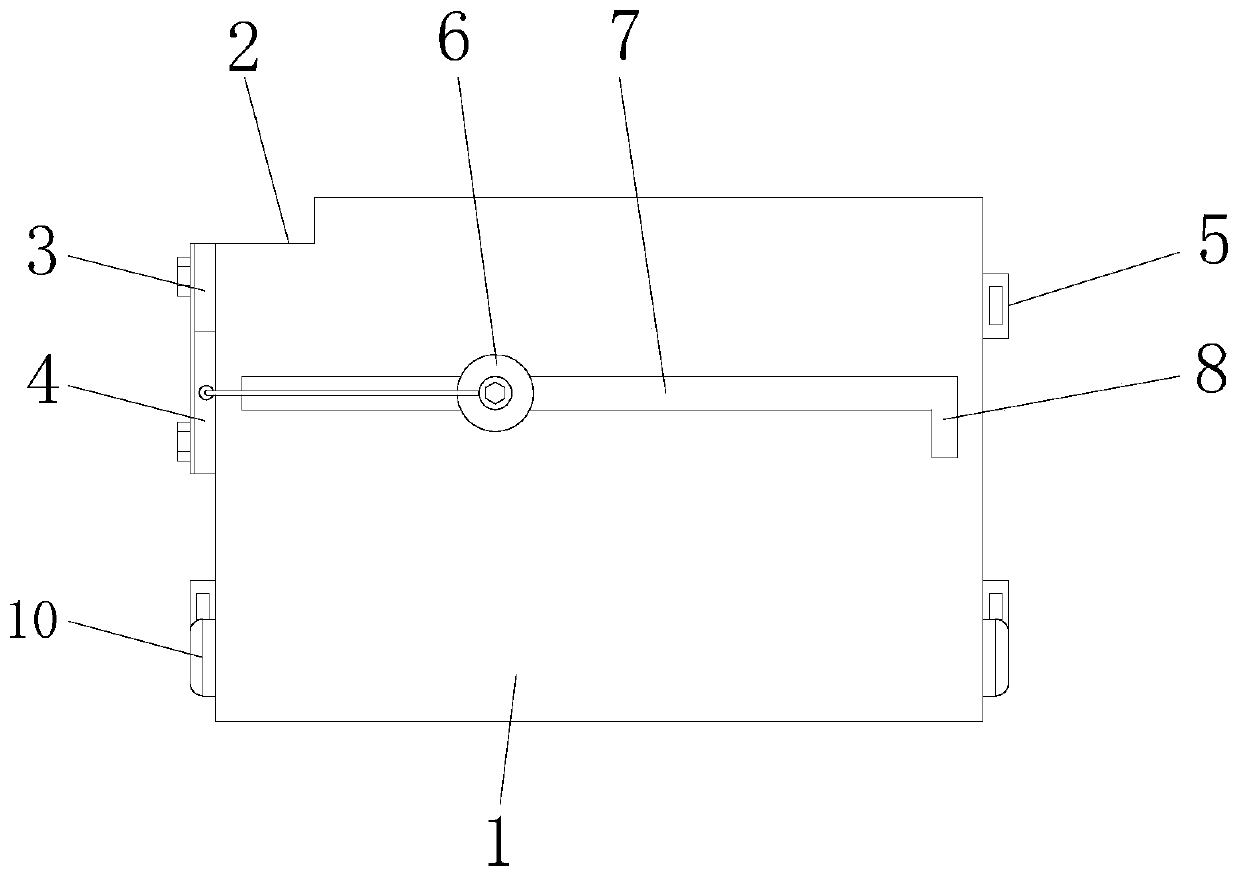

[0035] see Figure 1-5 , the present invention provides the following technical solutions: a storage box for accommodating wire binding, including a box body 1, an end above the box body 1 is provided with a wire binding outlet 2, an opening is provided at the bottom of the box body 1, and the inside of the opening slides An adjustment plate 11 is connected, and a horizontal chute 7 is provided on both sides of the box body 1. A connecting shaft 12 is slidably connected to the inside of the chute 7, and a handle 6 is connected to both ends of the connecting shaft 12, and a handle 6 is connected to the box body. 1 The side close to the tie outlet 2 is connected by a retractor.

[0036] Further, the retractor is a telescopic cable box 4, and the telescopic cable box 4 is selected from Dongguan Fushifa Plastic Products Co., Ltd. FSF-00001 type cable box.

[0037] By adopting the above-mentioned technical scheme, the main body of the telescopic cable box 4 is fixed on the side of...

Embodiment 2

[0048] see Image 6 , This embodiment differs from Embodiment 1 in that: further, the retractor is an extension spring 16 .

[0049] By adopting the above technical scheme, one end of the tension spring 16 is fixed on the side of the box body 1 by a bolt, and the other end of the tension spring 16 is fixed on a handle 6 by a bolt, and the tension is applied to the connecting shaft 12 by the tension spring 16, Therefore, the connecting shaft 12 can drive the push plate 17 to move the wires 15 to one side of the wire outlet 2 as the number of the wires 15 inside the box body 1 decreases.

Embodiment 3

[0051] This embodiment differs from Embodiment 1 in that: further, the adjustment plate 11 is provided with a support plate 14 on one side inside the box body 1 , and the support plate 14 and the adjustment plate 11 are connected by three adjustment springs 13 .

[0052] By adopting the above technical solution, by adjusting the settings of the spring 13 and the abutting plate 14, the device can be better adapted to tie wires 15 of different lengths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com