Method for judging complete carburization of tooth crest

A determination method and tooth top technology, applied in geometric CAD, special data processing applications, etc., can solve the problems of increased brittleness of the tooth top and easy fracture of the tooth top

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

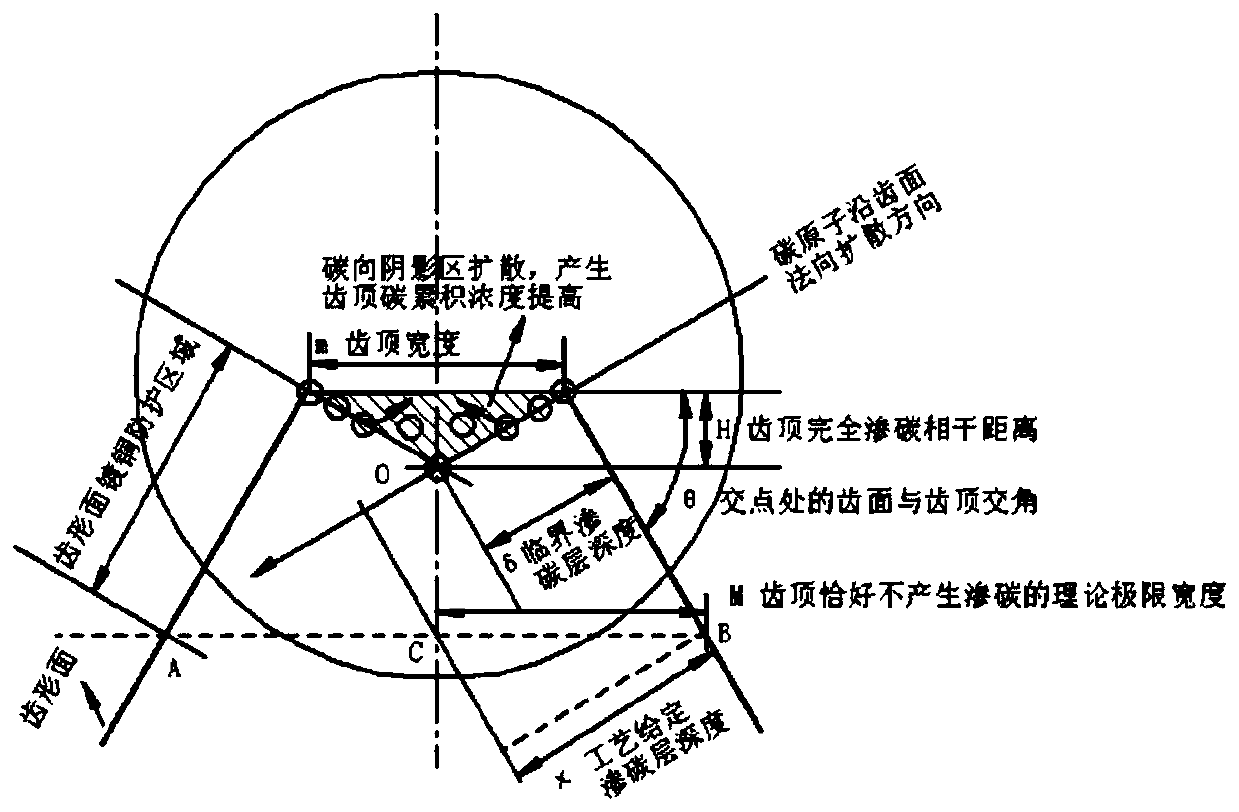

[0030] The technical solution of the present invention is: a simplified method for judging whether the tooth tip is completely carburized when the carburized layer depth is (0.8-1.3) mm. Firstly, a single tooth profile of the gear is intercepted and partially enlarged.

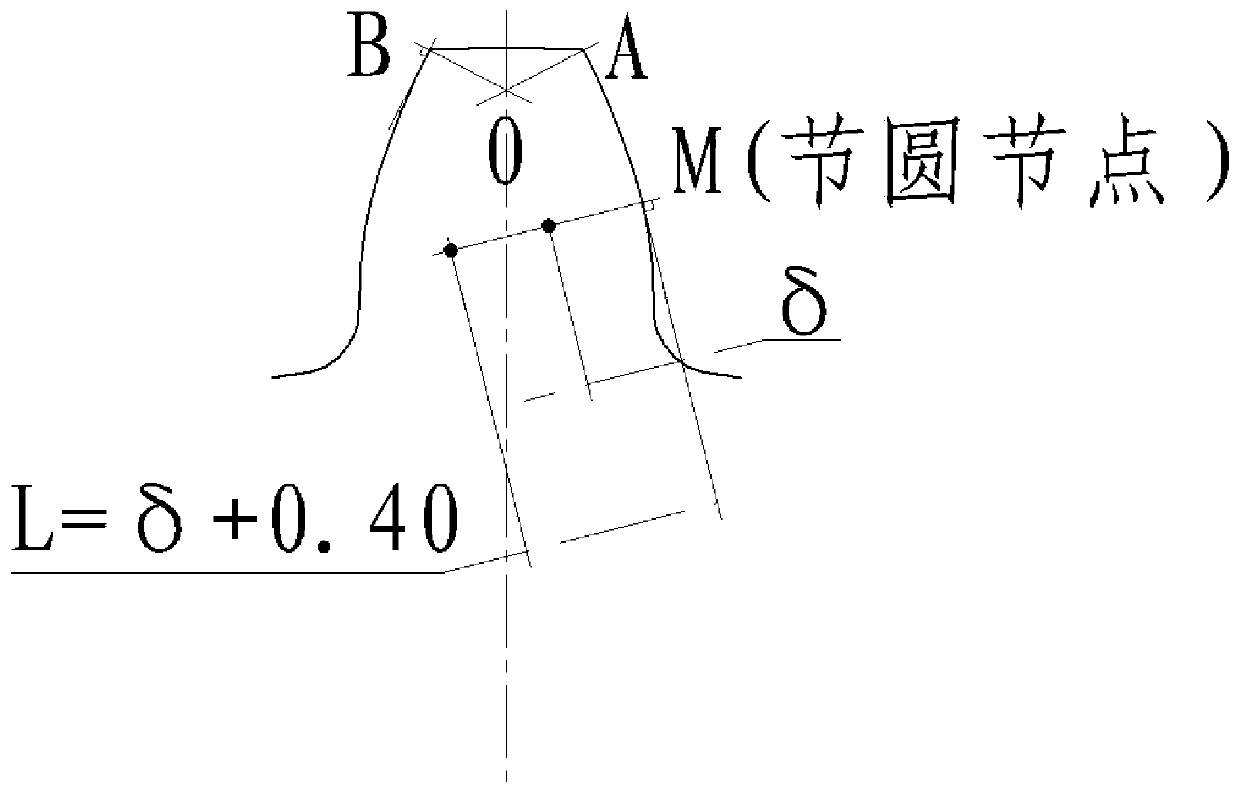

[0031] Such as figure 1 As shown, the normal line of the intersection point is made from the intersection point A of the tooth profile surface and the tooth top to the inside of the tooth profile, and the distance n between the normal line at the intersection point A and the intersection point O of the center line of the tooth top is measured.

[0032] Considering that the tooth shape of the front edge of the carburized layer on both sides of the tooth surface is relatively thin, the front edge of the carburized layer on both sides of the tooth surface may overlap and cause the low carbon concentration area to overlap, and the carbon concentration in the overlapping area reaches the eutectoid composition, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com