A kind of carbon black-filled natural rubber masterbatch and its preparation method and application

A natural rubber and black natural technology, applied in mechanical equipment, springs made of plastic materials, transportation and packaging, etc., can solve the problems of rubber modulus stress and strength reduction, increased wastewater treatment costs, and unstated flocculation products. Achieve the effect of reducing the probability of re-aggregation, avoiding the increase of waste water treatment cost, and overcoming the reduction of carbon black surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

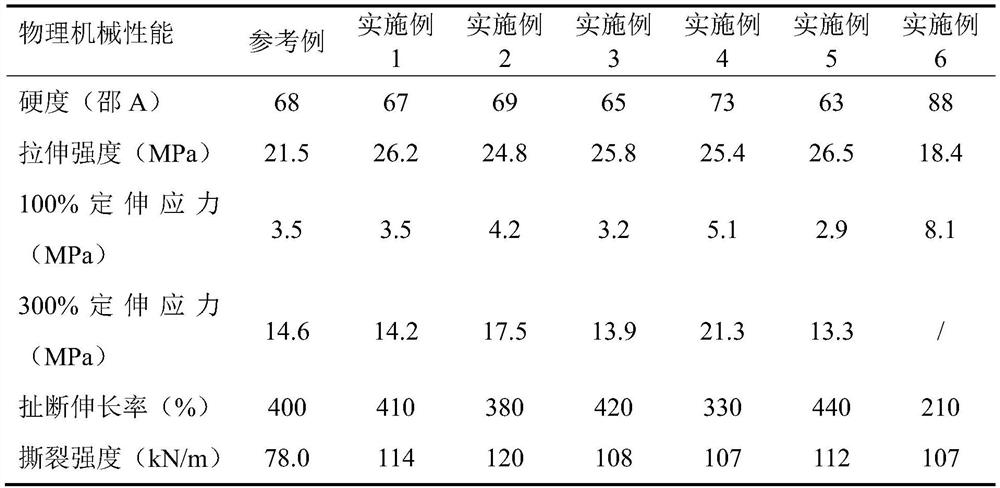

Examples

Embodiment 1~6

[0034] (1) Material preparation

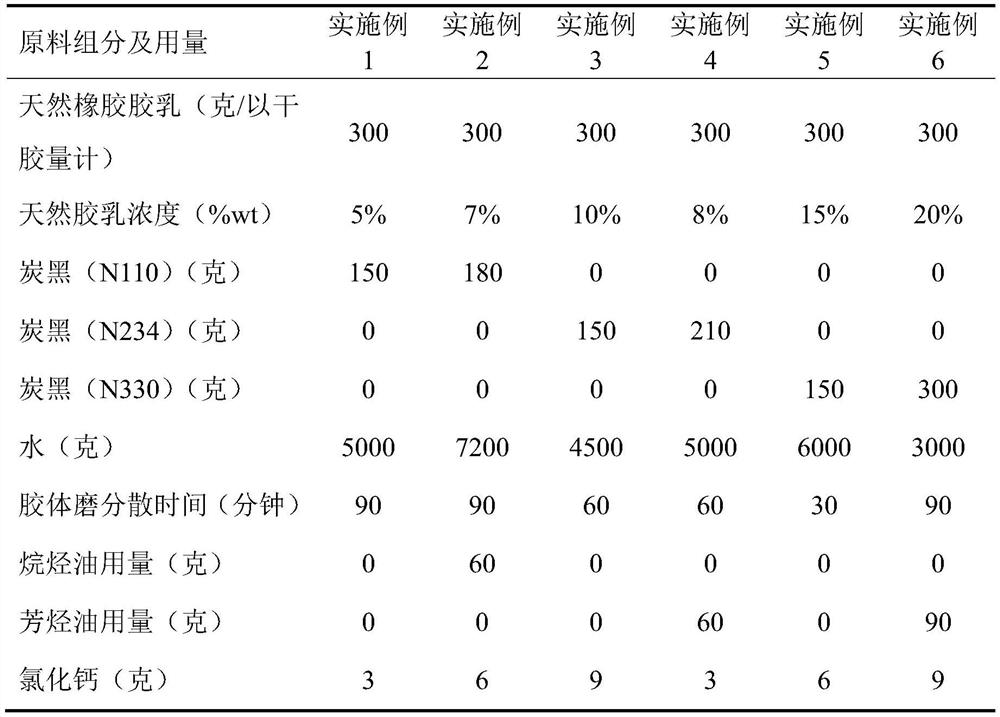

[0035] Press the proportioning ingredients in Table 1.

[0036] Reagent consumption and process condition of table 1 embodiment

[0037]

[0038] (2) Preparation of carbon black suspension

[0039] According to the formula and control conditions listed in Table 1, metered water and carbon black were added to the reactor, and carbon black slurry was prepared by colloid mill circulation grinding method. The colloid mill is connected in series with the carbon black slurry storage tank, and the carbon black slurry dispersed by the colloid mill is pumped back to the carbon black slurry storage tank. That is, add carbon black to the carbon black storage tank, add water to adjust the concentration of carbon black to 2.5-9.0%wt, start the colloid mill, and make the colloid mill disperse the carbon black slurry in the carbon black slurry storage tank at a high speed for 30-90 Minutes, to obtain carbon black in water to form a well-dispersed carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com