A kind of preparation method of gravure nc ink environment-friendly high-transparency phthalocyanine blue 15:4

A phthalocyanine blue, environmentally friendly technology, applied in the direction of organic dyes, etc., can solve problems such as not ideal, large product quality differences, large differences in the quality of derivatives, etc., and achieve the effect of reducing re-aggregation, improving gloss and improving anti-crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Step 6: Preparation of Phthalocyanine Blue 15:4

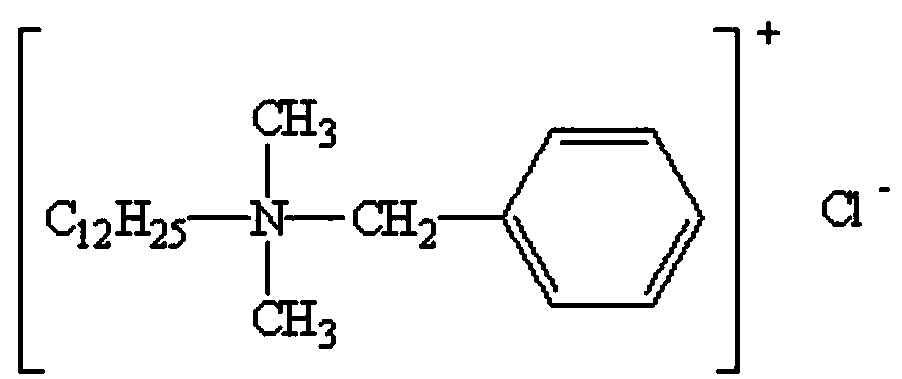

[0056] Phthalocyanine blue 15:3 slurry 2300 kg (dried), add derivative A filter cake 184 kg (dried) and beat for 0.5 hours, add liquid caustic soda to adjust PH=7-7.5, heat up to 90°C and keep stirring for 2 hours, After the heat preservation is over, add water to cool down and filter through a filter press, wash with purified water to a conductivity of ≤100μs / cm, and dry to obtain an environmentally friendly and highly transparent phthalocyanine blue 15:4 product.

Embodiment 2

[0058] Step 6: Preparation of Phthalocyanine Blue 15:4

[0059] Phthalocyanine blue 15:3 slurry 2300 kg (dried), add 276 kg of derivative A filter cake (dried), beating for 0.5 hours, add liquid caustic soda to adjust PH=7-7.5, heat up to 90°C and keep stirring for 2 hours, After the heat preservation is over, add water to cool down and filter through a filter press, wash with purified water to a conductivity of ≤100μs / cm, and dry to obtain an environmentally friendly and highly transparent phthalocyanine blue 15:4 product.

Embodiment 3

[0061] Step 6: Preparation of Phthalocyanine Blue 15:4

[0062] Phthalocyanine blue 15:3 slurry 2300 kg (dried), add derivative B filter cake 184 kg (dried), beating for 0.5 hours, add liquid caustic soda to adjust PH=10-10.5, heat up to 90°C and keep stirring for 3 hours, The derivative B is fully adsorbed on the pigment molecules. Then add dilute hydrochloric acid solution to adjust PH = 7-7.5 and stir for 0.5 hours, add water to cool down and filter through a filter press, wash with purified water to a conductivity of ≤100μs / cm, and dry to obtain an environmentally friendly and highly transparent phthalocyanine blue 15:4 product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com