Workbench glass cover plate device

A glass cover, glass cover technology, applied in the direction of measuring devices, instruments, measuring instrument components, etc., can solve the problems of poor repeatability, inconvenient manual loading and unloading, poor positioning accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

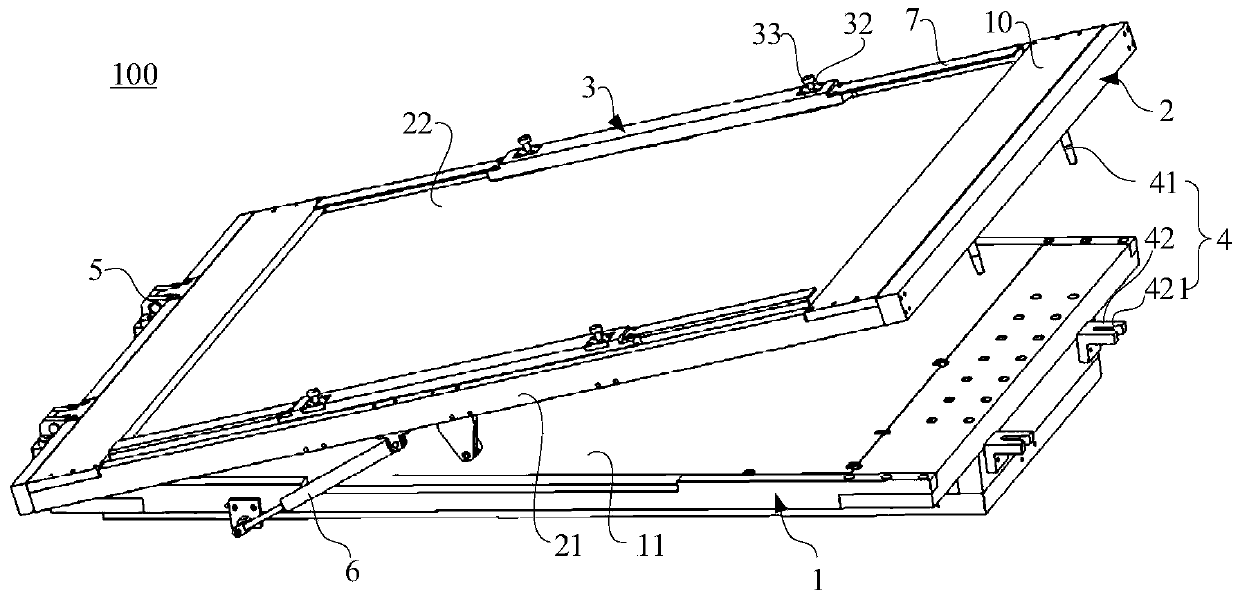

[0031] Please refer to Figure 1 to Figure 3 , this embodiment provides a workbench glass cover device 100 , including a lower glass cover 1 and an upper glass cover 2 .

[0032] In this embodiment, the lower glass cover 1 and the upper glass cover 2 are both rectangular structures, the upper glass cover 2 is covered on the lower glass cover 1 , and the first end of the upper glass cover 2 is connected to the first end of the lower glass cover 1 . One end is hinged, for example, it can be hinged through the hinge 5, and the upper glass cover 2 can be flipped relative to the lower glass cover 1 around the hinge between the lower glass cover 1 and the upper glass cover 2. For example, one end can be set to connect the lower glass cover 1 and the upper glass cover 2 respectively. The cylinder 6 of the upper glass cover 2 drives the upper glass cover 2 to turn over relative to the lower glass cover 1, and a linear motor can also be used to perform the turning operation, or manual ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap