Connector fool-proof wiring method

A connector and fool-proof technology, which is applied in the field of connector fool-proof wiring, can solve the problem of difficult to judge the wrong insertion position, wrong insertion, damage, etc., and achieve the effect of avoiding circuit damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

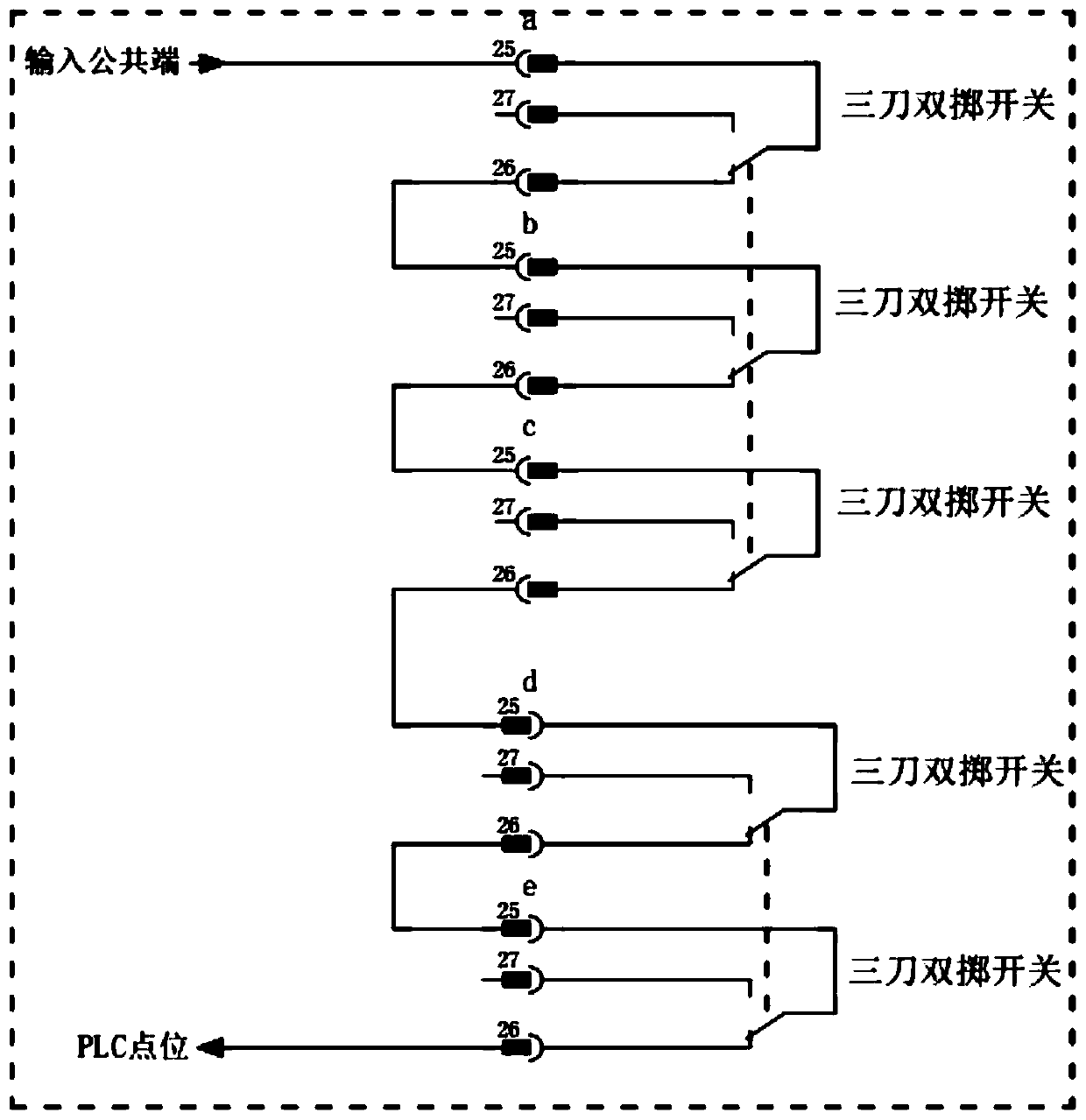

[0017] The embodiment of the present application provides a connector fool-proof wiring method, which is used to solve the problem that the existing equipment is prone to wrong insertion when using multiple identical connectors, and it is difficult to judge the specific connection once the wrong insertion is made. The wrong position leads to the problem that the equipment line is easily damaged due to wrong insertion. It can be realized according to the size of the connector, the number of pins, male and female, and the application with the IO points of the PLC controller to obtain the correctness of the connector. The feedback of the use status can effectively avoid the technical effect of the circuit being destroyed due to the wrong insertion of the connector.

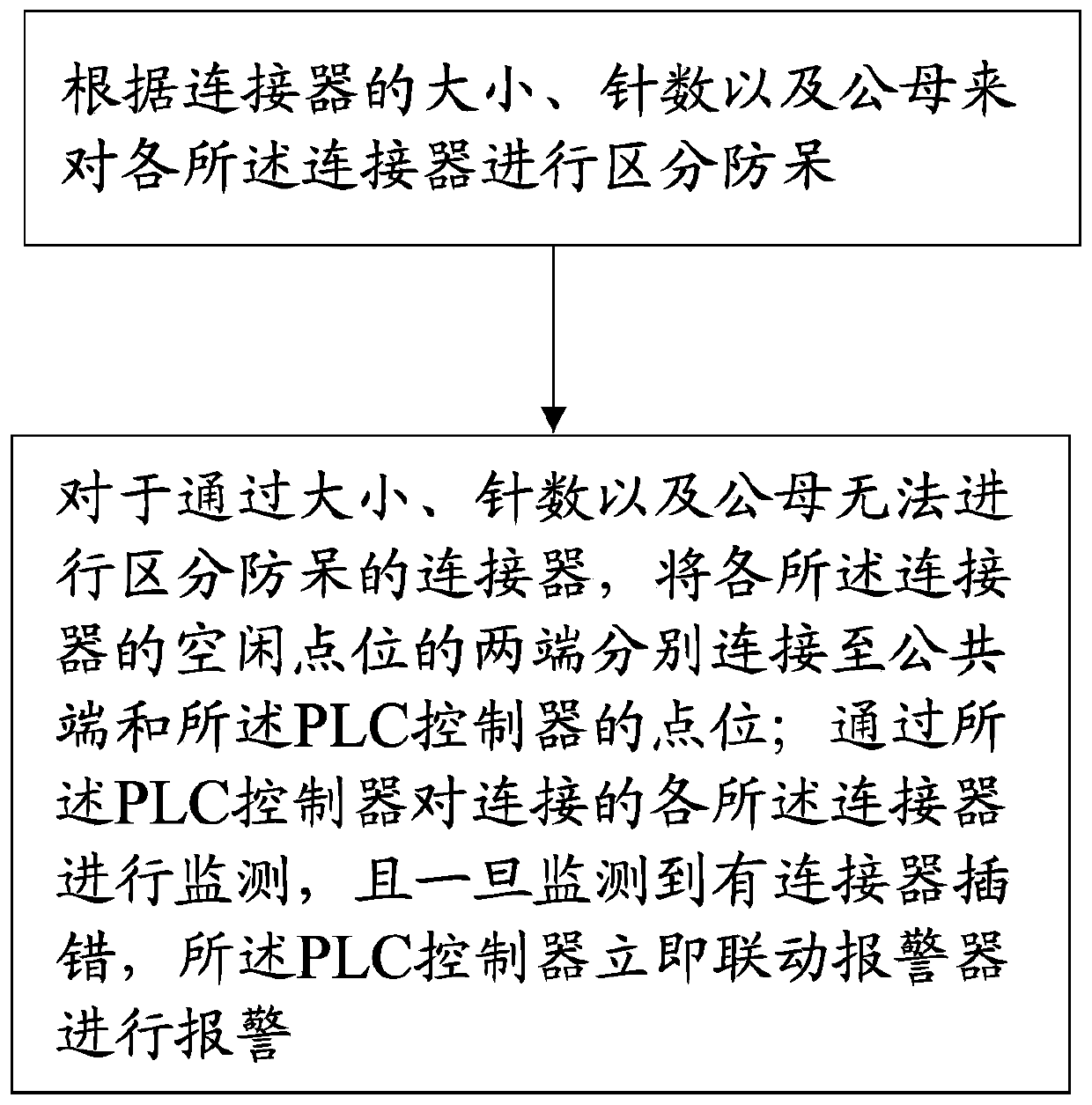

[0018] The general idea of the technical solution in the embodiment of the present application is as follows: First, distinguish and prevent fooling of each connector according to the size, number of pins, and male ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com