A kind of preparation method of sensor for high-voltage electrical appliances

A technology of high-voltage electrical appliances and sensors, which is applied in the field of preparation of sensors for high-voltage electrical appliances, can solve problems such as failure to install, malfunction, and sensor failure, and achieve the effect of reducing width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following embodiments can make those skilled in the art understand the present invention more comprehensively, but do not limit the present invention to the scope of the described embodiments.

[0034] The sensor includes a sensor shell and a capacitor. The sensor shell is formed by butting together two sensor shells arranged in half, and after the two sensor shells are combined, a cavity for accommodating the capacitor is formed.

[0035] The preparation method of the sensor for high-voltage electrical appliances of the present invention is achieved through the following steps:

[0036] S1 shell processing: First, according to the design drawings, select the raw materials required for processing the sensor shell, and then process the required two sensor shells by injection molding.

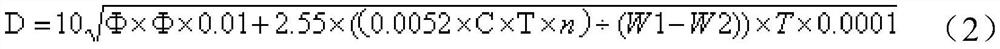

[0037] Material selection of S2 capacitor: According to the calculation of the space reserved for the installation of the capacitor in the sensor housing, select the raw materials requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com