Express bag packaging machine

A technology of bag bag and drag bag board, which is applied in the directions of packaging, transportation packaging, and packaging protection. It can solve problems such as dropping, uneven express bags, and slowing down packaging efficiency, and achieve high conveying efficiency, high degree of automation, and good performance. The effect of express bag delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

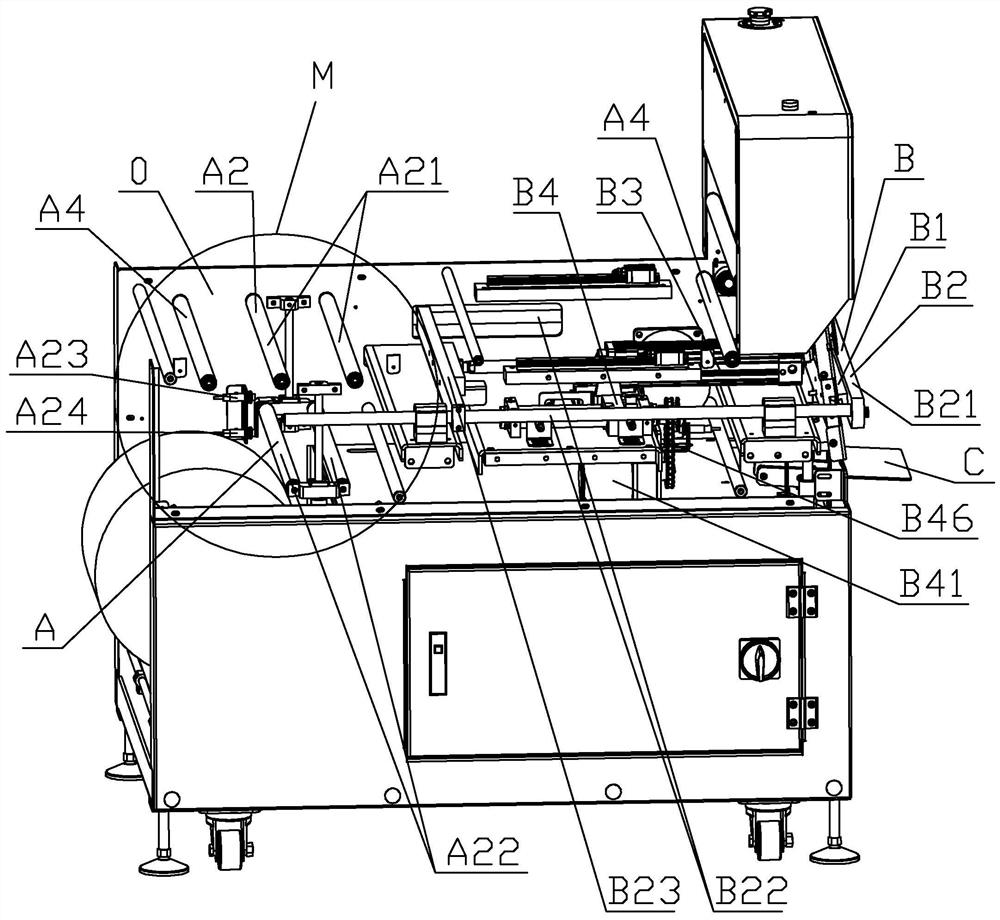

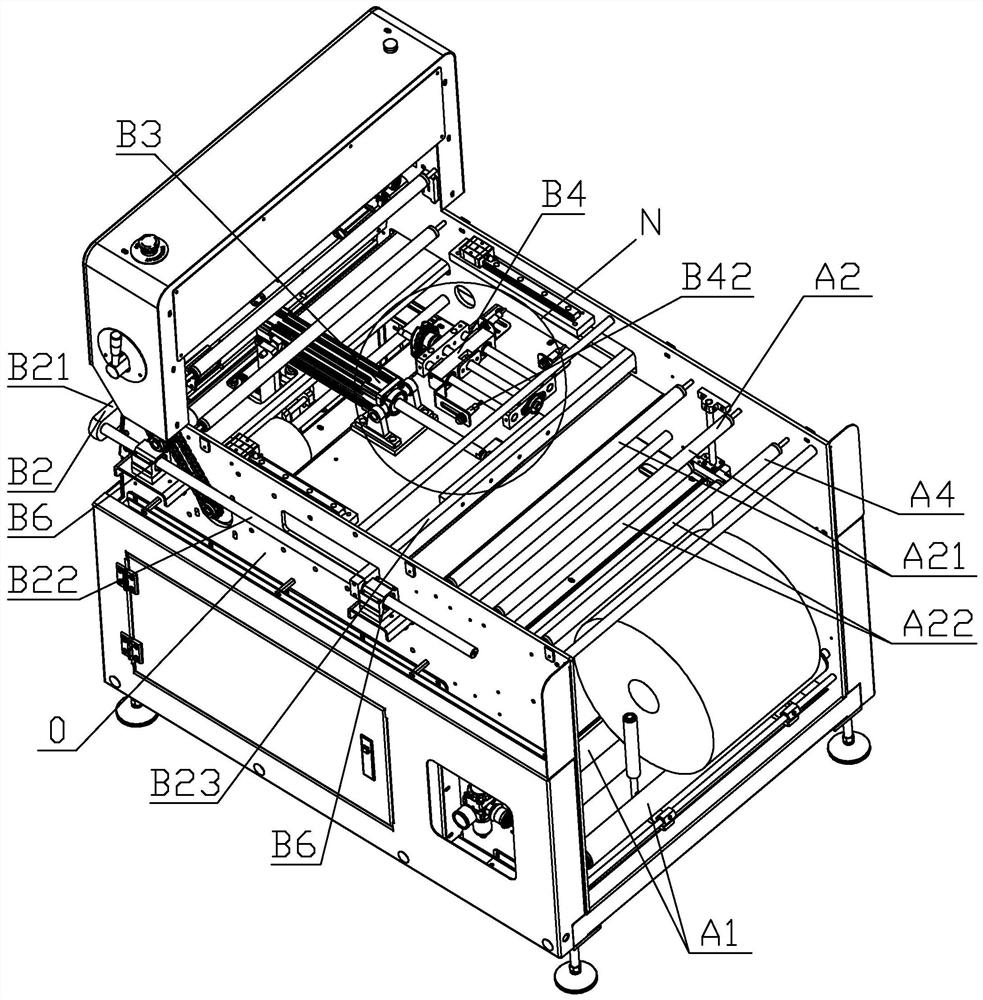

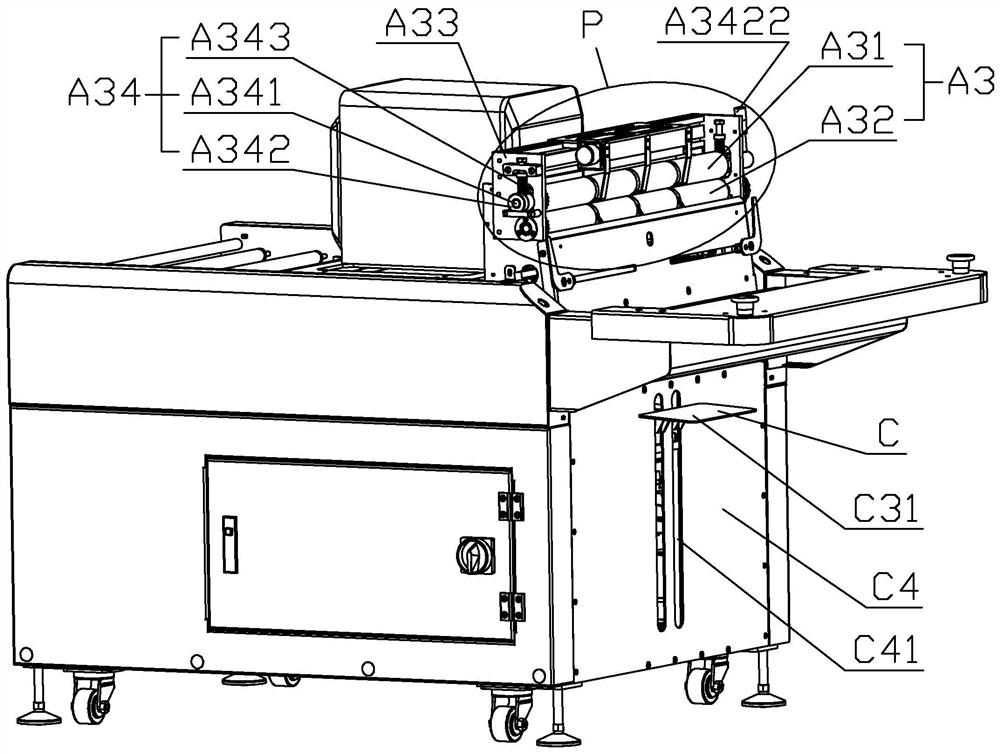

[0032]Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9 are specific embodiments of the express bag packaging machine of the present invention. This embodiment includes a conveying mechanism A for conveying the courier bag, a sealing mechanism B for sealing the mouth of the courier bag, and a drag bag mechanism C for receiving the courier bag and the items in it. The input roller group A1 of the bag, the winding roller group A2 used to wind the courier bag conveyed from the input roller group A1, and the rubber roller group A3 arranged at the output end to clamp and output the courier bag, the winding roller group A2 It includes the fixed winding roller A21 arranged at the top and the moving winding roller A22 arranged at the bottom. The moving winding roller A22 can be arranged on the housing 0 up and down, and the courier bags between the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com