Formwork removal equipment for prefabricated bridge piers of prefabricated bridges and formwork removal process for prefabricated bridge piers

A prefabricated and bridge technology, used in bridge construction, bridges, bridge parts, etc., can solve problems such as large space occupation, concrete spalling, mold damage, etc., and achieve the effect of full disassembly process, avoiding relative sliding, and reducing impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

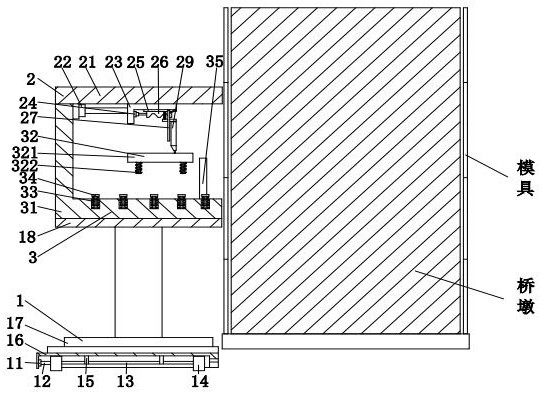

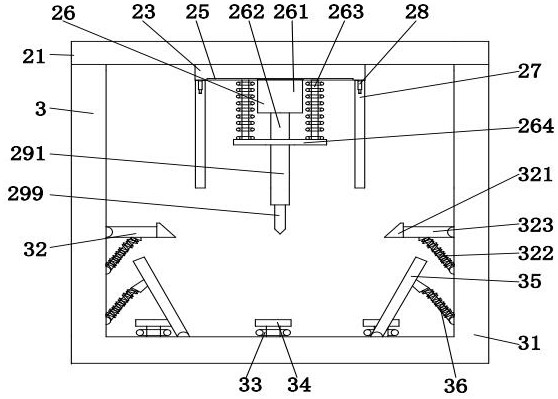

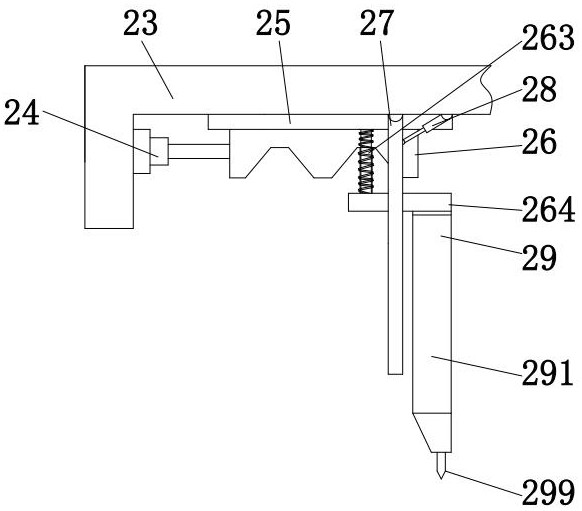

[0033] Such as Figures 1 to 5 As shown, a prefabricated bridge pier demolition equipment includes a jacking mechanism 1, a demoulding mechanism 2 and a collection mechanism 3, wherein the jacking mechanism 1 is equipped with a collection mechanism 3, and the collection mechanism 3 is internally equipped with Demolition mechanism 2.

[0034] Described jacking mechanism 1 comprises No. 1 motor 11, No. 1 rotating shaft 12, No. 2 rotating shaft 13, tire 14, fixed short block 15, mobile frame 16, elevator 17 and fixed horizontal plate 18, wherein said moving machine A No. 1 groove is provided below the frame 16, and the No. 1 motor 11 is installed on the left side of the No. 1 groove. The inside of the No. 1 groove is symmetrically provided with tires 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com