A three-swirl classifying cyclone and its combustion chamber

The technology of swirl classification and swirl device is applied in the field of combustion chamber, which can solve the problems of complex engine structure and fuel supply system, reduce coking of main combustion stage fuel nozzles, and high weight, so as to achieve weight reduction, prevent premature coking, and reduce fuel consumption. System simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

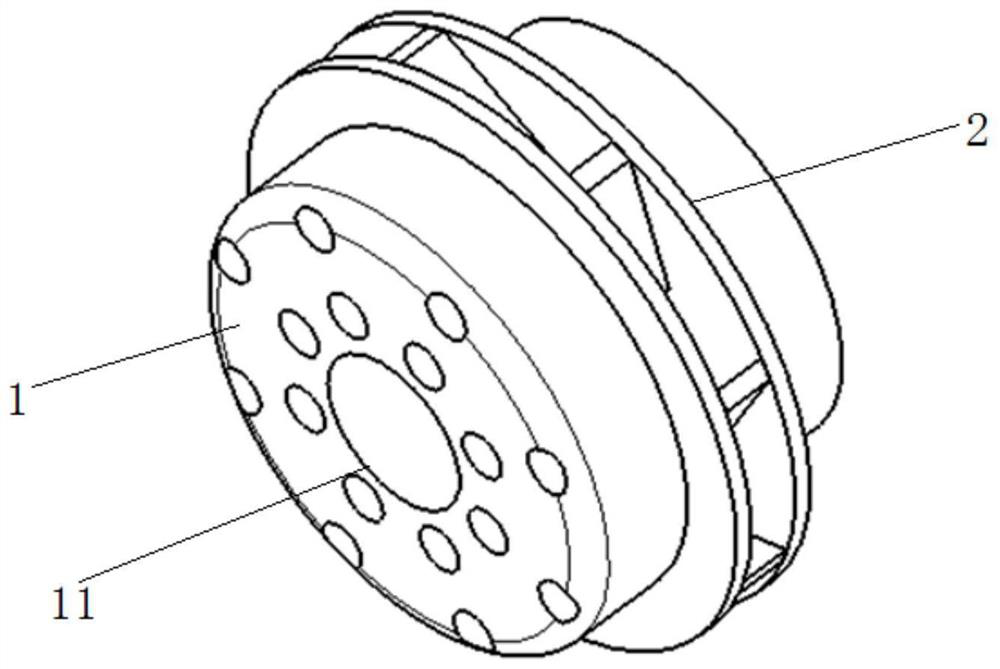

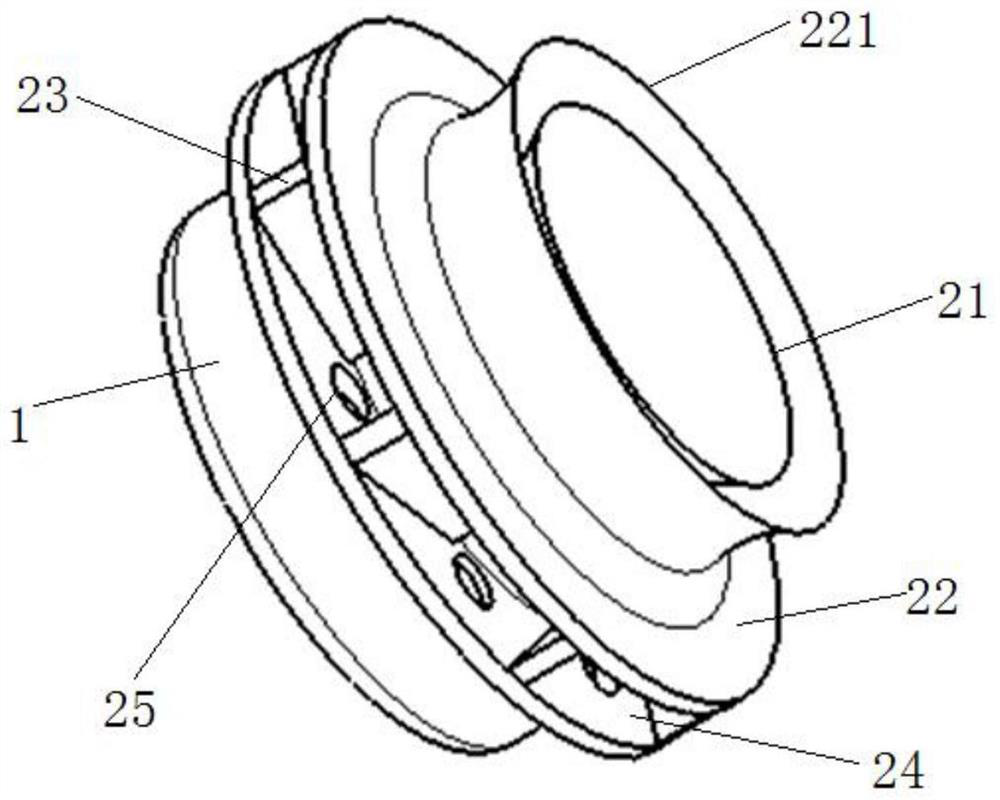

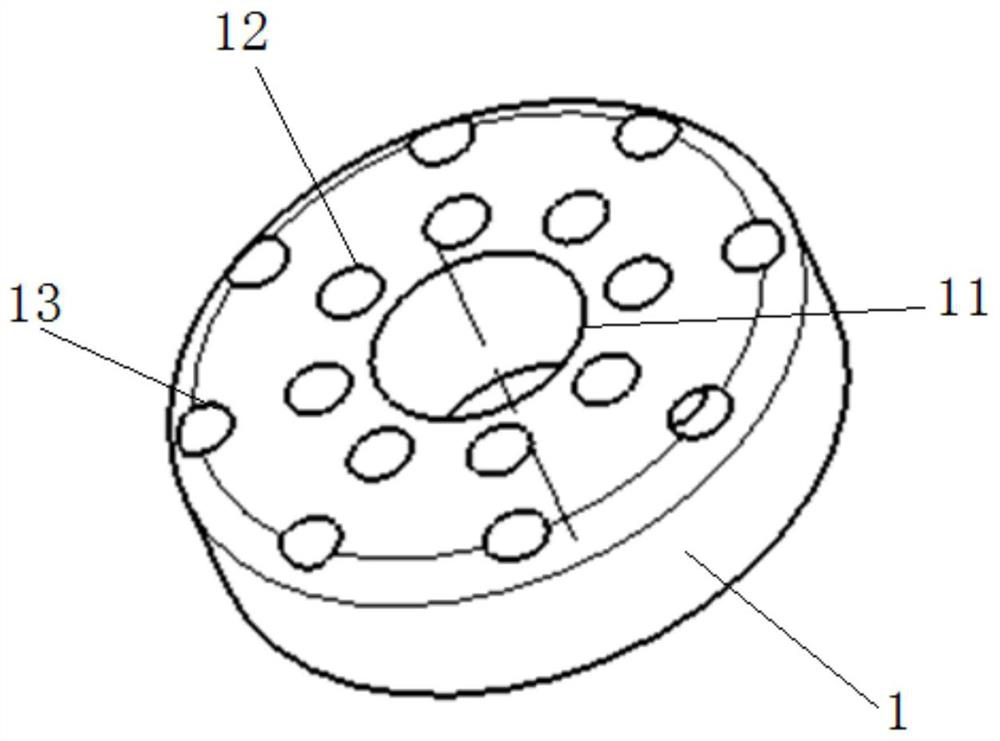

[0028] Such as figure 1 and figure 2 As shown, a three-swirl classifying cyclone of the present invention integrates the pre-combustion level obliquely cut hole type cyclone, the main combustion level obliquely cut hole type cyclone and the main combustion level radial cyclone, which includes a shaft To the connecting piece 1 and the radial connecting piece 2, the center of the axial connecting piece 1 is provided with an axial through hole 11, and the radial connecting piece 2 includes a coaxial first venturi tube 21 and a second venturi tube arranged at intervals 22. In the annular space between the first venturi tube 21 and the second venturi tube 22, multiple groups of blades 23 arranged in an annular array are fixedly connected. The installation angle of the blades 23 is between 30 and 45 degrees. The number of blades 23 is 9 Up to 16 groups, the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com