Pipe expanding device

A pipe rod and air outlet pipe technology, applied in the field of pipe diameter expansion equipment, can solve the problems of reducing pipe expansion efficiency and increasing cost, and achieve the effect of improving pipe expansion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

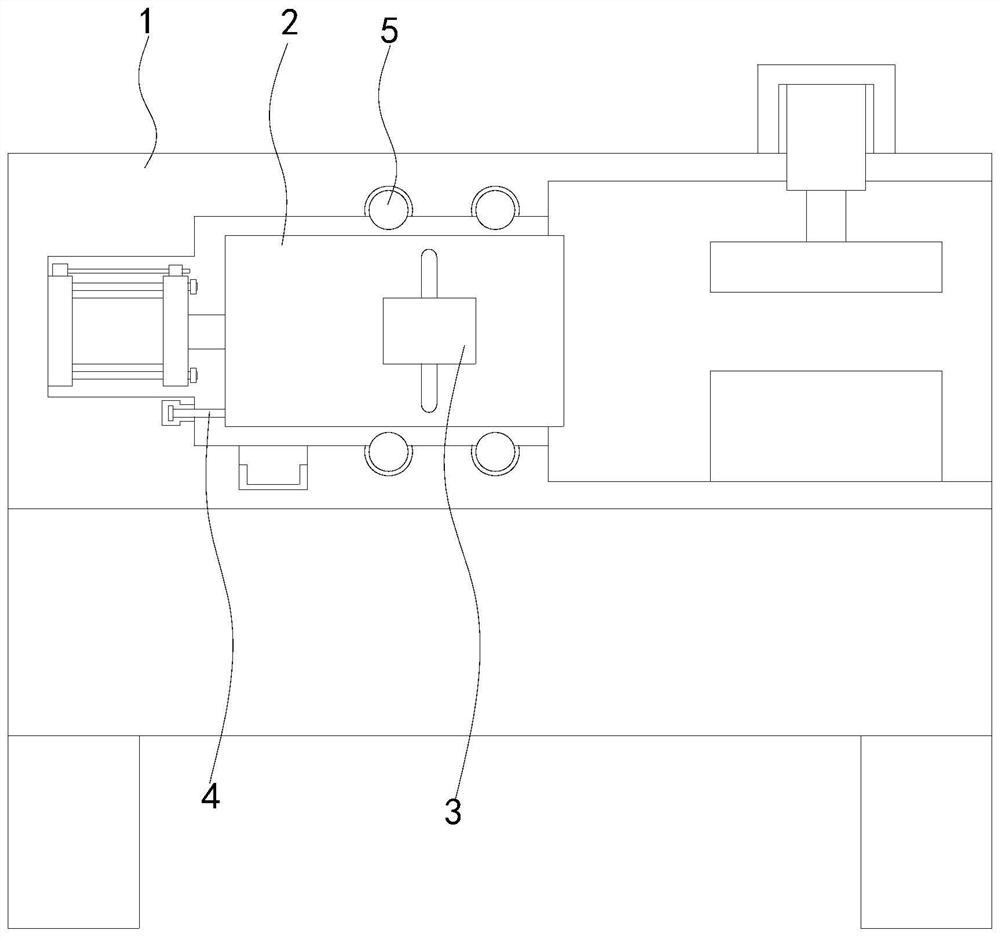

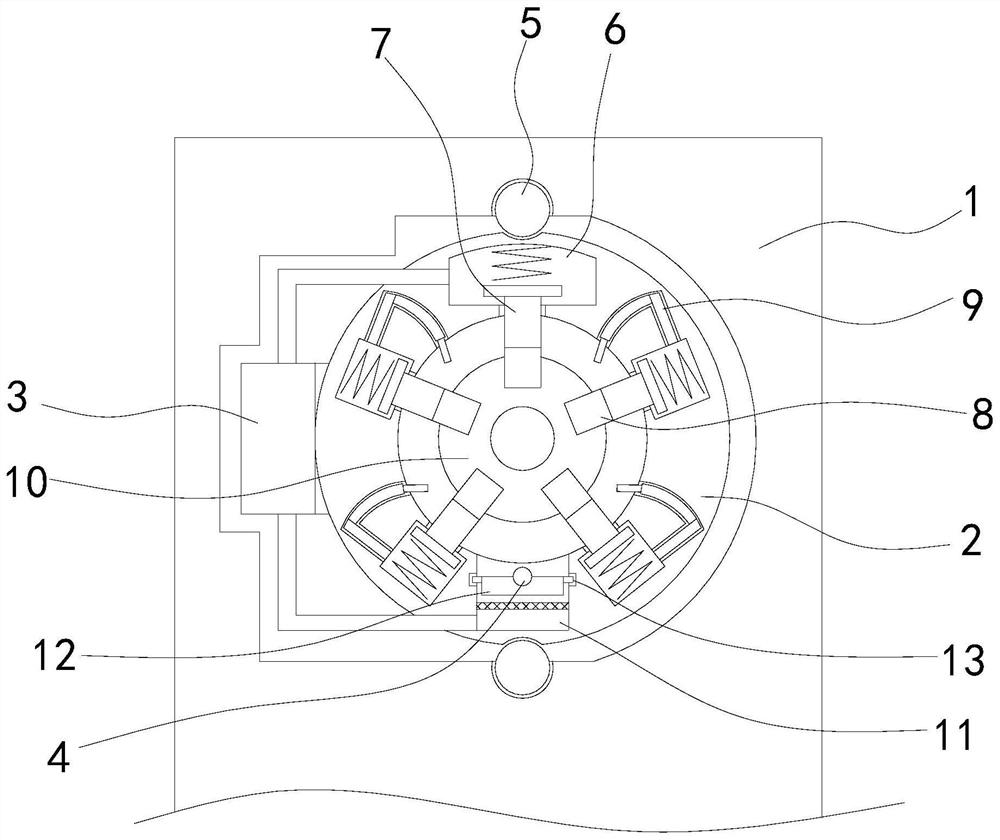

[0026] see Figures 1 to 7 , a schematic diagram of a planar structure and a schematic diagram of a three-dimensional structure of a pipe expanding device.

[0027] A pipe expanding device, comprising a device main body 1, a pipe expanding device 2 is movably installed on the left side of the device main body 1, an oiling chamber 6 is provided at the upper end of the pipe expanding device 2, and a first trigger block is movably installed inside the oiling chamber 6 7. A lower oil chamber 11 is provided at the lower end of the pipe expanding device 2, and a slag scraping rod 4 is movable installed inside the lower oil chamber 11.

[0028] In a specific implementation, a pipe expansion rod 10 is fixedly installed at the middle end of the pipe expansion device 2, and the side of the lower end of the first trigger block 7 is arranged in an inclined arc, so that when the pipe expansion device 2 moves to the right under the action of the hydraulic rod, The expansion rod 10 can be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com