A water injection automatic filter backwashing device

A backwashing device and automatic filtration technology, applied in the direction of filtration separation, fixed filter element filter, separation method, etc., can solve the problems of heavy cleaning labor, intermittent water injection, and unguaranteed water quality, so that no manual operation is required Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

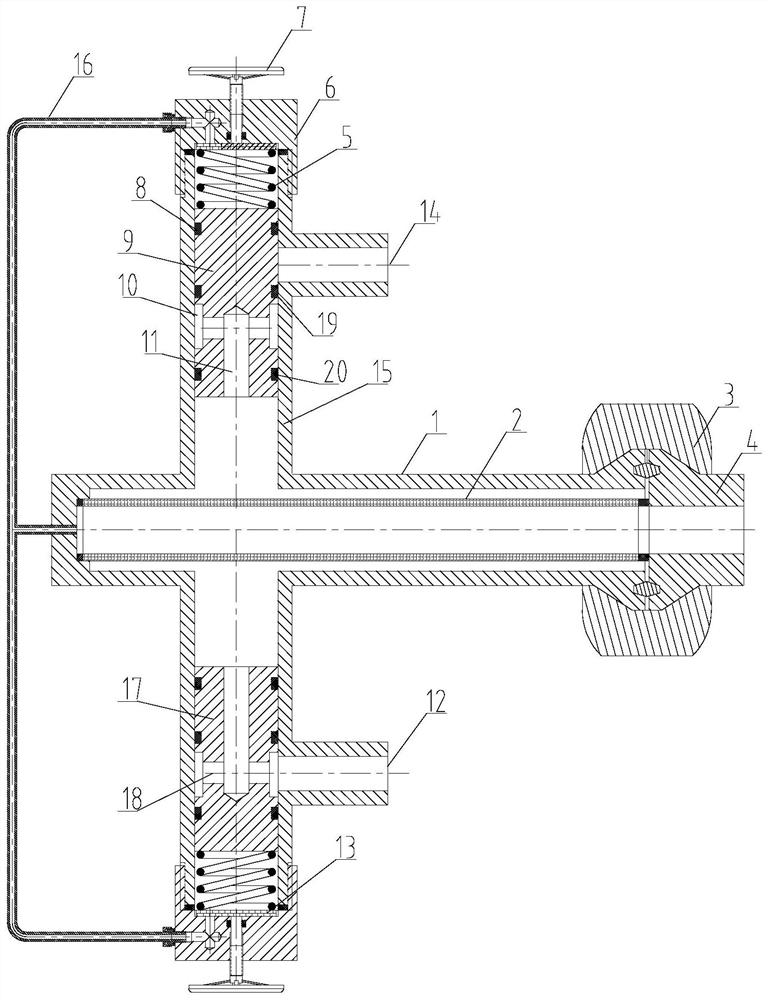

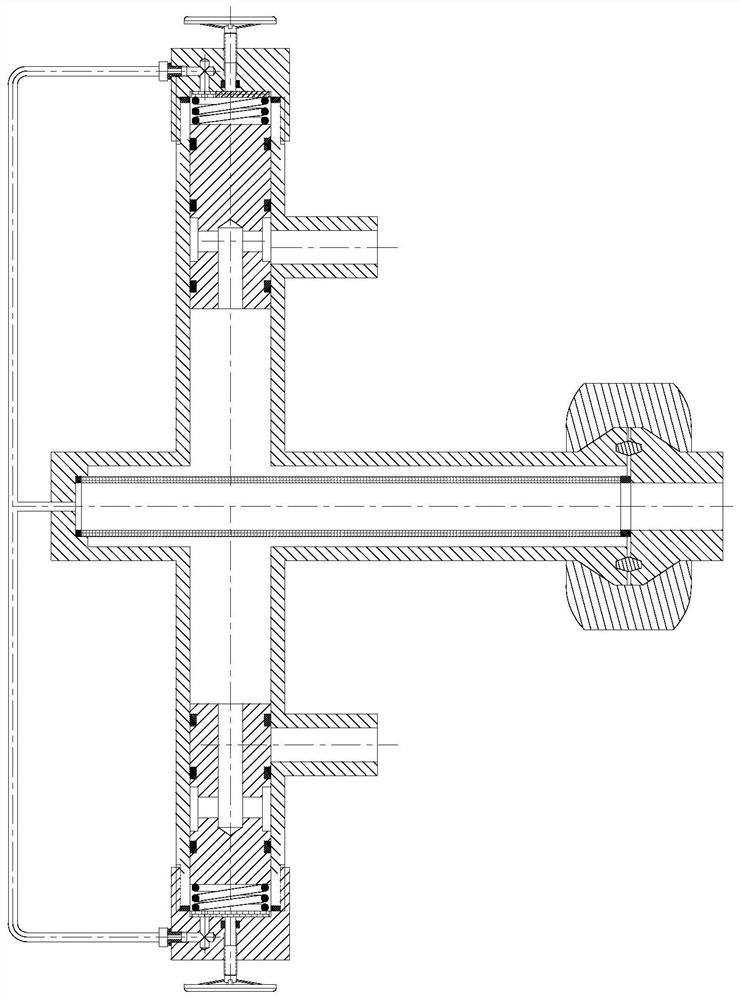

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] Depend on figure 1 join figure 2 As shown, a water injection automatic filter backwashing device includes a housing 1, one side of the housing 1 is connected to the water outlet pipe 4 through a clamp 3, the other side of the housing 1 is sealed and connected to the filter cartridge 2, and the other side of the filter cartridge 2 One side is sealingly connected with clamp 3;

[0019] The upper and lower sides of the housing 1 are respectively connected with a bypass pipe 15, and the inner hole of the upper bypass pipe 15 is connected with the backwash piston 9 with a clearance fit, and the upper part of the backwash piston 9 is provided with a spring 5;

[0020] There is a central hole 11 in the lower part of the backwash piston 9, and a side hole 18 is opened horizontally in the middle of the backwash piston 9, and the side hole 18 communicates with the center ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com