Measurement and control machine for intelligent manufacturing

A technology of intelligent manufacturing and rails, applied in the direction of conveyor objects, cleaning methods and tools, cleaning methods using tools, etc., can solve problems such as accumulation of foreign objects, inability to be detected by infrared sensors, inability to detect products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

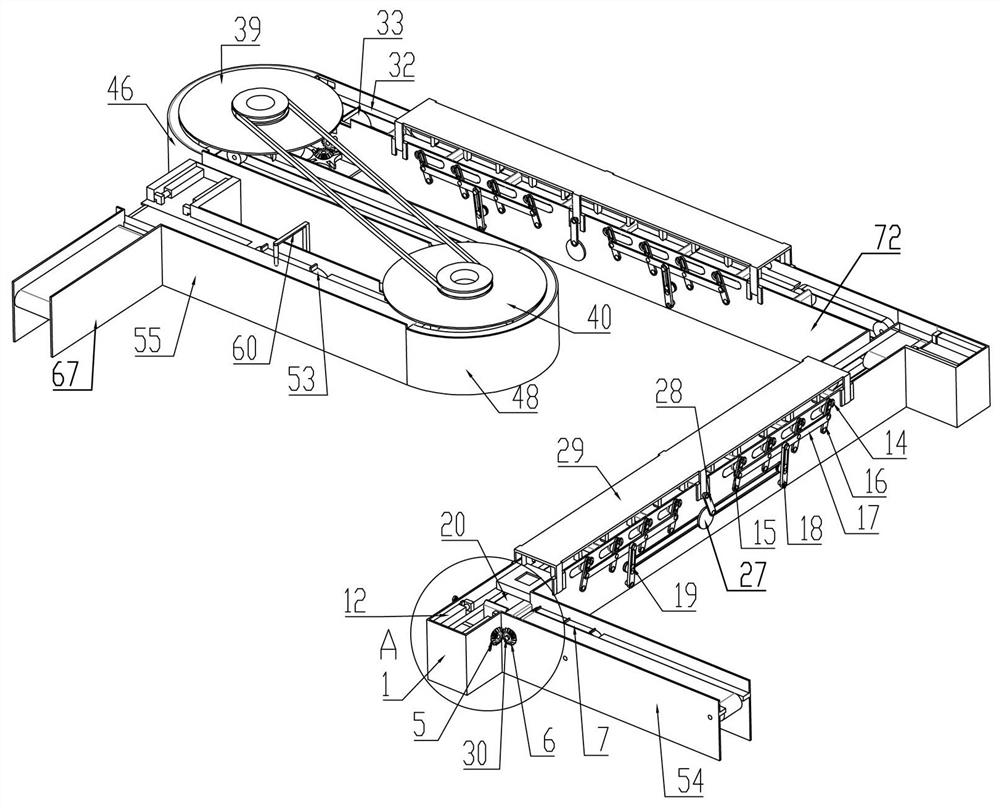

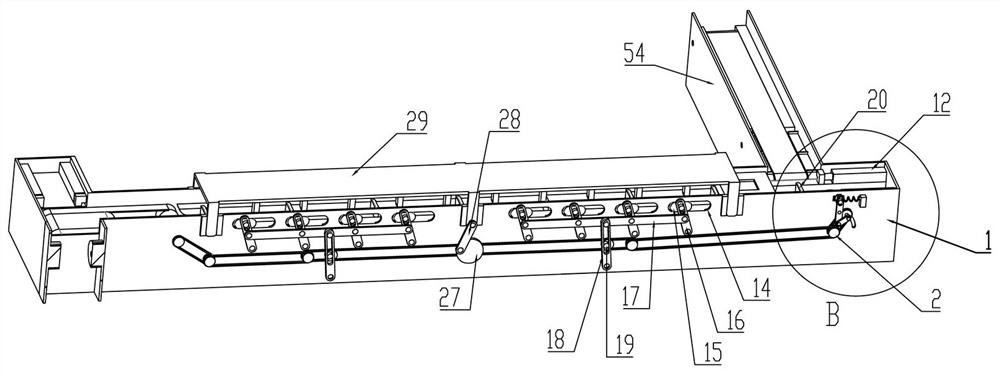

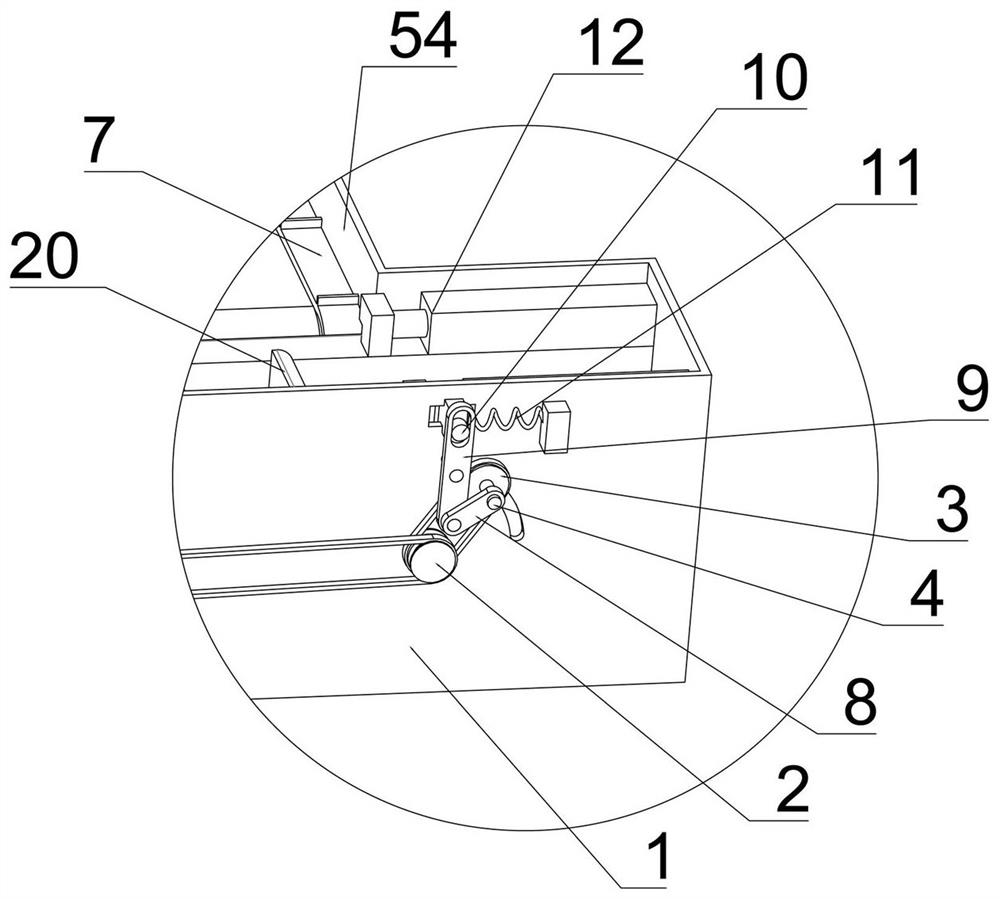

[0031]Embodiment 1, the present invention is a measurement and control machine for intelligent manufacturing, including a track 1, characterized in that the track 1 is fixedly connected with a conveying track 54, and the conveying track 54 is rotatably connected with a conveying belt, and the conveying belt A belt drive motor is connected, the belt drive motor is connected to an external power supply, a drive motor is fixedly connected to the track 1, the drive motor is connected to an external power supply, the drive motor is fixedly connected to an extension sprocket, and the extension sprocket is coaxial Fixedly connected with a power drive sprocket, the power drive sprocket is connected with a transmission drive sprocket 2 through a chain, the transmission drive sprocket 2 is rotatably connected to the track 1, and the transmission drive sprocket 2 is coaxial A transmission drive pulley is fixedly connected, and the transmission drive pulley is connected with a driven pulle...

Embodiment 2

[0034] Embodiment 2, on the basis of Embodiment 1, when the mold is transmitted on the track 1, it drives the cleaning sponge 15 to slide left and right. When the cleaning sponge 15 slides left and right, the mold is easily transmitted on the track 1 When the resistance of the cleaning sponge 15 is too large, the mold cannot be transferred. To solve the above problems, this embodiment provides an intermittent conveying device to solve the above problems. Specifically, the track 1 is slidingly connected with a transmission ruler 20 left and right, so The transmission ruler 20 is fixedly connected with a plurality of sliding clamps, and both sides of the transmission ruler 20 are rotatably connected with an up and down sliding link 21, and one end of the up and down sliding link 21 is rotatably connected with a drive link 22, and the up and down The other end of the sliding link 21 is rotatably connected to a limit link 24 which is rotatably connected to the track 1, and the driv...

Embodiment 3

[0036] Embodiment 3, on the basis of Embodiment 1, when the mold passes through the longitudinal track, the cleaning device can only clean the surroundings of the mold, but cannot clean the bottom of the mold, and the detection device at the bottom of the mold cannot detect the mold, thus causing the mold to be undetectable In order to solve the above problems, this embodiment provides a mold bottom cleaning device. Specifically, a transmission belt 32 is rotatably connected to the longitudinal rail 72, and the transmission belt 32 is externally connected to a motor, and the motor is externally connected to a power supply. 72 is rotatably connected with a cleaning roller baffle 33, and a plurality of mold baffles are evenly distributed on the upper circumference of the cleaning roller baffle 33, and the cleaning roller baffle 33 is coaxially fixedly connected with a baffle driven bevel gear 34. The baffle driven bevel gear 34 is meshed with a baffle driving bevel gear 35, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com