Steel pipe surface paint brushing device for protective fence machining

A technology for guardrails and steel pipes, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of low displacement of steel pipes and the inability to achieve paint brushing effects on the surface of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

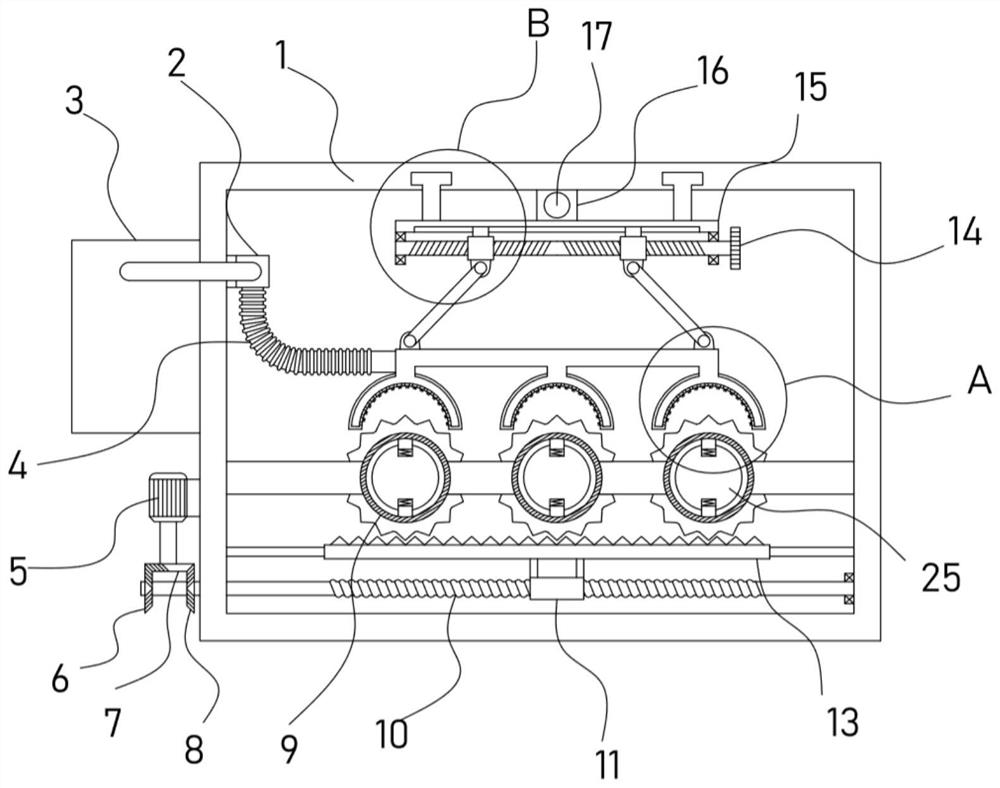

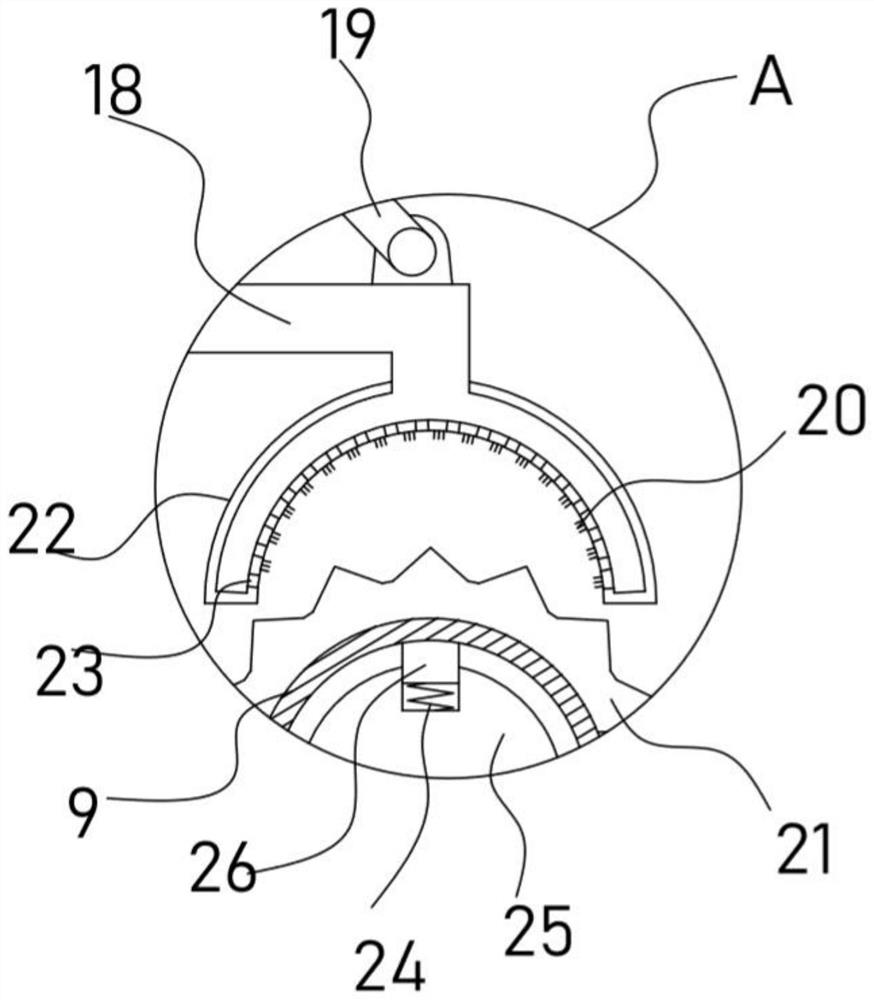

[0023] see Figure 1-4 , a steel pipe surface painting device for guardrail processing, comprising a fixed frame 1, a paint box 3 is fixed on the fixed frame 1, and several parallel rotating columns 25 are mounted on the fixed frame 1, and on the rotating column 25 A snap-fit limit mechanism for fixing the steel pipe 9 is provided. The fixing frame 1 is provided with a conveying pipe 18 communicating with the paint tank 3. The conveying pipe 18 is connected with a paint brush vertically corresponding to the steel pipe 9. mechanism, the fixed frame 1 is driven with a sliding frame 15 through a longitudinal drive mechanism, and the sliding frame 15 is connected with the delivery pipe 18 through a lifting adjustment mechanism. The drive is connected with a transmission mechanism for driving the rotating column 25 to rotate.

[0024] When the device paints the surface of the steel pipe 9, it is limited by the clamping limit mechanism provided. Specifically, the clamping limit m...

Embodiment 2

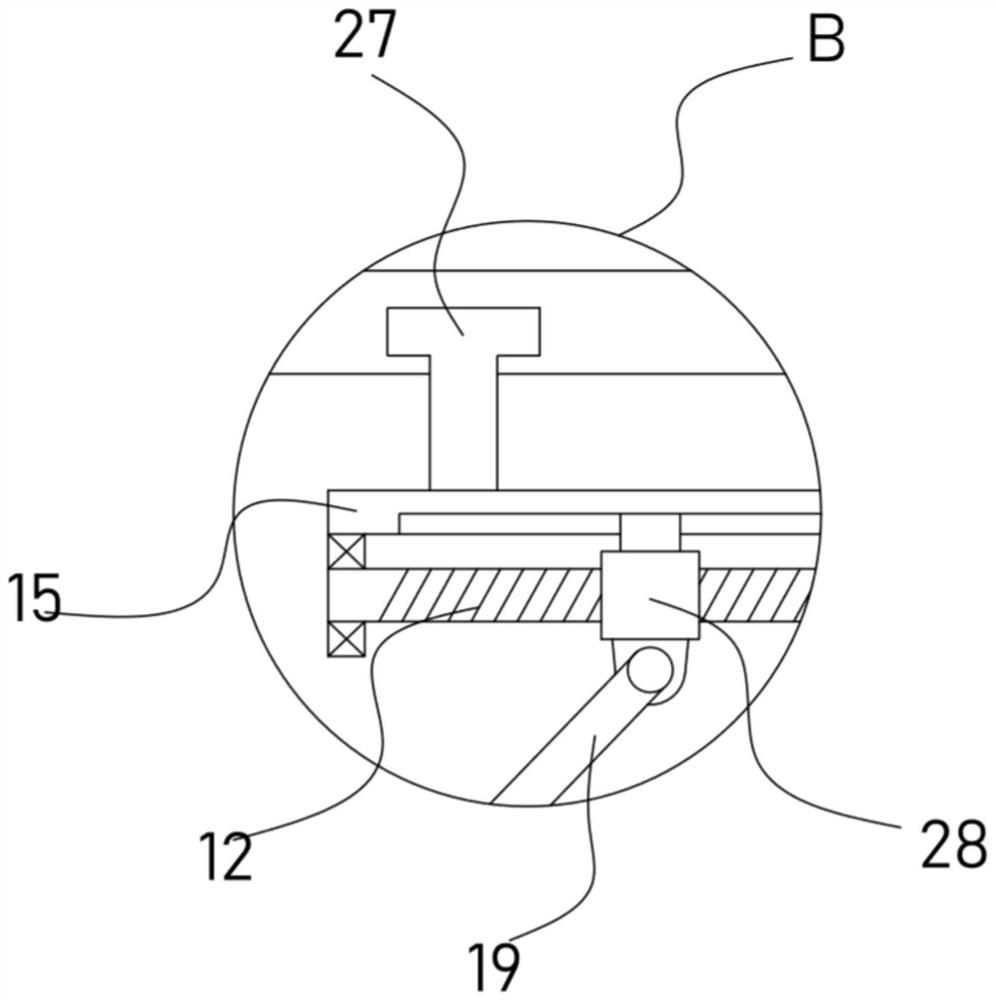

[0029] On the basis of Embodiment 1, in addition, the device is also provided with a longitudinal drive mechanism including a sliding frame 15, on which a longitudinal threaded block 16 is fixed, and the longitudinal threaded block 16 is internally threaded to be threaded with a longitudinal screw 17. A T-shaped slider 27 slidably embedded in the fixed frame 1 is fixed on the sliding frame 15 . The lifting adjustment mechanism includes two screw mandrels 12 that are coaxially fixed on the sliding frame 15 and are screwed in the opposite direction. The handwheels 14 are fixed on the screw mandrels 12, and the screw rods 12 are threaded with the sliding frame. 15 is slidably connected with a screw mandrel slider 28, and a suspender 19 is hinged between the screw mandrel slider 28 and the delivery pipe 18.

[0030] Through the above settings, turning the hand wheel 14 can drive the screw rod 12 to rotate, and the screw rod 12 drives the two screw rod sliders 28 to move toward or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com