Grid rid forming method

A forming method and grid rib technology, applied in the field of grid rib forming, can solve the problems of fiber accumulation, high points, uneven distribution of demolding fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

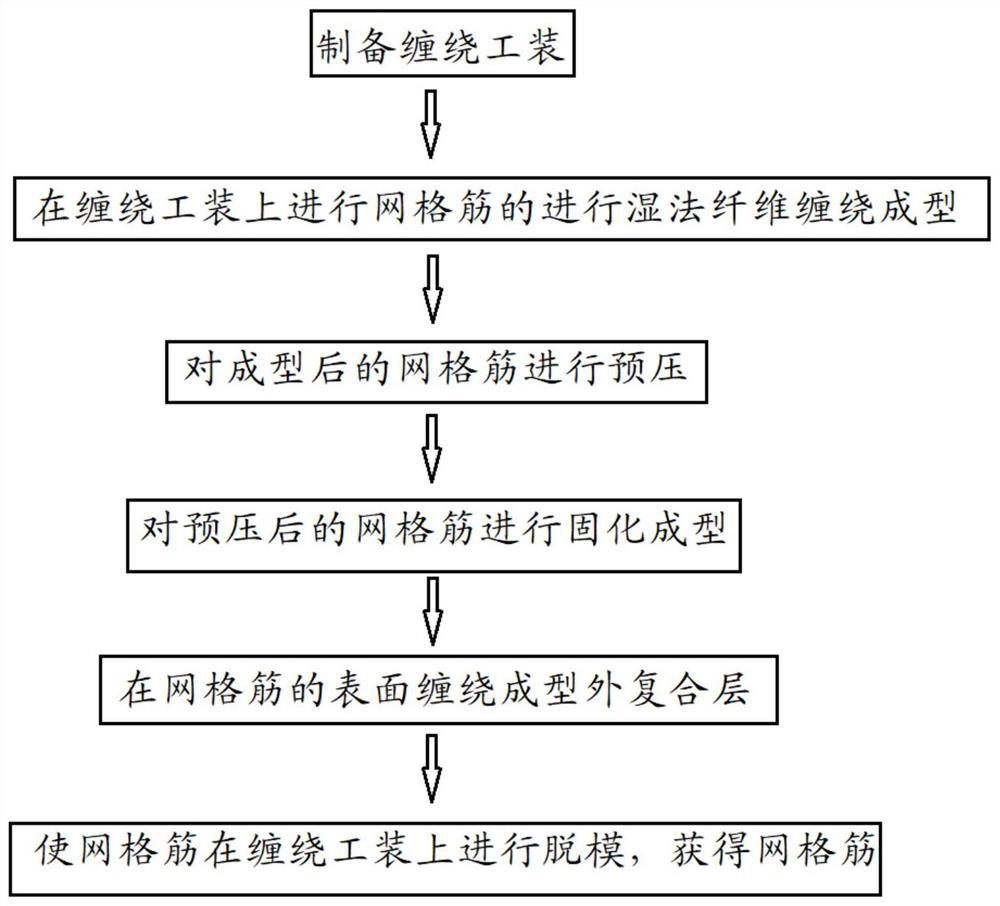

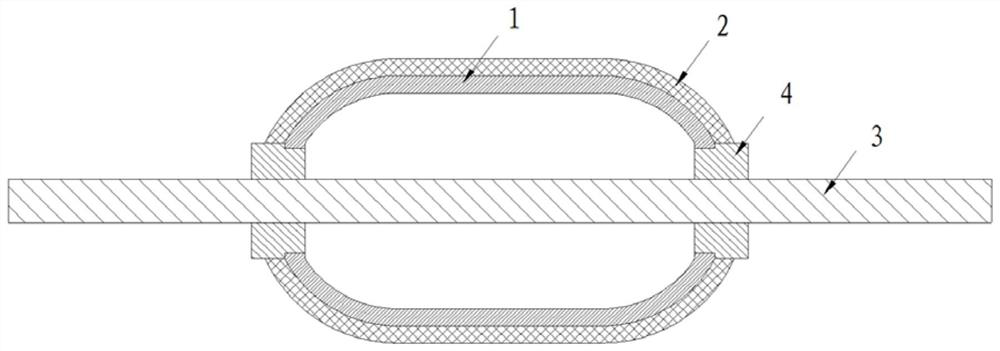

[0020] see figure 1 , a method for forming grid bars provided by an embodiment of the present invention includes:

[0021] Step 1, prepare winding tooling..

[0022] Step 2, performing wet fiber winding forming of the mesh ribs on the winding tooling.

[0023] Step 3, preloading the formed grid tendons.

[0024] Step 4, curing and molding the pre-pressed grid bars.

[0025] In step 5, the outer composite layer is formed by winding on the surface of the grid tendons.

[0026] Step 6, demoulding the grid bars on the winding tooling to obtain the grid bars.

[0027] Specific embodiments of the present application Due to the preparation of the winding tooling, the wet fiber winding molding of the grid bars is carried out on the winding tooling, the formed grid bars are pre-pressed, and the pre-pressed grid bars are solidified and formed. The surface of the grid ribs is wound to form an outer composite layer, so that the grid ribs are demolded on the winding tooling to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com