Device for discharging, tray loading and tray changing of DBC products

A product and tray loading technology, which is applied in the equipment field of DBC product unloading, loading, and changing trays, can solve the problems of not meeting the requirements of production line merging, incomplete functions, and unsatisfactory mechanisms for compatibility with multiple products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

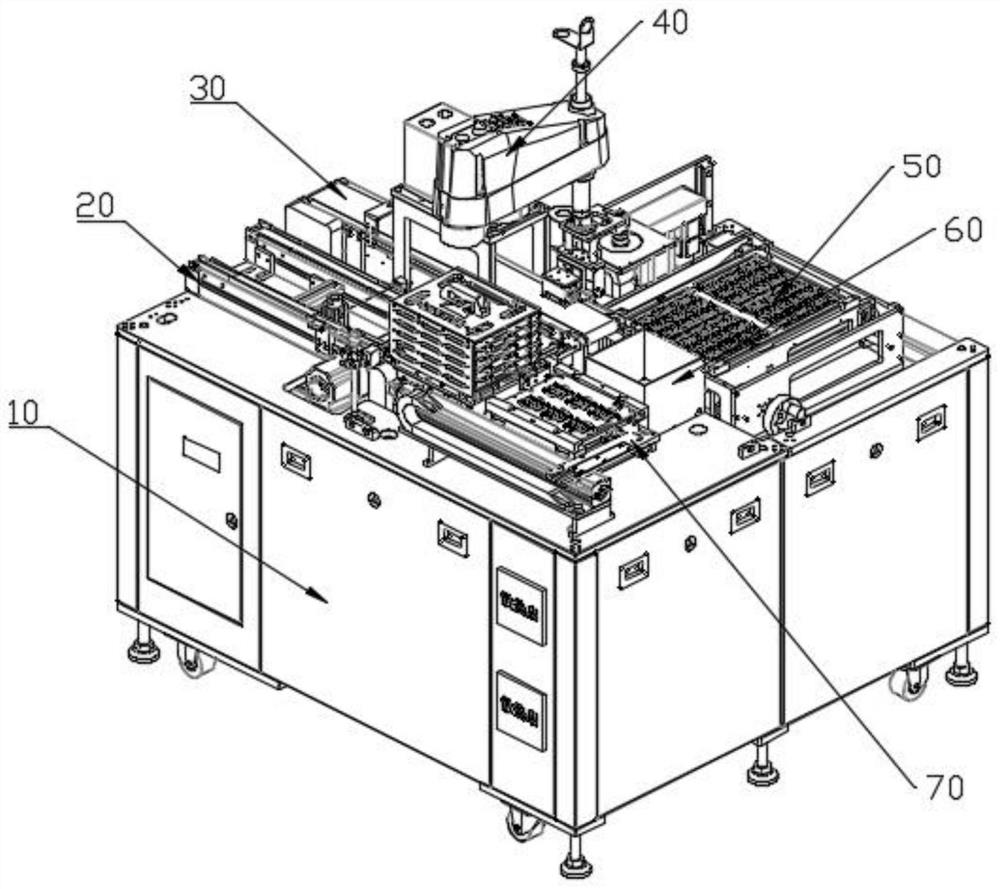

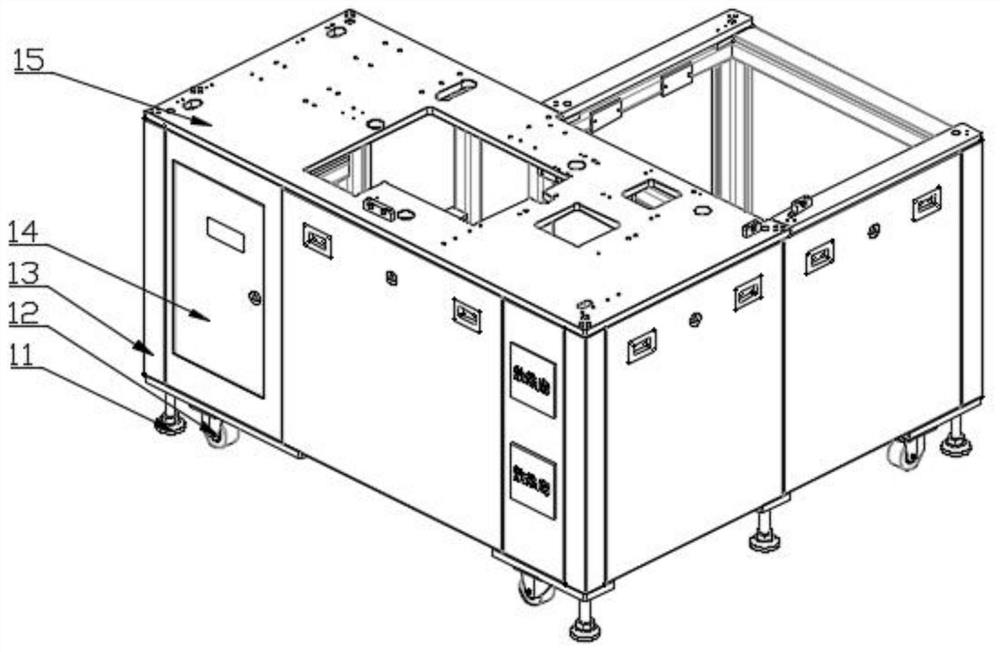

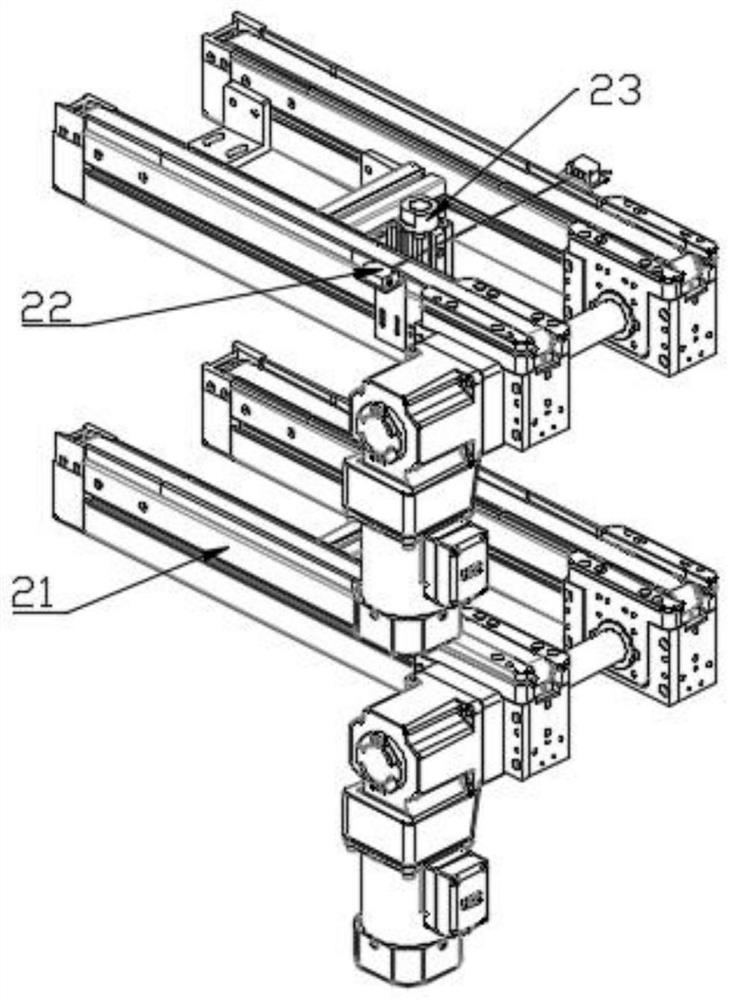

[0034] see Figure 1-8 , in an embodiment of the present invention, a device for unloading, loading, and changing disks of DBC products includes a frame assembly 10, on which a basket feeding and discharging line body 20, and a NG material removal and buffering flow belt are fixed. 30. Product grabbing component 40, carrier lifting and positioning component 50, vision correction module 60, and basket lifting component 70; wherein the frame component 10 plays the role of support and fixing, and the NG material is removed through the basket in and out line body 20 The mutual cooperation between the buffer flow belt 30, the product grabbing component 40, the carrier lifting and positioning component 50, the vision correction module 60 and the basket lifting component 70 realizes the automatic clamping and switching of the pallet, and the packing function is more powerful; the basket The material inlet and outlet line body 20 is used for the conveyance of the basket, which is simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com