Patents

Literature

36results about How to "Reduce the number of manual interventions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

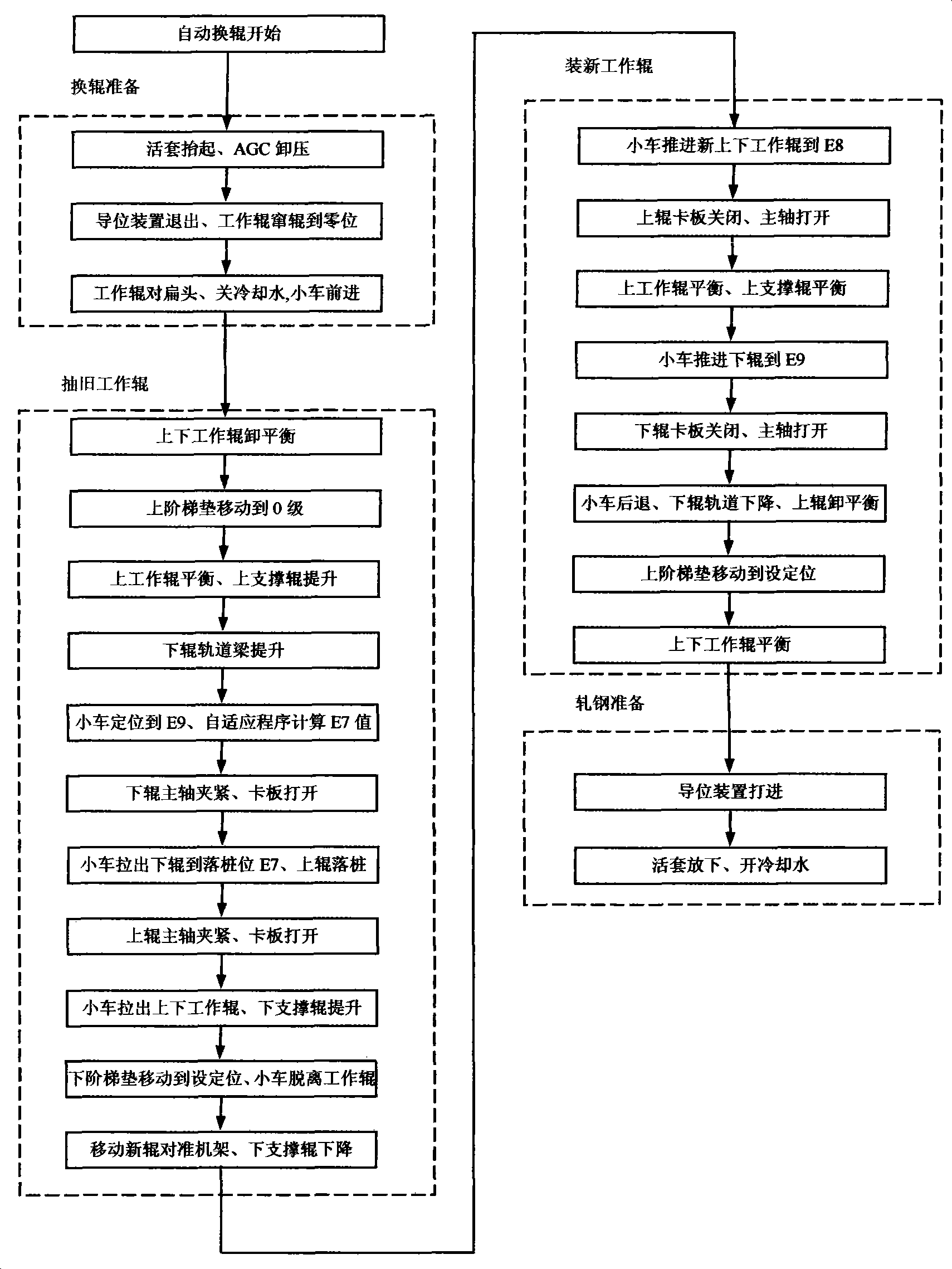

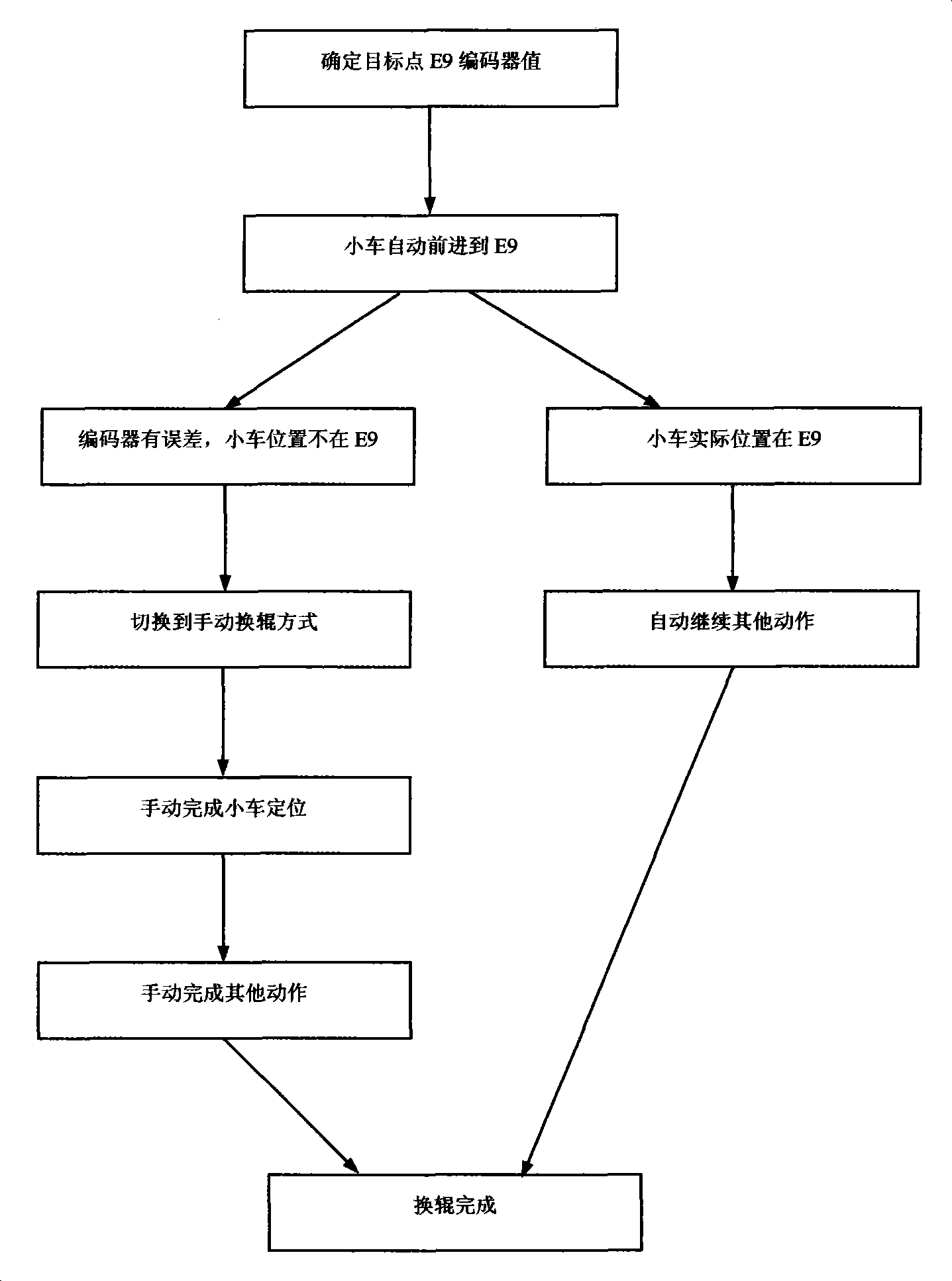

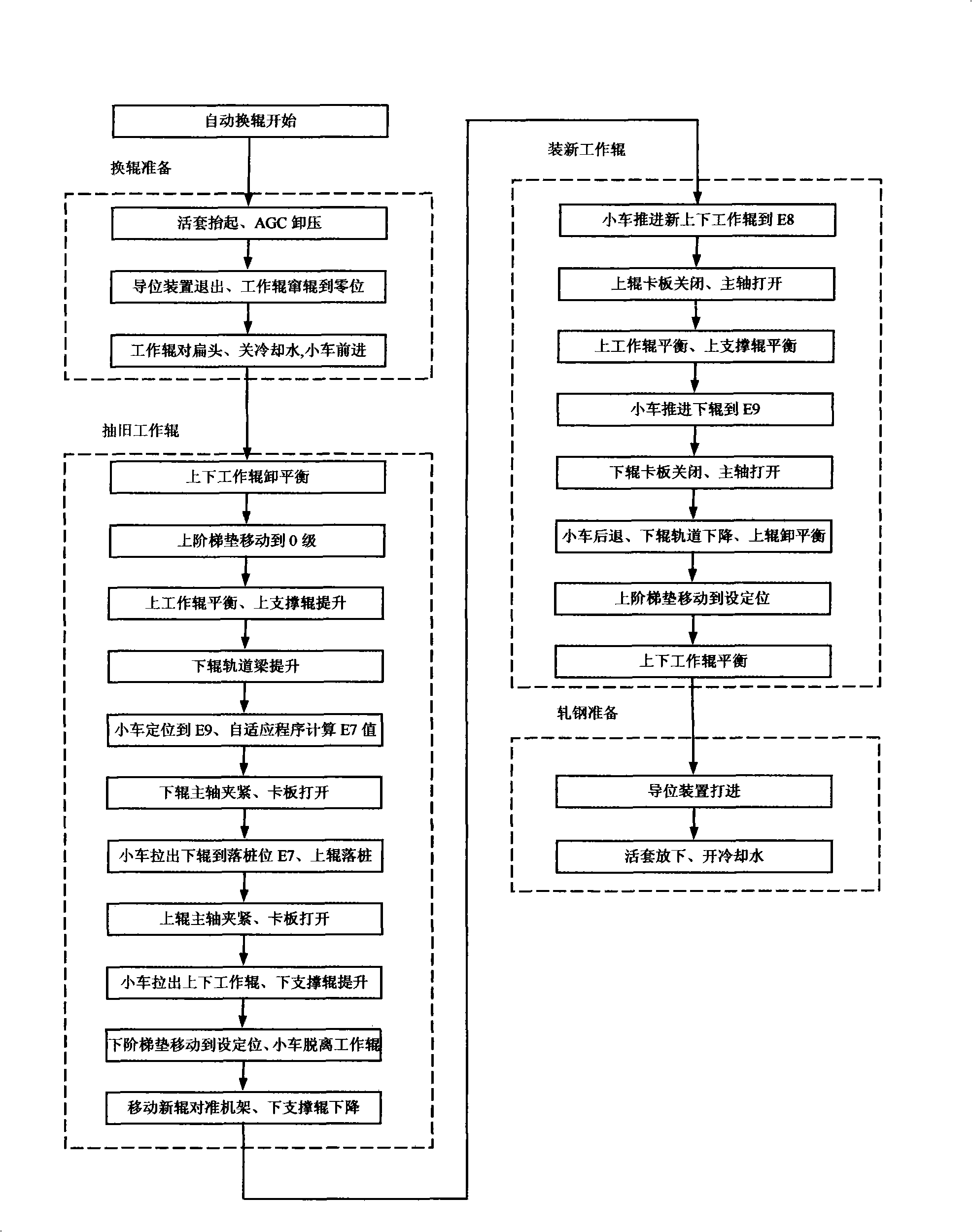

Control method for full-automatically changing work roll of hot rolling finisher

InactiveCN101433918AOptimizing the Work Roll Changing ProcessShorten the timeMetal rolling stand detailsRoll mill control devicesPower flowContact position

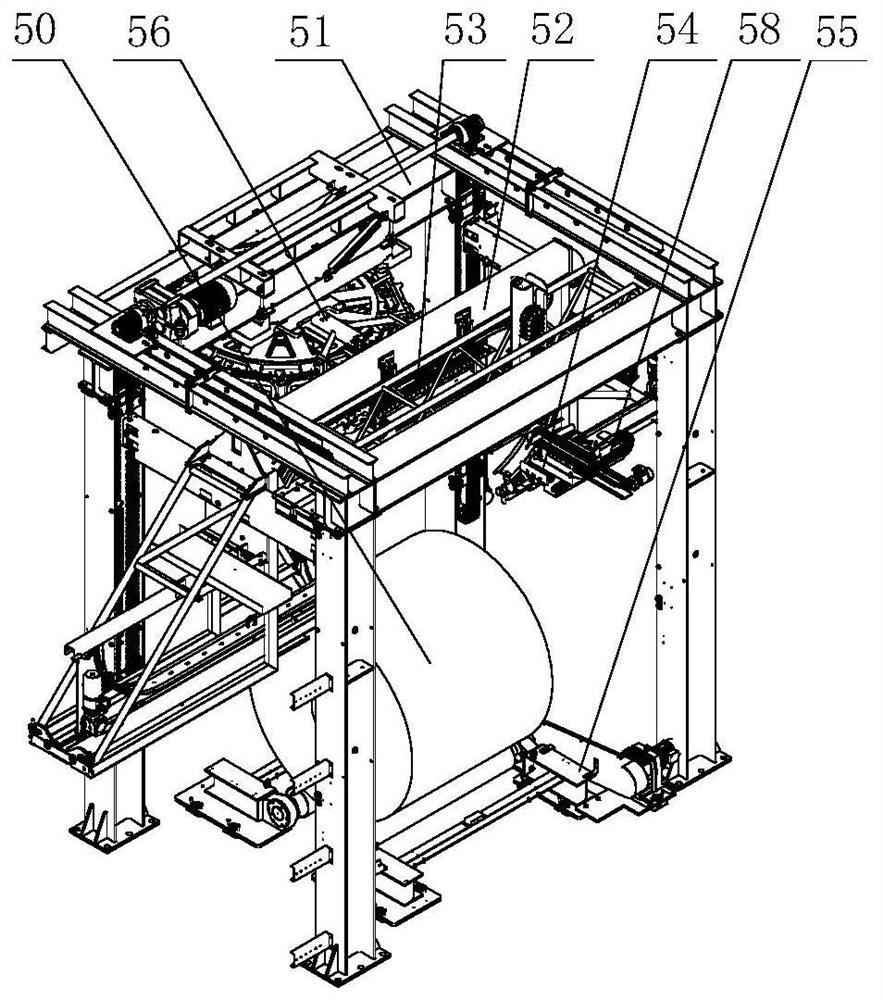

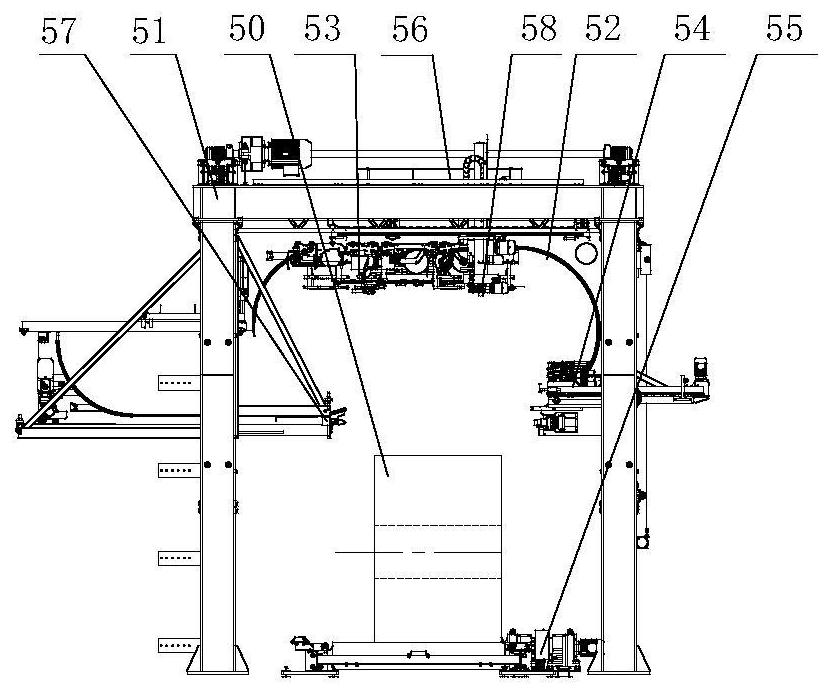

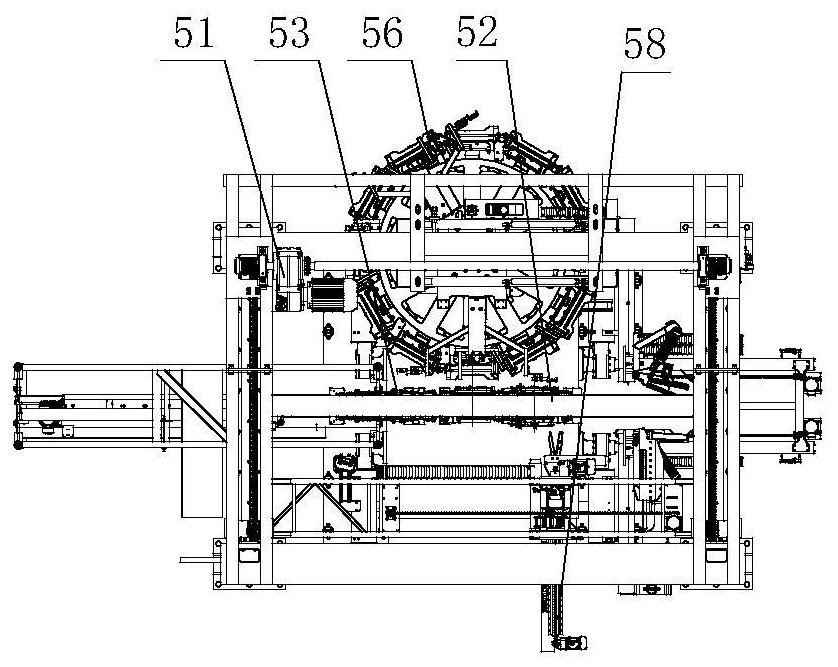

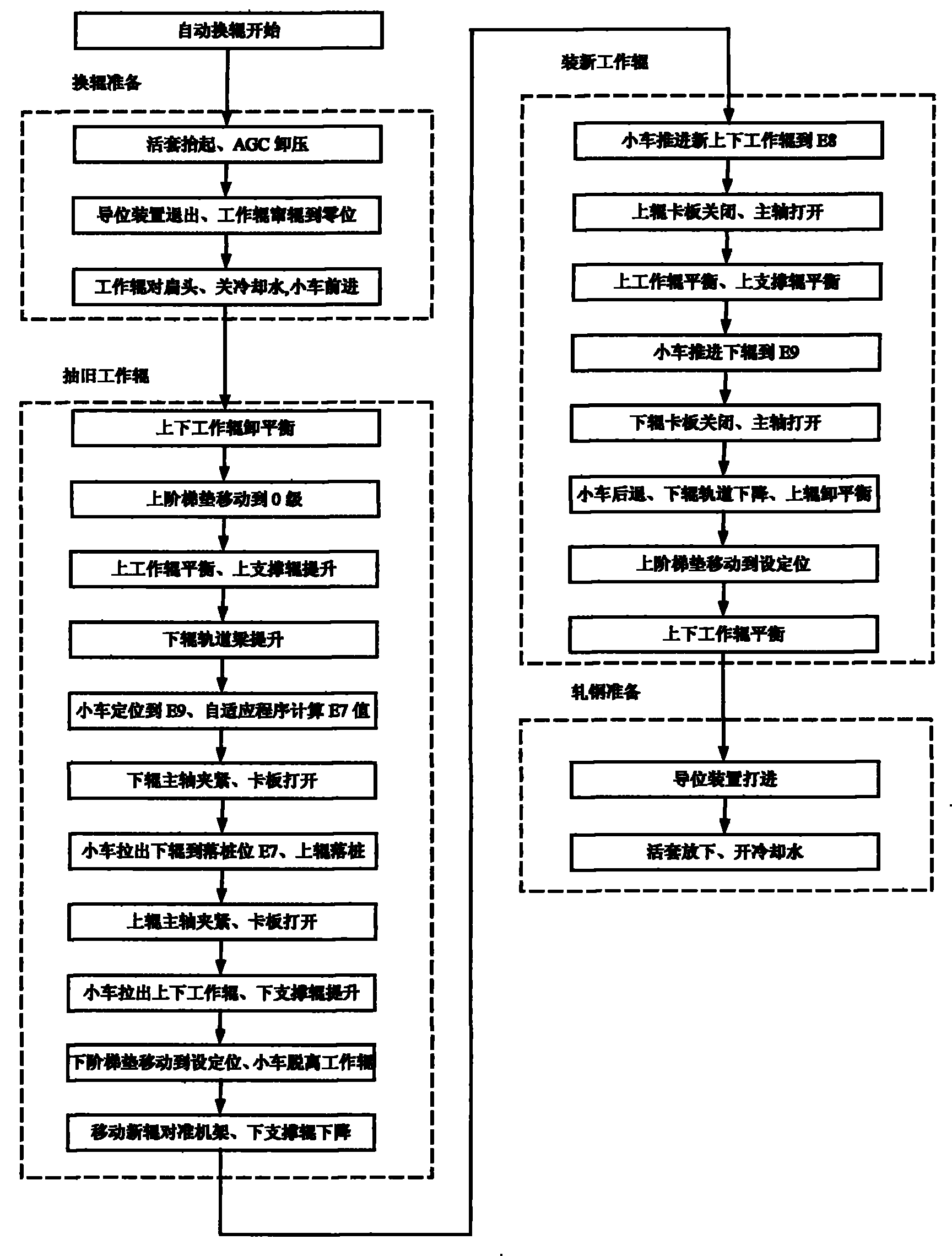

The invention relates to a method for controlling full automatic roll changing of a hog finishing mill. Hardware used by the method consists of a controller, a server, an operating computer and a roll changing bogie, wherein the server and the operating computer are connected with the controller respectively, and the controller controls operation of the roll changing bogie. The control method comprises the following steps in sequence: preparation of roll changing, disassembly of the prior working roll, assembly of a novel working roll, and preparation of steel rolling, wherein jacked pile position value E7 of the roll changing bogie on an upper working roll realizes relative position control by a self-adapting positioning method; the position value E7 is calculated by contact position value E9 of the roll changing bogie and a finishing machine frame minus 420 millimeters; and the contact position value E9 of the roll changing bogie and the finishing machine frame is obtained by judgment of the absolute position of the roll changing bogie before the finishing machine frame, the reference velocity, the actual velocity and the working current of a motor; and after automatic roll changing is subjected to manual interference, automatic roll changing is continuously completed by utilizing the breakpoint continuing function of an SFC module of programmed software P80i in the controller, and quick full automation of the roll changing process is realized.

Owner:WUHAN IRON & STEEL (GROUP) CORP

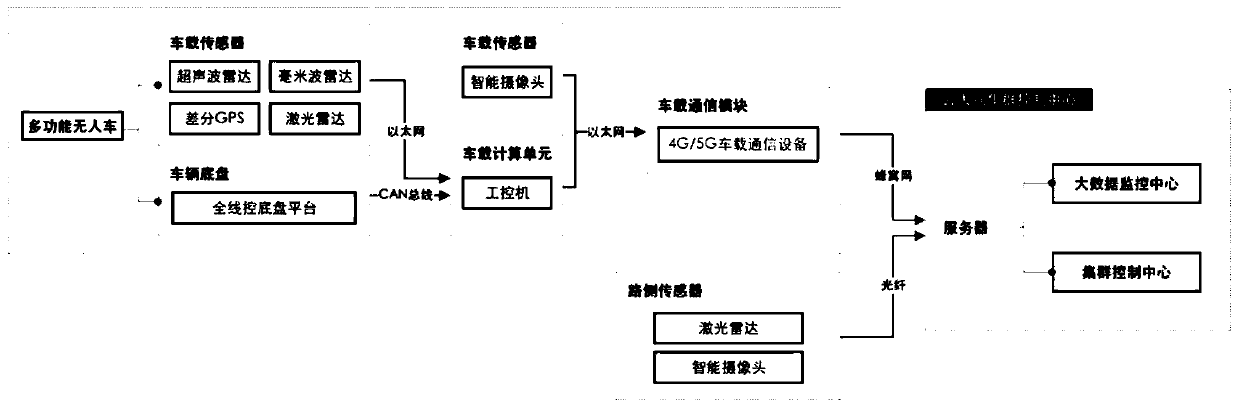

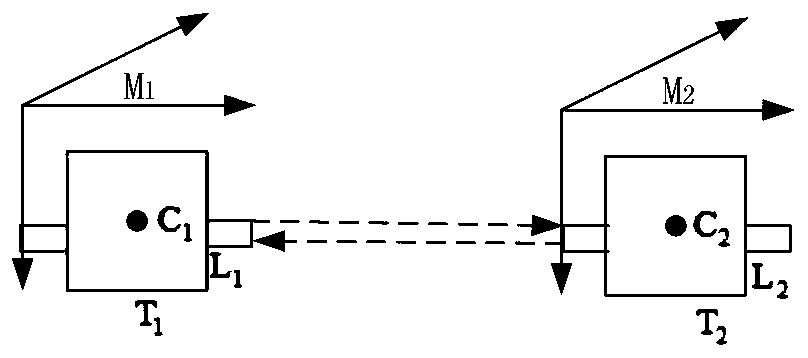

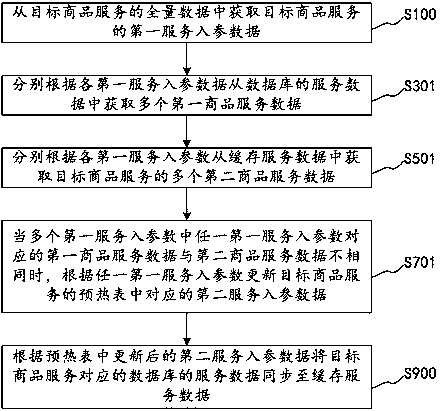

Cloud brain intelligent traffic system comprising multifunctional unmanned vehicles

ActiveCN111462481AImprove operational efficiencyReduce the number of manual interventionsDetection of traffic movementParticular environment based servicesOptical fiber transmissionEmbedded system

The invention provides a cloud brain intelligent traffic system comprising multifunctional unmanned vehicles. The cloud brain intelligent traffic system comprises the multifunctional unmanned vehicles, roadside environment sensing devices and a cloud brain cluster control center; the multifunctional unmanned vehicles communicate with the cloud brain cluster control center through a 4G / 5G network,sends state data of the multifunctional unmanned vehicles to the cloud brain cluster control center and receive control instructions of the cloud brain cluster control center; the roadside environmentsensing devices sense the environment information of positions where the roadside environment sensing devices are located and transmit the environment information to the cloud brain cluster control center through optical fibers; the cloud brain cluster control center carries out real-time monitoring and remote monitoring on data of all the multifunctional unmanned vehicles in the intelligent traffic system and environment data sensed by the roadside environment sensing devices to form a big data database. According to the cloud brain intelligent traffic system, real-time communication and cloud control between vehicle ends and between the vehicle ends and the cloud end can be realized, so that the requirement of large-scale industrial deployment of future multifunctional unmanned vehiclescan be met.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

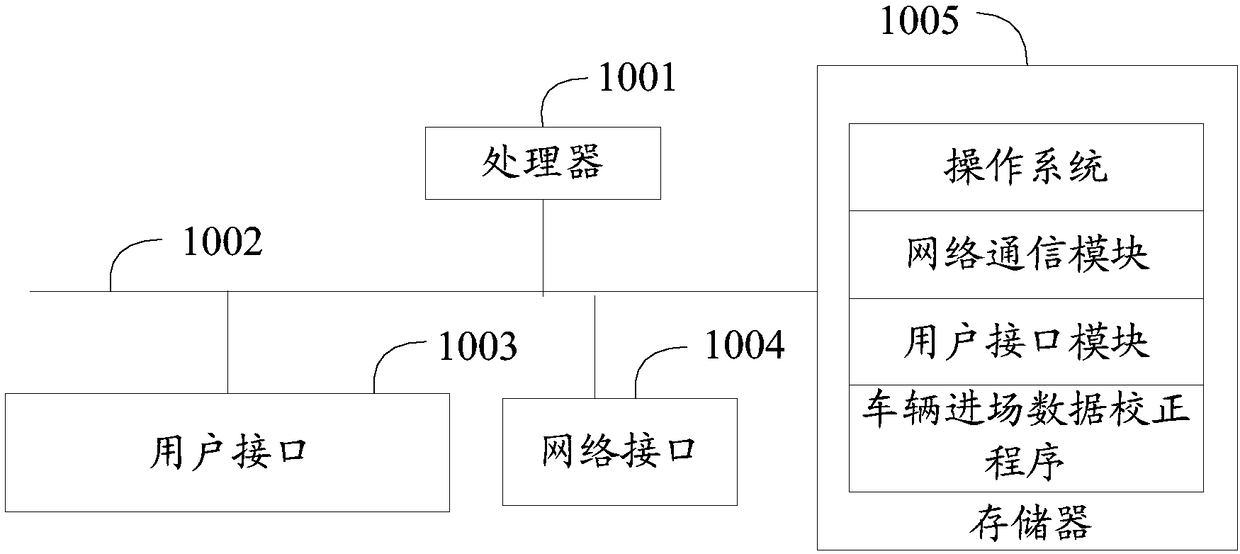

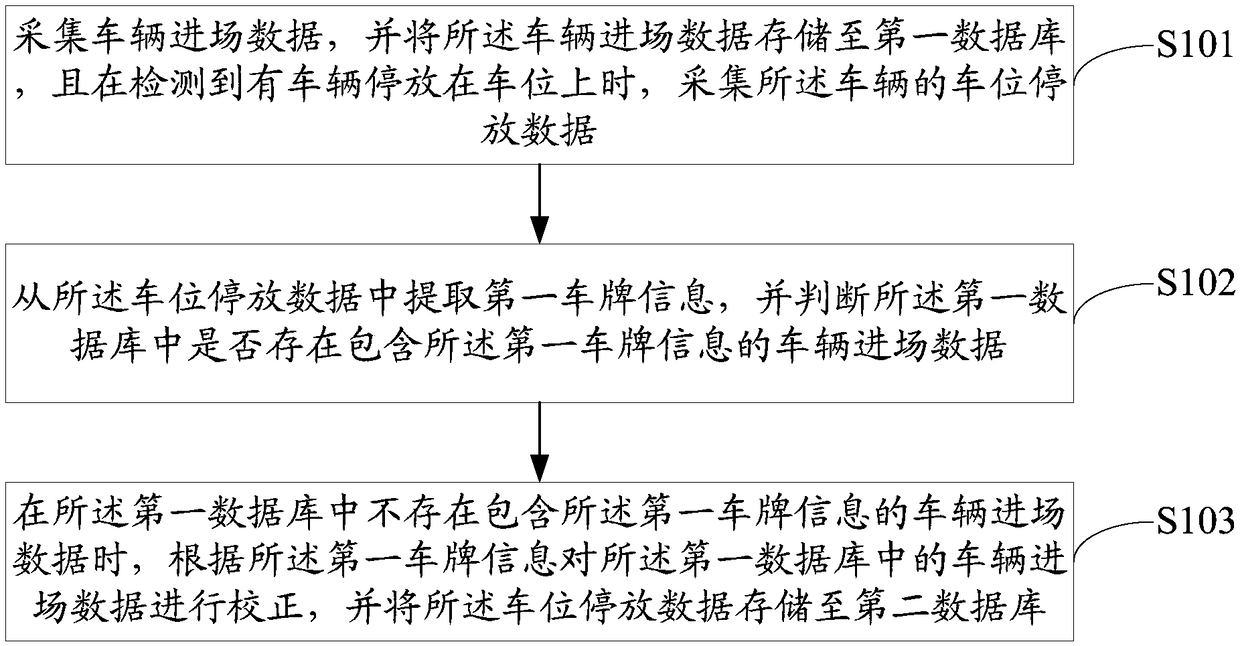

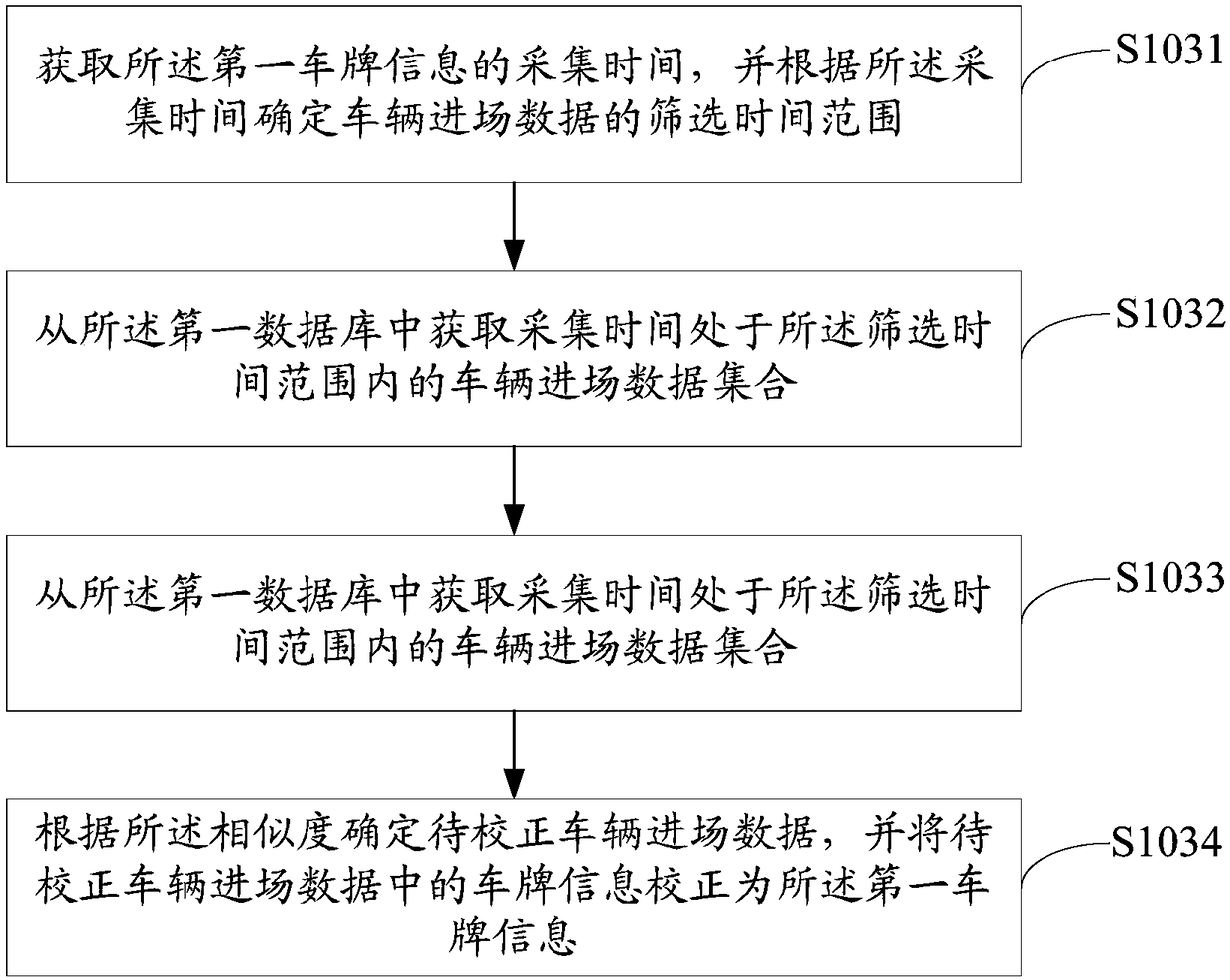

Vehicle entry data correction method, equipment and computer readable storage medium

InactiveCN108182378AImprove accuracyReduce the number of manual interventionsDatabase updatingRoad vehicles traffic controlParking spaceData store

The invention discloses a vehicle entry data correction method, equipment and a computer readable storage medium. The vehicle entry data correction method comprises the following steps: vehicle entrydata are acquired, the vehicle entry data are stored in a first database, and when a vehicle is detected to be parked on a parking space, the parking space parking data of the vehicle are acquired; first license plate information is extracted from the parking space parking data, and whether the vehicle entry data containing the first license plate information exist in the first database is judged;and when the vehicle entry data containing the first license plate information do not exist in the first database, the vehicle entry data in the first database are corrected according to the first license plate information, and the parking space parking data are stored in a second database. Thus, the vehicle entry data accuracy can be greatly improved, and the manual intervention times can be effectively reduced.

Owner:XIAN IRAIN IOT TECH SERVICES CO LTD

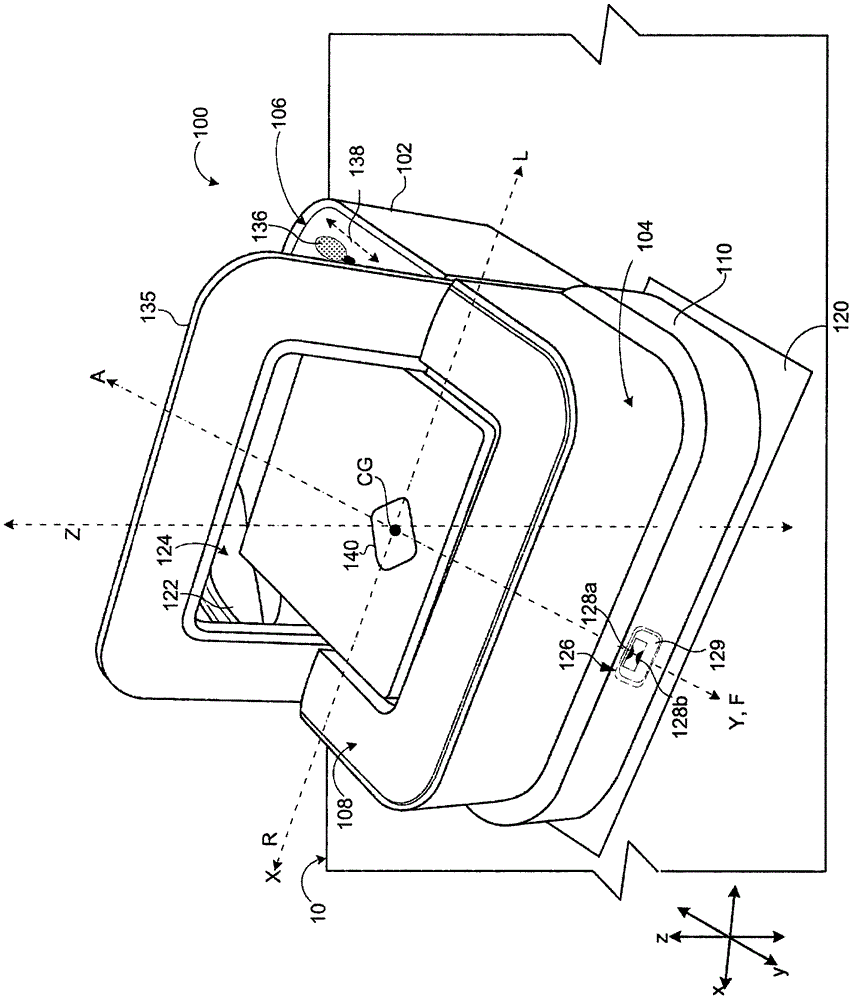

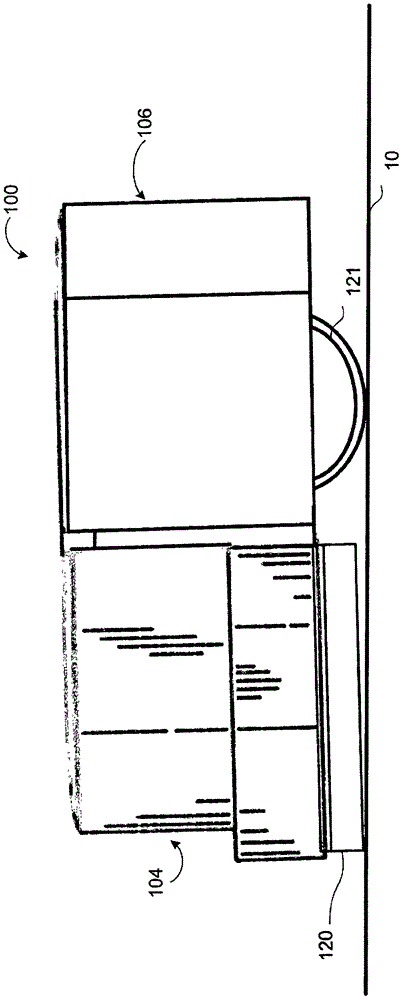

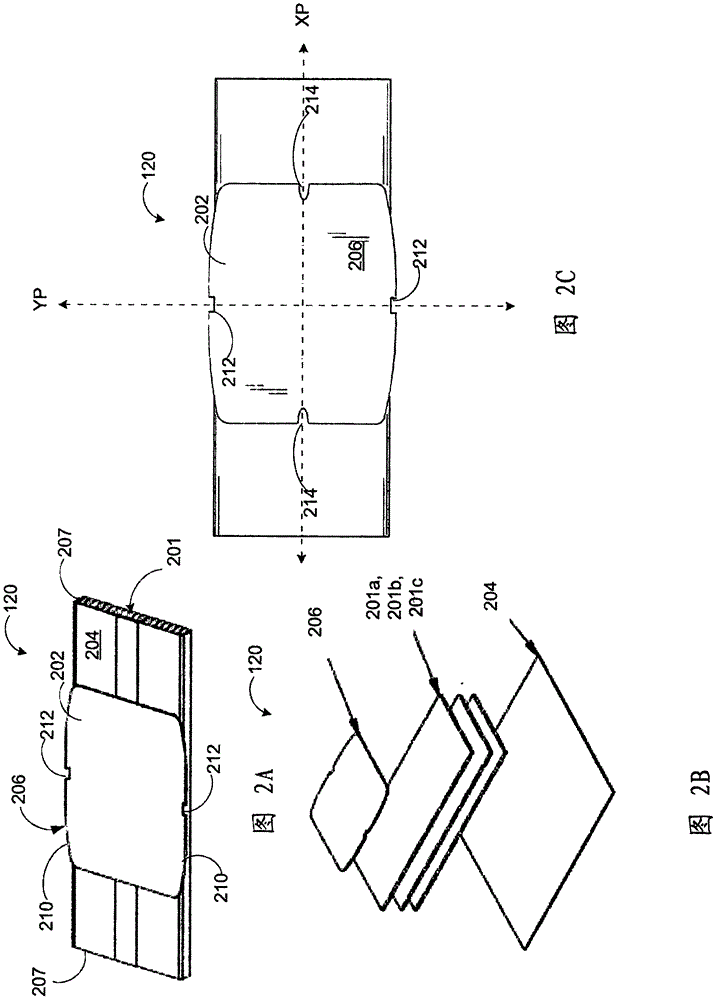

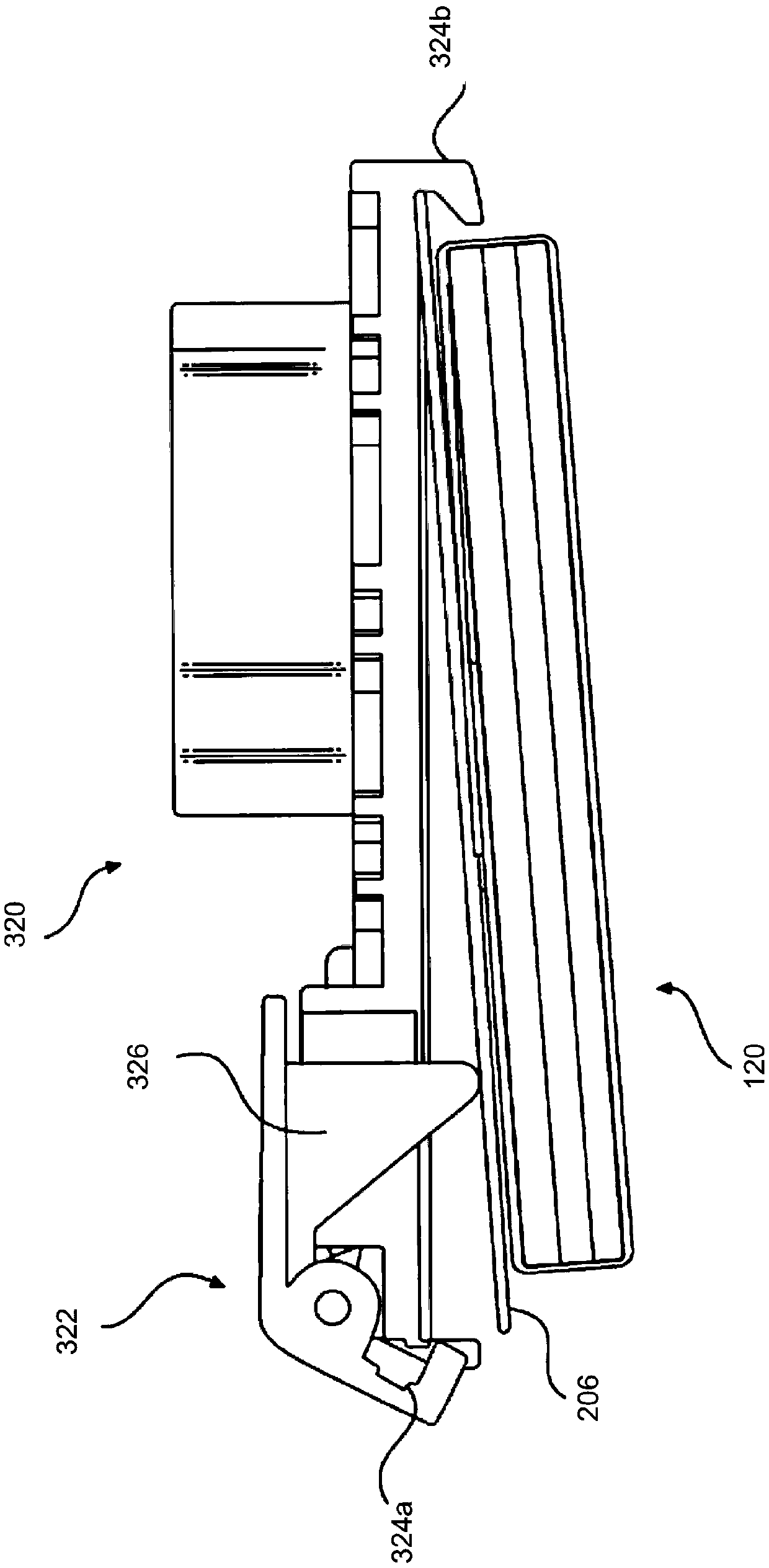

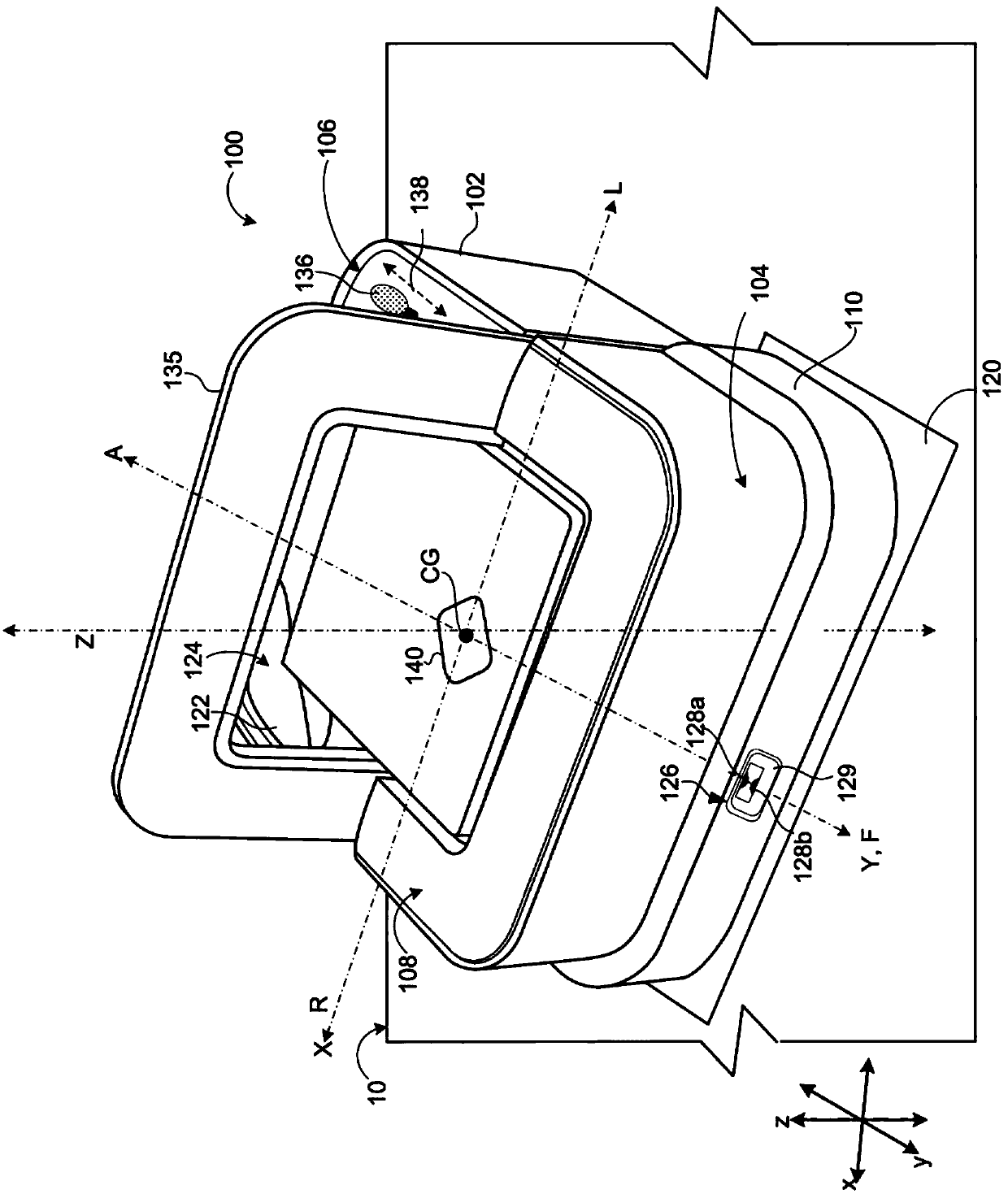

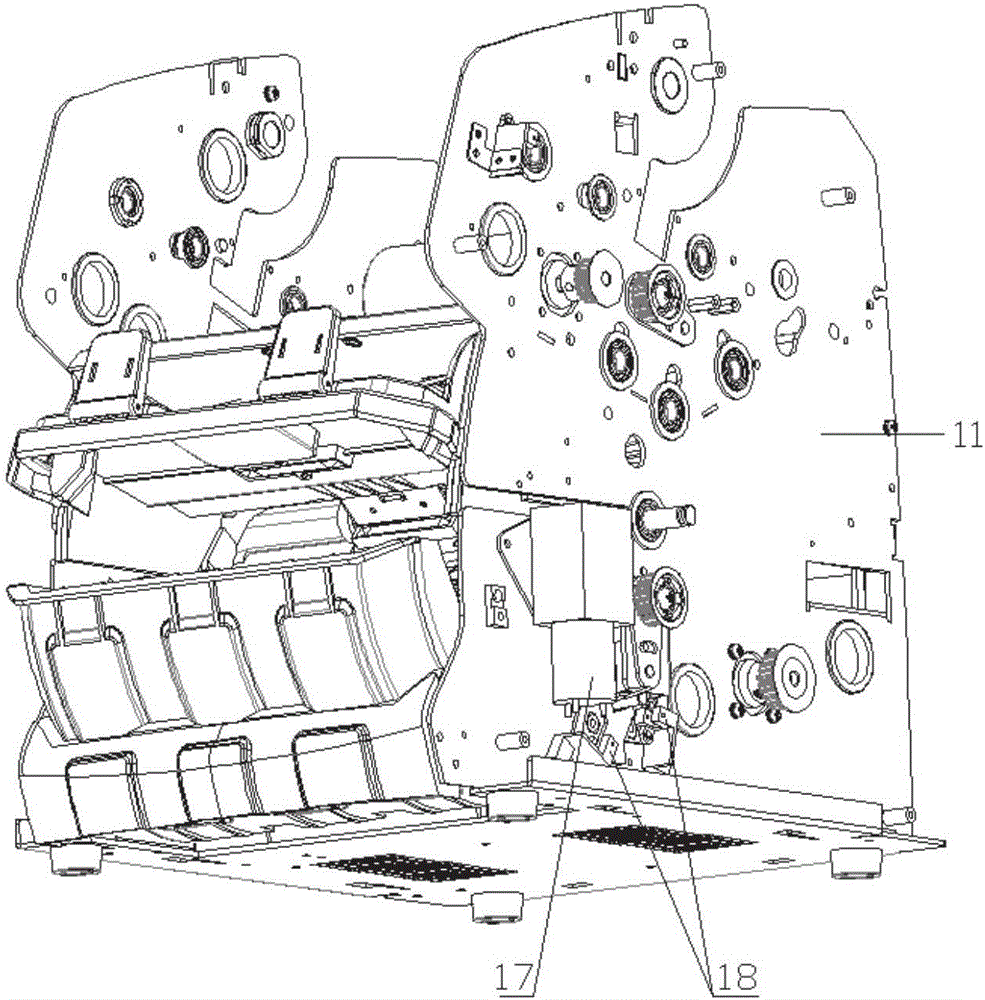

Autonomous floor cleaning with removable pad

ActiveCN106805851AEasy to operateReduce the number of manual interventionsCarpet cleanersFloor cleanersEngineeringMechanical engineering

An autonomous floor cleaning robot includes a body, a controller supported by the body, a drive supporting the body to maneuver the robot across a floor surface in response to commands from the controller, and a pad holder attached to an underside of the body to hold a removable cleaning pad during operation of the robot. The pad includes a mounting plate and a mounting surface. The mounting plate is attached to the mounting surface. The robot includes a pad sensor to sense a feature on the pad and to generate a signal based on the feature, which is defined in part by a cutout on the card backing. The mounting plate enables the pad sensor to detect the feature. The controller is responsive to the signal to perform operations including selecting a cleaning mode based on the signal, and controlling the robot according to a selected cleaning mode.

Owner:IROBOT CORP

Autonomous floor cleaning with removable pad

ActiveCN109512339AEasy to operateReduce the number of manual interventionsCarpet cleanersFloor cleanersMechanical engineeringAutonomous robot

The invention proposes a set of autonomous robot cleaning pads, and each of the cleaning pads includes a pad body including opposite width surfaces comprising a cleaning surface and a mounting surface; pad type identifying features indicating the types of cleaning pads; and a mounting plate fixed over the mounting surface of the pad body and including a notch, wherein the notch at least partiallydefines the pad type identifying features when the cleaning pads are mounted on the robot, the mounting plate enables the pad sensor of the robot to detect the pad type identification features.

Owner:IROBOT CORP

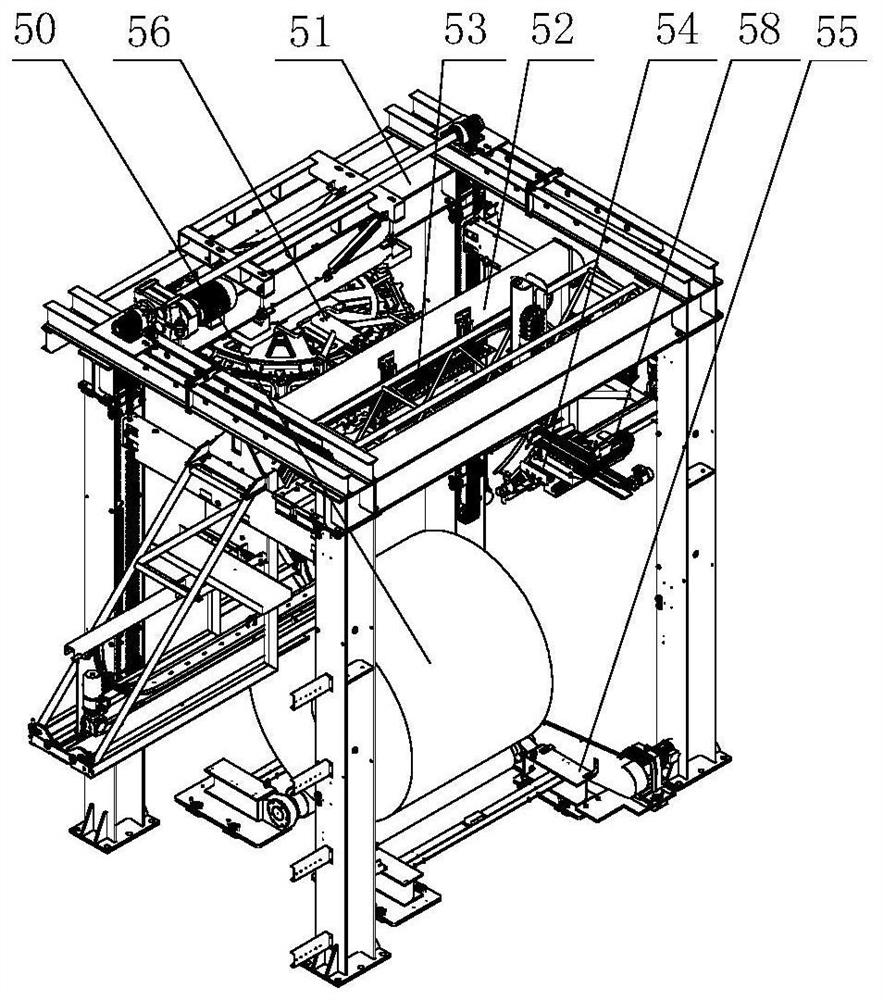

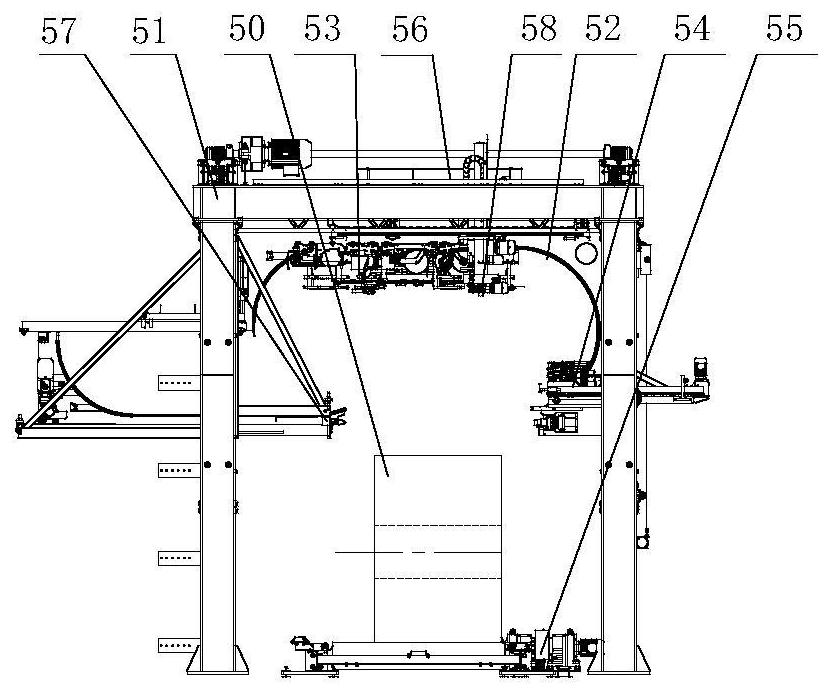

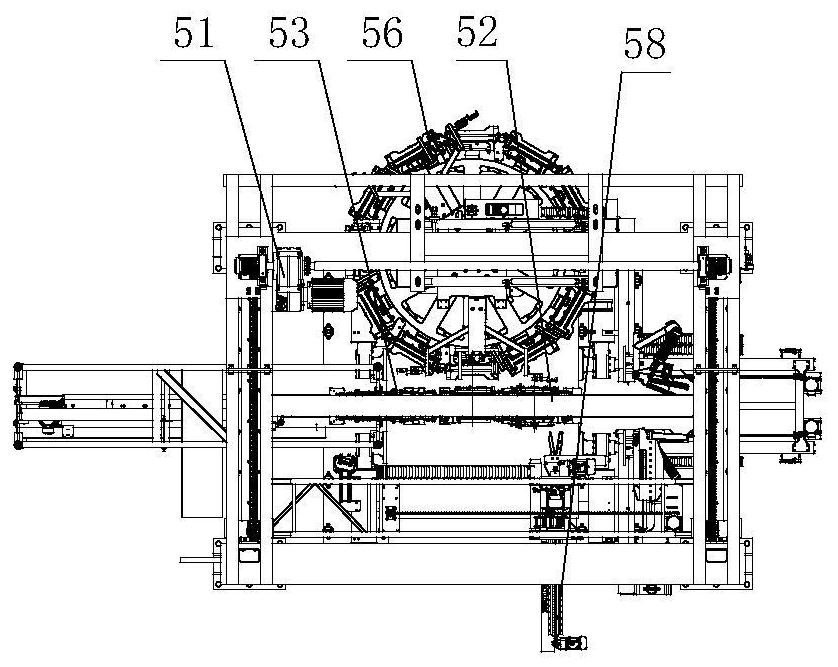

Winding packaging machine for automatic coiled material packaging line

ActiveCN112623308AImprove packaging efficiencyAchieve windingWrapping material feeding apparatusWrapper twisting/gatheringControl systemPack material

The invention discloses a winding packaging machine for an automatic coiled material packaging line. The winding packaging machine comprises a fixing frame, a coil library, an annular track, a rotary ground roller, a coiled material inner hole inspection device and a control system, wherein the winding trolley is used for winding a packaging material on a coiled material, the coil library is used for storing at least two packaging materials and supplementing the packaging material to the winding trolley, the annular track is arranged on the fixing frame and is used for guiding the winding trolley to run, the rotary ground roller is used for driving the coiled material to rotate. Provided are a coiled material inner hole inspection device and a control system. According to the winding packaging machine for the automatic coiled material packaging line, through cooperation of the winding trolley, the annular track and the coil library, winding of packaging materials on coiled materials can be achieved, and the packaging efficiency of the coiled materials is improved; before each time of winding and packaging, the coiled material inner hole inspection device checks, analyzes and judges whether a coiled material inner hole meets the winding and packaging conditions or not, and collision accidents of the winding trolley are effectively prevented; and the winding trolley is automatically supplemented with packaging materials through the coil library, the manual intervention frequency can be reduced, and the automation degree is high.

Owner:TAIER HEAVY IND

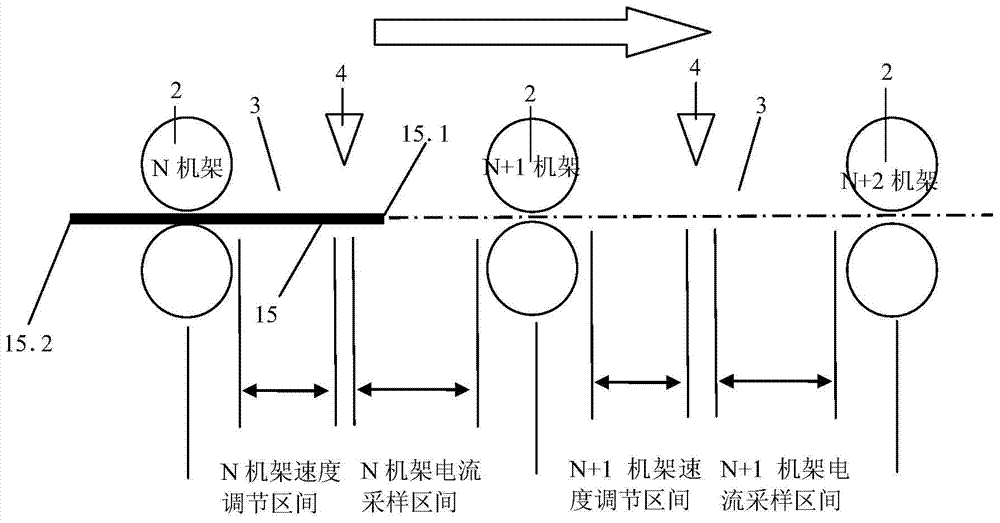

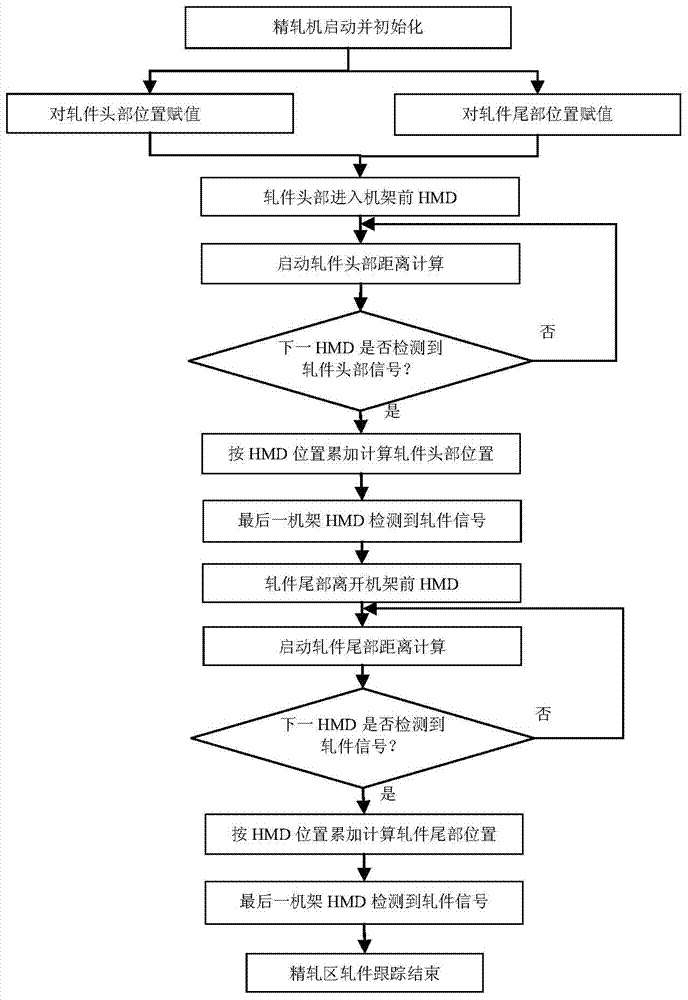

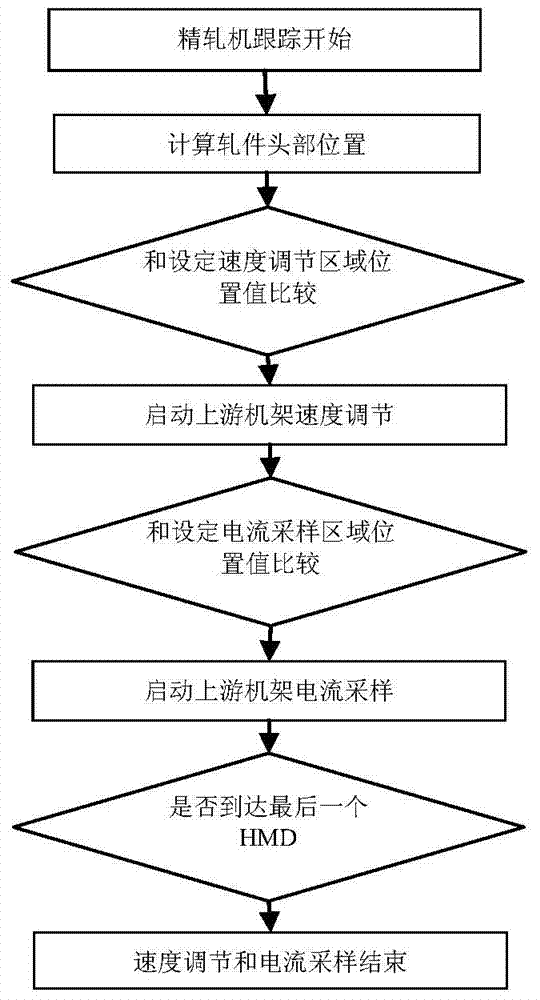

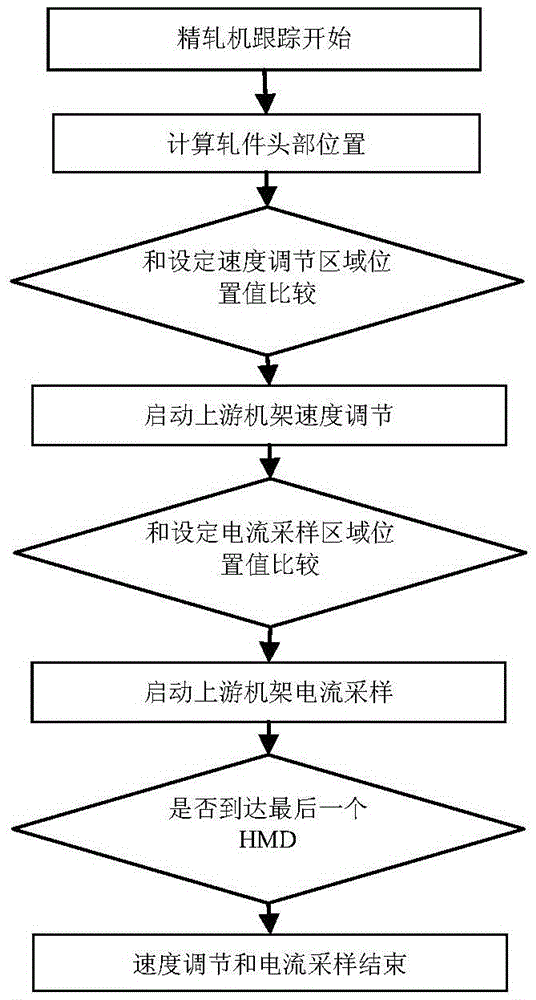

Rolled piece position tracking device and tracking method for sectional material hot rolling finishing mill

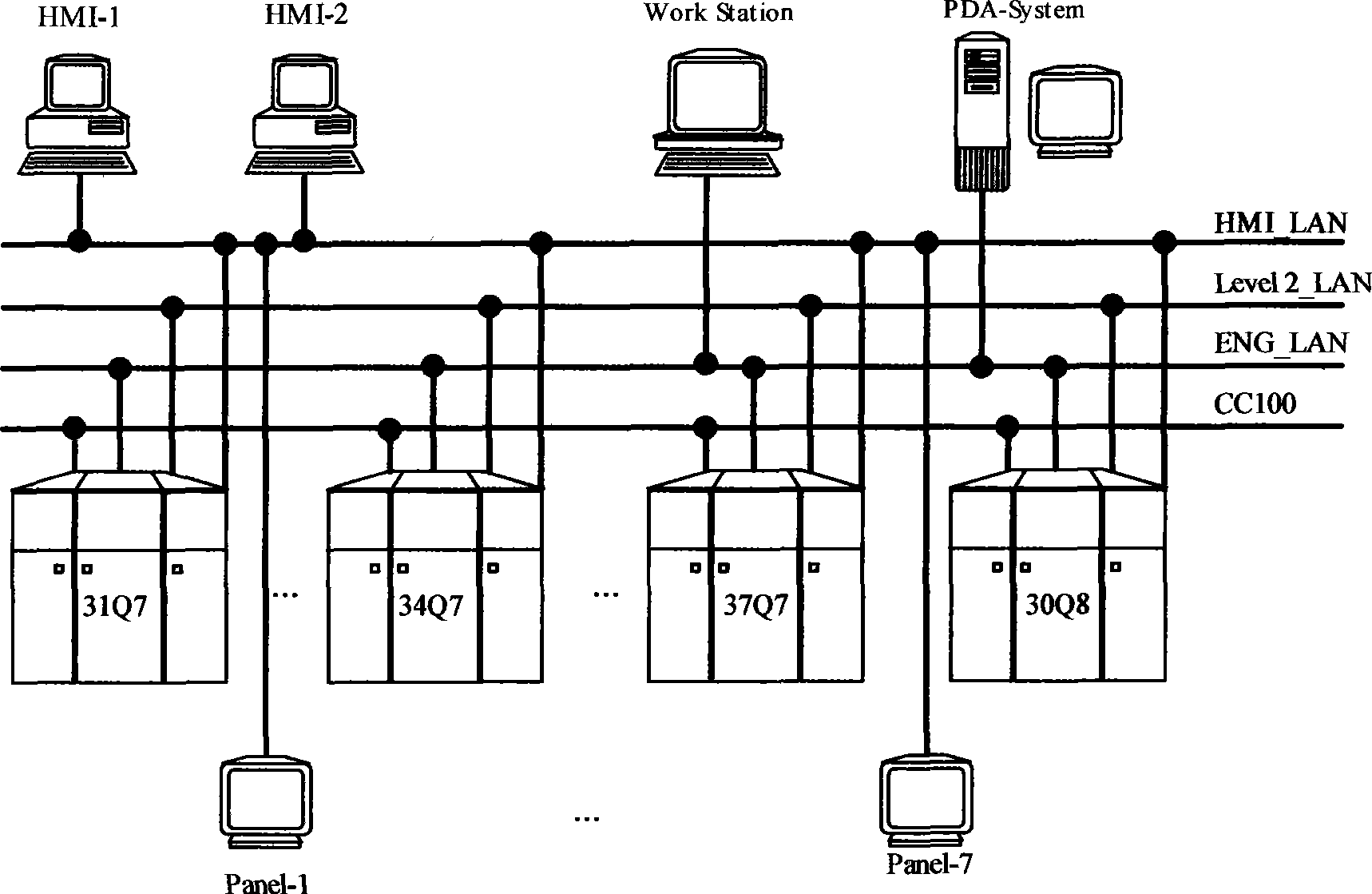

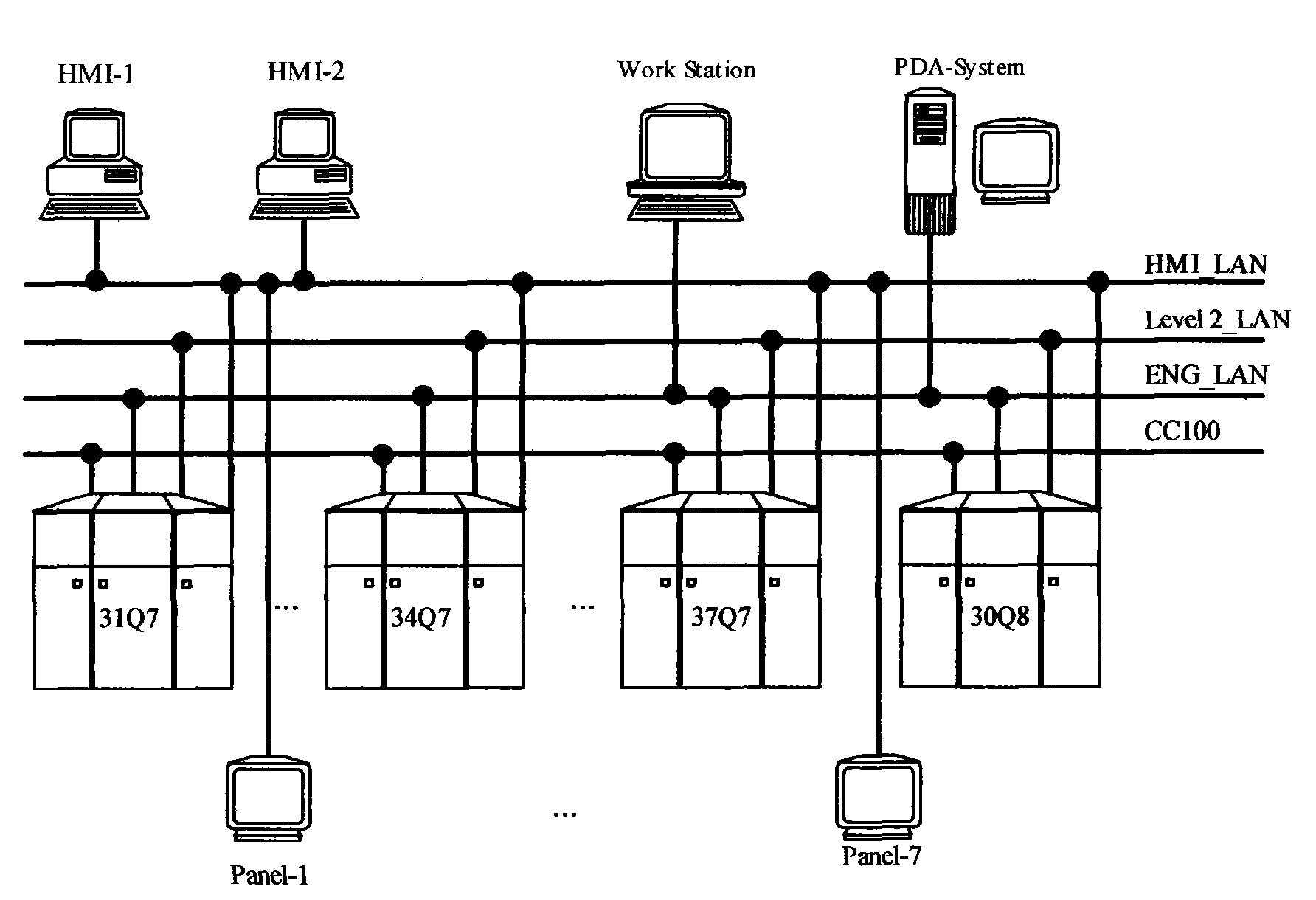

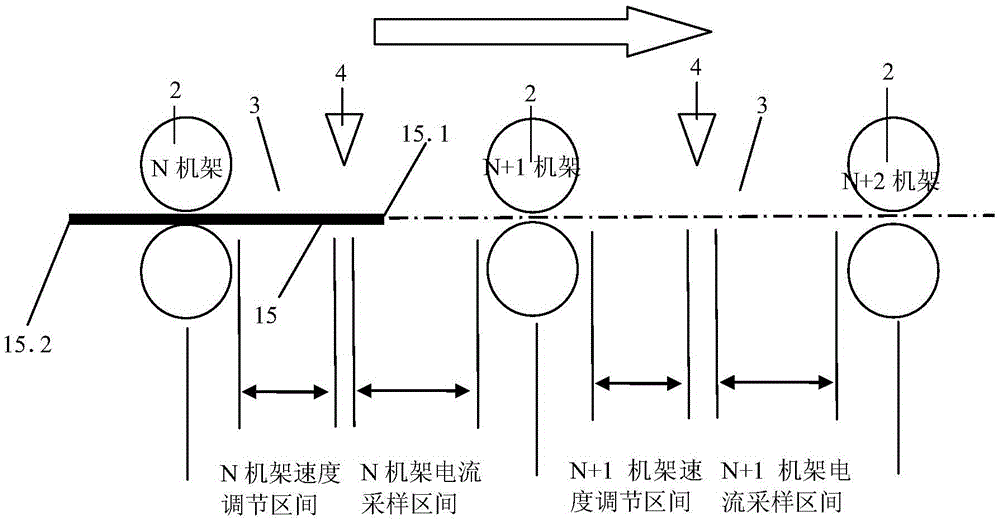

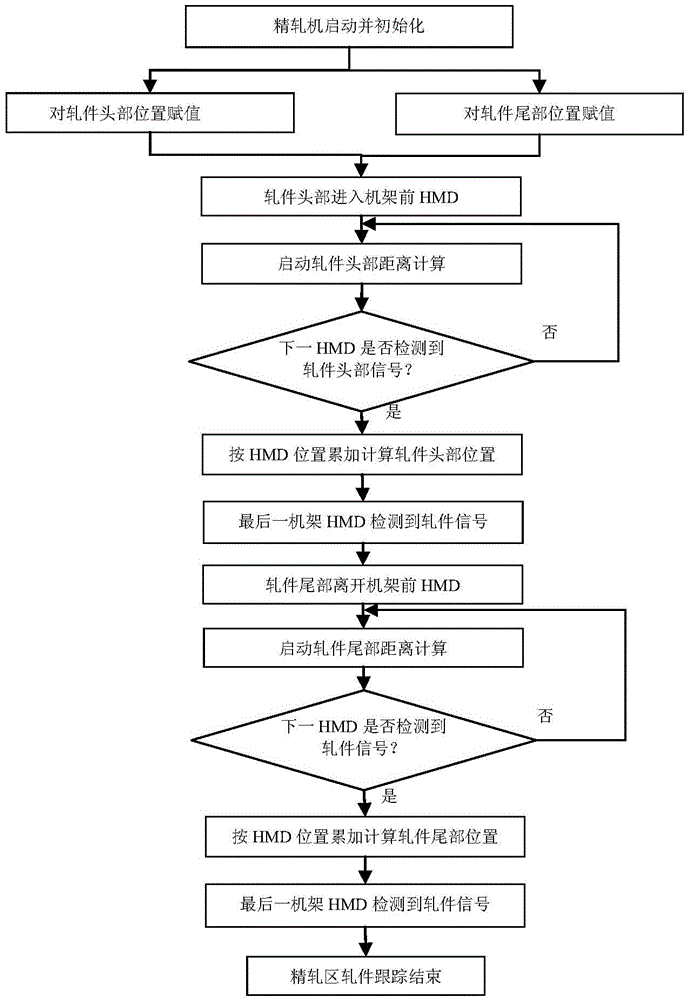

ActiveCN103499946AImprove location tracking accuracyReduce the number of manual interventionsNumerical controlLocal area networkEngineering

The invention discloses a rolled piece position tracking device for a sectional material hot rolling finishing mill. The rolled piece position tracking device comprises a machine frame, a tracking region, a zero current sampling section, a tension adjustment section, a hot metal detector, a frequency converter, a man-machine interface local area network, a high-performance controller, a man-machine interface server and a local control panel, wherein the zero current sampling section and the tension adjustment section are arranged in the tracking region, and a rolled piece position tracking control module is arranged in the high-performance controller. A rolled piece position tracking method for a sectional material hot rolling finishing mill comprises the following steps that 1, the rolled piece position tracking control module is started; 2, the position of a rolled piece in the tracking region is calculated and is compared with the position values of the tension adjustment section and the zero current sampling section; 3, the rolled piece position tracking control module finishes the tracking procedure of the current tracking region according to cascade signals and steel occluding current change signals. The rolled piece position tracking device and the rolled piece position tracking method have the characteristics that the rolled piece tracking precision is high, the manual intervention is little, the yield of hot rolling sectional materials is high, the failure rate is low, and the labor cost is low. The rolled piece position tracking device and the rolled piece position tracking method can be widely applied to the technical field of sectional material hot rolling automation control.

Owner:通用电气(武汉)自动化有限公司

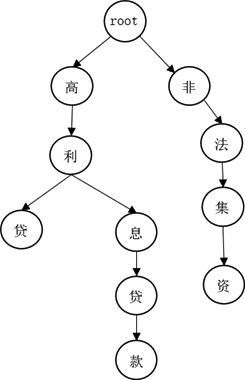

Sensitive word recognition method based on big data

PendingCN114385775AImprove recognition accuracyReduce labor timeNatural language data processingMachine learningWord listTrie

The invention discloses a sensitive word recognition method based on big data. The method comprises the steps of 1, collecting text data by utilizing crawler software, performing sensitive marking on the text data to obtain a sensitive text D1 and a normal text D2, performing sensitive word classification and grade marking on sensitive words, and storing the sensitive words into a sensitive word list S; 2, carrying out new word discovery through an N-gram model, and amplifying the sensitive word lists S; and 3, carrying out deformation processing on each sensitive word in each sensitive word list S to obtain deformed sensitive words. 4, filtering the sensitive words in the sensitive word list S based on a Trie tree and a BERT model; according to the method, the accuracy and efficiency of auditing and identifying the sensitive words are improved.

Owner:NANJING SHICHAZHE INFORMATION TECH CO LTD

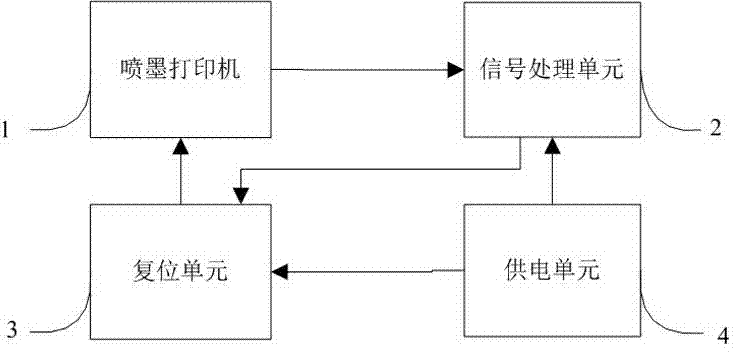

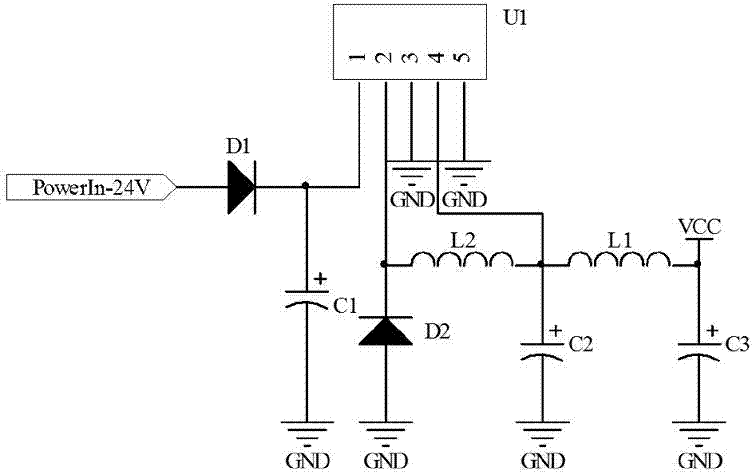

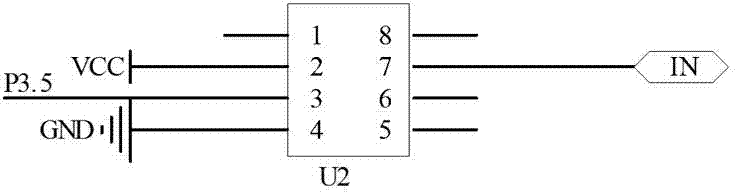

Automatic resetting system and method for inkjet printer

ActiveCN104290472ASolve the problem of cracking the encryption by the small ink cartridge chipContinuously workingOther printing apparatusProcess errorError reporting

The invention discloses an automatic resetting system for an inkjet printer. The system comprises a signal processing unit, a resetting unit and a power supply unit, wherein the signal processing unit is electrically connected with the resetting unit while the power supply unit is used for supplying power, the signal processing unit receives error reporting signals from the inkjet printer and transmits the processed error reporting signals to the resetting unit, and the resetting unit controls a resetting ink box chip and a paper box according to the categories of the error reporting signals. The system solves the encryption problem of the ink box chip, meanwhile the paper extraction state of the paper box is changed so that the inkjet printer can reset and continuously work, the manual participating frequency is reduced, manpower resources are saved, the automatic resetting system is a circuit board and small in size and can be directly installed in the inkjet printer without changing the structure of the inkjet printer, and movement of the inkjet printer cannot be obstructed. The invention further provides an automatic resetting method for the inkjet printer.

Owner:SHENZHEN JUDING MEDICAL DEVICE

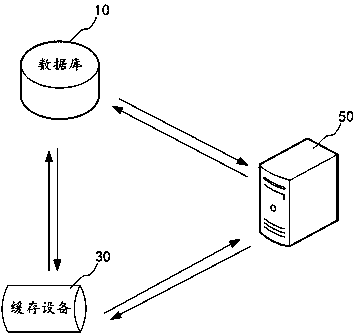

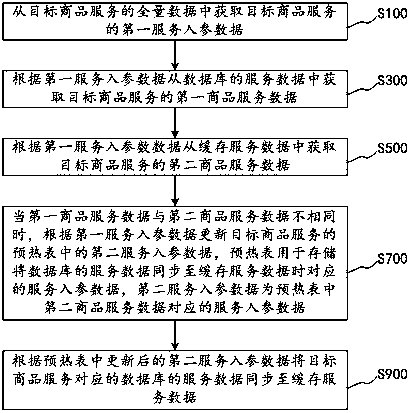

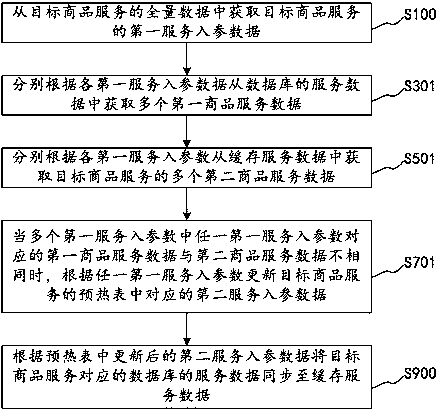

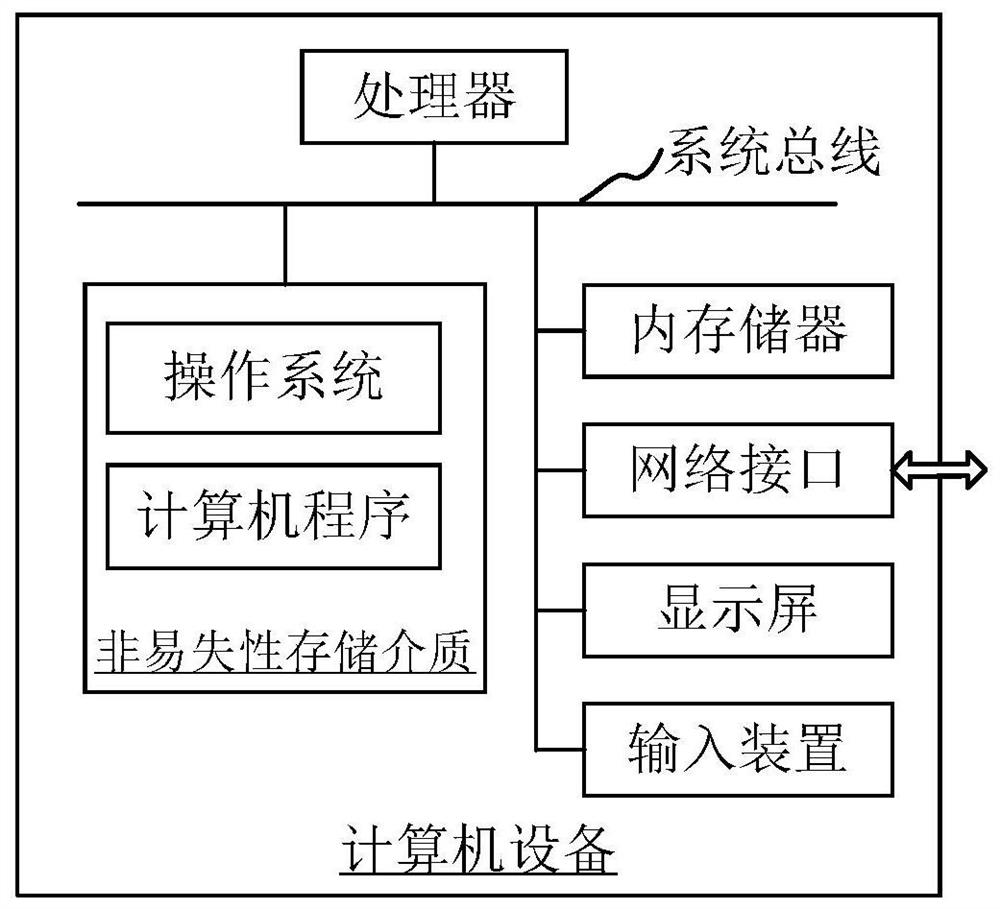

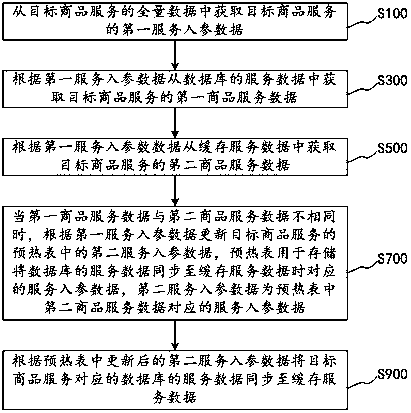

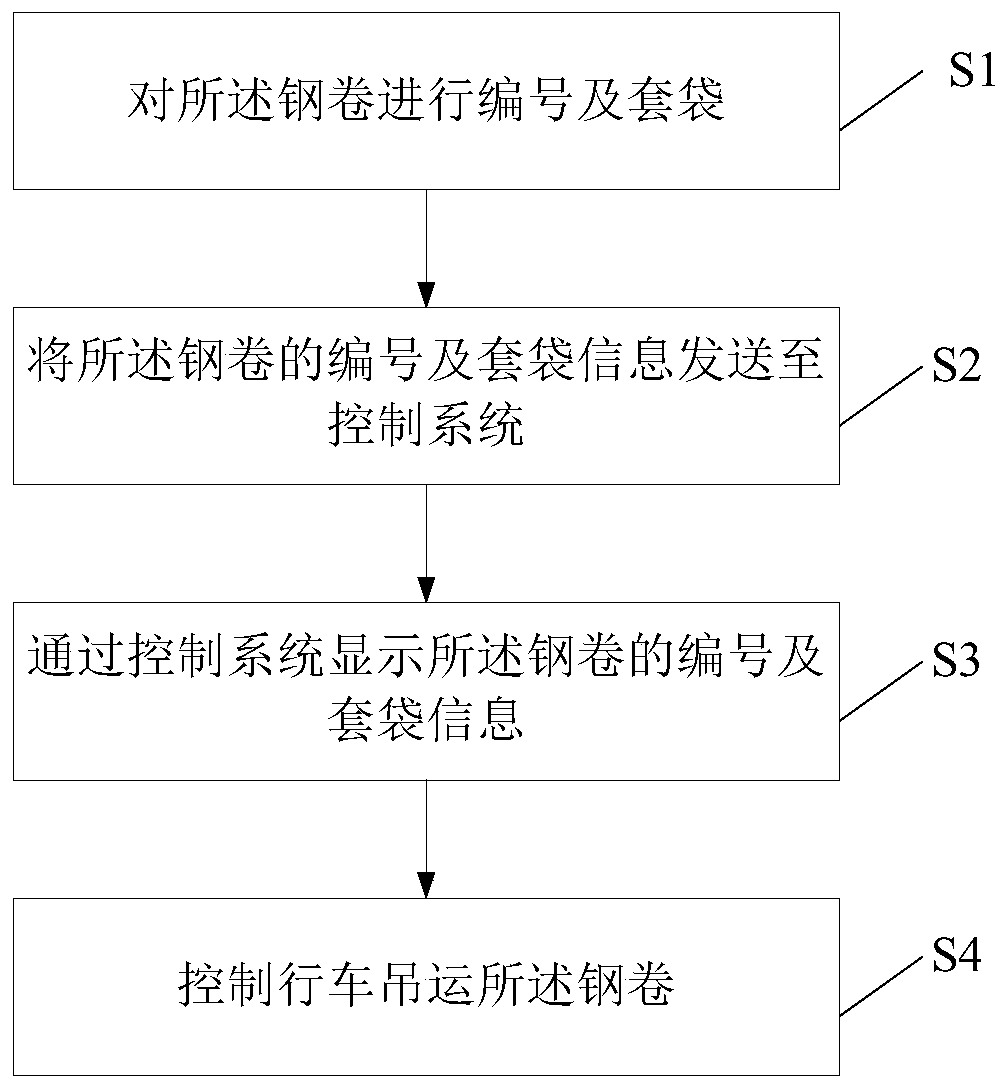

Data processing method and device, computer equipment and storage medium

ActiveCN111222089AImprove timelinessLow costNoise figure or signal-to-noise ratio measurementCharacter and pattern recognitionData miningOperations research

The invention relates to the technical field of commodity service data processing, in particular to a commodity service data processing method and device, computer equipment and a storage medium. Themethod comprises the steps of obtaining first service entry parameter data of a target commodity service from total data of the target commodity service; obtaining first commodity service data of thetarget commodity service from service data of a database according to the first service parameter data, and obtaining second commodity service data of the target commodity service from cache service data; when the first commodity service data is different from the second commodity service data, updating second service parameter data in a preheating table of the target commodity service according to the first service parameter data; and synchronizing the service data of the database corresponding to the target commodity service to cache service data according to the updated second service parameter in the preheating table. According to the method, the updating and caching process of the commodity service data can be automatically monitored.

Owner:南京苏宁电子信息技术有限公司

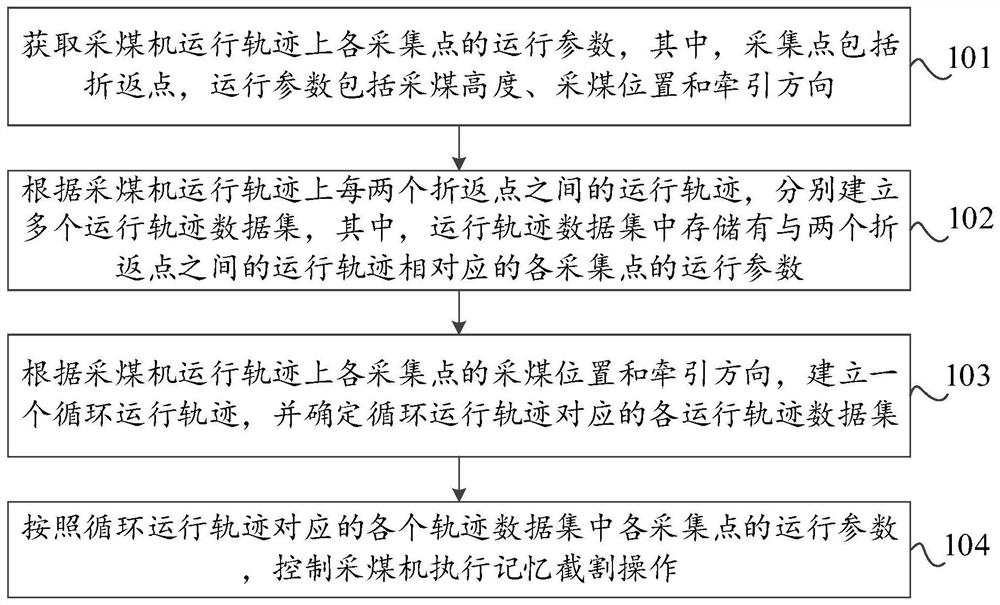

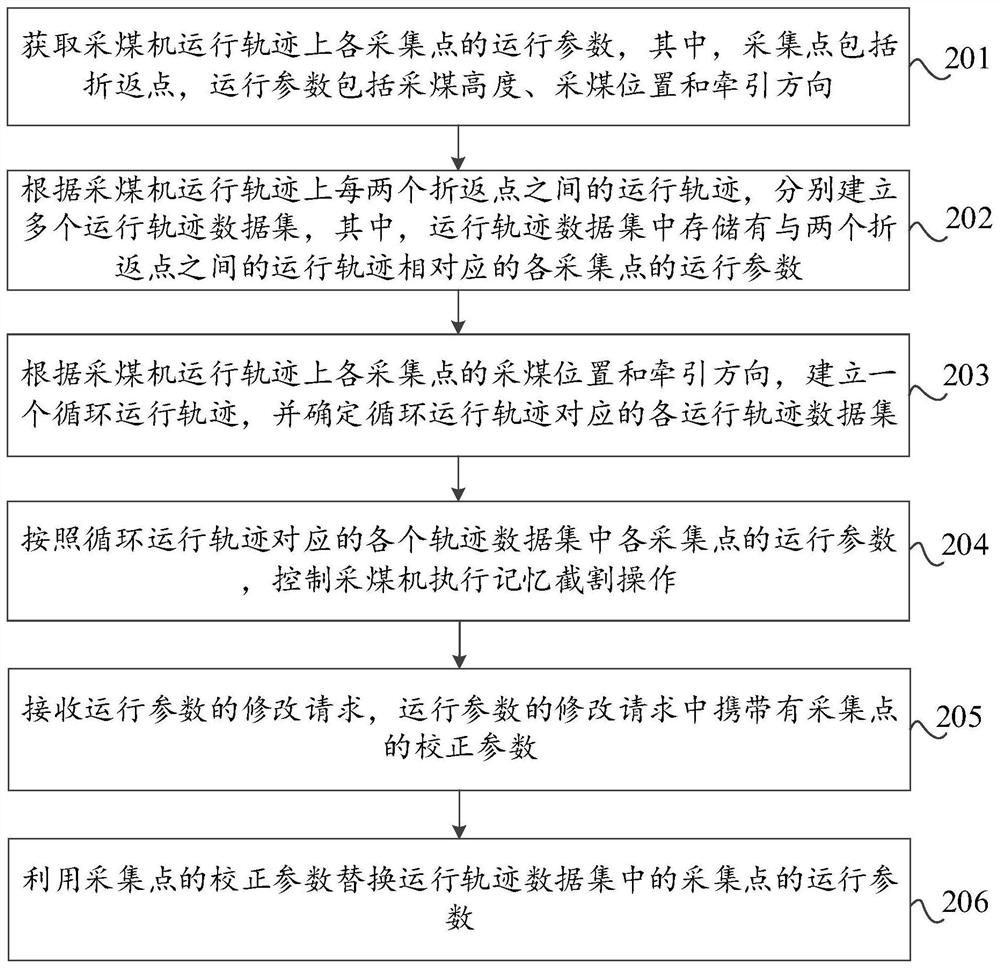

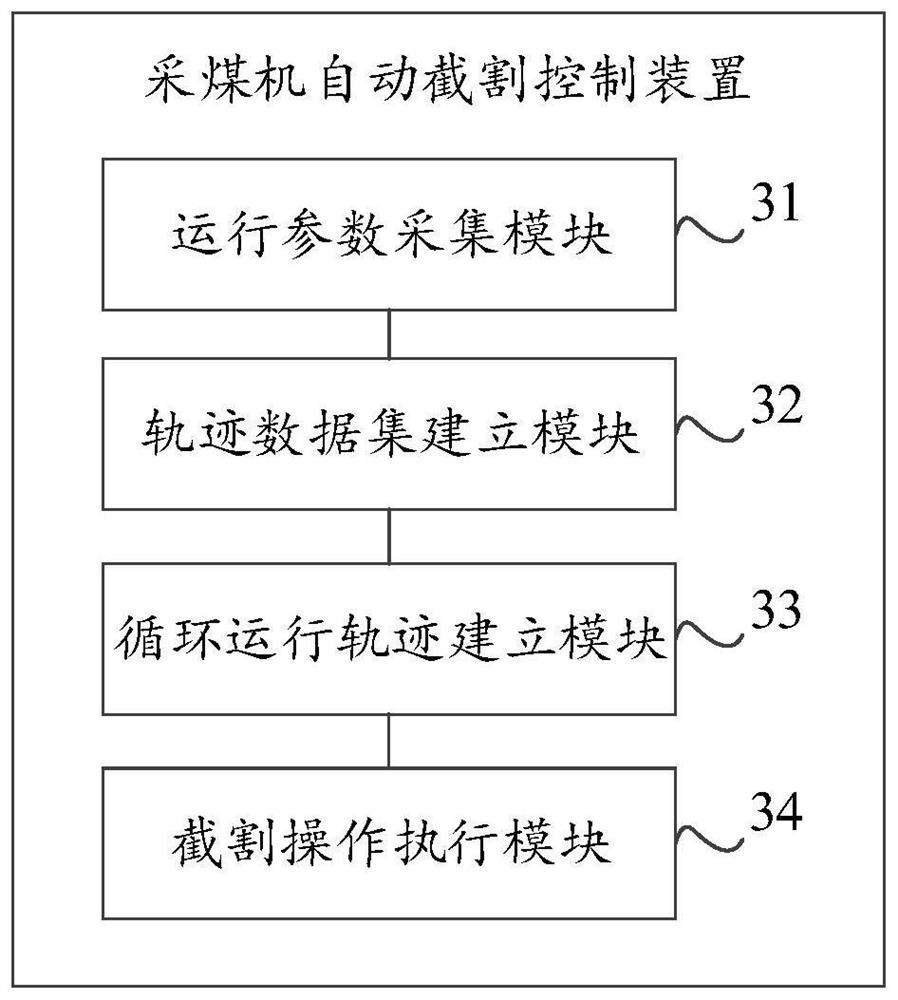

Automatic cutting control method, device and system for coal mining machine and storage medium

PendingCN112943241AReduce the number of manual interventionsMemory cutting operation is true and accurateSlitting machinesTotal factory controlData setControl engineering

The invention discloses an automatic cutting control method, device and system for a coal mining machine, a storage medium and computer equipment. The method comprises the steps that operation parameters of all collection points on an operation track of the coal mining machine are obtained, wherein the collection points comprise turning-back points, and the operation parameters comprise the coal mining height, the coal mining position and the traction direction; according to the operation track between every two turning-back points on the operation track of the coal mining machine, a plurality of operation track data sets are established, wherein the operation parameters of all the collection points corresponding to the operation track between every two turning-back points are stored in the operation track data sets; according to the coal mining position and the traction direction of all the collection points on the operation track of the coal mining machine, a circulating operation track is established, and all the operation track data sets corresponding to the circulating operation track are determined; and according to the operation parameters of all the collection points in all the track data sets corresponding to the circulating operation track, the coal mining machine is controlled to execute memory cutting operation. According to the method, the memory cutting accuracy of the coal mining machine can be improved.

Owner:SANY HEAVY EQUIP

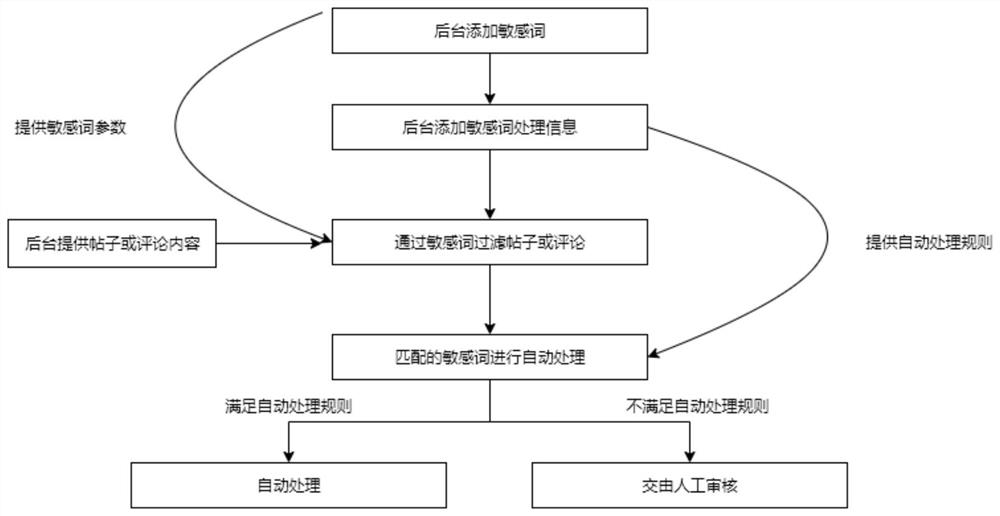

Automatic sensitive word processing method and system

PendingCN112948664AProcessing speedReduce the number of manual interventionsWebsite content managementSpecial data processing applicationsProgramming languageWord processing

The invention discloses an automatic sensitive word processing method and system. The method comprises the following steps: adding sensitive words; adding processing information for the sensitive words; filtering the to-be-audited content through the sensitive words; and automatically processing the sensitive words contained in the to-be-audited content. The method and the system provided by the invention at least have the following technical effects: the processing speed of the background on the sensitive words when the data volume is huge is greatly increased, meanwhile, the number of manual intervention times can be greatly reduced, automatic processing is realized, and review errors such as missed checking and wrong checking are effectively reduced.

Owner:上海观察者信息技术有限公司

Paper currency sorter

PendingCN106355749AImprove inventory efficiencyLow costCoin/currency accepting devicesPulp and paper industry

Owner:SUZHOU RIBAO TECH

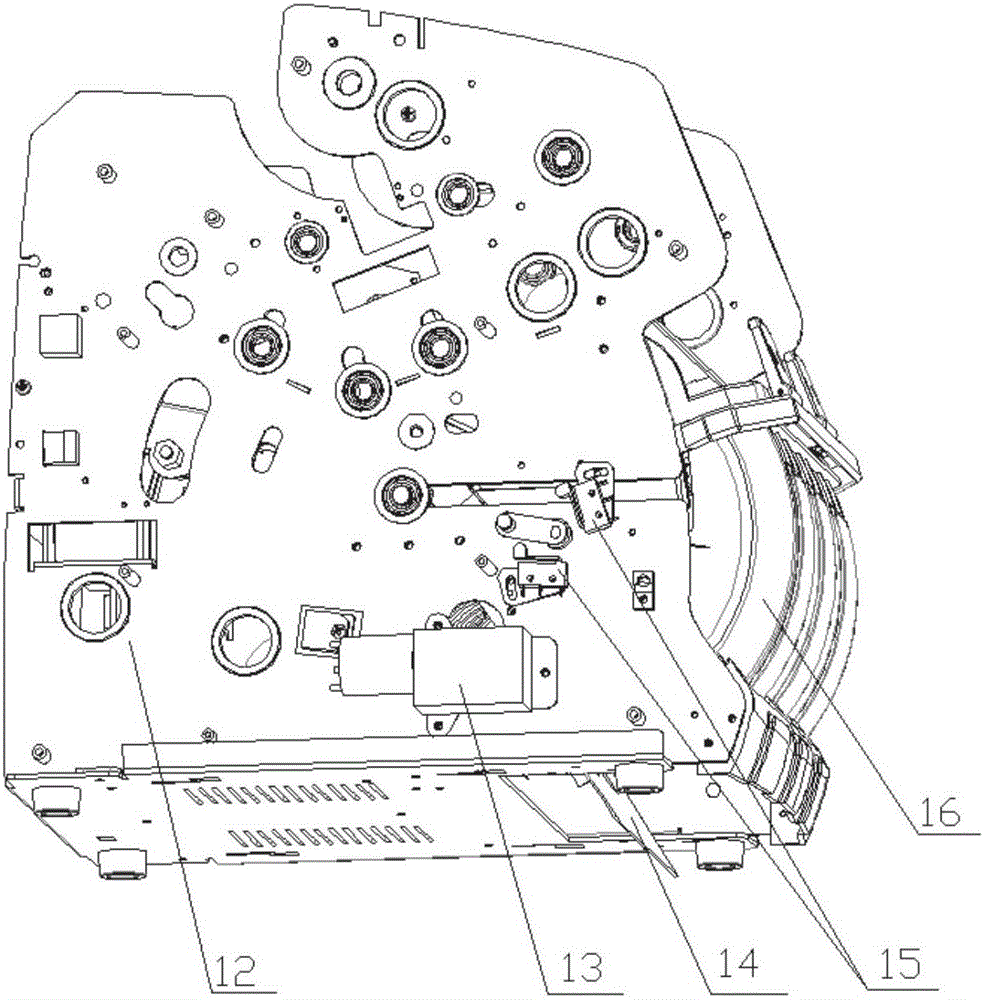

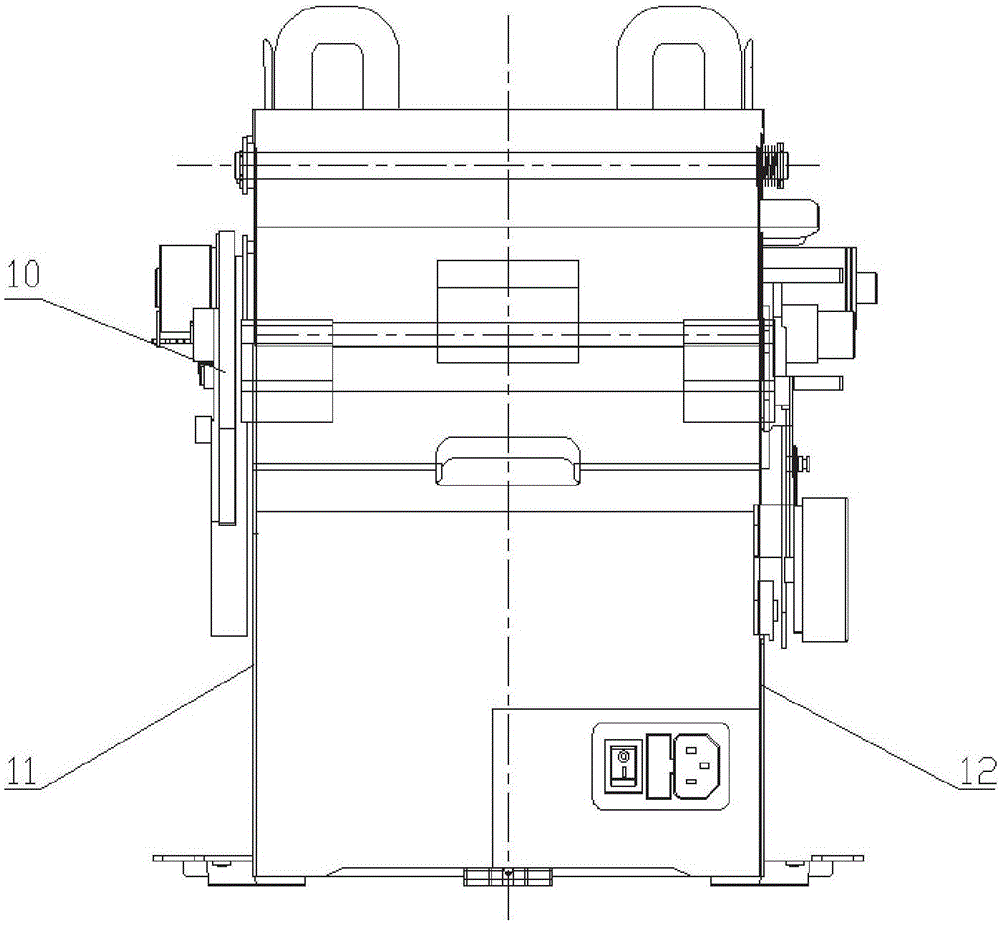

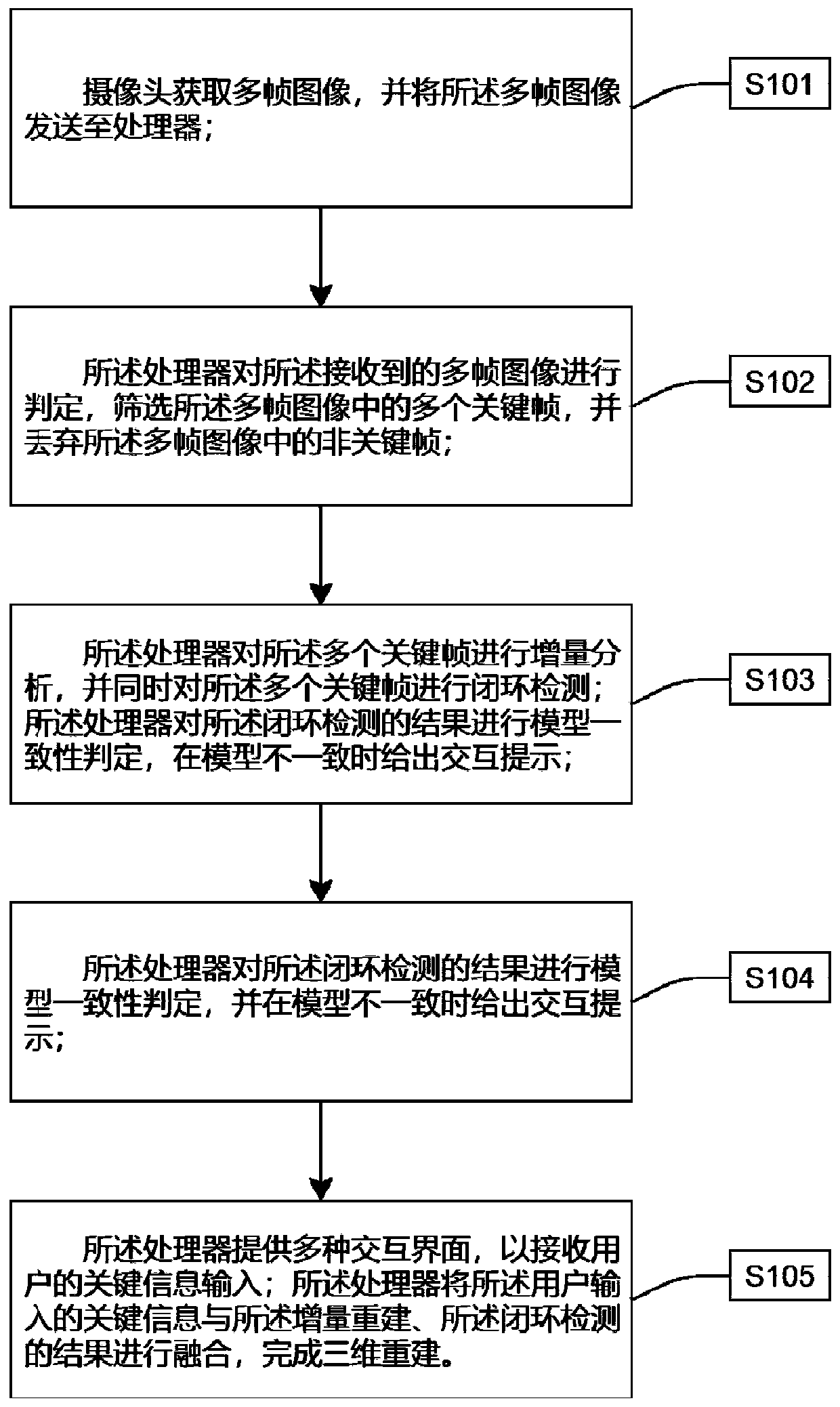

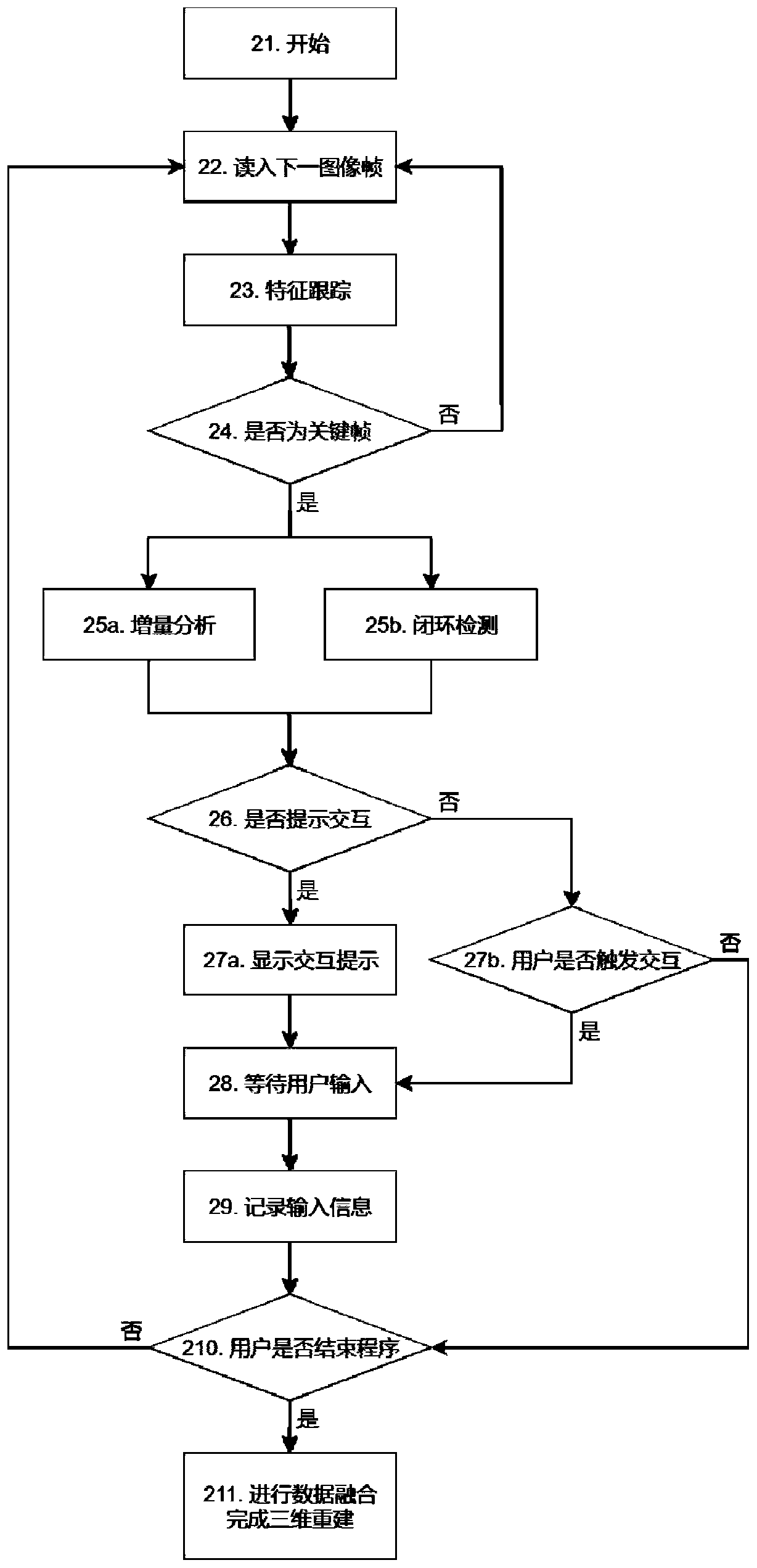

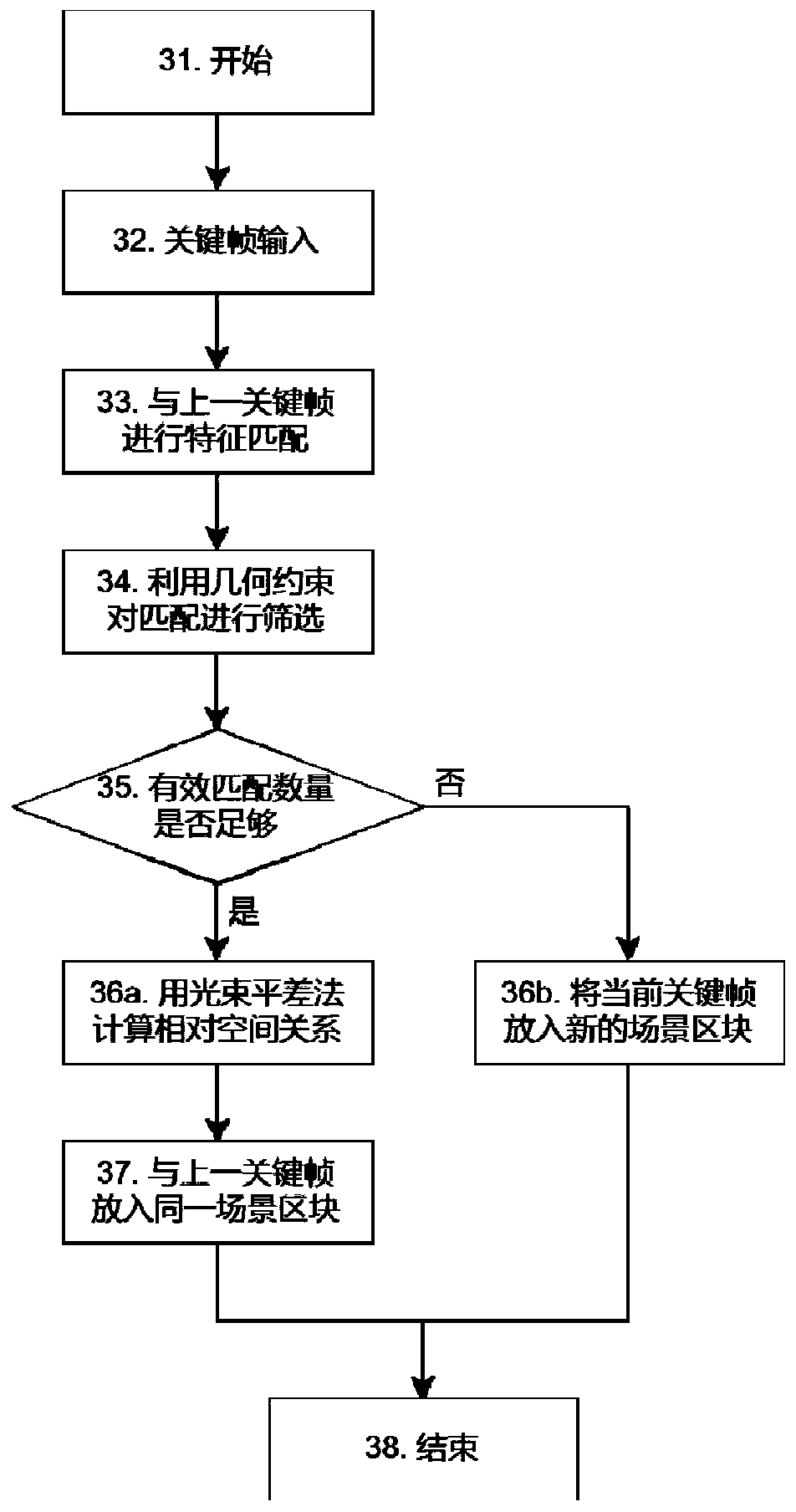

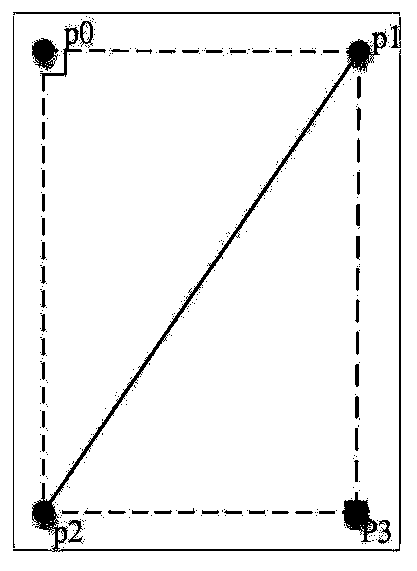

Image-based three-dimensional reconstruction method and image-based three-dimensional reconstruction system

InactiveCN110322549AIncrease sampling densityImprove reconstruction results3D modellingMultiple frameClosed loop

The invention discloses an interactive three-dimensional reconstruction method based on an image, and the method comprises the steps that a camera obtains a plurality of frames of images, and transmits the plurality of frames of images to a processor; a processor judges the received multiple frames of images and screens out multiple key frames from the multiple frames of images; the processor performs incremental analysis on the plurality of screened key frames and performs closed-loop detection at the same time; the processor is used for carrying out model consistency judgment on incrementalanalysis and closed-loop detection results and giving an interaction prompt when models are inconsistent; the processor provides a plurality of interactive interfaces (3D-3D alignment, 3D-2D alignmentand 2D-2D matching), so that a user can input key information conveniently; the processor fuses key information input by a user with incremental analysis and closed-loop detection results to completethree-dimensional reconstruction. According to the method, an automatic processing algorithm is properly combined with user interaction, and the accuracy of a reconstruction result is improved.

Owner:TSINGHUA UNIV

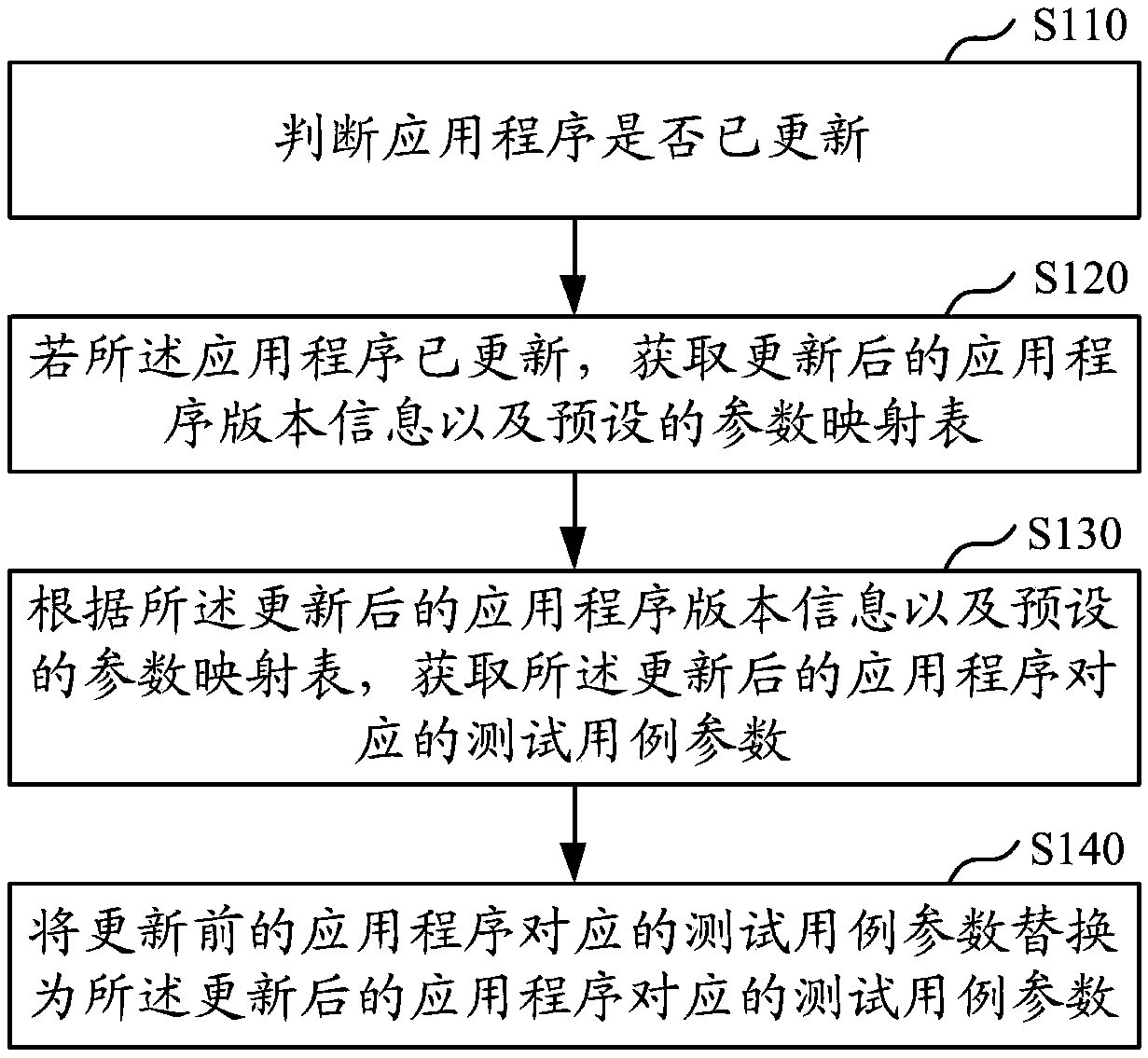

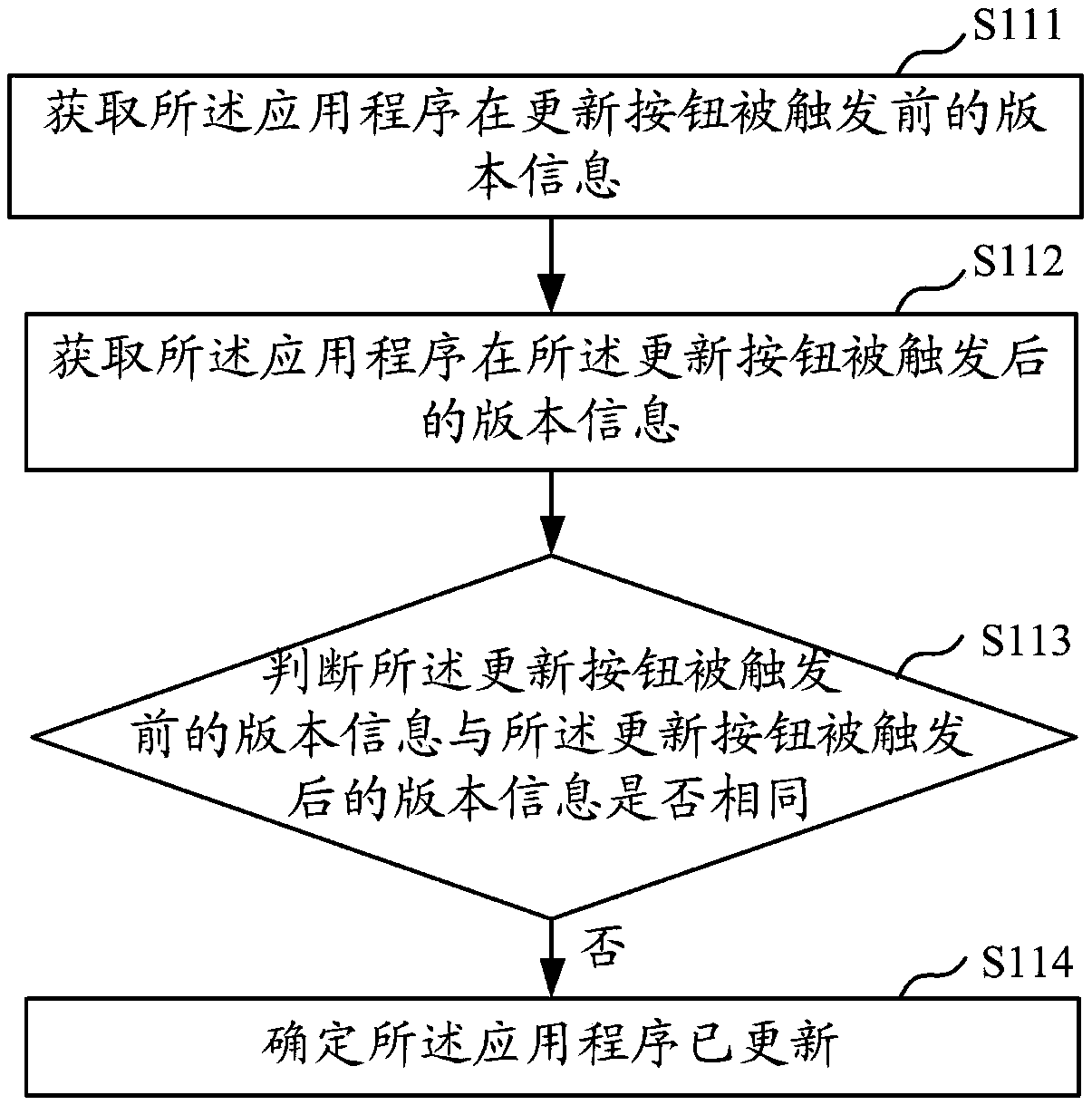

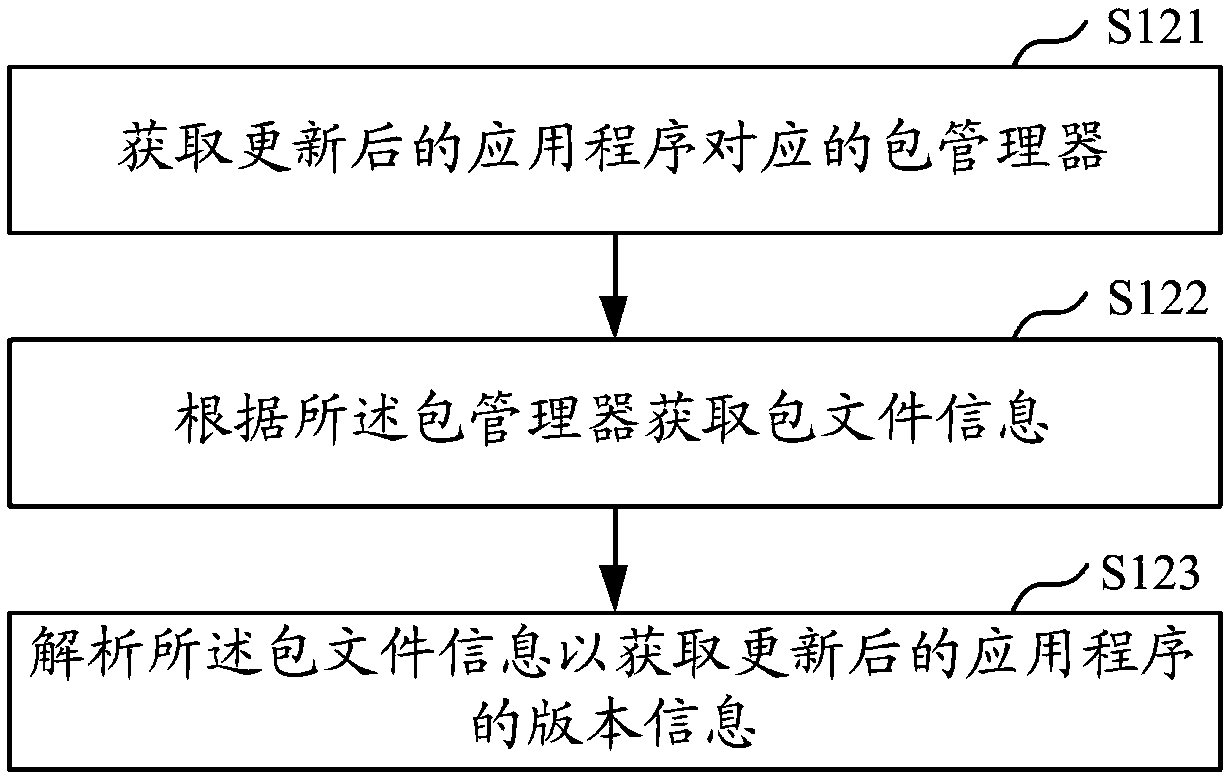

Test case parameter replacement method and device, computer equipment and storage medium

PendingCN108829587AImplement automatic modificationReduce the number of manual interventionsSoftware testing/debuggingComputer equipmentApplication software

The embodiment of the invention provides a test case parameter replacement method and device, computer equipment and a storage medium. The method comprises the steps that whether an application is updated is judged; if the application is updated, version information of the application after update and a preset parameter mapping table are acquired; according to the version information of the application after update and the preset parameter mapping table, test case parameters corresponding to the application after update are acquired; and test case parameters corresponding to the application before update are replaced with the test case parameters corresponding to the application after update. Through the embodiment, automatic modification of the test case parameters can be realized, manualintervention times are reduced, and test efficiency improvement is benefited.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

Unmanned vehicle control method and device, logistics distribution vehicle and storage medium

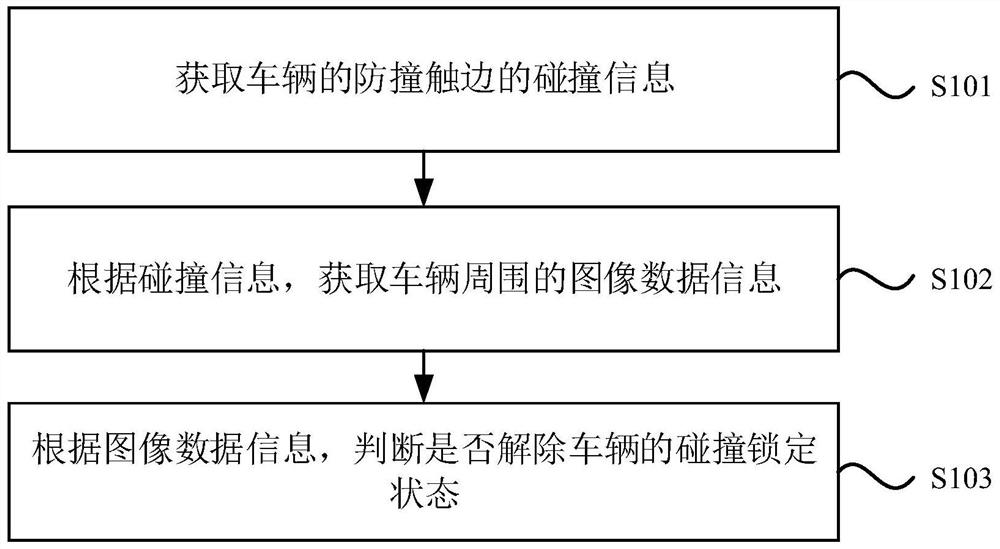

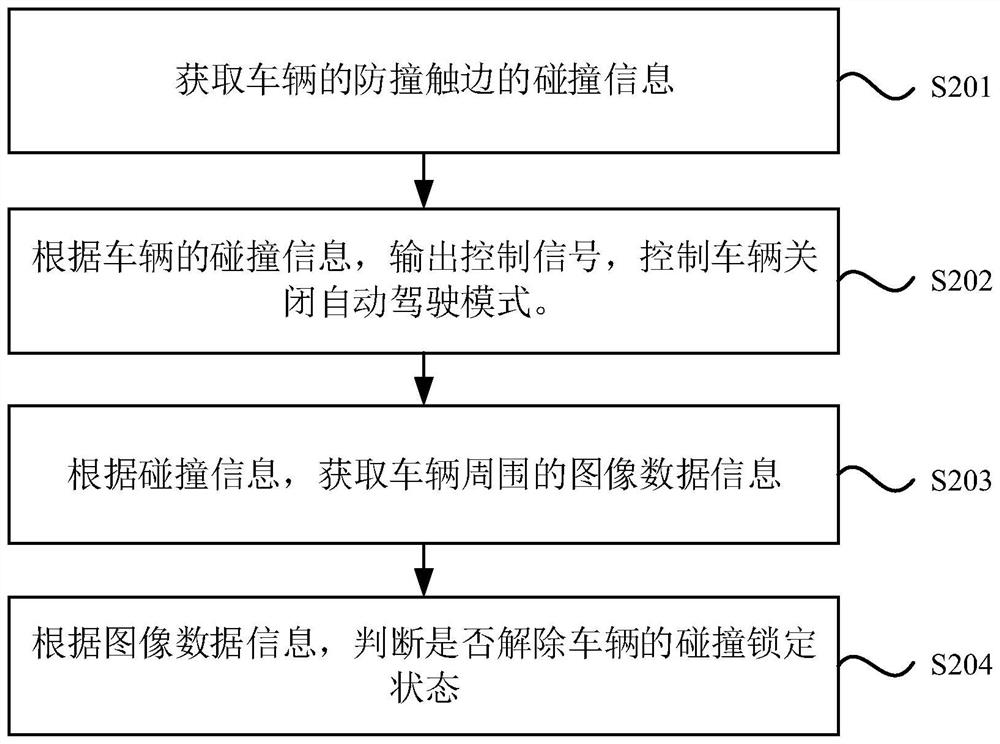

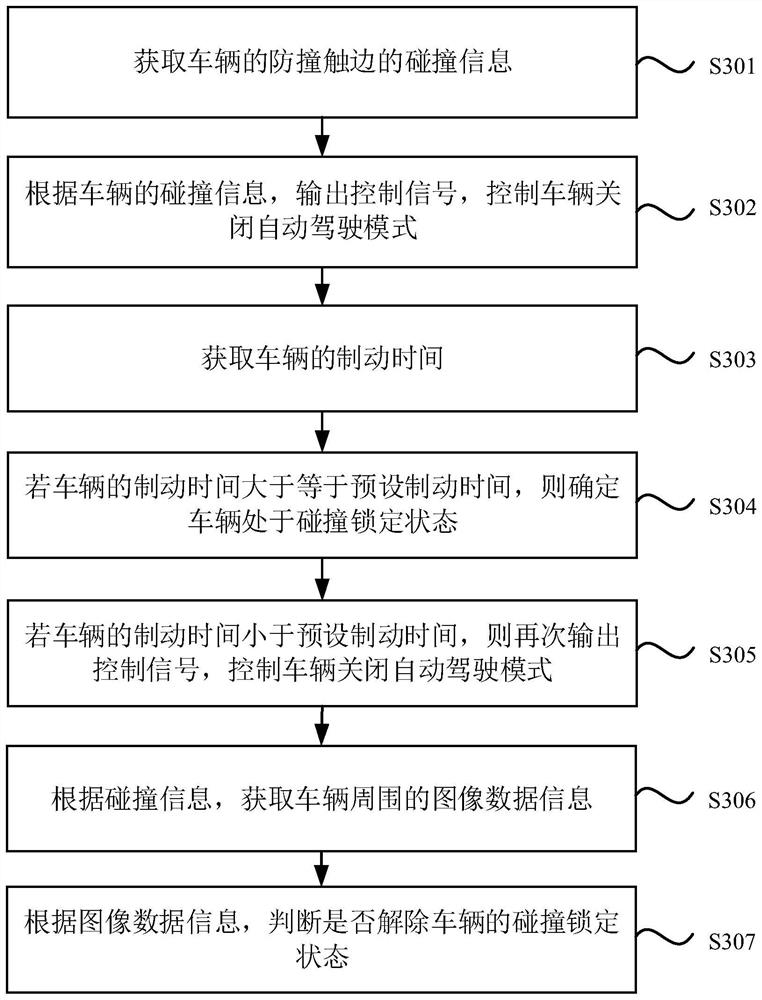

PendingCN114379591AImprove the efficiency of autonomous drivingReduce the number of manual interventionsControl devicesRoad trafficImaging data

The embodiment of the invention discloses a control method and device of an unmanned vehicle, a logistics distribution vehicle and a storage medium. The control method of the unmanned vehicle comprises the steps that collision information of an anti-collision touch edge of the vehicle is acquired; acquiring image data information around the vehicle according to the collision information; and judging whether the collision locking state of the vehicle is released or not according to the image data information. Through the control method of the unmanned vehicle, when the unmanned vehicle is collided, under the condition that the safety of the vehicle and other road traffic participants is protected, the number of manual intervention times of operation and maintenance personnel is reduced as much as possible, the automatic driving operation efficiency of the vehicle is improved, and secondary accidents or traffic jams are avoided.

Owner:上海易咖智车科技有限公司

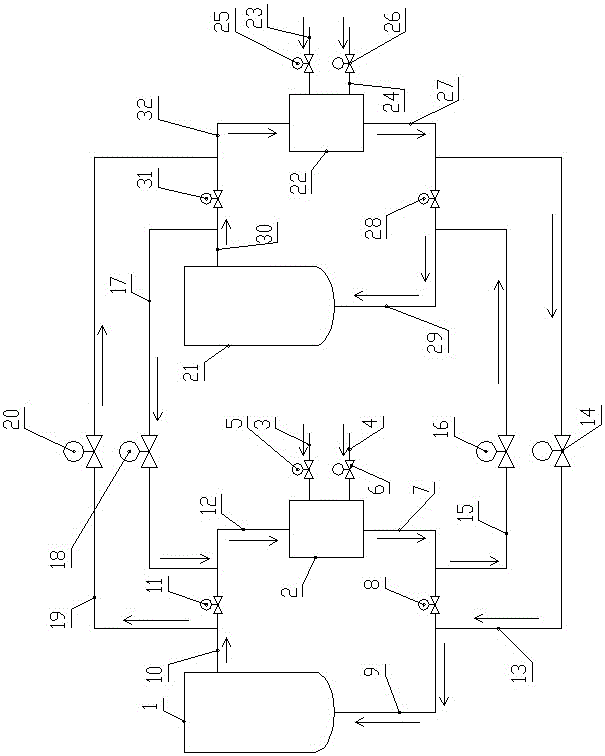

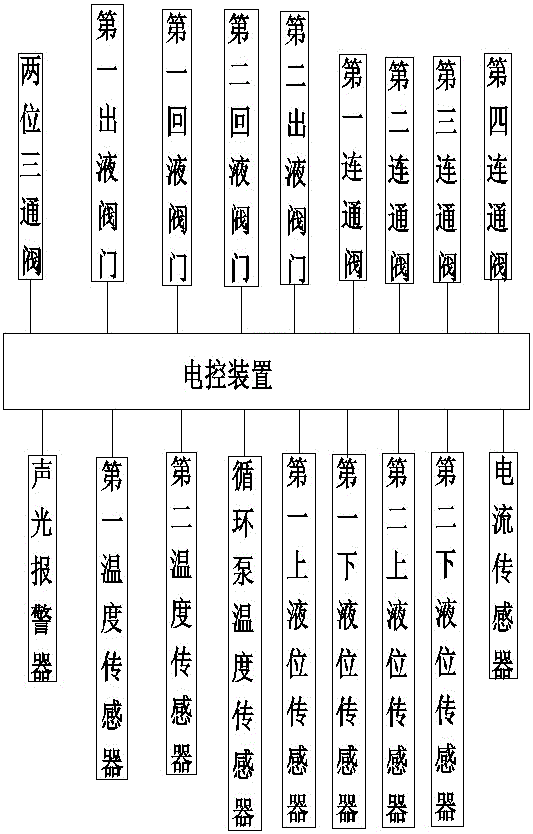

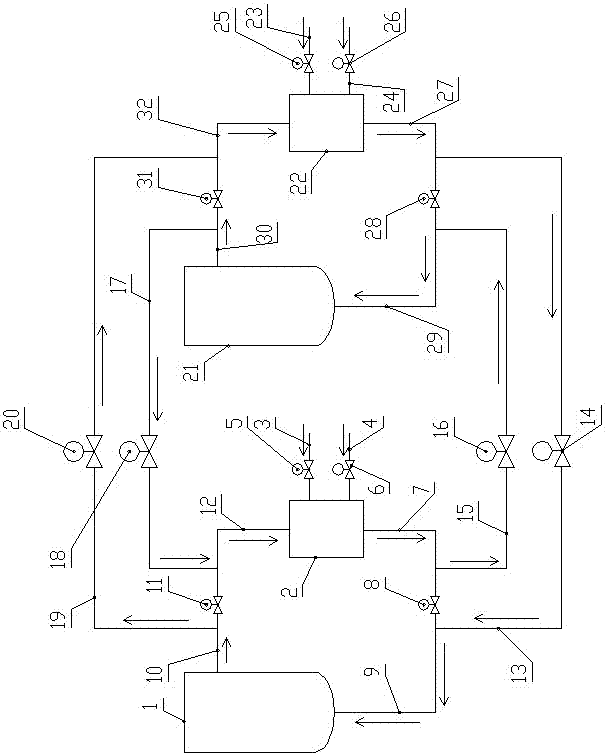

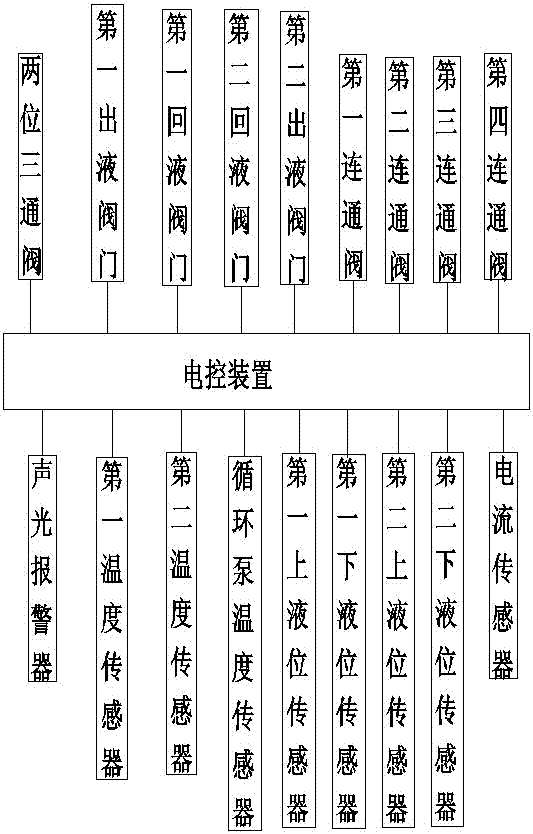

Double-tank double-temperature-control redundant hot-standby low-temperature control system and control method thereof

ActiveCN106598093AImprove fault toleranceDoes not affect normal operationTemperature control using electric meansTemperature controlControl system

The invention discloses a double-tank double-temperature-control redundant hot-standby low-temperature control system which comprises a first tank, a first low-temperature control unit, a second tank and a second low-temperature control unit. The invention also discloses a control method of the double-tank double-temperature-control redundant hot-standby low-temperature control system. The control method is carried out according to eight working modes and four steps and has very high fault-tolerant performance. The failure of any single device does not affect the normal operation of the system. The eight working modes can be automatically switched for the control system, and regular timing switching can make the components of the system used so as to avoid negative effect on the device due to long-term idle. The control system may automatically switch in failure and may solve problems in most case cases by using own fault-tolerant performance of the system, greatly reduces the number of manual intervention times, reduces labor intensity, and improves the operation efficiency and the degree of automation.

Owner:郑州格兰高环境工程有限公司 +1

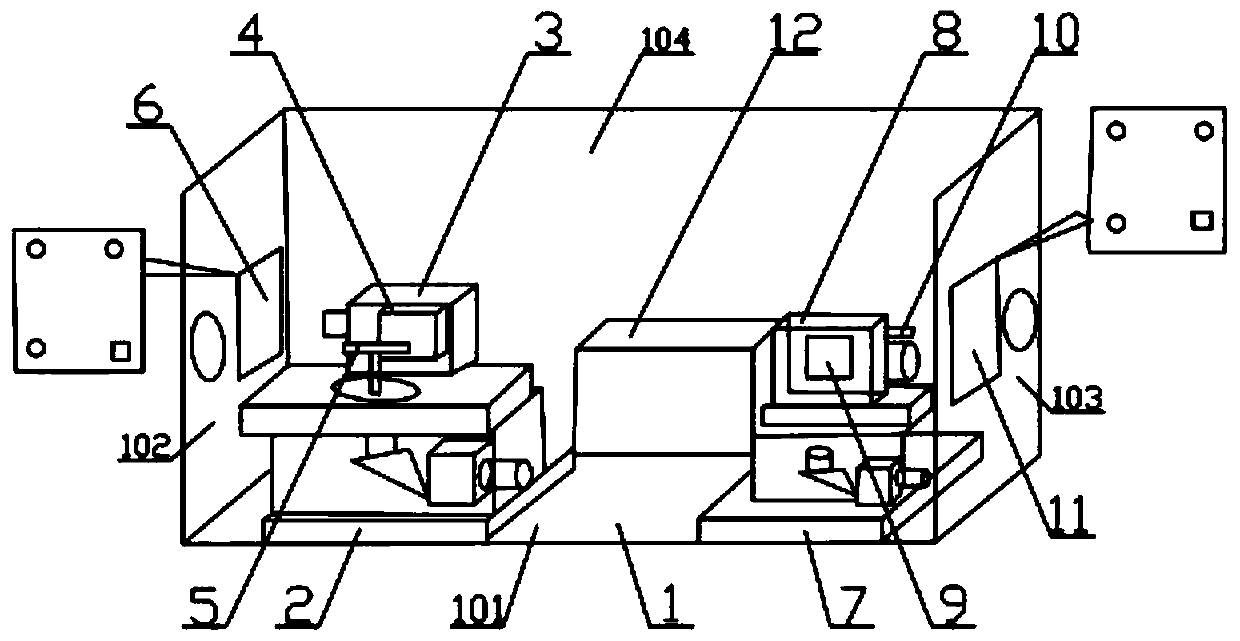

Target pose measurement system and method based on feature point position correction

ActiveCN110610518AAccurately Solve Relative PoseHigh accuracy of solutionImage enhancementImage analysisTarget surfaceRadiology

Owner:LANZHOU JIAOTONG UNIV

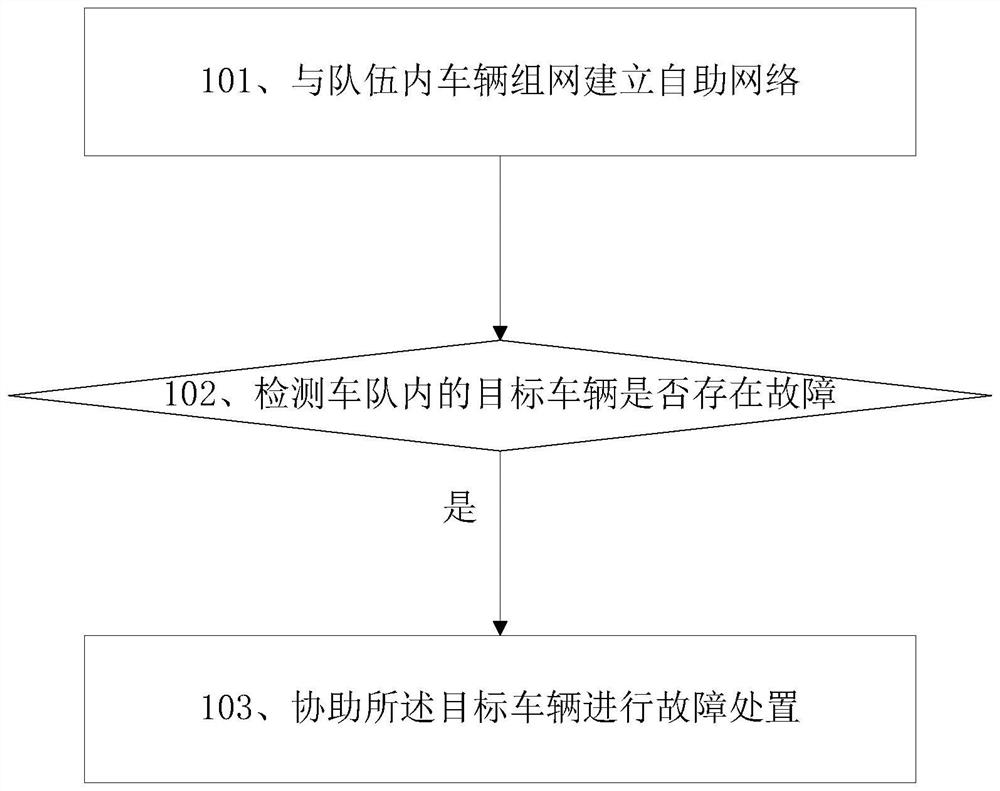

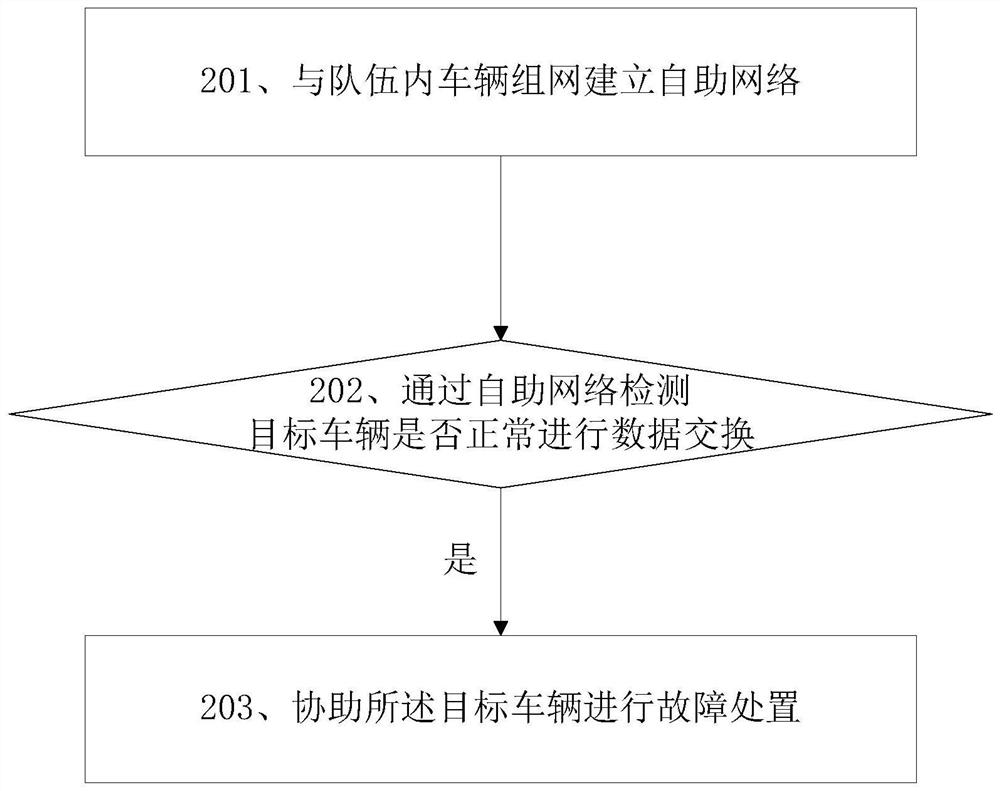

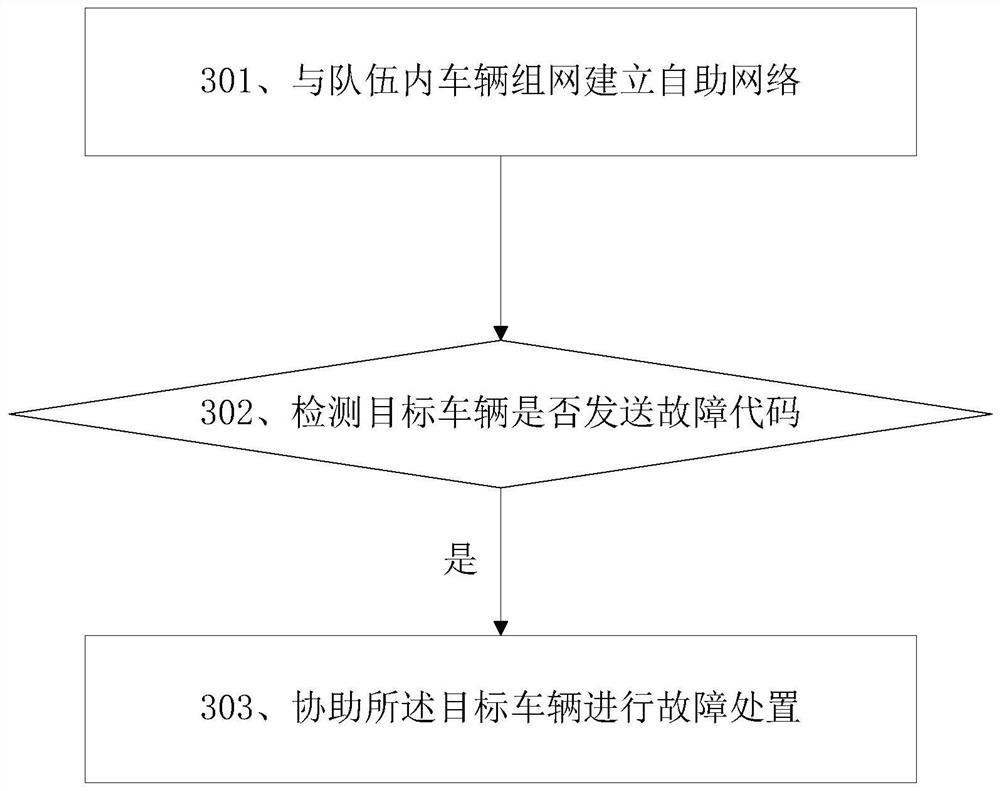

Autonomous self-service motorcade management method and device

InactiveCN111882855AReduce the number of manual interventionsSave human resourcesRoad vehicles traffic controlReal-time computingFleet management

The embodiment of the invention discloses an autonomous self-service motorcade management method and device. The method and device are used for managing an unmanned motorcade. The method comprises thefollowing steps: networking with vehicles in a team to establish a self-service network; detecting whether a target vehicle in the motorcade has a fault or not; and if yes, assisting the target vehicle to perform troubleshooting. According to the autonomous self-service motorcade management method and device, it can be guaranteed that in the driving process of an automatic driving motorcade, somecommon faults can be automatically handled, the number of times of manual intervention is reduced, and manpower resources are saved.

Owner:LAUNCH TECH CO LTD

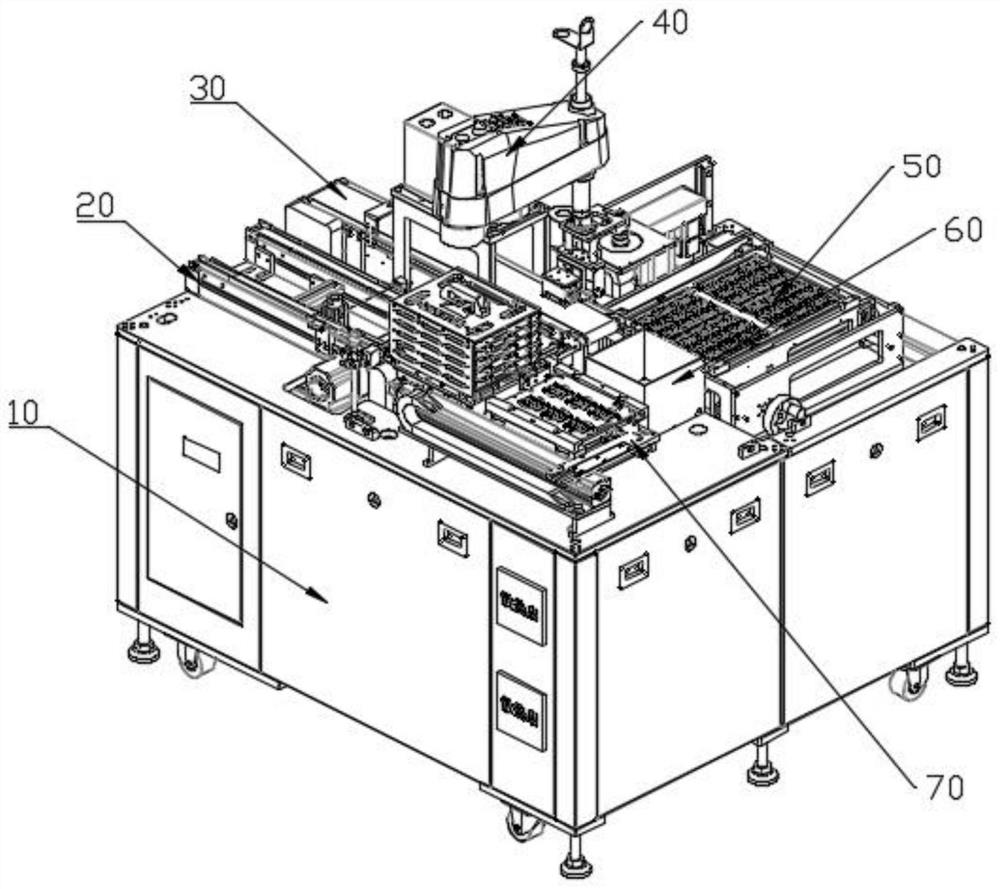

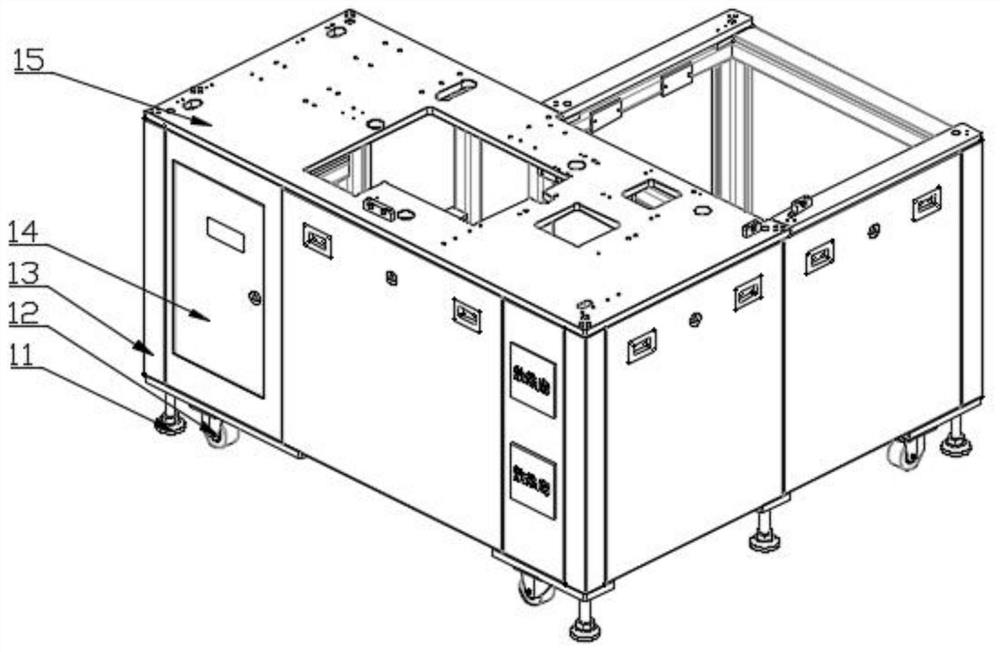

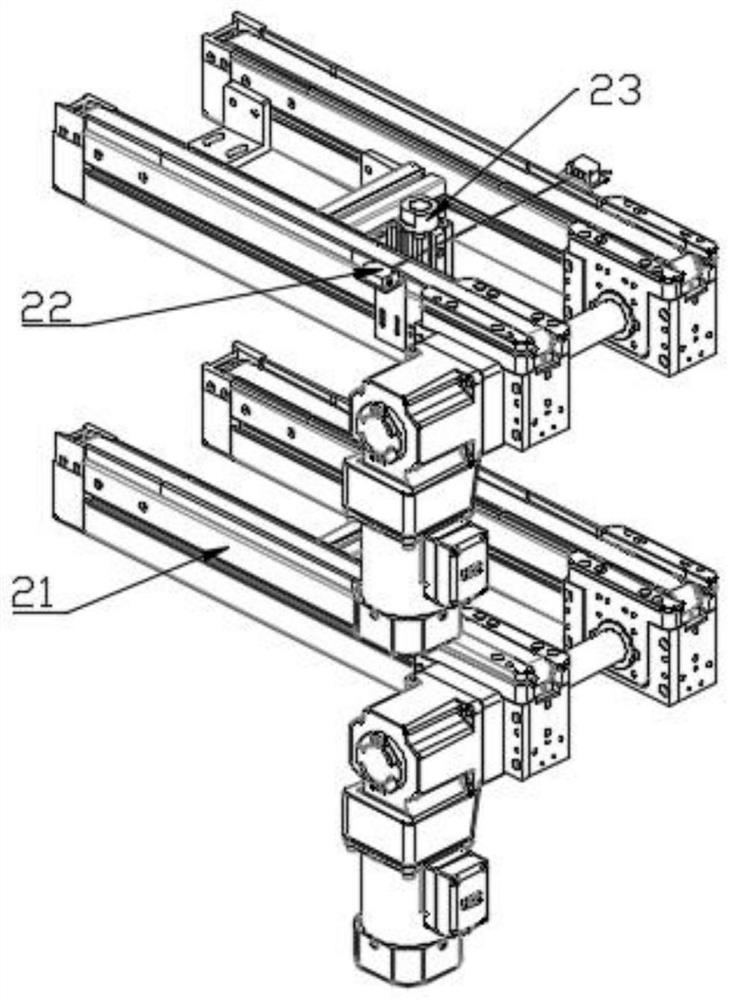

Device for discharging, tray loading and tray changing of DBC products

InactiveCN111846425ARealize automatic clamping switchingPacking is powerfulPackaging automatic controlIndividual articlesEngineeringMaterial transfer

The invention discloses a device for discharging, tray loading and tray changing of DBC products, and relates to the technical field of material transfer. The device for discharging, tray loading andtray changing of the DBC products comprises a rack assembly, wherein a lifting basket feeding and discharging line body, an NG material excluding temporary storage conveyor, a product grabbing assembly, a carrier lifting positioning assembly, a visual deviation rectifying module and a lifting basket lifting assembly, the lifting basket feeding and discharging line body is used for conveying a lifting basket, the NG material excluding temporary storage conveyor is used for temporary storage, outflow and in-place sensing of NG products, the product grabbing assembly is used for grabbing a product, the carrier lifting positioning assembly is used for fixing a front track flow carrier, the lifting basket lifting assembly is used for automatic opening and closing of a lifting basket, automatictaking and changing of trays and precise position on a tray, automatic grabbing and switching of the tray can be achieved, a packing function is powerful, a manual intervention frequency can be effectively reduced, and the device is wide in application and high in flexibility, and can be applied to product discharging of various production lines.

Owner:ZHIHUIXUANTIAN INTELLIGENT SYST (HANGZHOU) CO LTD

Double-tank dual-temperature-control redundant hot-standby low-temperature temperature control system and its control method

ActiveCN106598093BImprove fault toleranceDoes not affect normal operationTemperature control using electric meansTemperature controlControl system

The invention discloses a double-tank double-temperature-control redundant hot-standby low-temperature control system which comprises a first tank, a first low-temperature control unit, a second tank and a second low-temperature control unit. The invention also discloses a control method of the double-tank double-temperature-control redundant hot-standby low-temperature control system. The control method is carried out according to eight working modes and four steps and has very high fault-tolerant performance. The failure of any single device does not affect the normal operation of the system. The eight working modes can be automatically switched for the control system, and regular timing switching can make the components of the system used so as to avoid negative effect on the device due to long-term idle. The control system may automatically switch in failure and may solve problems in most case cases by using own fault-tolerant performance of the system, greatly reduces the number of manual intervention times, reduces labor intensity, and improves the operation efficiency and the degree of automation.

Owner:郑州格兰高环境工程有限公司 +1

Winding packaging machine for automatic coil packaging line

ActiveCN112623308BImprove packaging efficiencyAchieve windingWrapping material feeding apparatusWrapper twisting/gatheringWinding machineControl system

Owner:TAIER HEAVY IND

Control method for full-automatically changing work roll of hot rolling finisher

InactiveCN101433918BIncrease profitRaise the ratioMetal rolling stand detailsRoll mill control devicesBogieWork roll

The invention relates to a method for controlling full automatic roll changing of a hog finishing mill. Hardware used by the method consists of a controller, a server, an operating computer and a roll changing bogie, wherein the server and the operating computer are connected with the controller respectively, and the controller controls operation of the roll changing bogie. The control method comprises the following steps in sequence: preparation of roll changing, disassembly of the prior working roll, assembly of a novel working roll, and preparation of steel rolling, wherein jacked pile position value E7 of the roll changing bogie on an upper working roll realizes relative position control by a self-adapting positioning method; the position value E7 is calculated by contact position value E9 of the roll changing bogie and a finishing machine frame minus 420 millimeters; and the contact position value E9 of the roll changing bogie and the finishing machine frame is obtained by judgment of the absolute position of the roll changing bogie before the finishing machine frame, the reference velocity, the actual velocity and the working current of a motor; and after automatic roll changing is subjected to manual interference, automatic roll changing is continuously completed by utilizing the breakpoint continuing function of an SFC module of programmed software P80i in the controller, and quick full automation of the roll changing process is realized.

Owner:武钢集团有限公司

A profile hot rolling finishing mill rolling piece position tracking device and tracking method

ActiveCN103499946BImprove location tracking accuracyReduce the number of manual interventionsNumerical controlFailure rateMan machine

The invention discloses a rolled piece position tracking device for a sectional material hot rolling finishing mill. The rolled piece position tracking device comprises a machine frame, a tracking region, a zero current sampling section, a tension adjustment section, a hot metal detector, a frequency converter, a man-machine interface local area network, a high-performance controller, a man-machine interface server and a local control panel, wherein the zero current sampling section and the tension adjustment section are arranged in the tracking region, and a rolled piece position tracking control module is arranged in the high-performance controller. A rolled piece position tracking method for a sectional material hot rolling finishing mill comprises the following steps that 1, the rolled piece position tracking control module is started; 2, the position of a rolled piece in the tracking region is calculated and is compared with the position values of the tension adjustment section and the zero current sampling section; 3, the rolled piece position tracking control module finishes the tracking procedure of the current tracking region according to cascade signals and steel occluding current change signals. The rolled piece position tracking device and the rolled piece position tracking method have the characteristics that the rolled piece tracking precision is high, the manual intervention is little, the yield of hot rolling sectional materials is high, the failure rate is low, and the labor cost is low. The rolled piece position tracking device and the rolled piece position tracking method can be widely applied to the technical field of sectional material hot rolling automation control.

Owner:通用电气(武汉)自动化有限公司

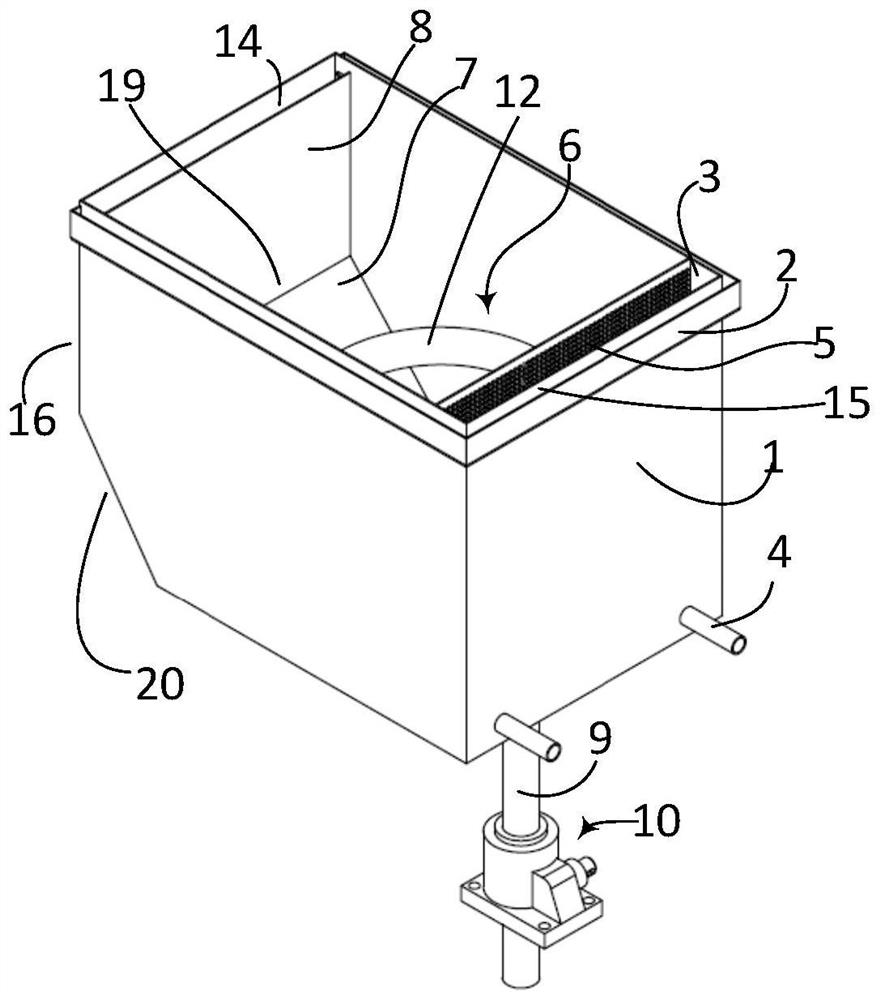

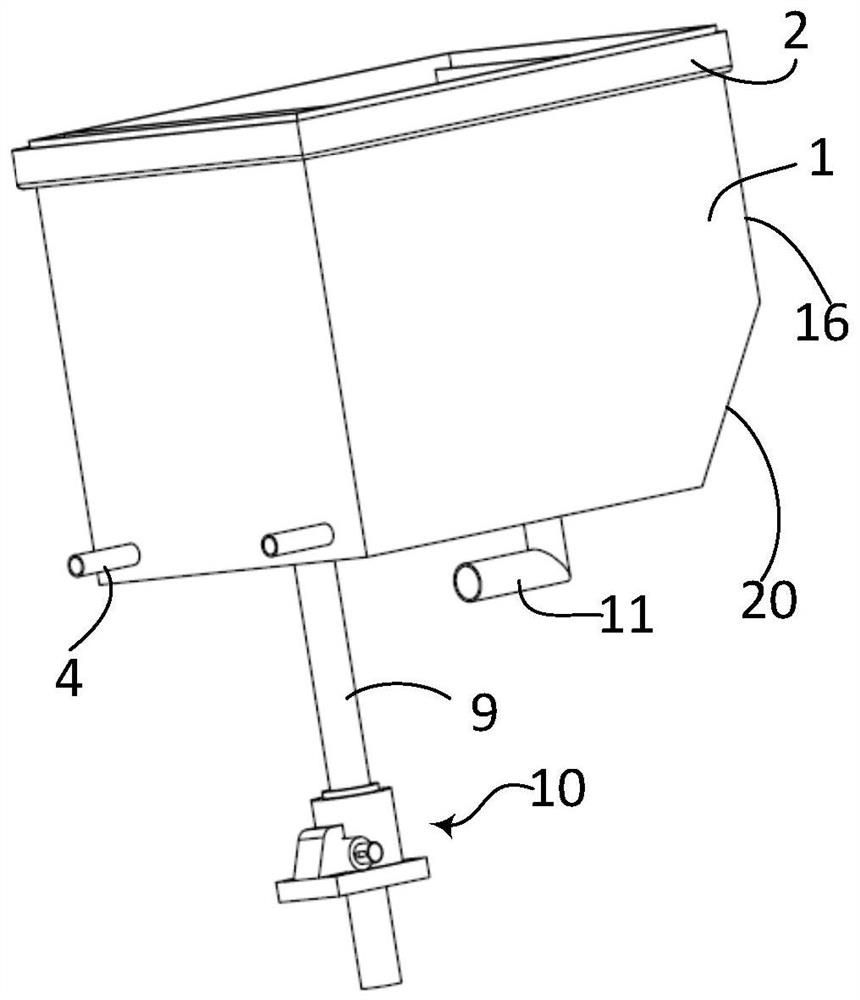

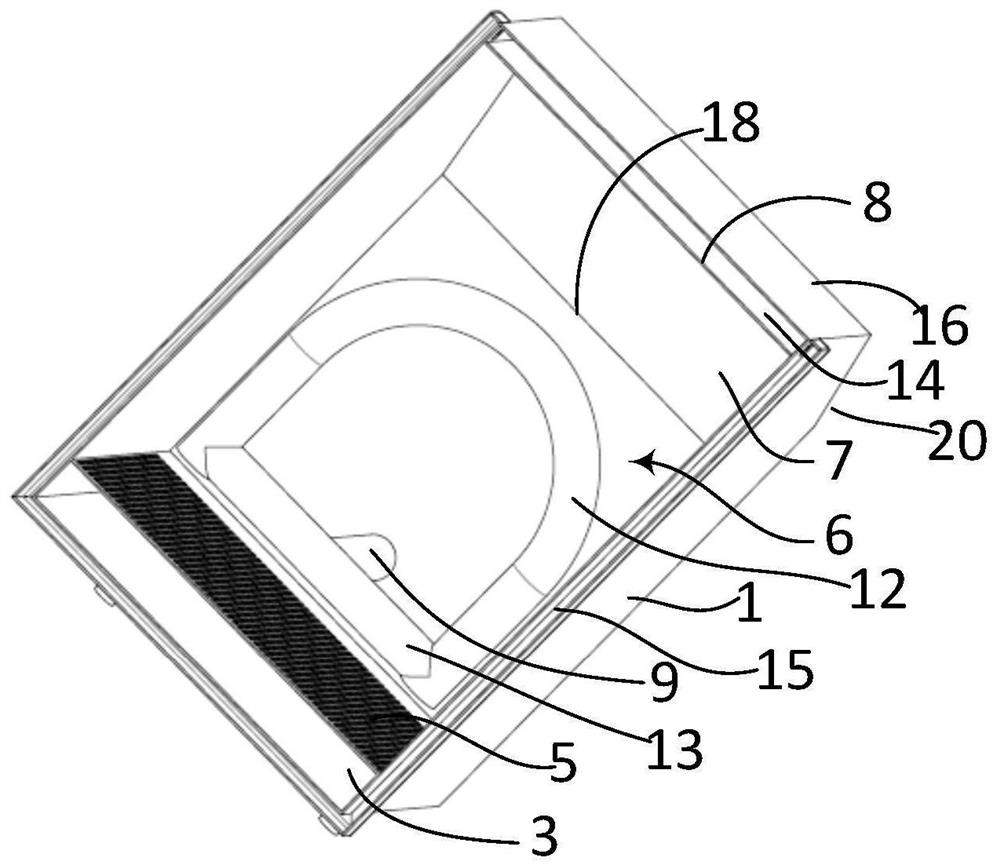

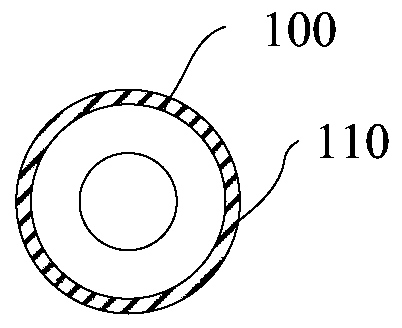

Spinning coagulating bath device

ActiveCN112708953AStable startLightweightArtificial thread manufacturing machinesSpinningEngineering

The invention discloses a spinning coagulating bath device, and belongs to the technical field of textile machinery. The spinning coagulating bath device comprises a water tank (1), a water diversion partition plate (8) and a bundling godet assembly (6), wherein the water diversion partition plate (8) is arranged in the water tank (1), so that a containing space in the water tank (1) is divided into a first containing space (17) and a second containing space (14) by the water diversion partition plate (8); the bundling godet assembly (6) is arranged in the first containing space (17); a first through hole (18) is formed in the bottom of the second containing space (14), and the second containing space (14) communicates with the outside through the first through hole (18); and the height of the water diversion partition plate (8) is smaller than the top edge of the water tank (1). According to the spinning coagulating bath device, stable fluid in a coagulating bath body can be guaranteed, and in addition, due to the arrangement of the water diversion partition plate (8), it is guaranteed that the water tank (1) can be completely filled with solvent, and the gap requirement of cooling side blowing is met.

Owner:CHINESE TEXTILE ACAD

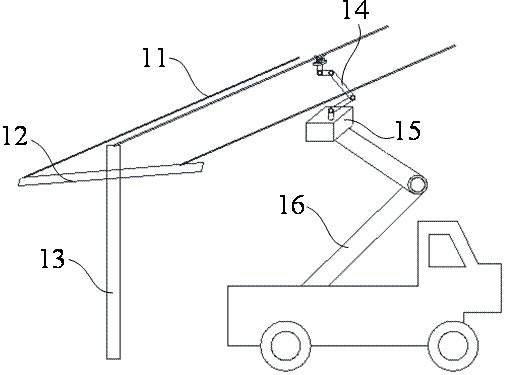

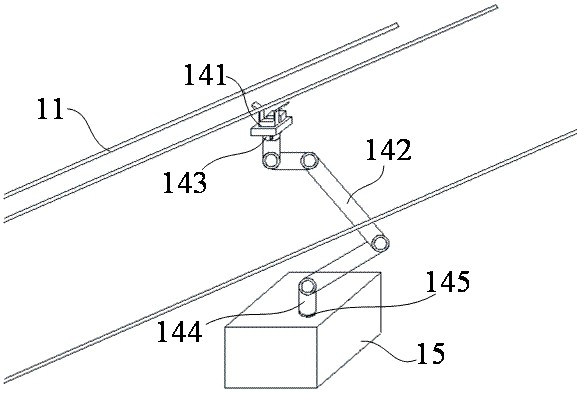

Collision detection method of live working robot and live working robot

ActiveCN112548986BSatisfy level of fine controlAvoid damageProgramme-controlled manipulatorApparatus for overhead lines/cablesRobotic armCollision detection

Owner:国网瑞嘉(天津)智能机器人有限公司

Data processing method, device, computer equipment and storage medium

ActiveCN111222089BImprove timelinessLow costNoise figure or signal-to-noise ratio measurementCharacter and pattern recognitionEntry (data)Engineering

The present application relates to the technical field of commodity service data processing, in particular to a data processing method, device, computer equipment and storage medium for commodity service data. The method includes: obtaining the first service input parameter data of the target commodity service from the full data of the target commodity service; obtaining the first commodity service data of the target commodity service from the service data of the database according to the first service input parameter data, and Obtain the second commodity service data of the target commodity service from the cache service data; when the first commodity service data is different from the second commodity service data, update the first item in the warm-up table of the target commodity service according to the first service input parameter data Second service input parameter data: Synchronize the service data of the database corresponding to the target commodity service to the cache service data according to the updated second service input parameter data in the warm-up table. The above method can automatically monitor the process of updating and caching the commodity service data.

Owner:南京苏宁电子信息技术有限公司

Cloud brain intelligent transportation system including multifunctional unmanned vehicles

ActiveCN111462481BImprove operational efficiencyReduce the number of manual interventionsDetection of traffic movementParticular environment based servicesIntelligent transportation system itsOptical fiber transmission

The present invention provides a cloud-brain intelligent transportation system including a multifunctional unmanned vehicle, including: a multifunctional unmanned vehicle, a roadside environment sensing device, and a cloud-brain cluster control center; wherein the multifunctional unmanned vehicle communicates with a 4G / 5G network The cloud brain cluster control center communicates, sending the state data of the multi-functional unmanned vehicle to the cloud brain cluster control center and accepting the control instructions of the cloud brain cluster control center; It is transmitted to the cloud brain cluster control center; the cloud brain cluster control center conducts real-time monitoring and remote monitoring of the data of all multi-functional unmanned vehicles in the intelligent transportation system and the environmental data sensed by the roadside environmental sensing equipment to form a big data database. The cloud-brain intelligent transportation system can realize real-time communication and cloud control between the vehicle terminal and the vehicle terminal, and between the vehicle terminal and the cloud, so as to meet the needs of large-scale industrial deployment of multifunctional unmanned vehicles in the future.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

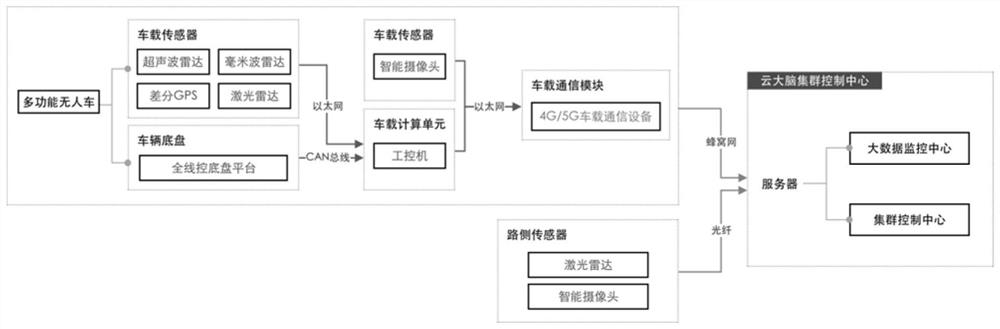

Steel coil hoisting method and hoisting system

ActiveCN110342403BTroubleshoot outagesImprove execution ratePackaging automatic controlLoad-engaging elementsControl systemClassical mechanics

The invention provides a steel coil hoisting method, and the method comprises the following steps of numbering and bagging, namely numbering the steel coils, selecting part of the steel coils to be bagged, and sending the serial numbers and the bagging information of the steel coils to a control system; displaying the serial number and the bagging information of the steel coils through the controlsystem; and sending a hoisting instruction to a travelling crane, wherein the travelling crane judges whether or not to hoist the steel coils to a specified position according to the bagging information of the steel coils in the control system. The steel coil hoisting method provided by the invention is reasonable in design and high in working efficiency, and can reduce the manual intervention times. The invention also provides a steel coil hoisting system.

Owner:MCC BAOSTEEL TECH SERVICE +1

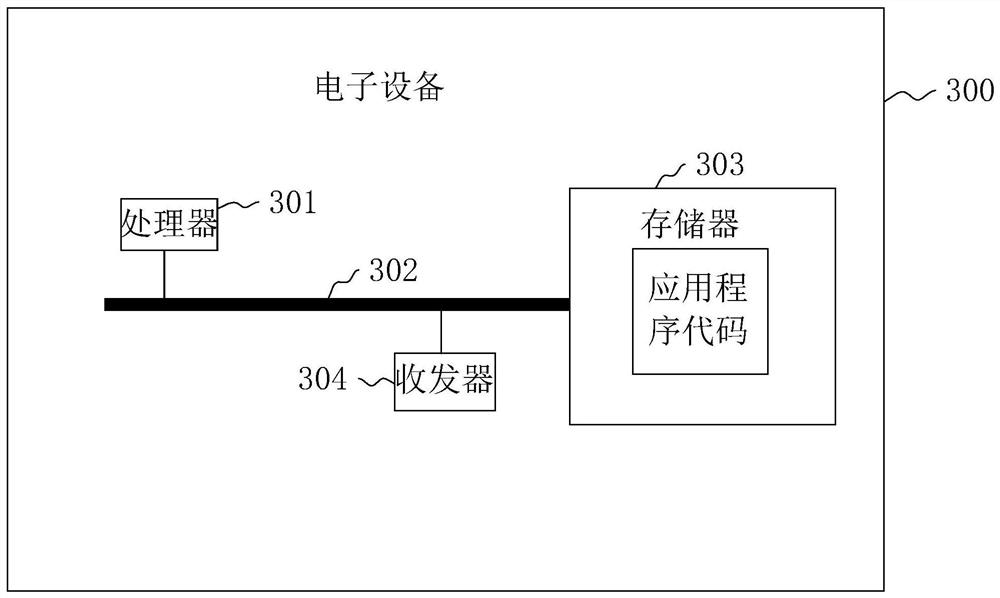

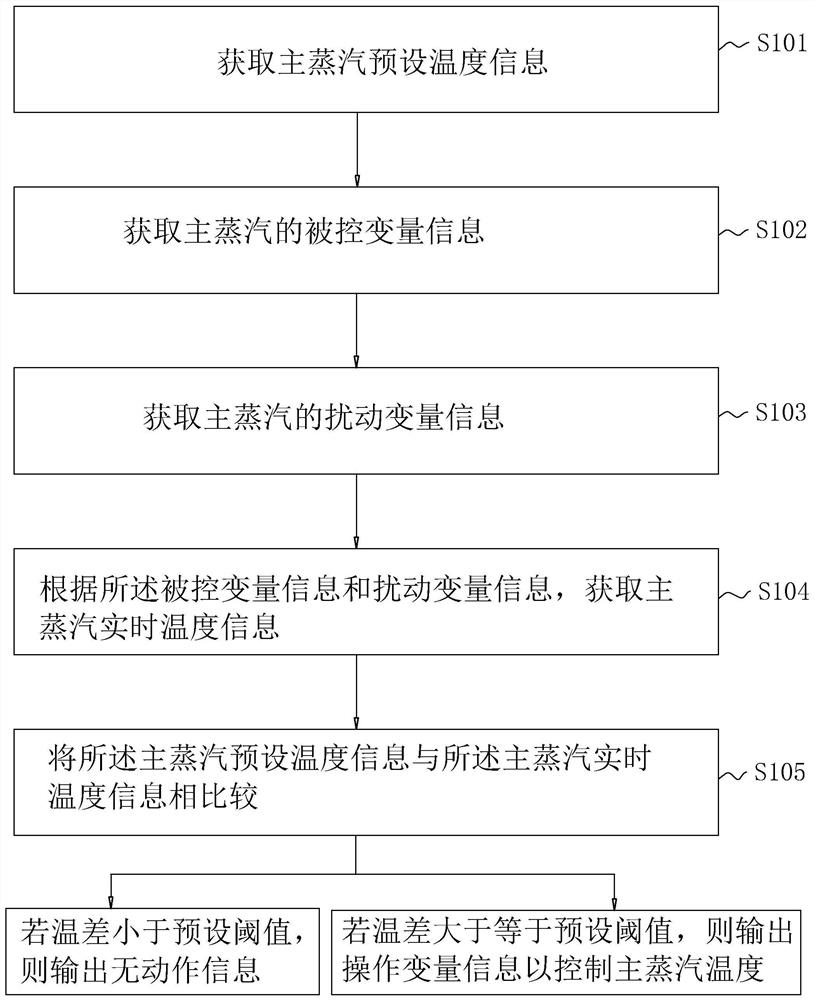

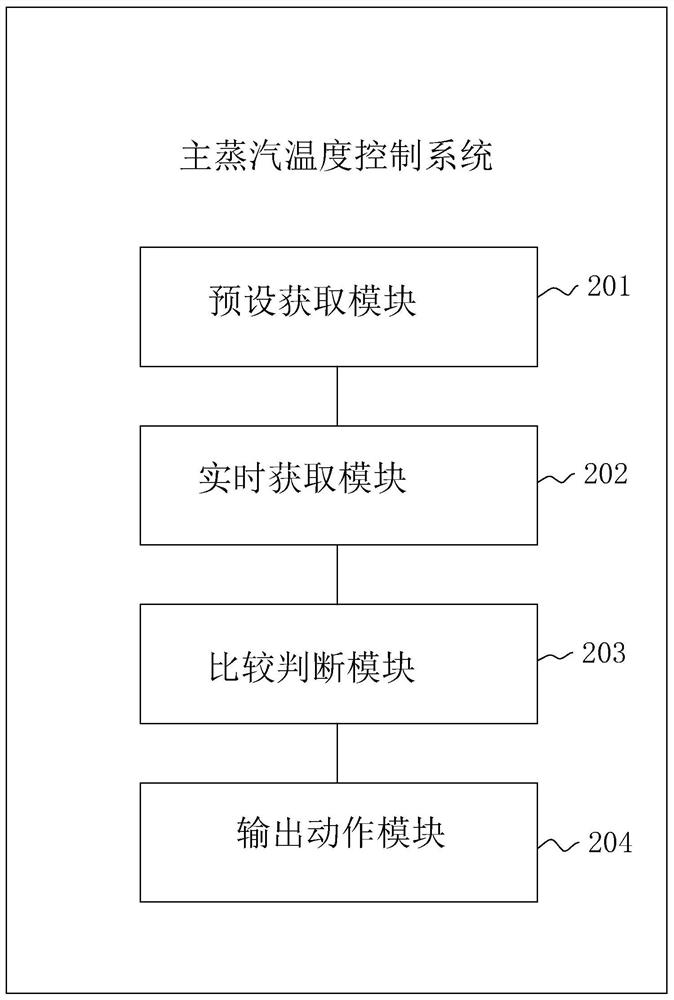

Main steam temperature control method and system and electronic equipment

PendingCN114355996AMeet the needs of automatic temperature controlReduce the number of manual interventionsTemperatue controlTemperature controlAutomatic control

The invention relates to the technical field of temperature control, in particular to a main steam temperature control method which comprises the steps that main steam preset temperature information is acquired; acquiring controlled variable information of main steam; disturbance variable information of main steam is obtained; acquiring main steam real-time temperature information according to the controlled variable information and the disturbance variable information; the main steam preset temperature information is compared with the main steam real-time temperature information; if the temperature difference is smaller than a preset threshold value, no-action information is output; if the temperature difference is larger than or equal to the preset threshold value, operation variable information is output to control the main steam temperature. The method has the effects of reducing the frequency of manual intervention and meeting the automatic control requirement of the main steam temperature.

Owner:HANGZHOU LUNENG ENVIRONMENTAL PROTECTION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com