Control method for full-automatically changing work roll of hot rolling finisher

A control method and technology of work rolls, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of non-roll changing methods and unrealized automatic roll changing, so as to reduce labor costs and optimize work rolls Roll changing process and the effect of increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

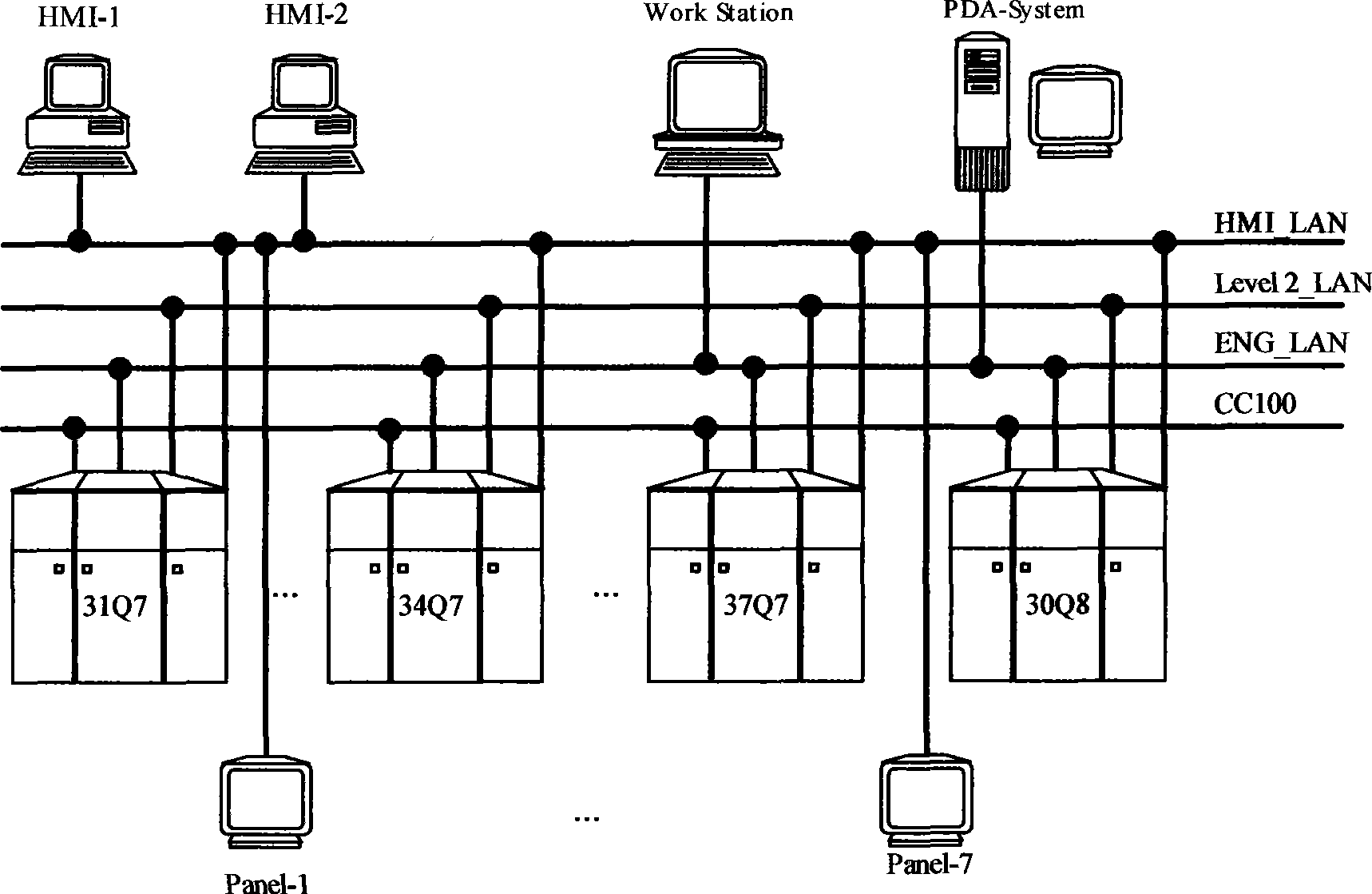

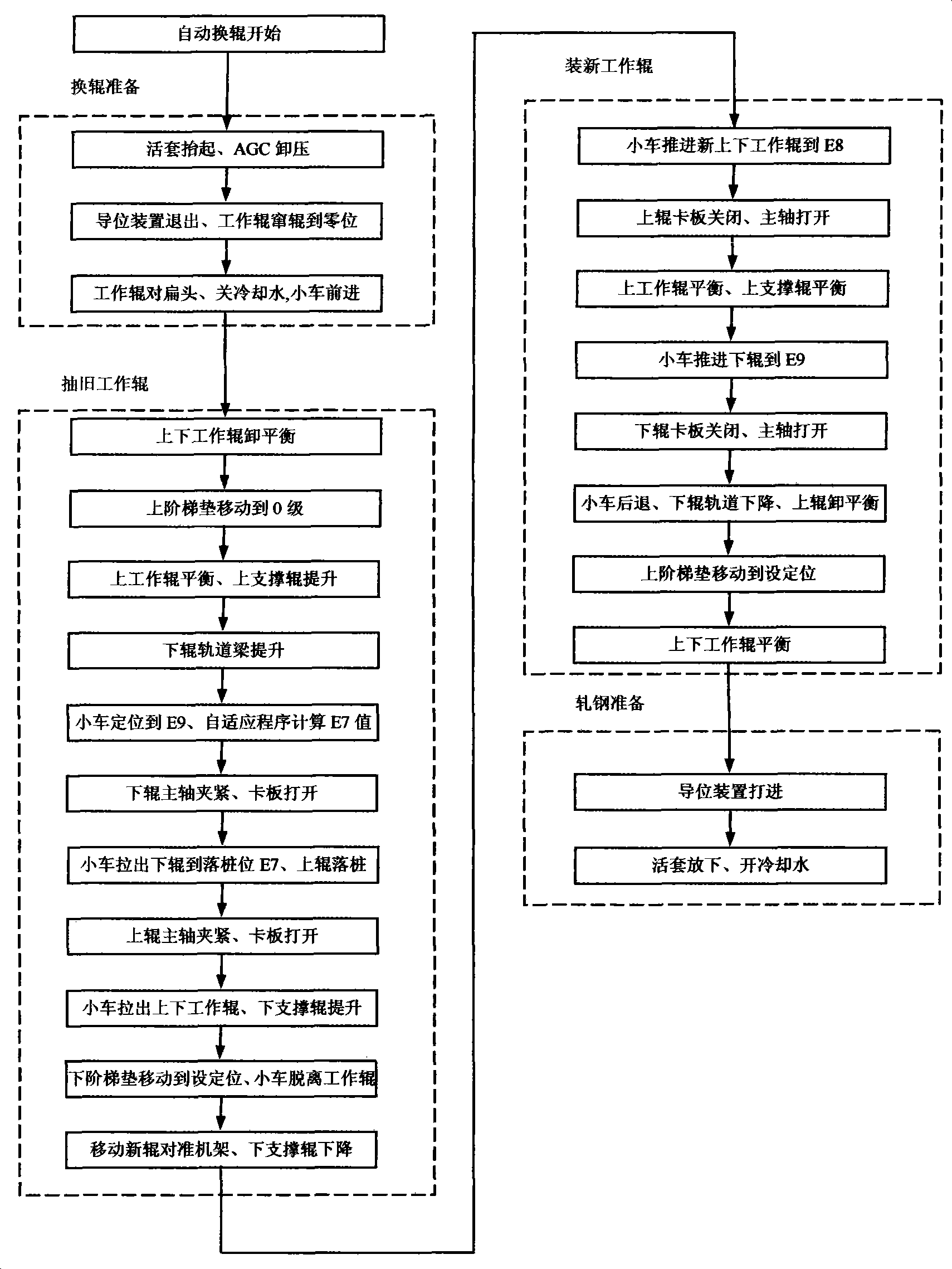

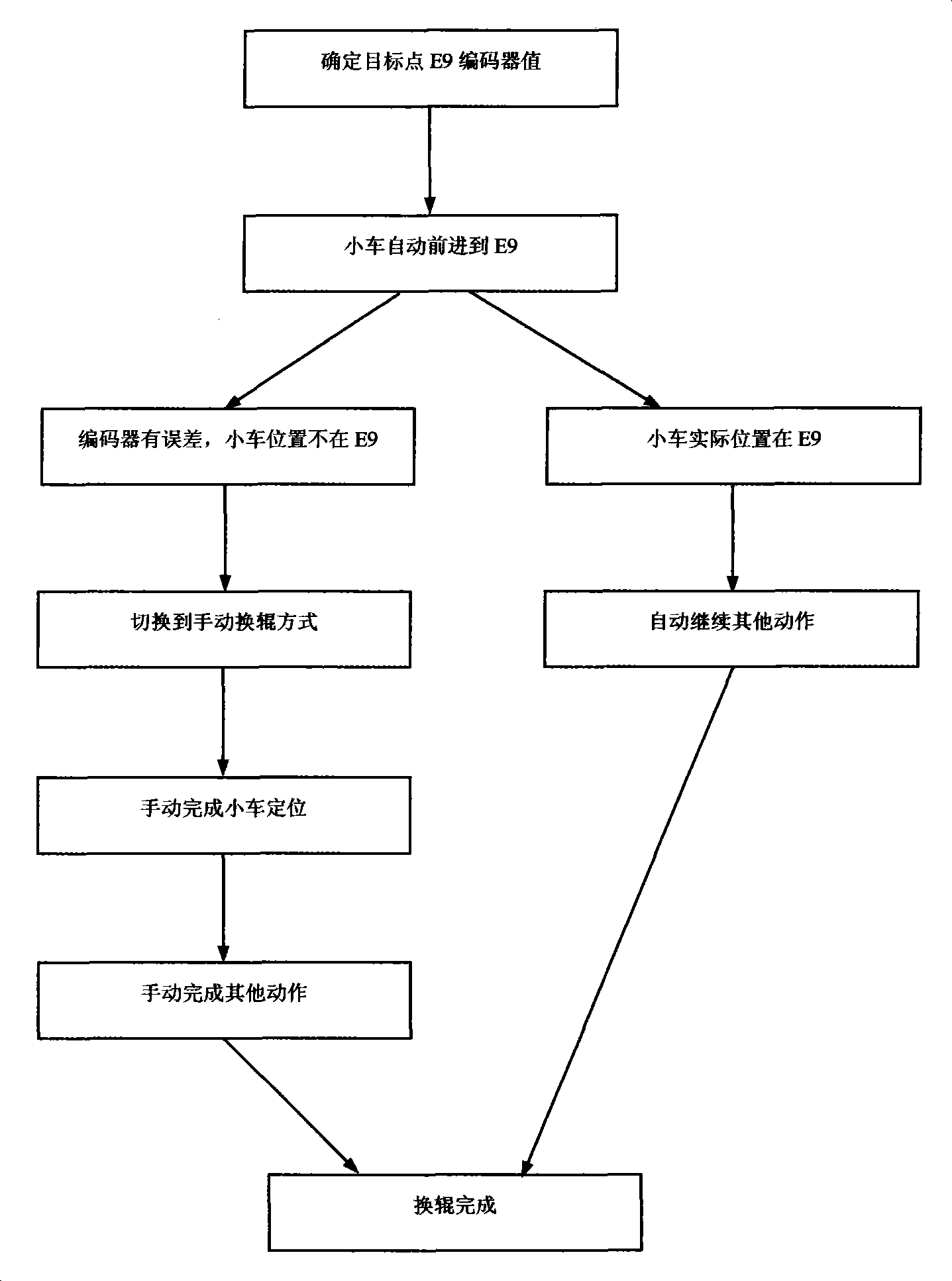

[0017] Each stand of the finishing mill controlled by the present invention adopts a VCM7750 HPCi controller, and each HPCi controller includes several resources (Resource) to realize different functions, and the roll change control is a resource of the HPCi controller, and the finishing mill automation control The system includes a total of 8 VCM7750HPCi (high-performance controller) controllers, 1 engineer server (Engineer Server), 1 human-machine interface server (HMI Server), 3 main screen operation computers (HMI), 7 local touch Operation panel (Local Panel), 2 engineer stations (Engineer Station), 1 data recording server (PDA). The controller rack, server, human-machine interface, engineer station, and data recording server communicate through 4-level networks. The 4-level networks are human-machine interface Ethernet (HMI LAN), engineer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com