Target pose measurement system and method based on feature point position correction

A technology of pose measurement and feature points, applied in image analysis, image enhancement, instruments, etc., can solve the problems of inapplicability to large-scale monitoring of roadbed settlement, large volume cannot install roadbed settlement monitoring system, high monitoring cost, etc., to reduce The number of manual interventions and the workload of manual inspections, the effect of improving work efficiency and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

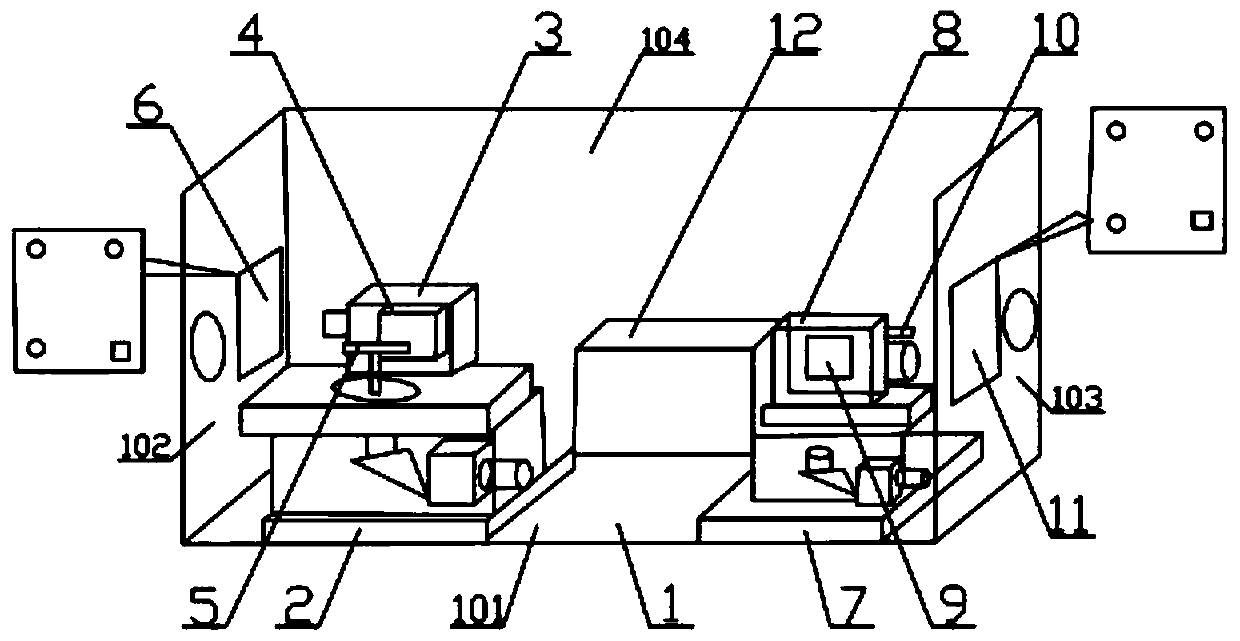

[0034] A target pose measurement system based on feature point position correction, such as figure 1As shown, it includes a seat body 1, which is characterized in that: a first adjustable bracket 2 and a second adjustable bracket 7 are installed on the bottom plate 101 of the seat body 1, and the first adjustable bracket 2 and the second adjustable bracket The brackets 7 are respectively located on the left side and the right side of the base plate 101. The first camera 3 and the first laser 5 are installed on the upper surface of the first adjustable bracket 2, and the first camera 3 is installed on the side of the first camera 3. An inclinometer 4, a second camera 8 and a second laser 10 are installed on the upper surface of the second adjustable bracket 7, a second inclinometer 9 is installed on the side of the second camera 8, and the base 1 The first feature point target surface 6 is provided on the left side plate 102 of the base body 1, the second feature point target s...

Embodiment 2

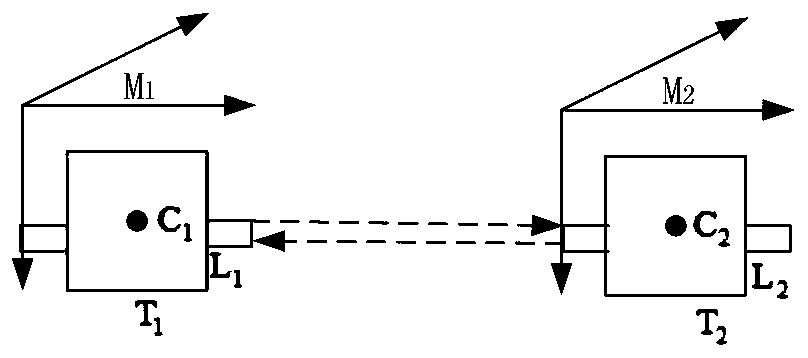

[0040] While the image-based subgrade settlement monitoring system transmits the settlement deformation information, it also accumulates and transmits the measurement errors of each transmission detection station. The final measurement accuracy will inevitably decrease with the increase in the number of transmission detection stations. The measurement error between the detection stations is transmitted, and the closed adjustment method in the railway subgrade surface settlement observation standard is used for reference, and the chain measurement method is constructed into a closed loop, and the accumulated error is eliminated by the closed adjustment method.

[0041] Such as figure 2 A closed loop is formed between the bit transfer stations shown. Every two adjacent measurement base stations in the round-trip dual camera chain are T 1 and T 2 , L, C, M are the light source, camera and target surface of the monitoring system, respectively. Light source L 1 where the coord...

Embodiment 3

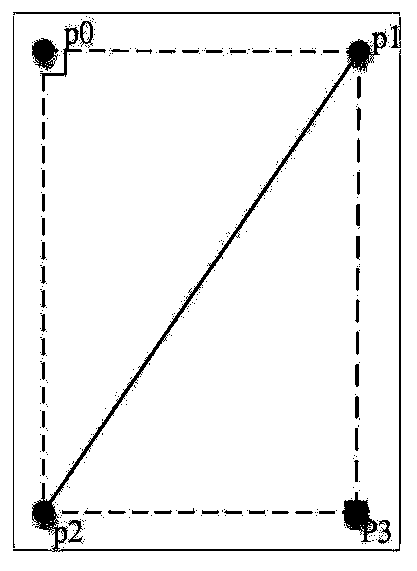

[0045] The correction of feature points is divided into feature point integrity type position correction and feature point missing type position correction. When the target surface or camera deflection angle is small or the background clarity is high, the number of feature points that can be collected is K=4, which can be The accuracy of centroid location of feature points and the integrity of image acquisition are judged by l and d of rectangular feature points. Such as image 3 As shown, the experimentally obtained feature point p 0 ,p 1 ,p 2 ,p 3 After the pixel coordinate value, use any one of the four feature points as an example p 0 Click to verify, Figure 5 It is a flow chart of complete position correction. First according to p 0 p 1 = d, p 0 p 2 = l and p 0 p 1 ⊥p 0 p 2 carry on p 0 with p 2 position, and then calculate p 3 Pixel coordinate value, and finally compare the calculated feature point coordinate value with the feature point positioning val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com