Automatic cutting control method, device and system for coal mining machine and storage medium

A control method and coal shearer technology, applied in the direction of earthwork drilling, cutting machinery, etc., can solve the problems of being unable to adapt to complex coal mining process sections, and achieve the reduction of manual intervention times, true and accurate memory cutting operations, and automatic cutting good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The invention will be described in detail below with reference to the accompanying drawings. It should be noted that the features in the embodiments and embodiments in the present application may be combined with each other in the case of an unable conflict.

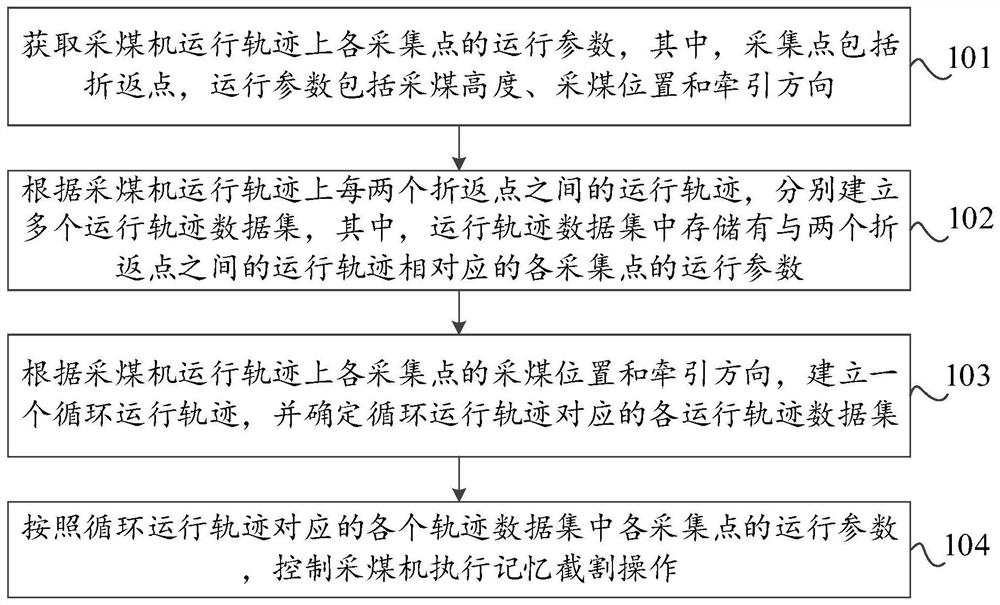

[0042] In one embodiment, if figure 1 As shown, a method of automatic cutting control method for a shearer is provided, and the method is applied to the motion controller of the coal minister, including the following steps:

[0043] 101. Access the operating parameters of each collected point on the running track of the coal, including the collection point including the folding point, the operating parameters include coal mining, coal mining position and traction direction.

[0044]Specifically, when the coal mining machine, the staff can set a run trajectory according to the actual operation requirements, and control the coal mining machine to travel and coal from this operational trajectory. Such processes are often...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com