Rolled piece position tracking device and tracking method for sectional material hot rolling finishing mill

A technology of tracking device and finishing mill, applied in the direction of digital control, electrical program control, etc., can solve problems such as tracking signal error, tracking signal misjudgment, rolling piece 15 data calculation failure, etc., to reduce the number of manual interventions and improve the position Tracking accuracy, effect of improving tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

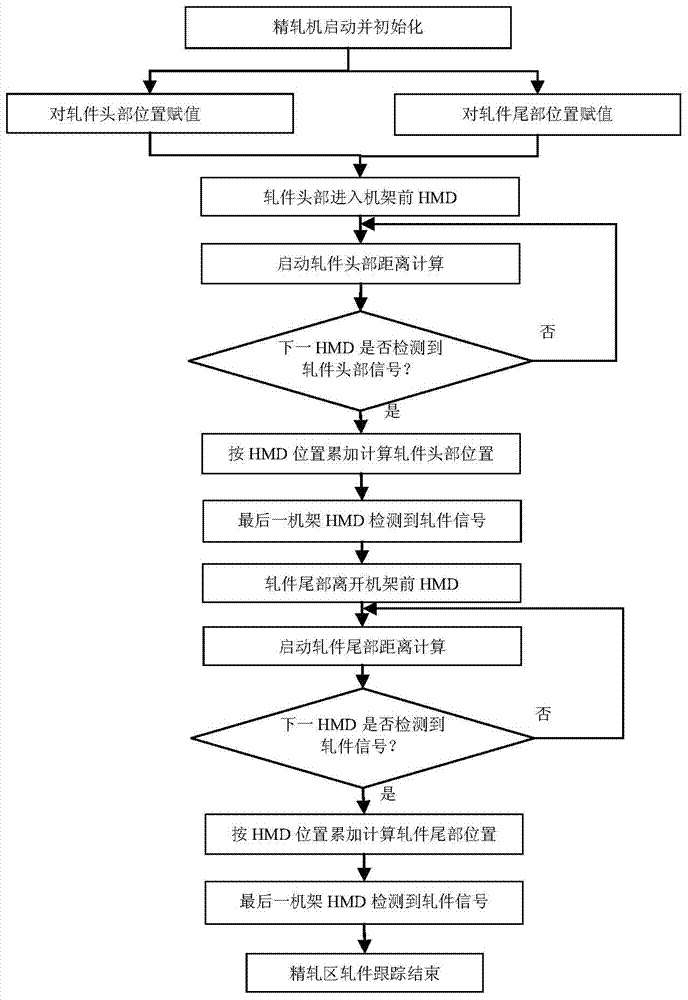

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

[0031] Figure 1 to Figure 3 The existing profile hot-rolling finishing mill rolling piece position tracking device and tracking method have been described in the background technology, and will not be repeated here.

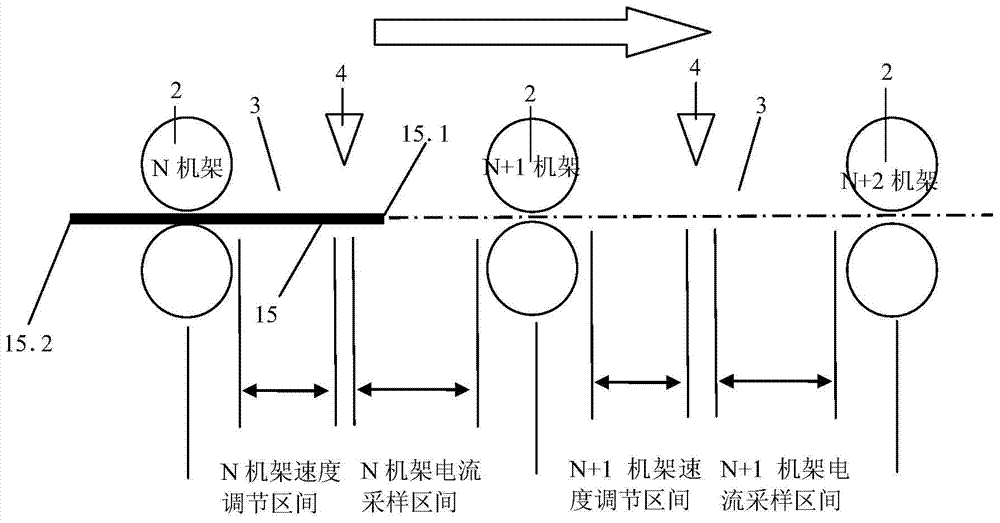

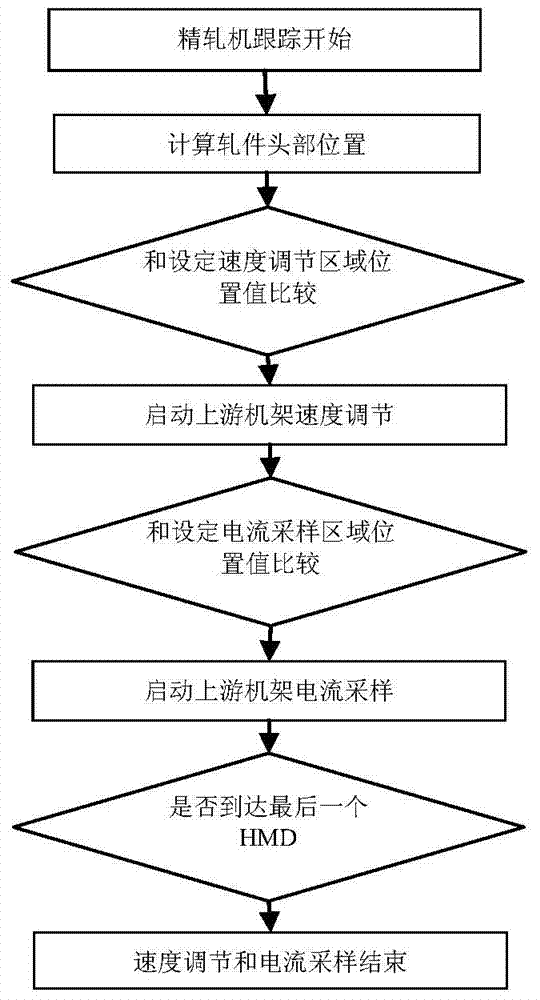

[0032] see Figure 4 to Figure 5 , the rolling piece position tracking device of the profile hot rolling finishing mill of the present invention comprises a finishing rolling area 1, a frame 2, a tracking area 3, a hot metal detector 4, a frequency converter 5, a man-machine interface local area network 6, a high-performance controller 7, Man-machine interface server 8 , local control panel 9 , workstation 10 , process data query device 11 , recorder network 12 , secondary local area network 13 and engineering control local area network 14 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com