Patents

Literature

46results about How to "Reduce damage accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

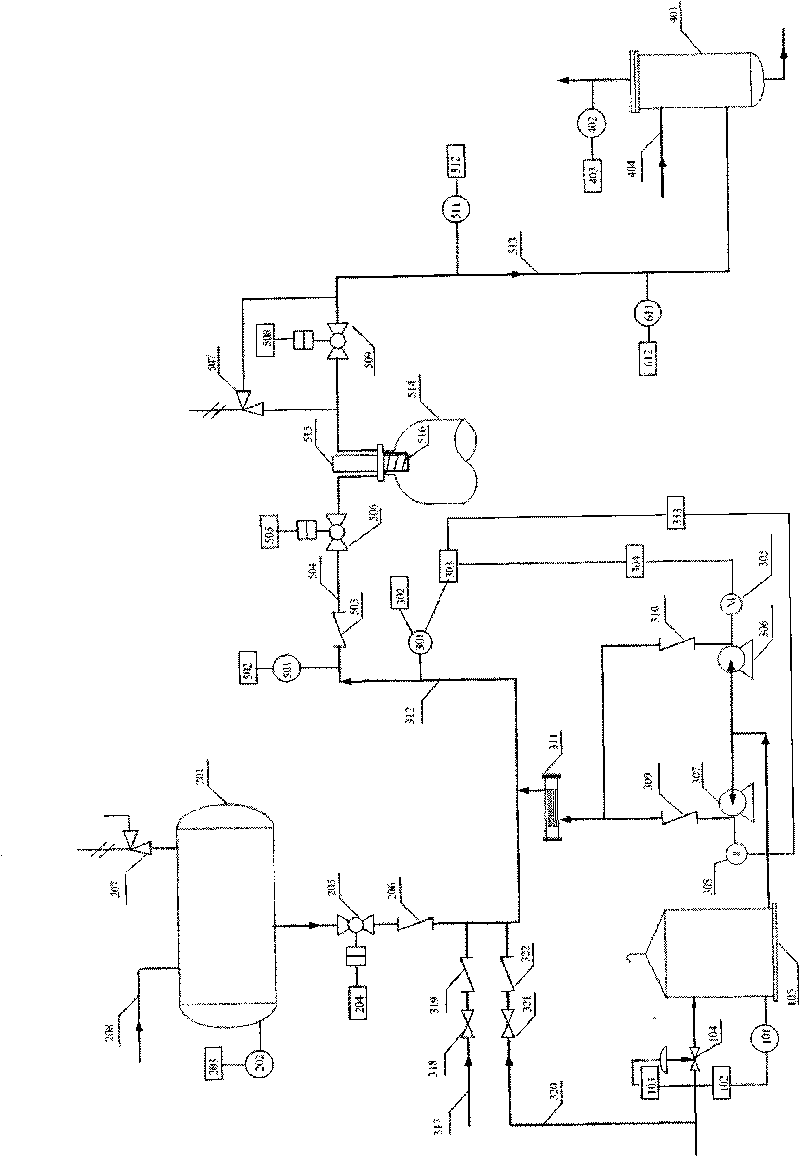

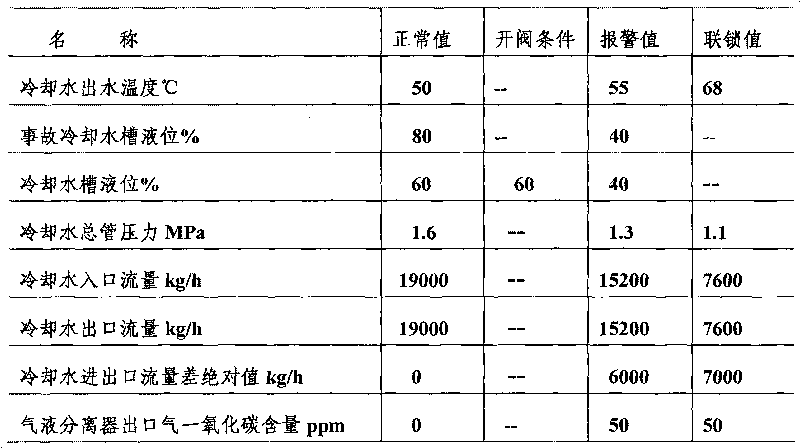

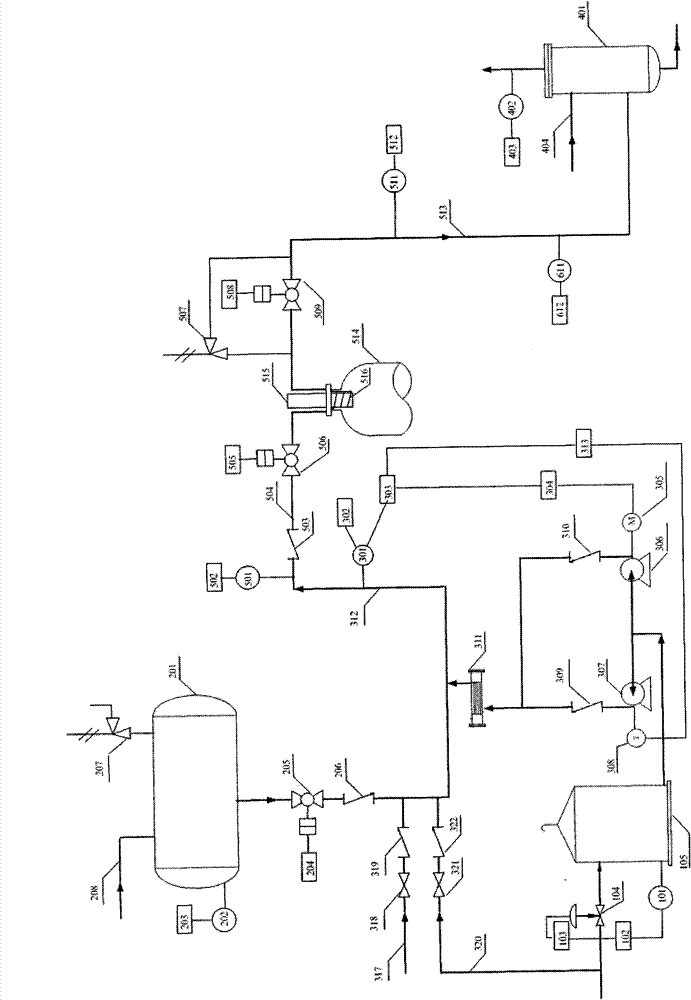

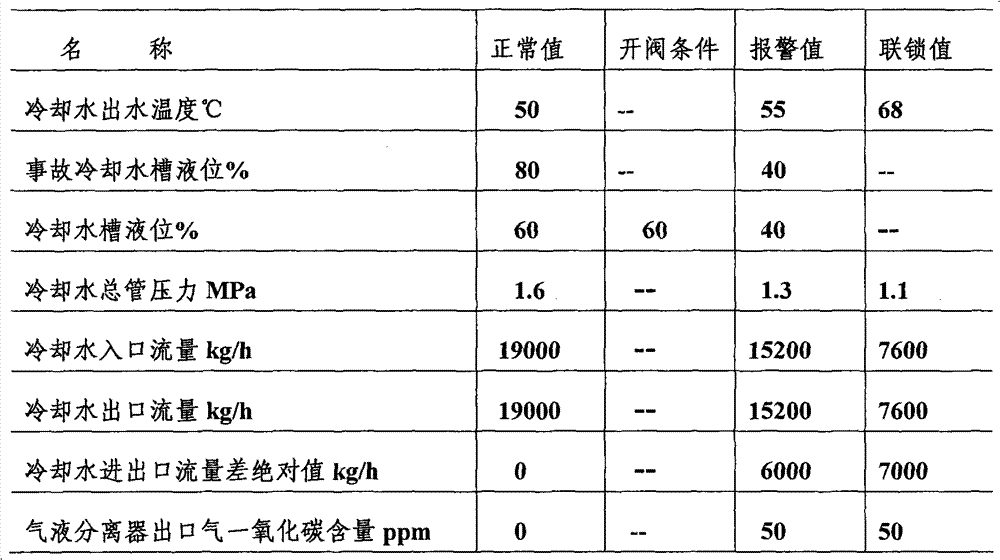

Mixed atomizer cooling protection system for entrained-flow reactor

ActiveCN101735858AGuaranteed continuous supplySupply is no longer limited by timeHydrogenGranular/pulverulent flues gasificationWater bathsEngineering

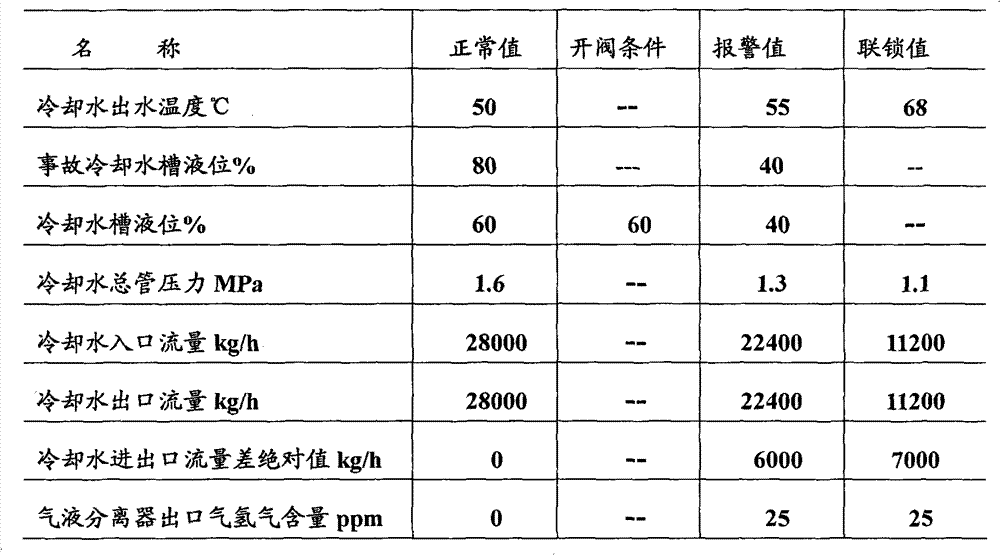

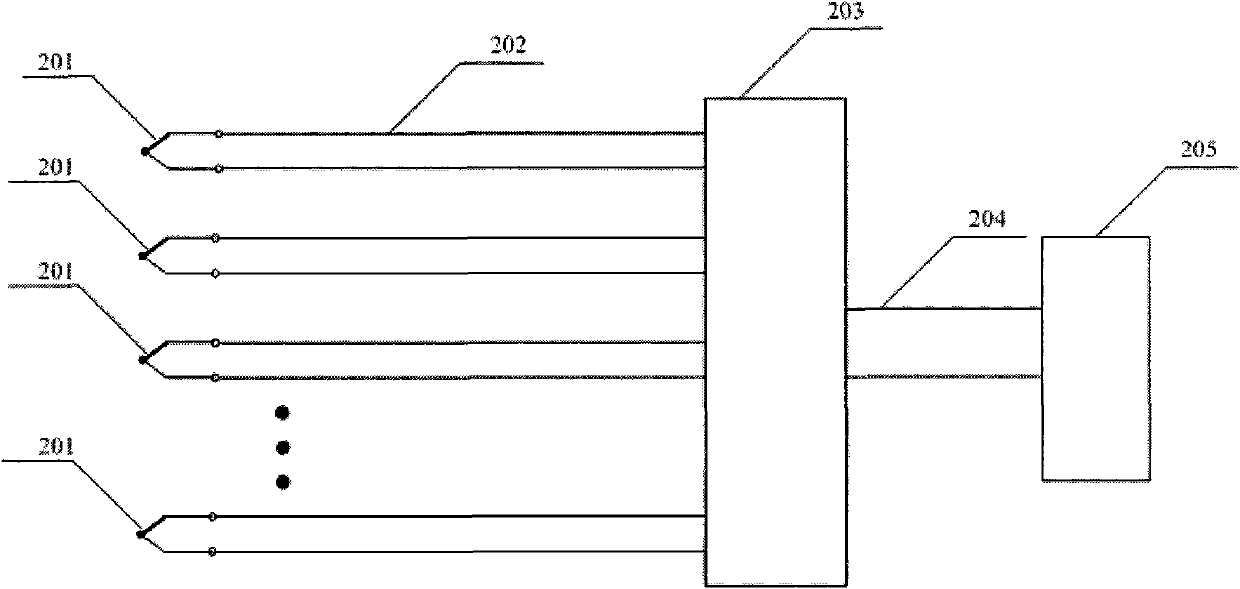

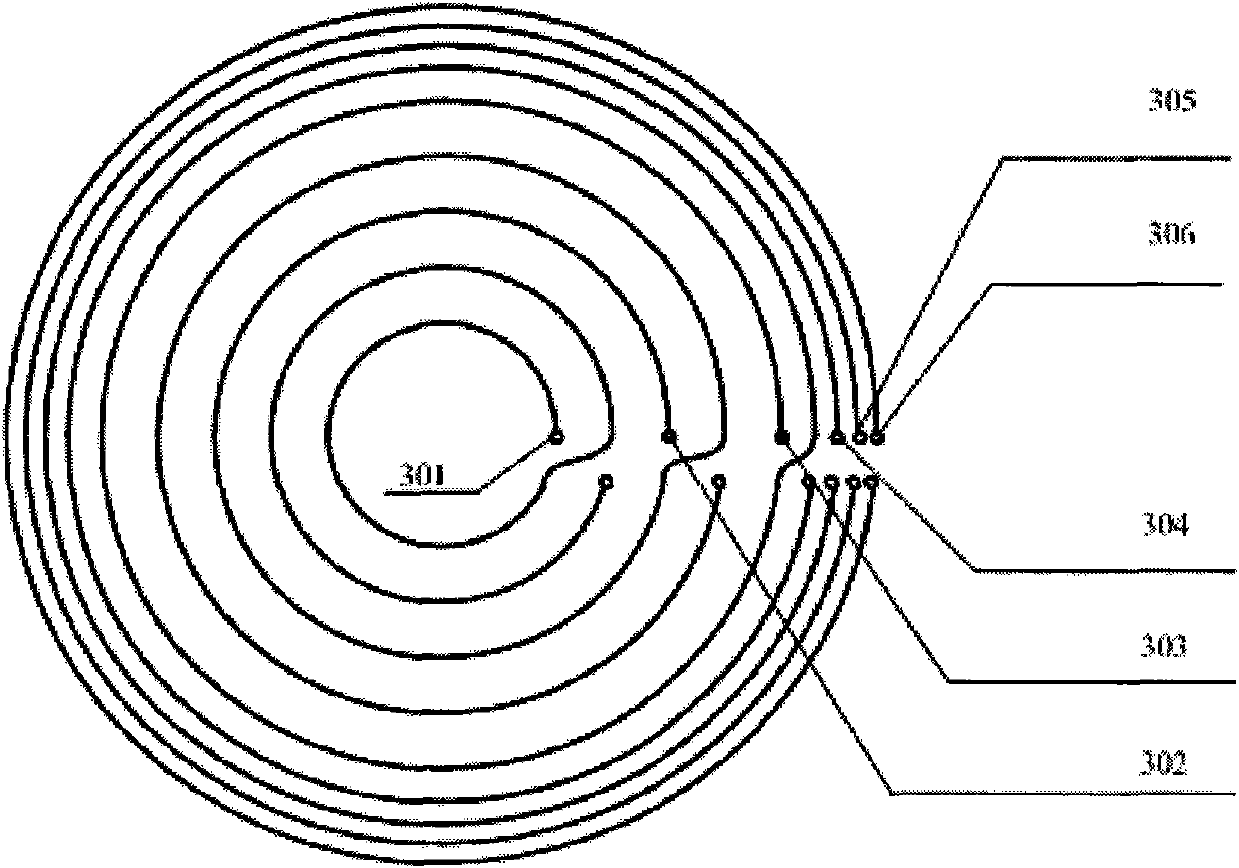

The invention discloses a mixed atomizer cooling protection system for an entrained-flow reactor. The cooling protection system comprises twelve subsystems such as a cooling water pump self-starting subsystem, a cooling water batch liquid level control subsystem, a cooling water header pressure indicating and alarming subsystem, an emergency cooling water bath protection subsystem, a mixed atomizer cooling water inlet flow protection subsystem, a mixed atomizer cooling water outlet flow indicating and alarming subsystem, a mixed atomizer cooling water outlet temperature indicating and alarming subsystem, etc. The mixed atomizer cooling protection system can effectively protect equipment of the mixed atomizer and the mixed atomizer cooling protection system, prolong the total service life of the mixed atomizer, improve the on-stream availability of the entrained-flow reactor, and ensure the safety of personnel and equipment.

Owner:XIAN ORIGIN CHEM TECH

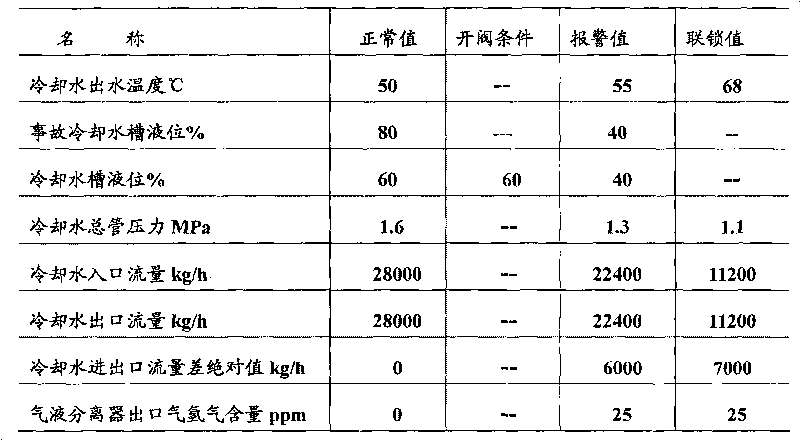

High-temperature reactor inner wall corrosion damage prewarning method

InactiveCN1975310ASolving Online Security Monitoring ProblemsReduce damage accidentsFurnace componentsChecking devicesSlagThermocouple

The invention discloses corrosion damage warning method of in-wall in high-temperature reactor, comprising the following steps: according to the quality and energy conservation principles calculate average temperature of gas and temperatures on the border of connected slag blanket at different position and height; obtain temperature in reactor by thermocouple, and according to this, calculate initial temperature distribution of exterior surface of flame retardant coating through Lagrange quadratic interpolation method; establish the steady-state thermal conductive partial differential reasoning equation of top and lateral section of the inner wall including the slag blanket; then calculate the inner wall temperature distribution and the thickness of the slag layer at different height including the slag blanket through the equation; predict the border position of solid slag blanket attached on the in-wall of the reactor; integrate into the corrosion damage warning message of in-wall of reactor after judgment and compare of thickness of the slag layer at different height of the in-wall in reactor to warning threshold value. The invention provides accurate, fast and lower-cost corrosion damage warning methods of in-wall in high-temperature reactor.

Owner:CENT SOUTH UNIV

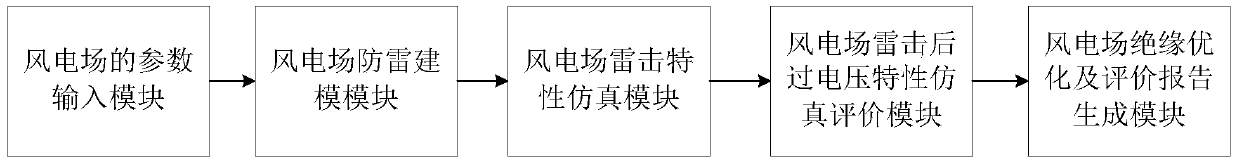

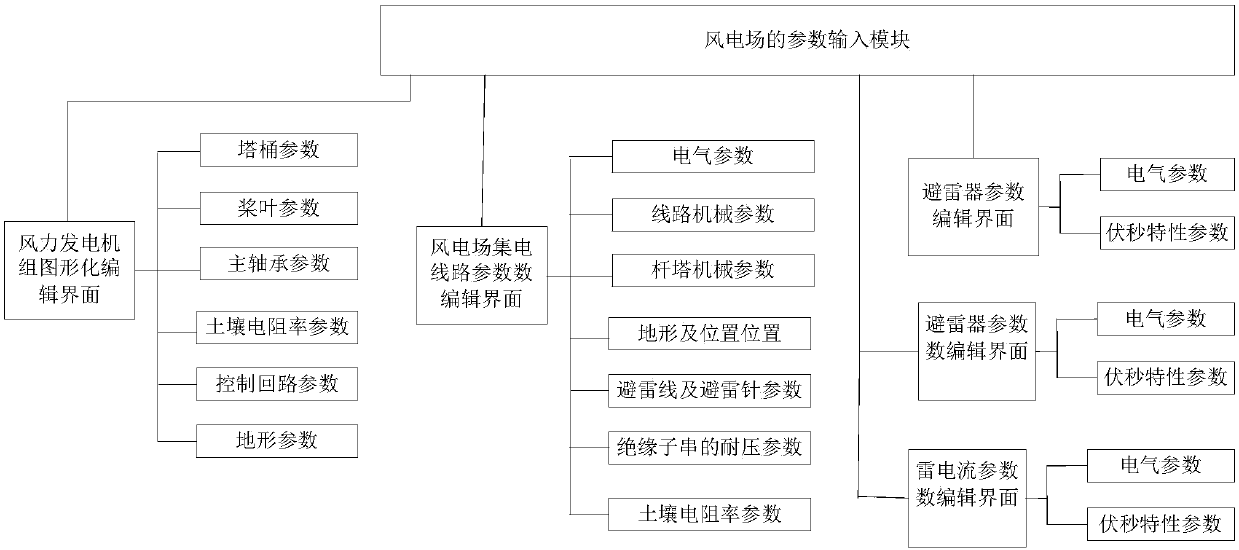

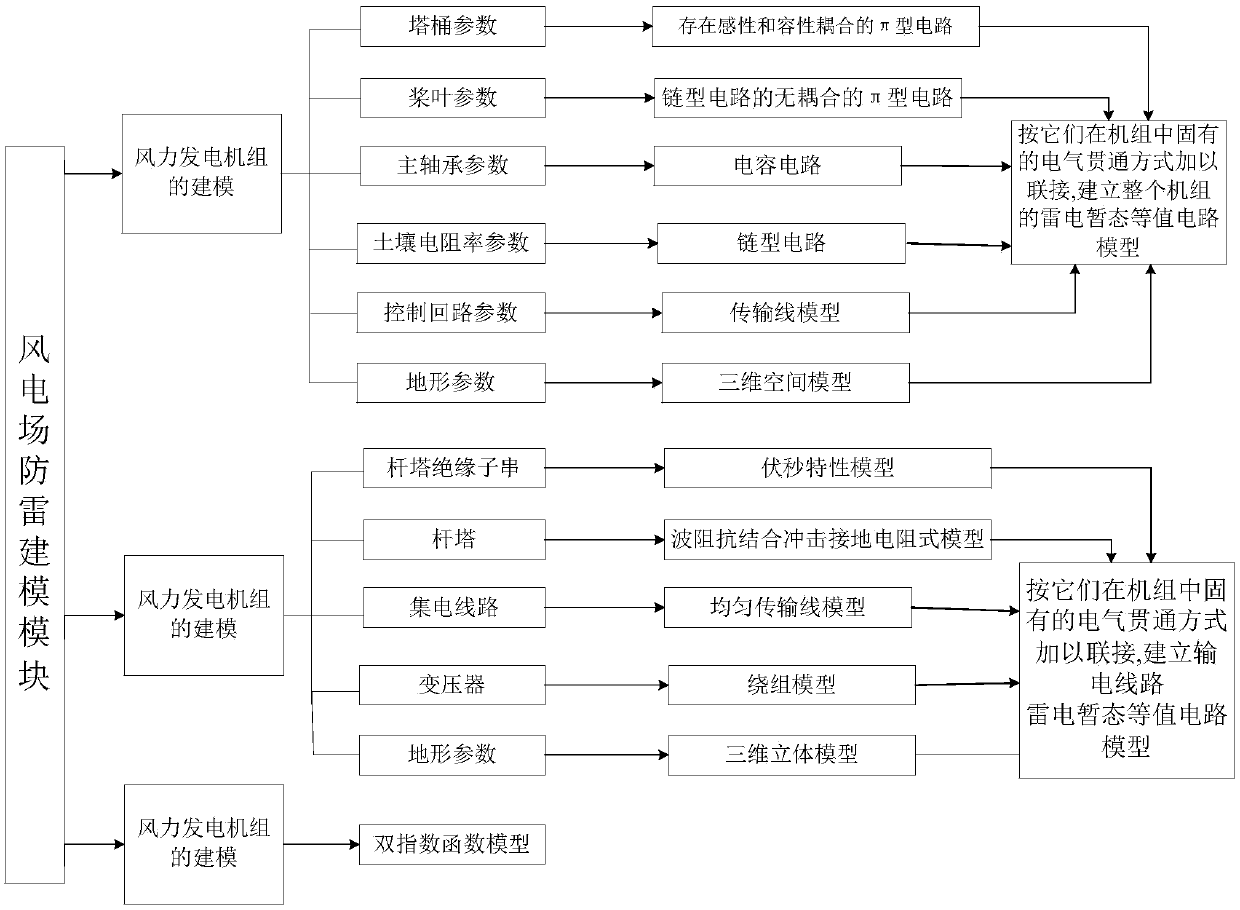

A lightning protection evaluation system for a wind power plant

ActiveCN109670205AImprove securityImprove reliabilityDesign optimisation/simulationWind energy generationOvervoltageTerrain

The invention relates to a lightning protection evaluation system for a wind power plant. In order to overcome the defect that the existing lightning protection test detection cannot well reflect theeffectiveness and safety of the lightning protection effect of the wind power plant lightning protection device, the system mainly comprises five modules of a parameter input module, a lightning protection modeling module, a lightning stroke characteristic simulation module, a post-lightning-stroke overvoltage characteristic simulation evaluation module and an insulation optimization and evaluation report generation module. The method comprises the following steps of firstly, establishing a model of a terrain, a fan, a line, a tower, a lightning arrester and a grounding system of the wind power plant, simulating the lightning stroke characteristic of the wind power plant on the basis, and simulating the overvoltage characteristic of the wind power plant after lightning stroke to complete the systematic evaluation of the lightning protection effect of the wind power plant. According to the present invention, the wind power plant lightning protection effect can be systematically and completely evaluated, the safety and reliability of the wind power plant are improved, the equipment damage accidents caused by lightning stroke are reduced, the generating capacity of the wind power plant is improved, and the economic income of the wind power plant is increased.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

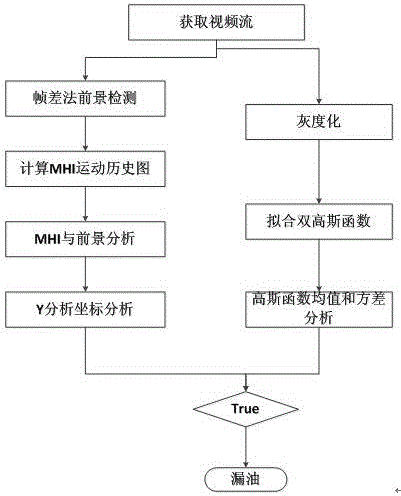

Transformer oil leak detection method

ActiveCN106340034AReduce damage accidentsImprove security monitoring effectImage enhancementImage analysisDirection informationTransformer oil

The invention discloses a transformer oil leak detection method comprising the following steps: S1, acquiring the image information of a detection area of a transformer before oil leak; and S2, acquiring the current image information of the detection area of the transformer, comparing and processing the image information before oil leak and the current image information to get the oil leak direction information of the detection area and the color information of the detection area, and judging whether the detection area leaks oil based on the oil leak direction information of the detection area and the color information of the detection area to get a detection result. The transformer oil leak detection method has the technical effects of high detection efficiency and high detection accuracy.

Owner:CHENGDU UNIV OF INFORMATION TECH

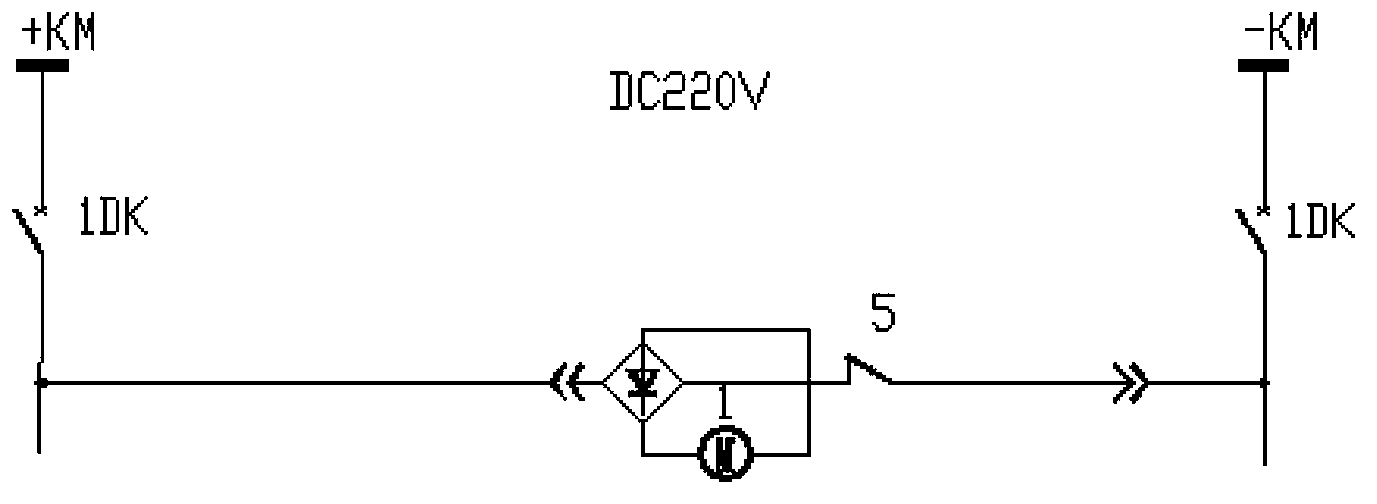

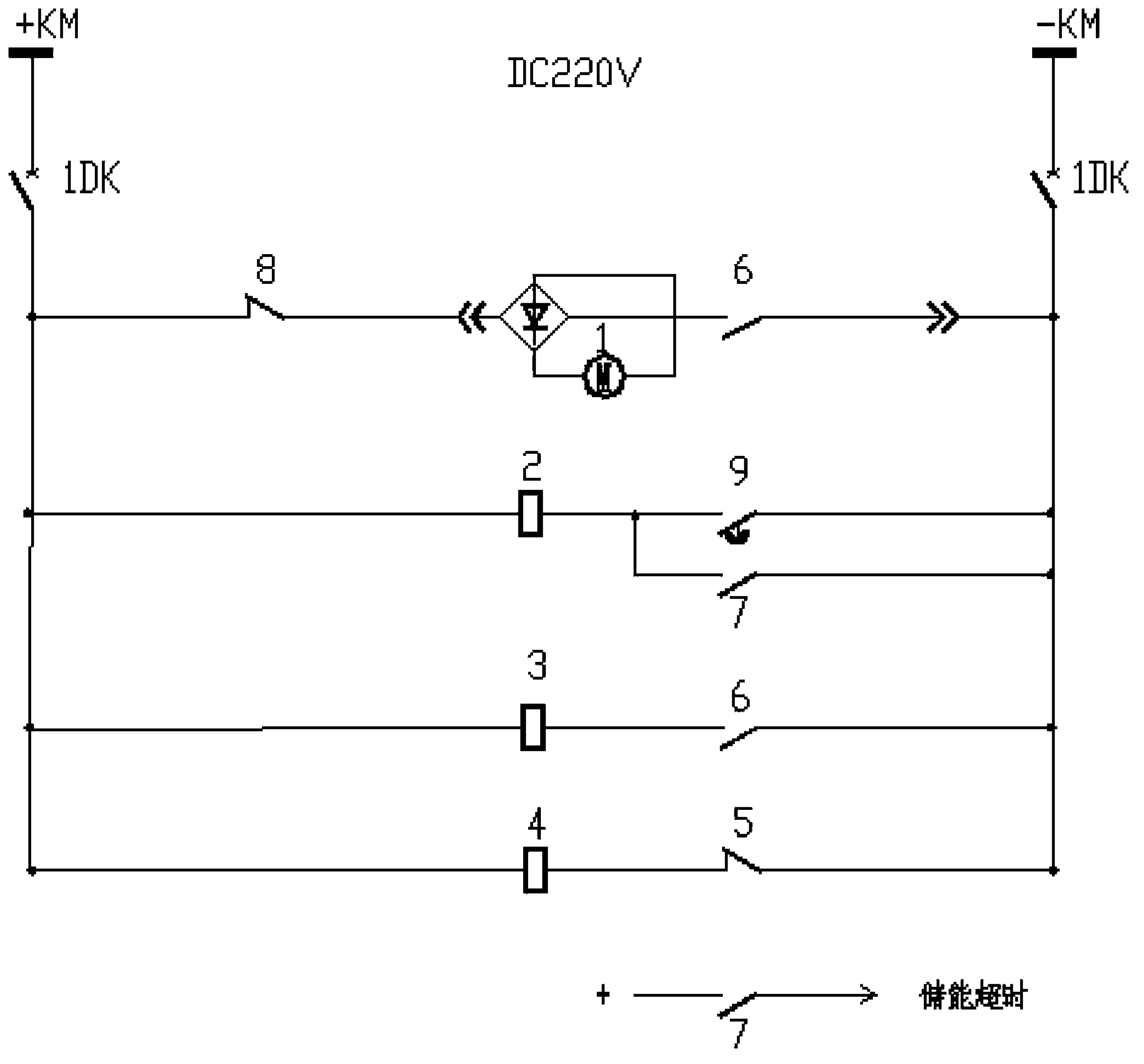

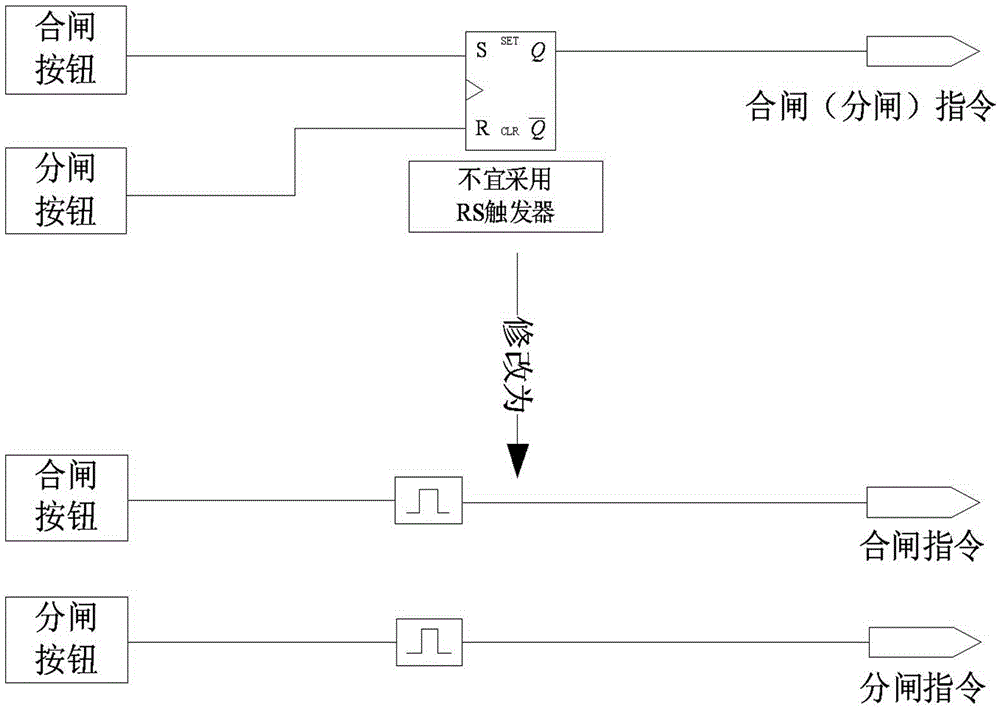

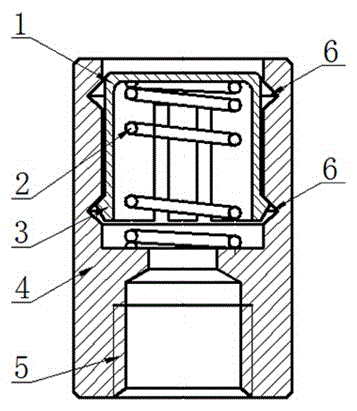

Vacuum circuit breaker energy storage motor protection circuit

InactiveCN103384059AImprove reliabilityReduce damage accidentsEmergency protective circuit arrangementsCircuit reliabilityTime delays

The invention discloses a vacuum circuit breaker energy storage motor protection circuit which comprises an energy storage motor. A direct-current switch is connected between the energy storage motor and a positive electrode of direct-current voltage, another direct-current switch is connected between the energy storage motor and a negative electrode of the direct-current voltage, the energy storage motor is sequentially parallelly connected with a second intermediate relay, a time relay and a first intermediate relay and serially connected with a first normally open contact of the first intermediate relay and a normally closed contact of the second intermediate relay, the second intermediate relay is serially connected with a time delay closing contact of the time relay, the time delay closing contact of the time relay is parallelly connected with a normally open contact of the second intermediate relay, the time relay is serially connected with a second normally open contact of the first intermediate relay, and the first intermediate relay is serially connected with a microswitch. Circuit reliability of the energy storage motor is improved, the accident of damage to the energy storage motor due to the failure can be reduced, and a medium-voltage distribution system is more reliable in operation.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

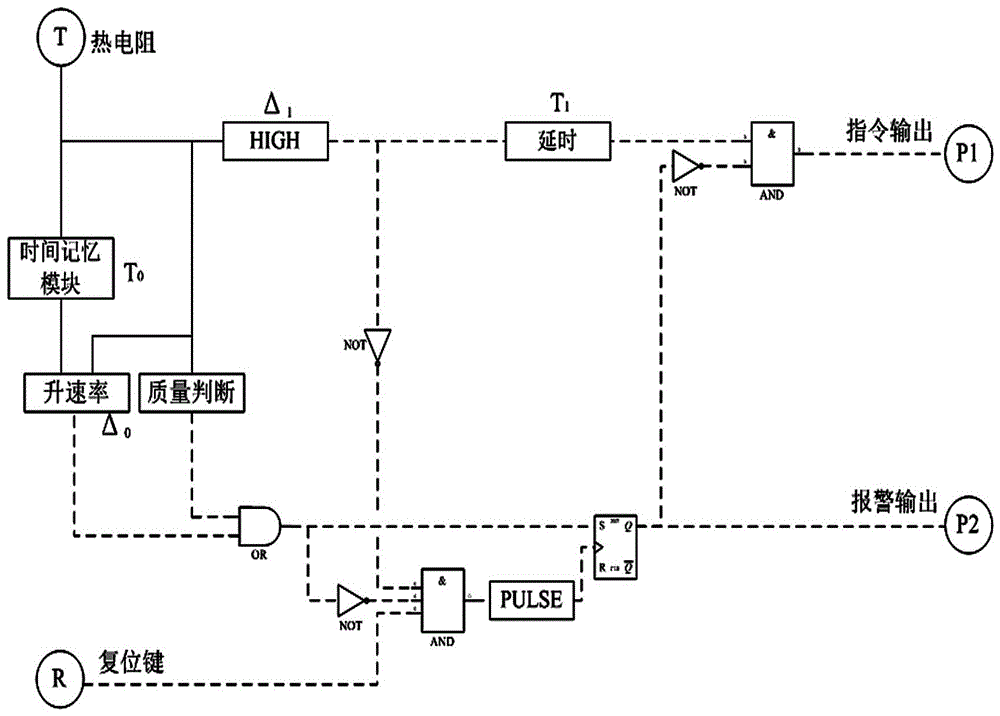

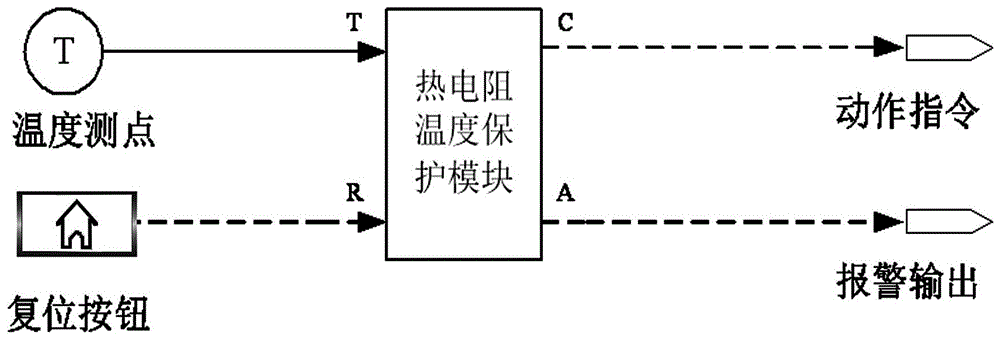

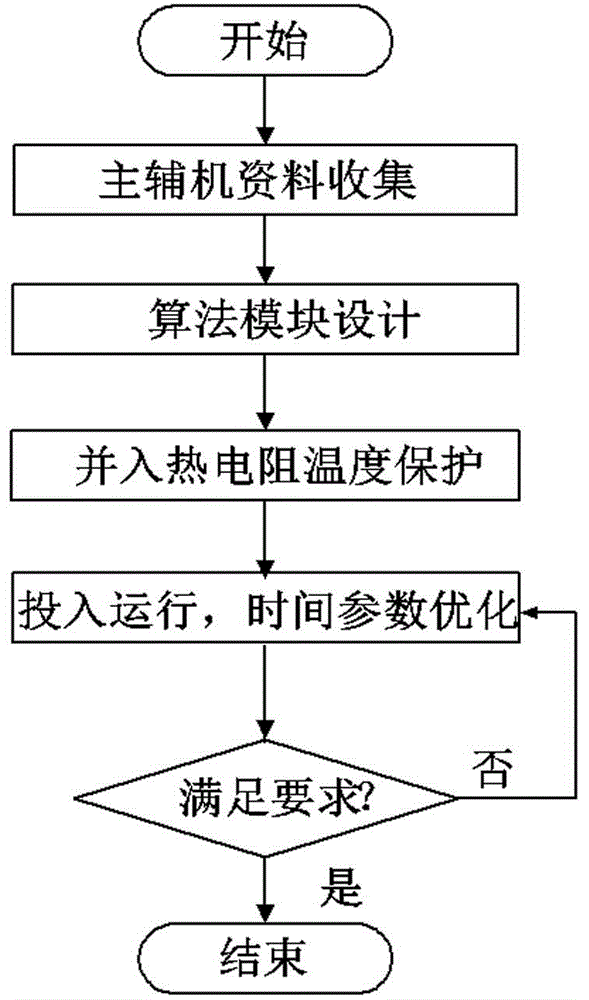

Method for preventing thermal resistor protection failure of thermal power plant DCS

InactiveCN106502229AWith a clear purposePerfect process method systemTotal factory controlProgramme total factory controlAutomatic controlEngineering

The invention belongs to the technical field of thermal generator unit automatic control, especially relates to a method for preventing thermal resistor protection failure of a thermal power plant DCS (Distributed Control System), and specifically relates to a method for preventing thermal resistor temperature protection failure of a thermal generator set. The method can be used to reform a thermal generator unit thermal resistor temperature protection system so as to improve the ability of the unit thermal process protection system to prevent misoperation. A thermal resistor temperature protection system of main and auxiliary equipment of a thermal power plant is taken as an optimized design object, false signals produced due to open circuit or virtual connection of a thermal resistor signal line are shielded, and the phenomenon that the temperature signal of the thermal resistor rises too fast and causes equipment mis-tripping is prevented. The method has the distinctive characteristics of simple field debugging process and easy project implementation. The reliability of the unit DCS thermal process protection system is improved effectively. The occurrence probability of misoperation events is reduced. The occurrence of unit tripping and equipment damage accidents is reduced. The number of non-stop times of the unit is reduced. The cost is lowered. The profit margin is improved. The method is of importance significance to improving the operation safety and economy of thermal generator units.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

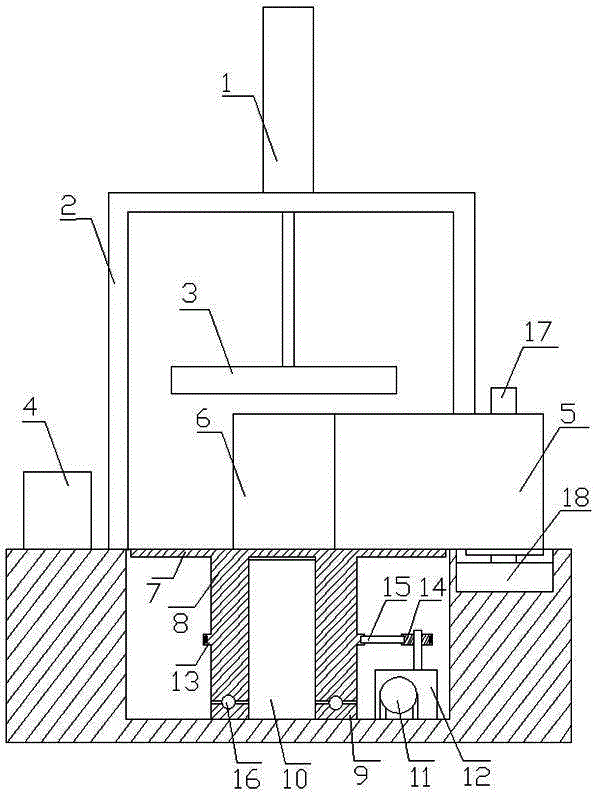

Automatic pressing and packaging machine for aluminum sheets

ActiveCN106364745AEasy to operateImprove efficiencyWrapping with article rotationBody rollReduction drive

The invention relates to an automatic pressing and packaging machine for aluminum sheets. The automatic pressing and packaging machine for aluminum sheets comprises a pressing device, a rotating device, a film fixing device and a control box. The control box controls the pressing device and the rotating device. The pressing device comprises a cylinder, a cylinder frame and a pressing plate, wherein the cylinder is fixed to the cylinder frame, and the pressing plate is fixed to an ejection rod of the cylinder. The rotating device comprises a turnplate, a rotating body, a rotating body base, a support column, a motor, a speed reducer, a big belt wheel, a small belt wheel, a belt and elastic balls. The turnplate is located below the pressing plate and integrally connected with the rotating body. The rotating body rolls on the rotating body base through the elastic balls. The support column stretches into an inner cavity of the rotating body base and the rotating body. The middle portion of the outer wall of the rotating body is integrally connected with the big belt wheel. The motor is connected with the speed reducer. The tail end of an output shaft of the speed reducer is connected with the small belt wheel. The small belt wheel drives the big belt wheel to rotate through the belt. According to the automatic pressing and packaging machine for aluminum sheets, operation is convenient, aluminum sheets can be pressed, manual film wrapping is not needed, and the efficiency is high; and it is guaranteed that damage, caused by transporting friction, to products is avoided.

Owner:广西南南铝箔有限责任公司

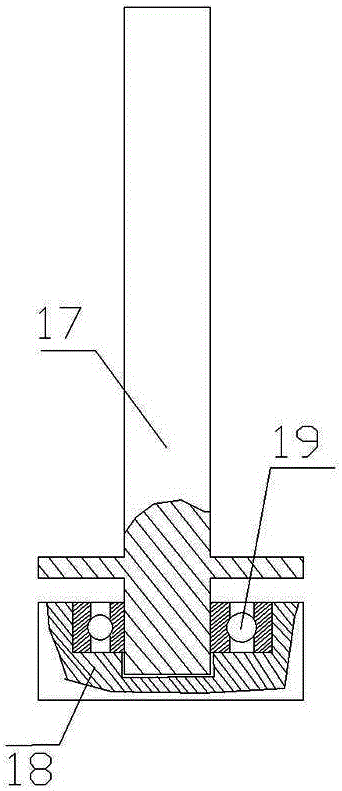

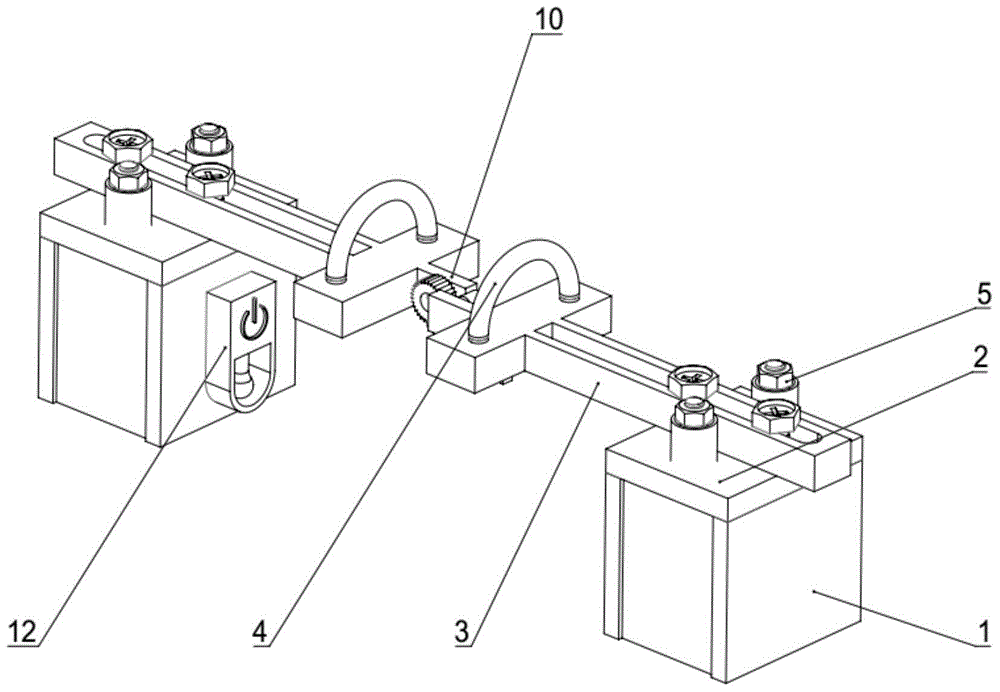

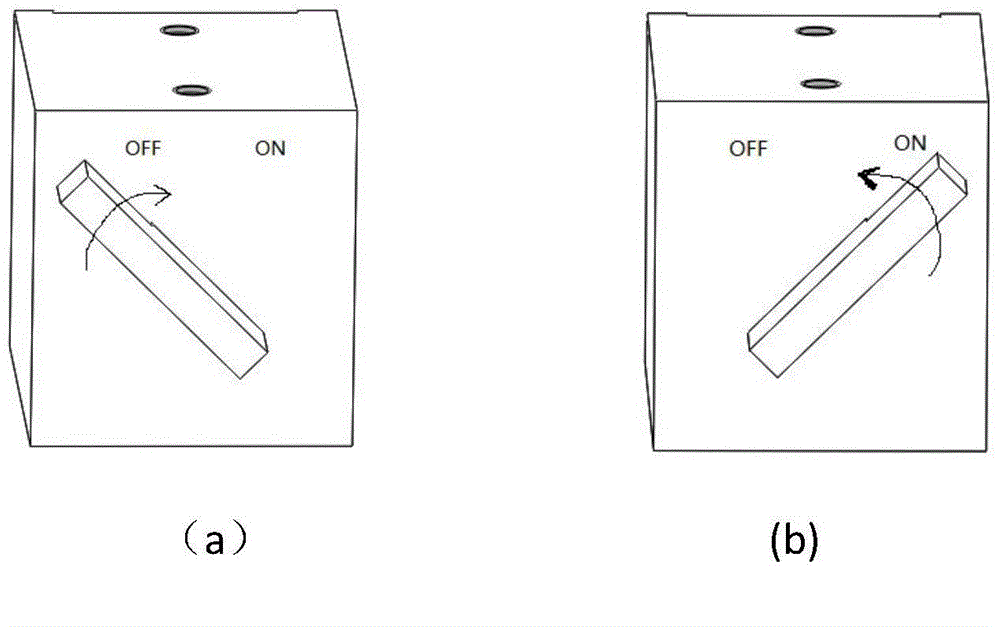

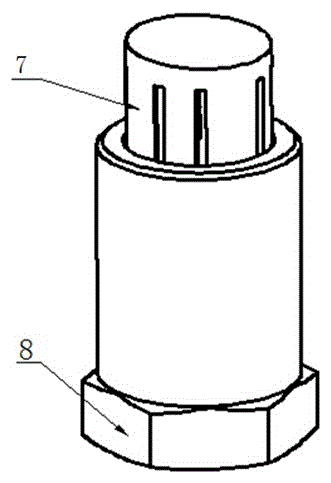

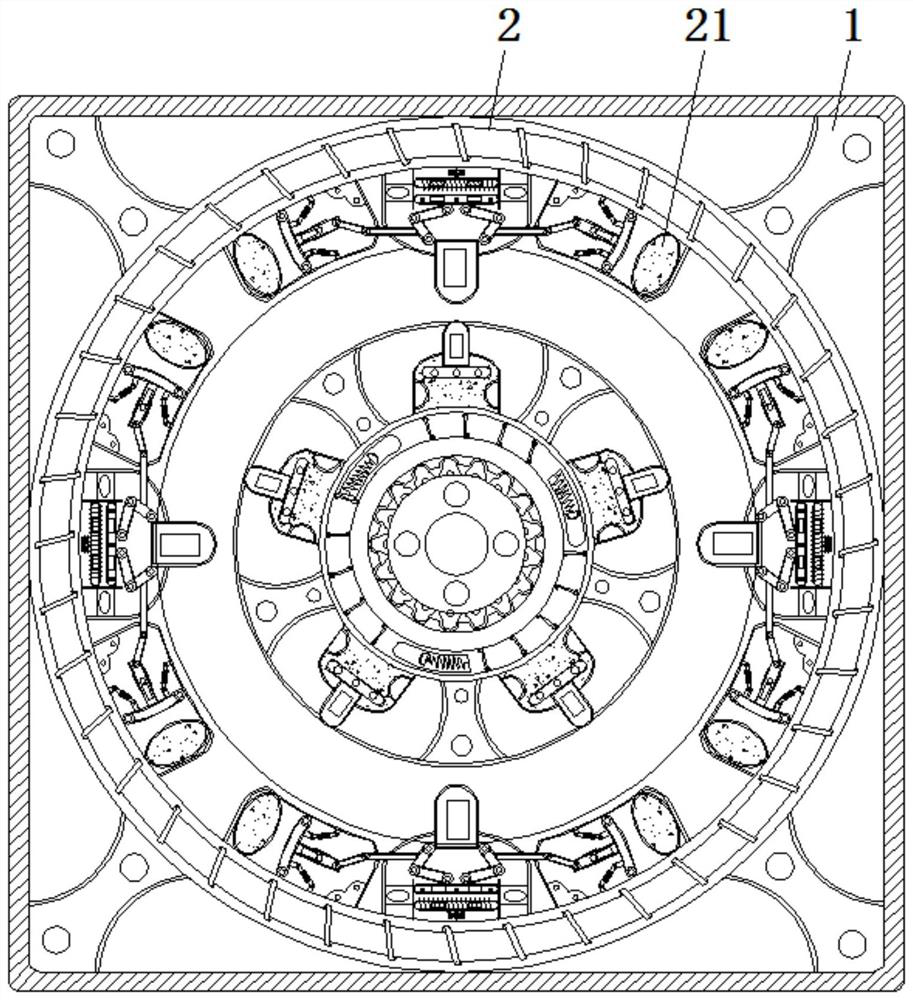

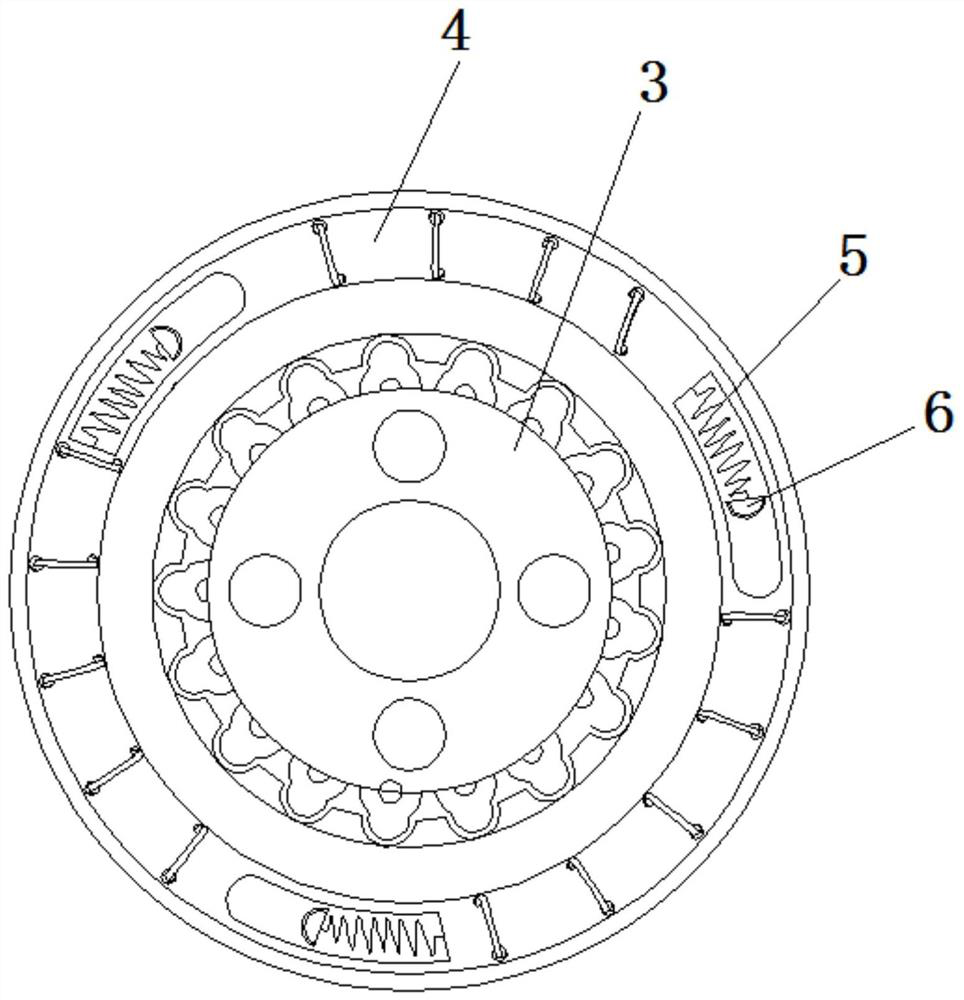

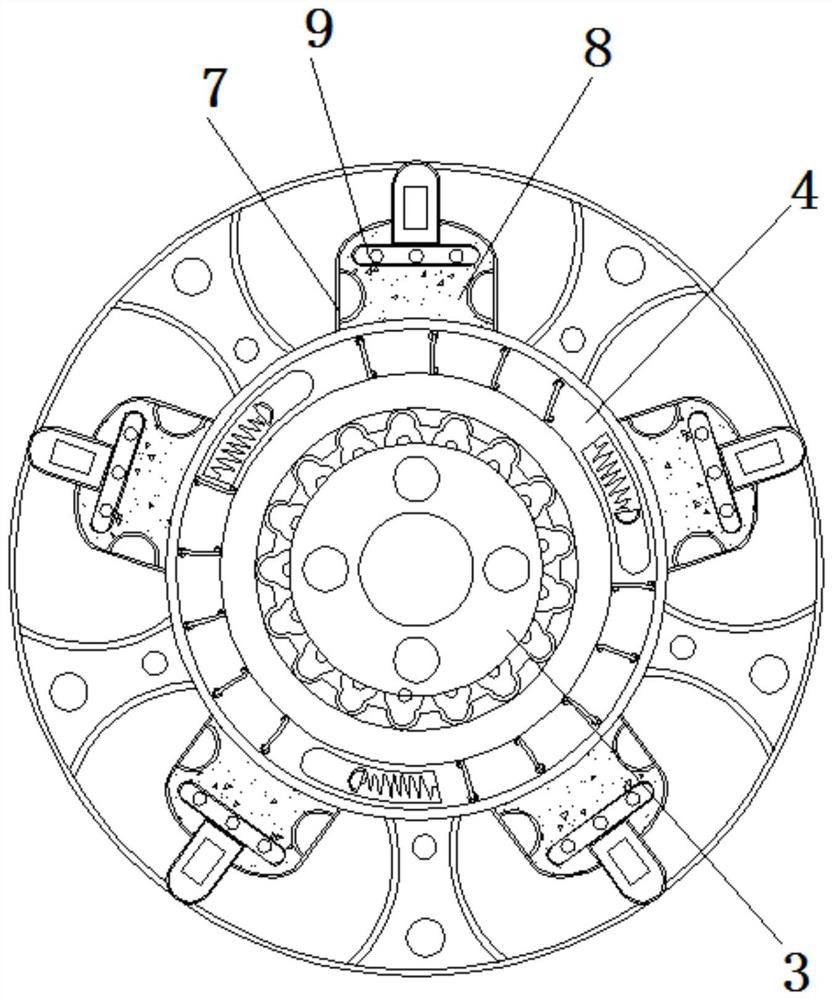

Magnetic lifting handle for assembling ferromagnetic precision workpieces

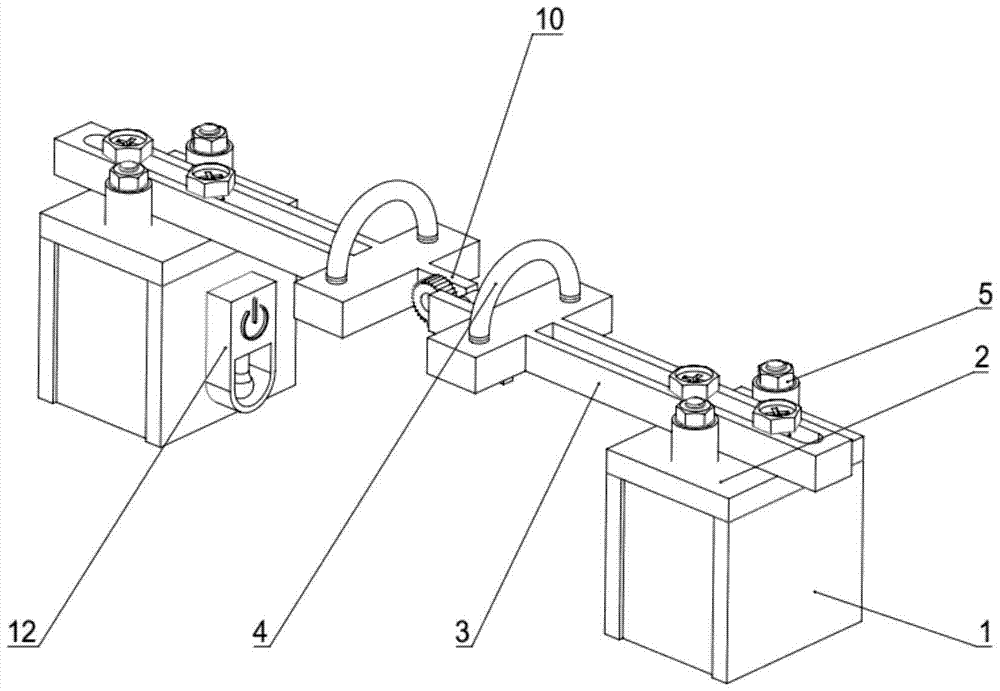

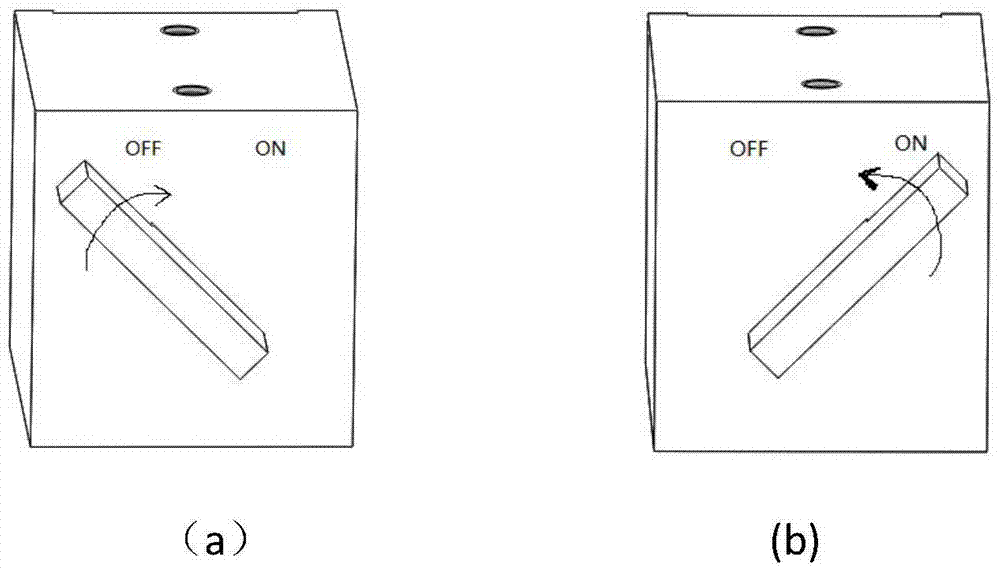

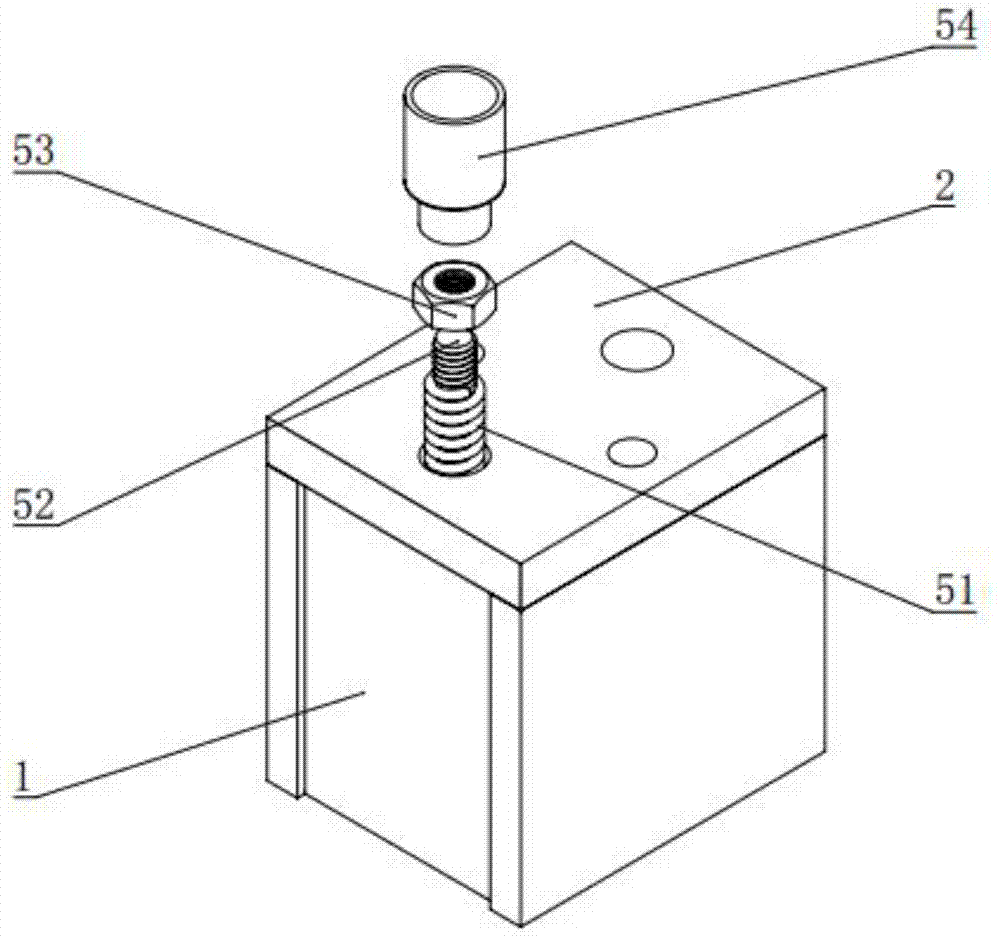

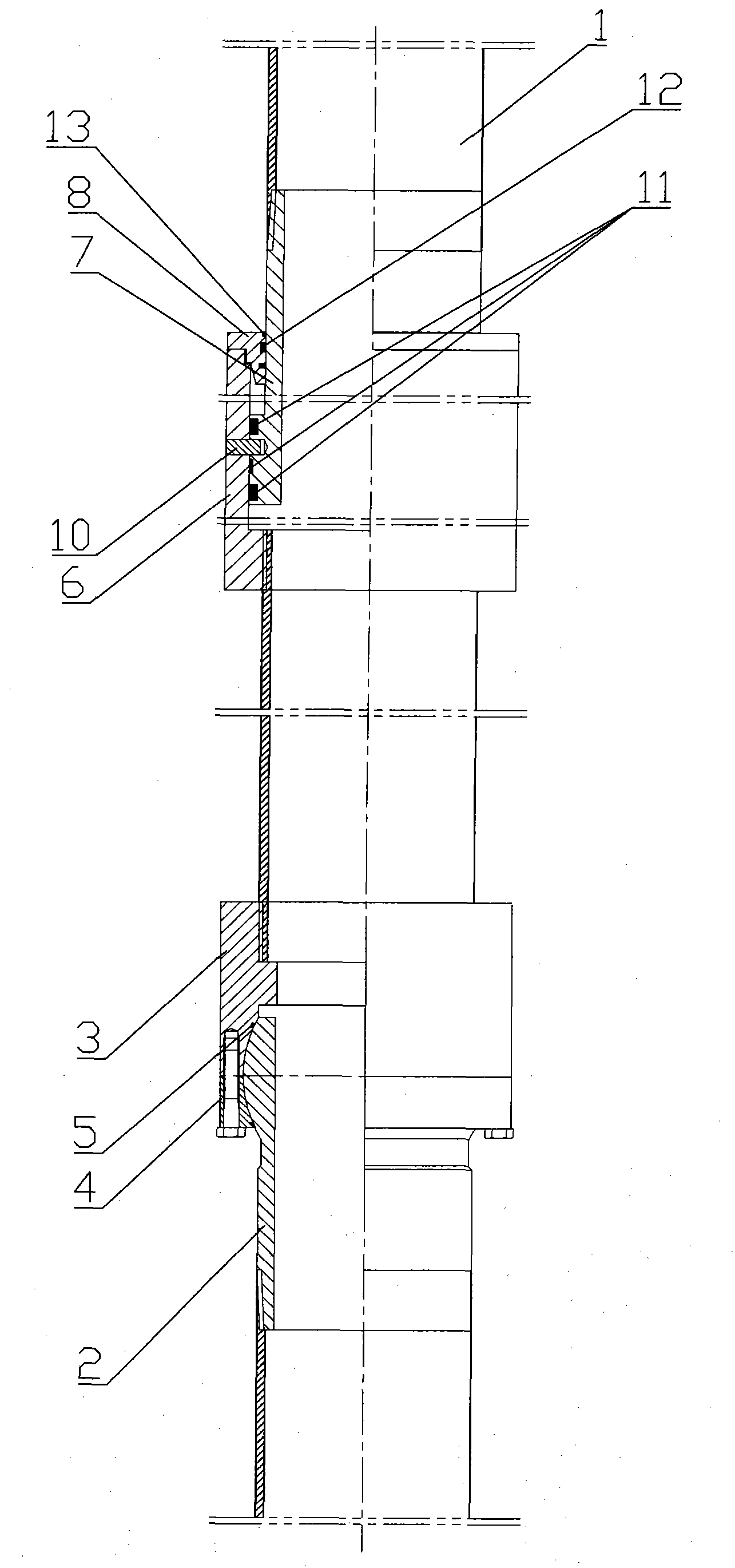

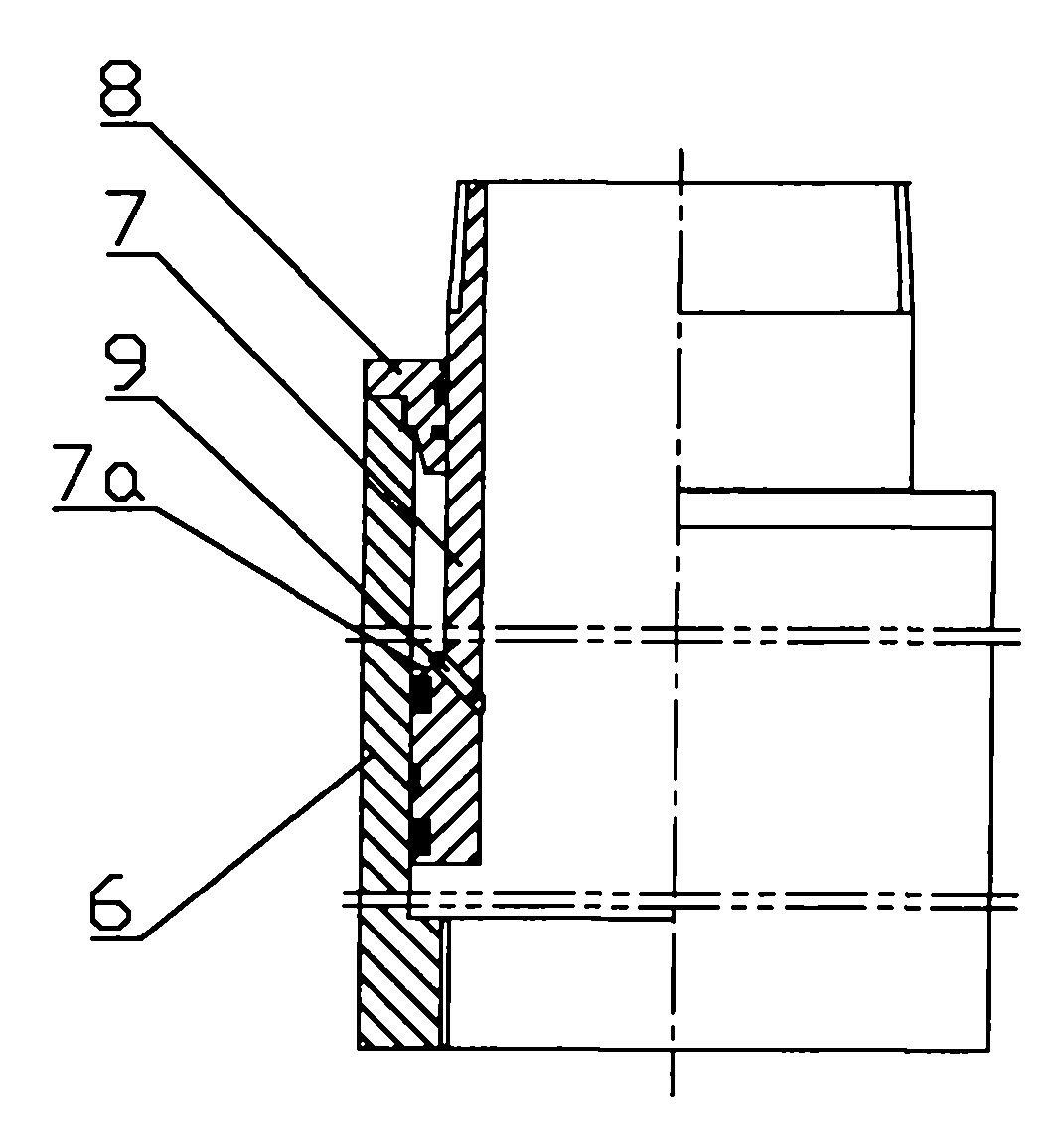

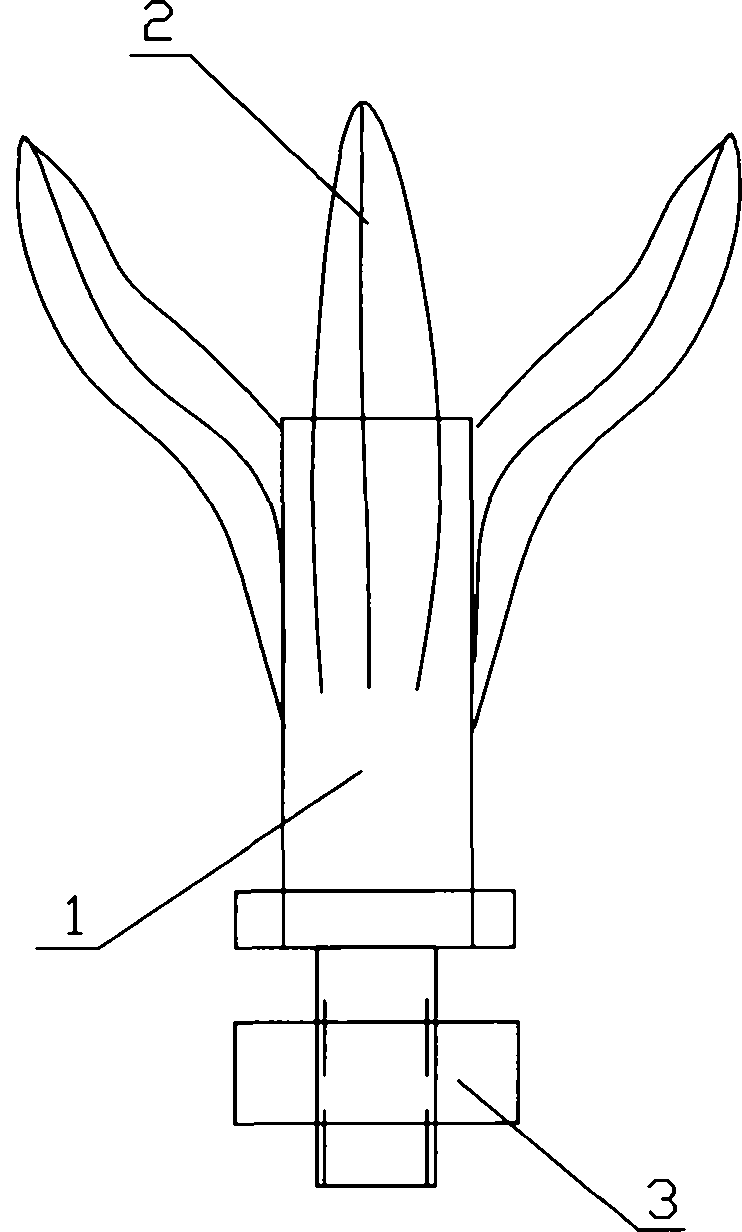

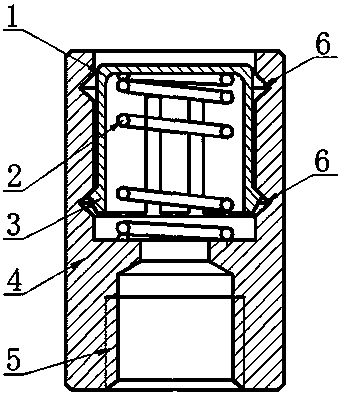

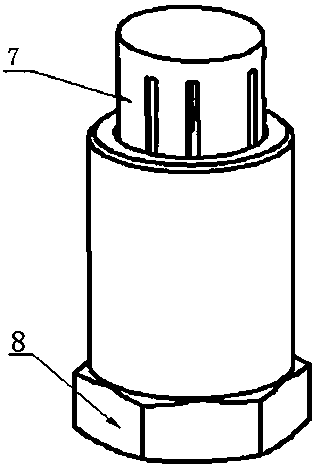

InactiveCN104900391AEasy and reliable extractionConvenient and Reliable MobilityInductances/transformers/magnets manufactureMetal-working hand toolsElectrical and Electronics engineeringEngineering

The invention relates to a magnetic lifting handle, in particular to a magnetic lifting handle for assembling ferromagnetic precision workpieces. The magnetic lifting handle comprises two magnetic actuating mechanisms and rotating adjustment mechanisms connected between the two magnetic actuating mechanisms, each magnetic actuating mechanism comprises a magnetic seat, a middle connecting plate, a force bearing arm, an elastic positioning mechanism and a handle, the upper end faces of the magnetic seat are fixedly connected with the force bearing arms through the middle connecting plates, through holes are formed in the middle connecting plates, the elastic positioning mechanisms connected with the upper end faces of the magnetic seats are arranged in the through holes, one end of each force bearing arm is connected with one side of the corresponding handle, a connecting arm for connecting the corresponding rotating adjustment mechanism is arranged on the other side of the handle, each rotating adjustment mechanism comprises a ratchet, a pawl, a rotating shaft and a spring, the ratchets are fixed on the connecting arm of one magnetic actuating mechanism, rotating ends of the pawls are connected with the connecting arm of the other magnetic actuating mechanism through the rotating shafts, and large ends of the pawls are connected with the handle of the other magnetic actuating mechanism through the springs. The magnetic lifting handle is simple in structure, convenient to use, stable and reliable, and the precision ferromagnetic workpieces can be assembled without being scratched and stained.

Owner:CHINA ELECTRIC POWER RES INST +1

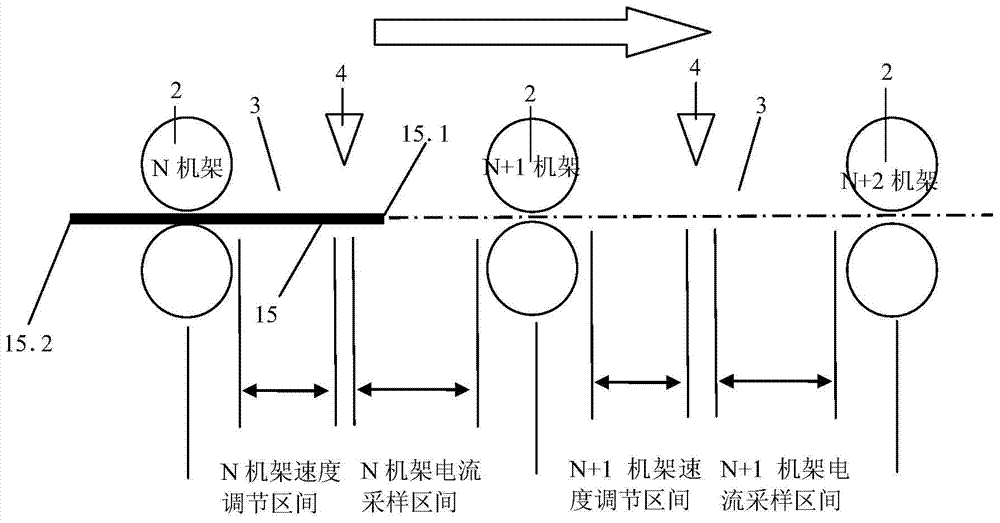

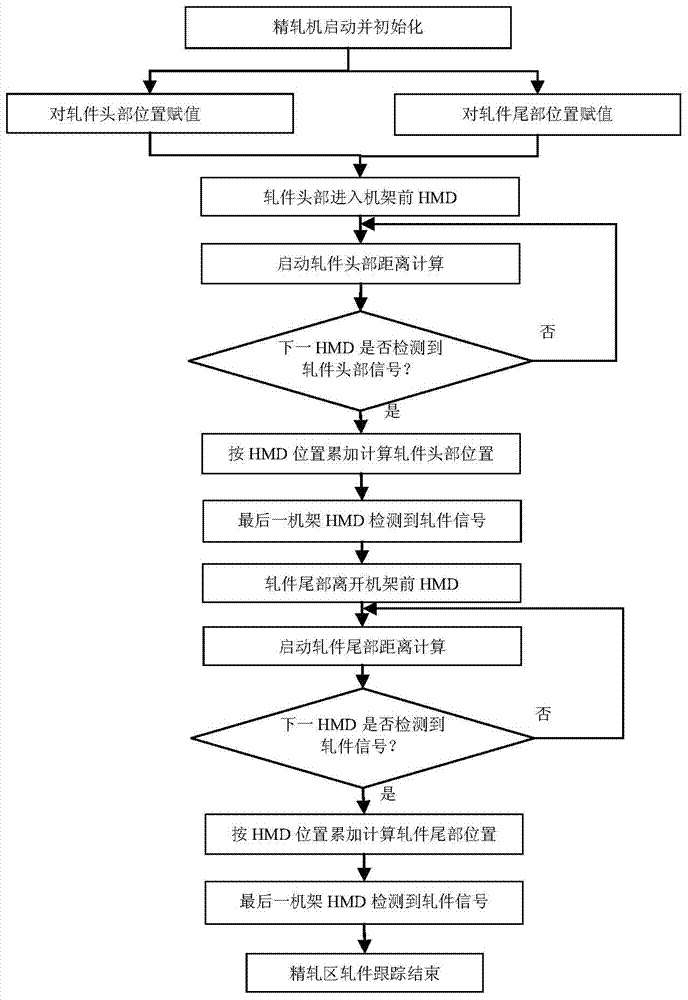

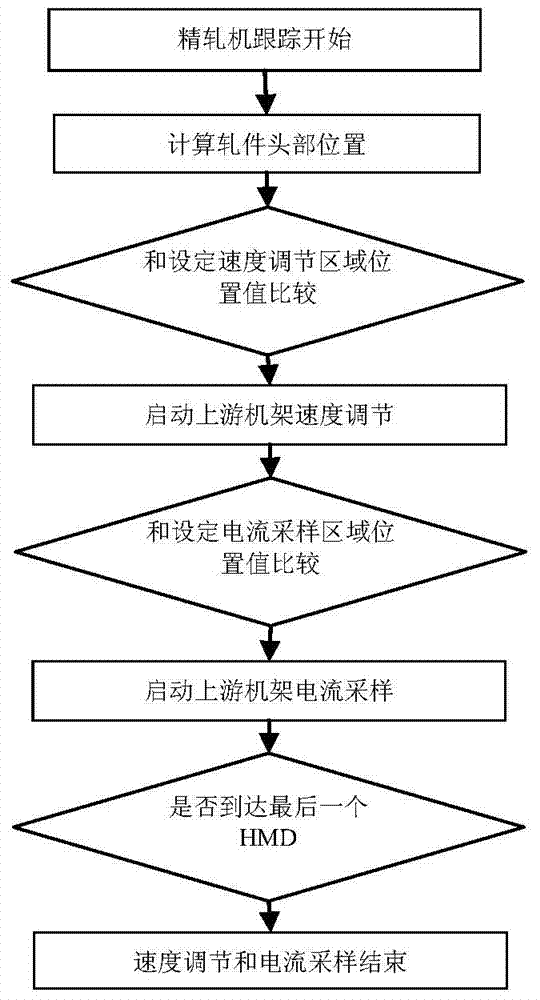

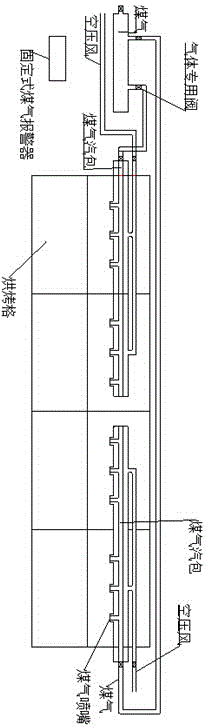

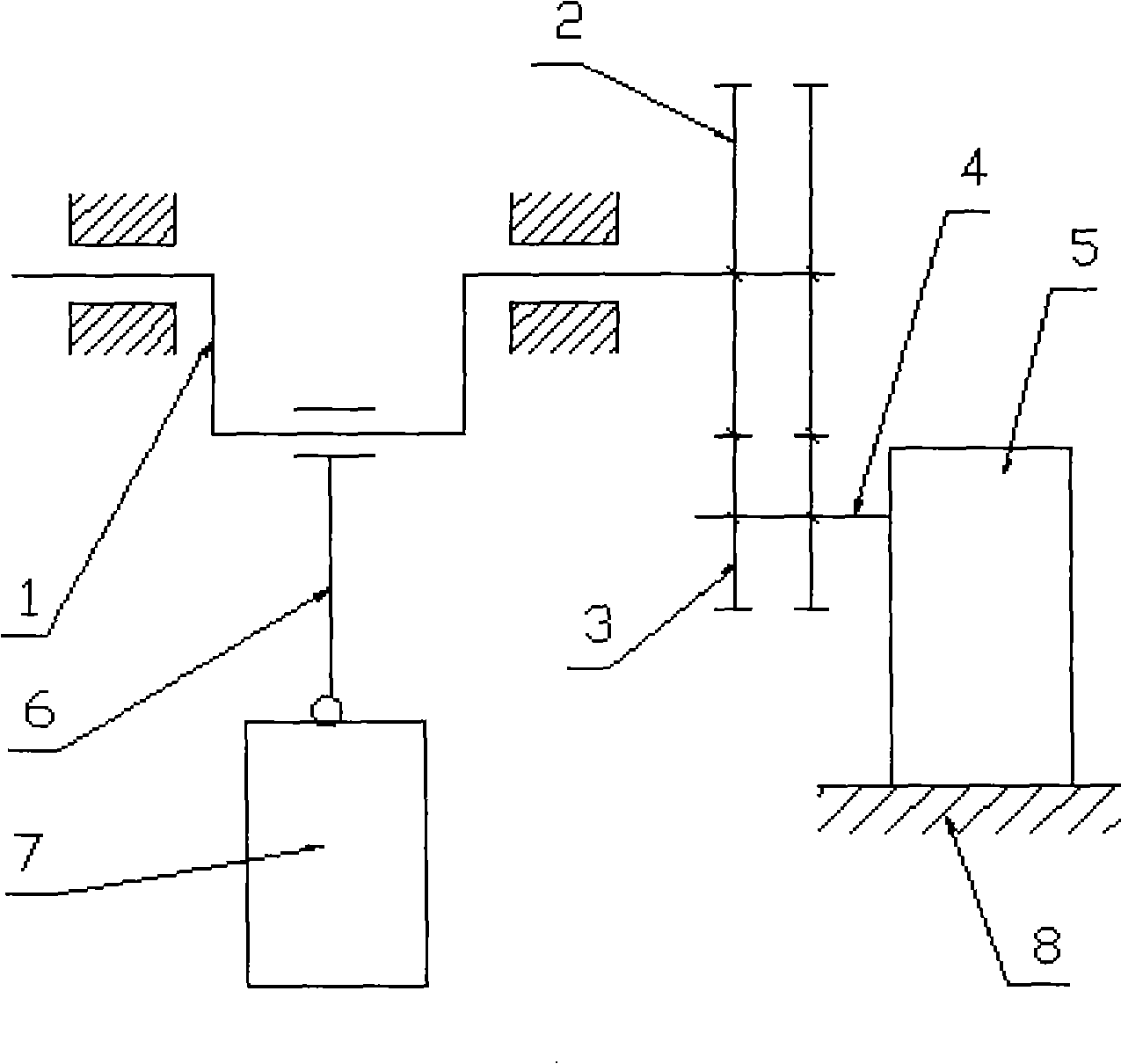

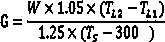

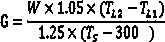

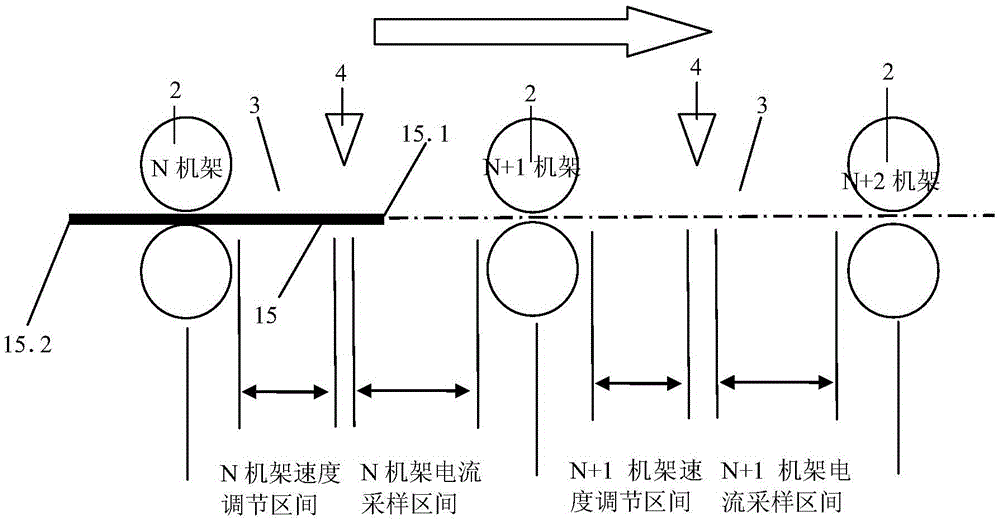

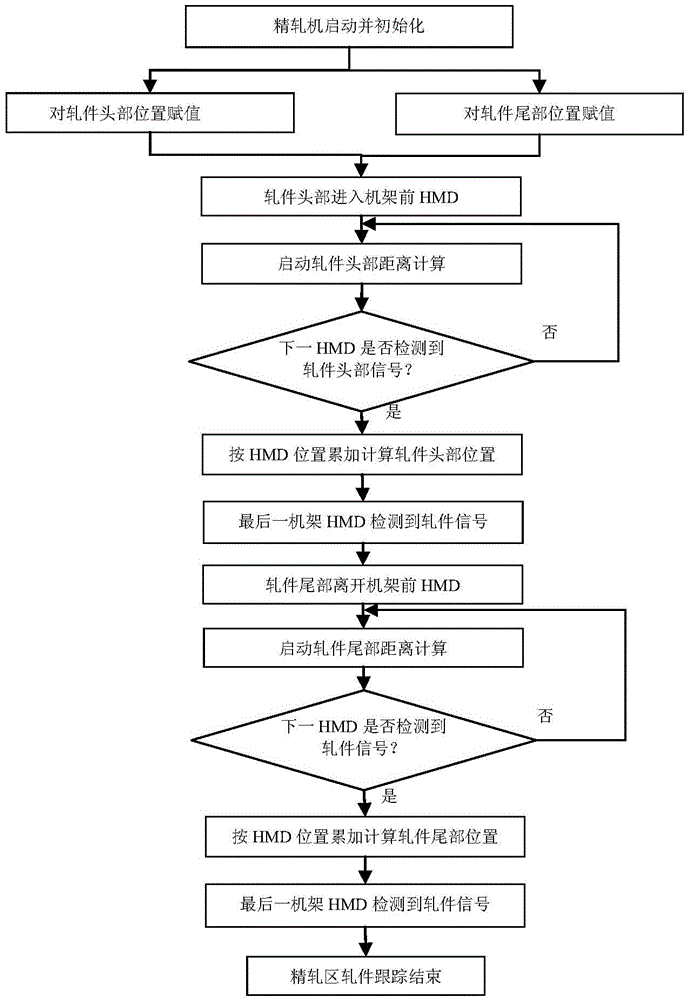

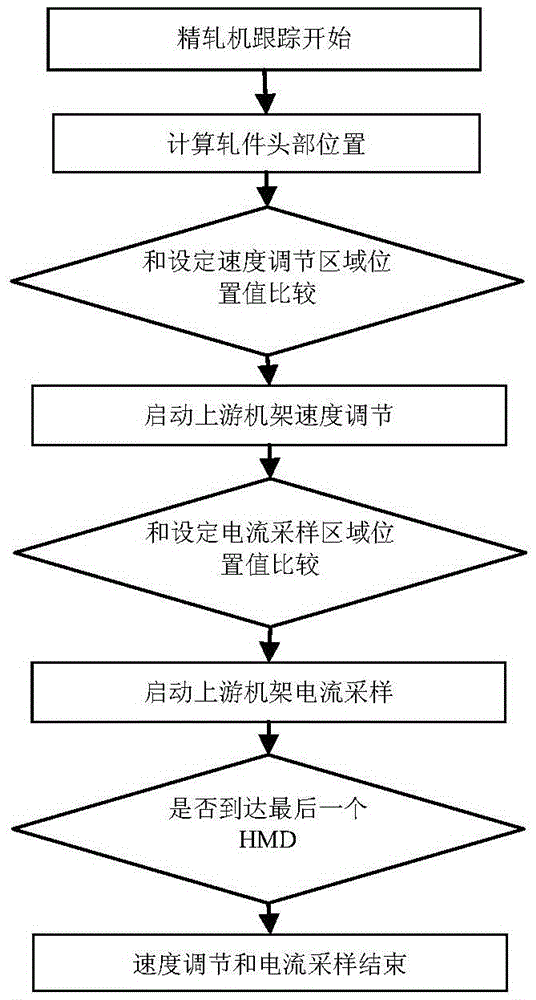

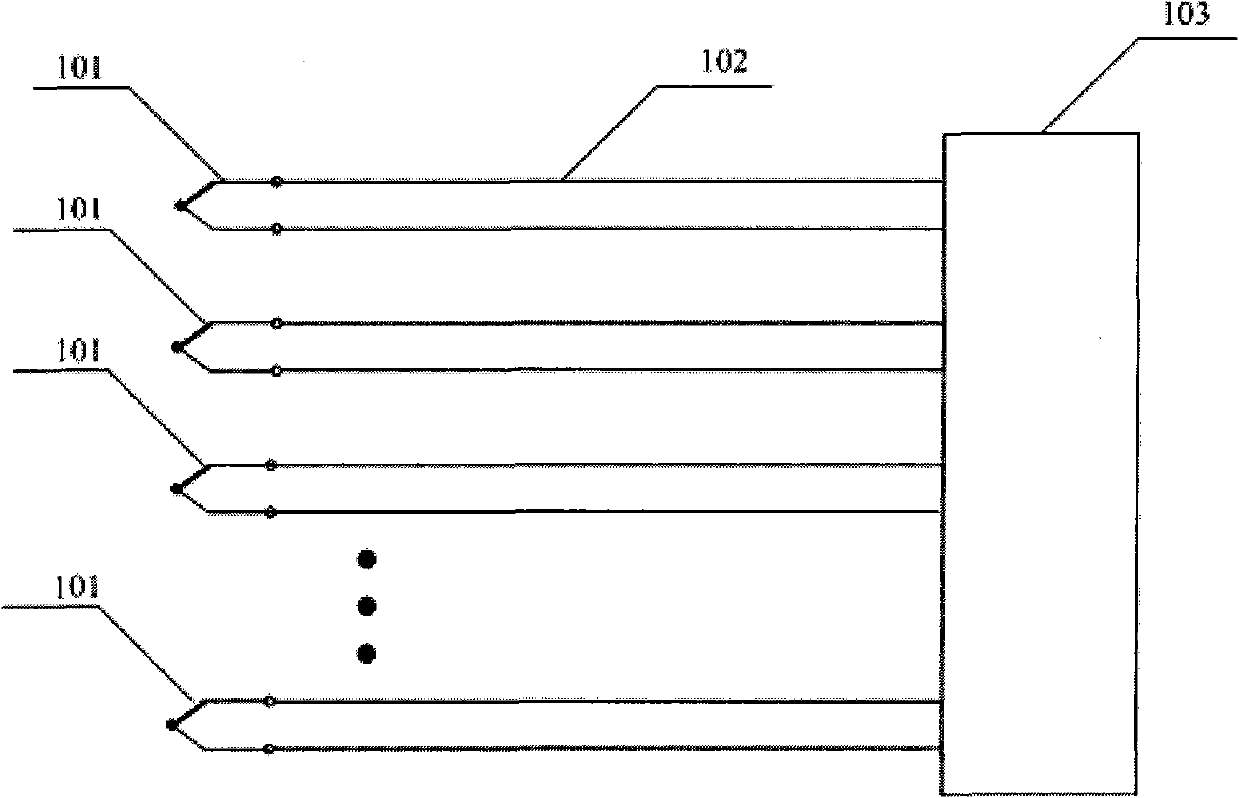

Rolled piece position tracking device and tracking method for sectional material hot rolling finishing mill

ActiveCN103499946AImprove location tracking accuracyReduce the number of manual interventionsNumerical controlLocal area networkEngineering

The invention discloses a rolled piece position tracking device for a sectional material hot rolling finishing mill. The rolled piece position tracking device comprises a machine frame, a tracking region, a zero current sampling section, a tension adjustment section, a hot metal detector, a frequency converter, a man-machine interface local area network, a high-performance controller, a man-machine interface server and a local control panel, wherein the zero current sampling section and the tension adjustment section are arranged in the tracking region, and a rolled piece position tracking control module is arranged in the high-performance controller. A rolled piece position tracking method for a sectional material hot rolling finishing mill comprises the following steps that 1, the rolled piece position tracking control module is started; 2, the position of a rolled piece in the tracking region is calculated and is compared with the position values of the tension adjustment section and the zero current sampling section; 3, the rolled piece position tracking control module finishes the tracking procedure of the current tracking region according to cascade signals and steel occluding current change signals. The rolled piece position tracking device and the rolled piece position tracking method have the characteristics that the rolled piece tracking precision is high, the manual intervention is little, the yield of hot rolling sectional materials is high, the failure rate is low, and the labor cost is low. The rolled piece position tracking device and the rolled piece position tracking method can be widely applied to the technical field of sectional material hot rolling automation control.

Owner:通用电气(武汉)自动化有限公司

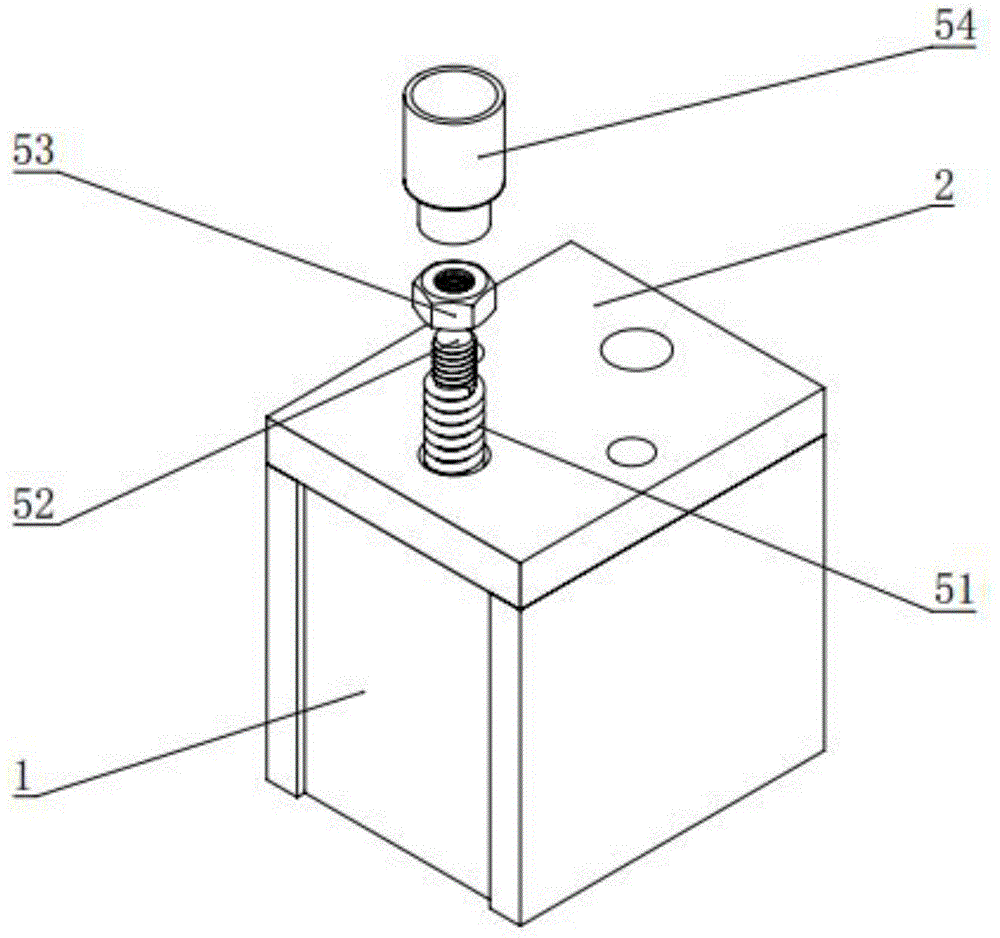

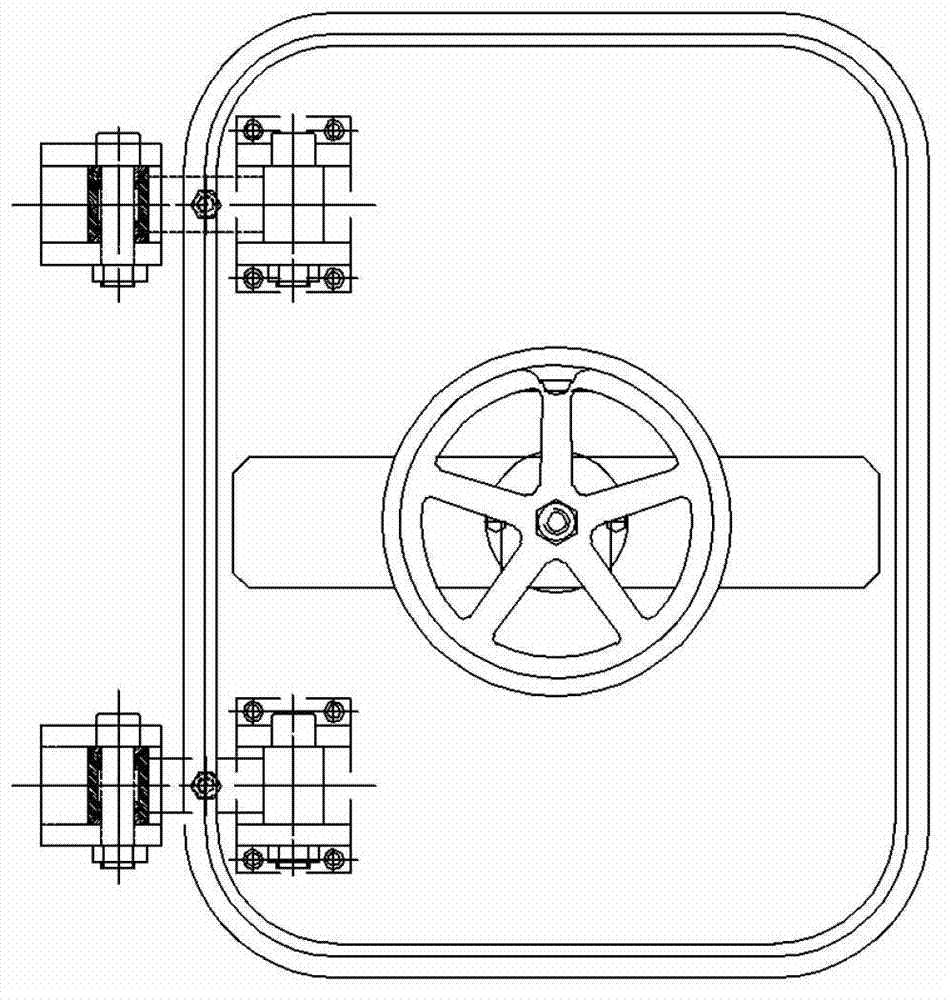

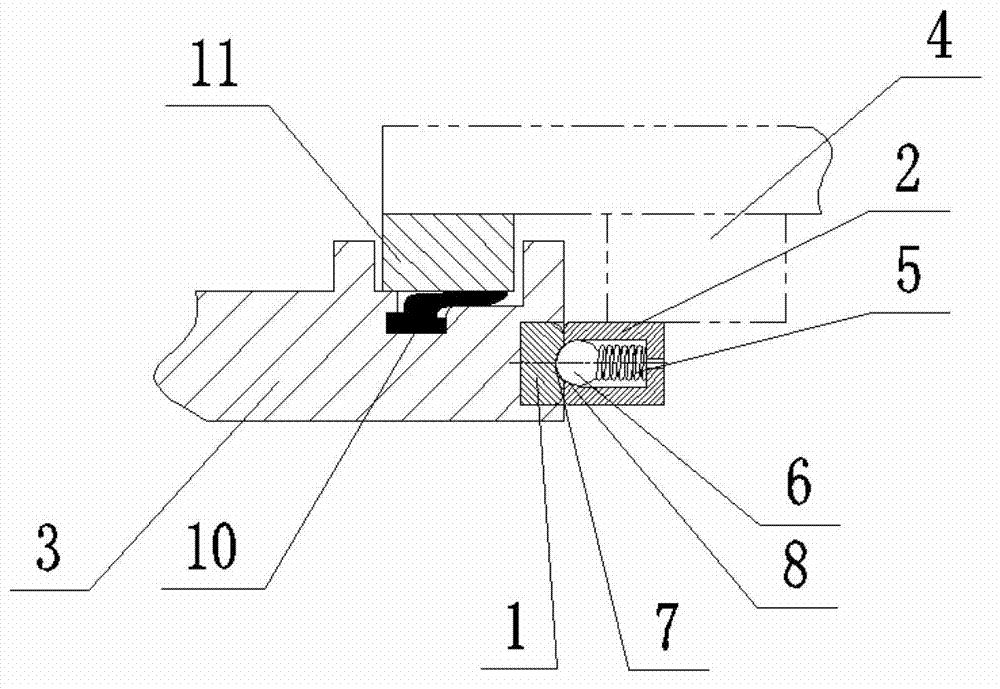

Spring locking device and cabin door comprising same

ActiveCN103195323ASimple structureImprove locking effectWing fastenersSealing arrangementsEngineeringMechanical engineering

The invention provides a spring locking device which comprises an upper clamping base and a lower clamping base, wherein the upper clamping base is fixed on the edge of a movable plate, a spherical groove is formed in one side, which is away from the movable plate, of the upper clamping base, the lower clamping base is of a cylindrical structure without a top end, and is fixed on a fixed plate by corresponding to the upper clamping base, and a clamping spring and a clamping ball the radius of which is equal to that of the spherical groove are arranged in an inner hole of the lower clamping base. In addition, the invention also provides a cabin door comprising the spring locking device. A sealing groove protruding out of the outer surface of a door sheet is formed in the periphery of the door sheet of the cabin door, and is concave, a seal is arranged at the bottom of the sealing groove, and a sealing ring corresponding to the sealing groove is arranged on a cabin body. The spring locking device is simple in structure, light in weight, and convenient to open or close; and a through hole-shaft structure is not used in the cabin door, and thus leakage channels and leakage area are reduced.

Owner:CHINA RAILWAY CONSTR HEAVY IND

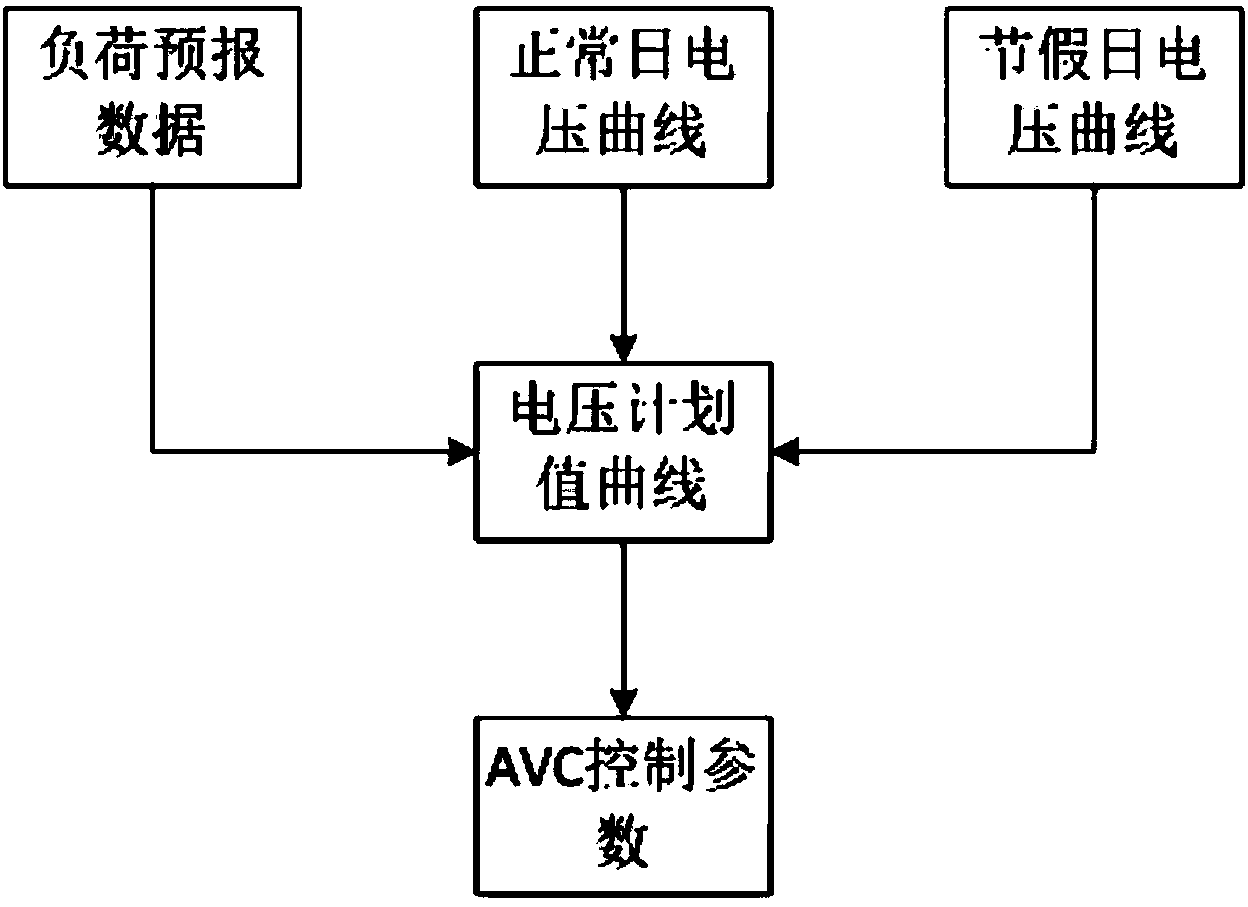

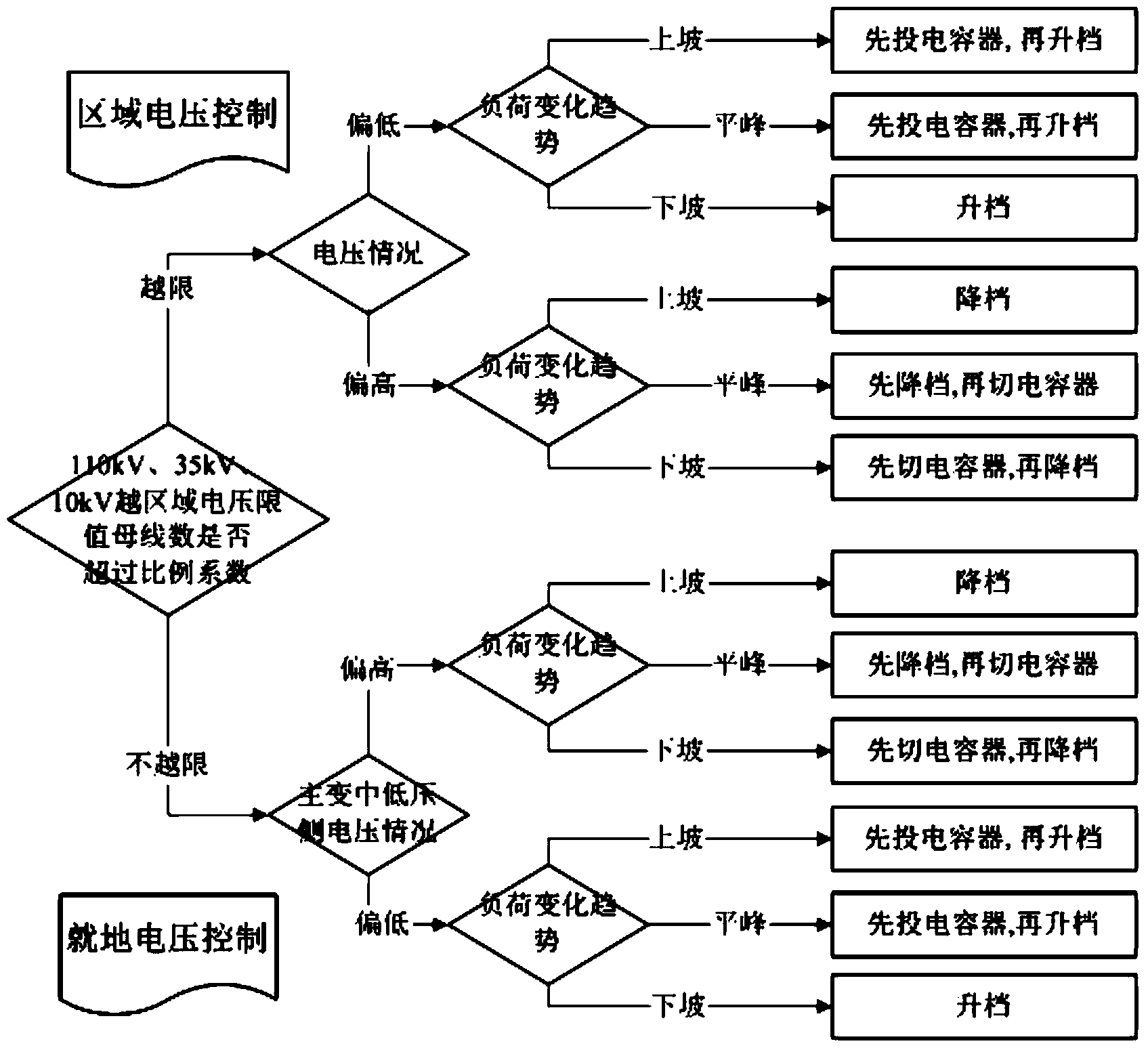

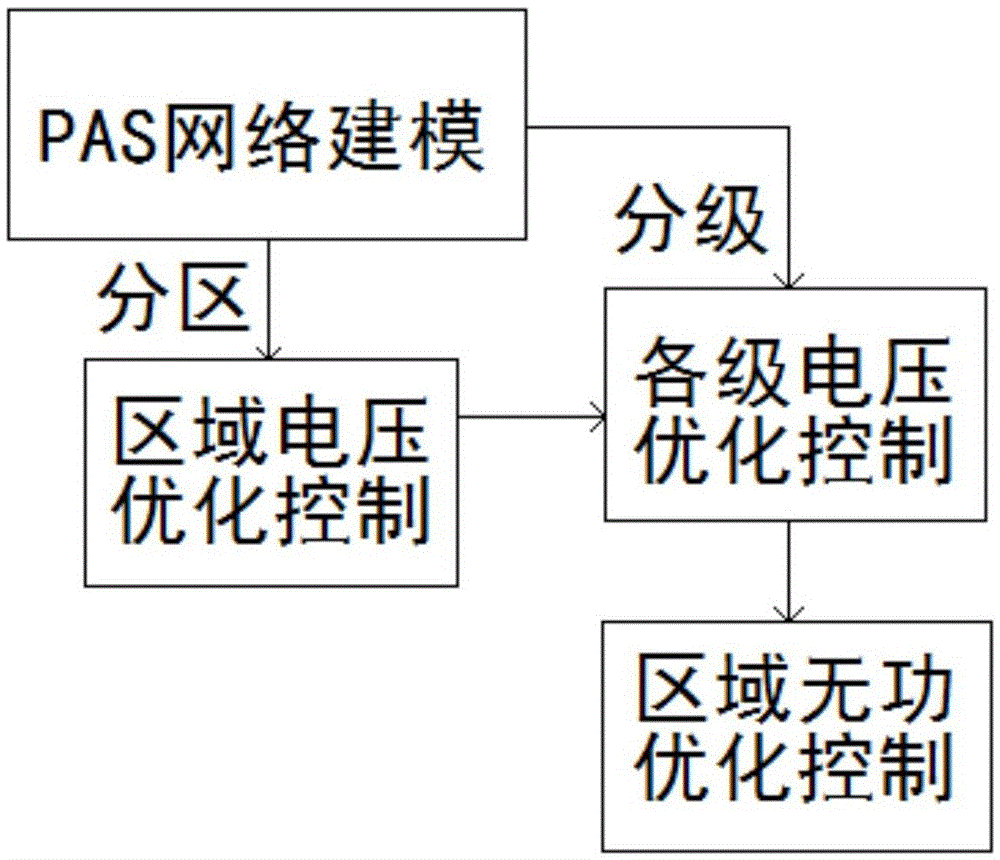

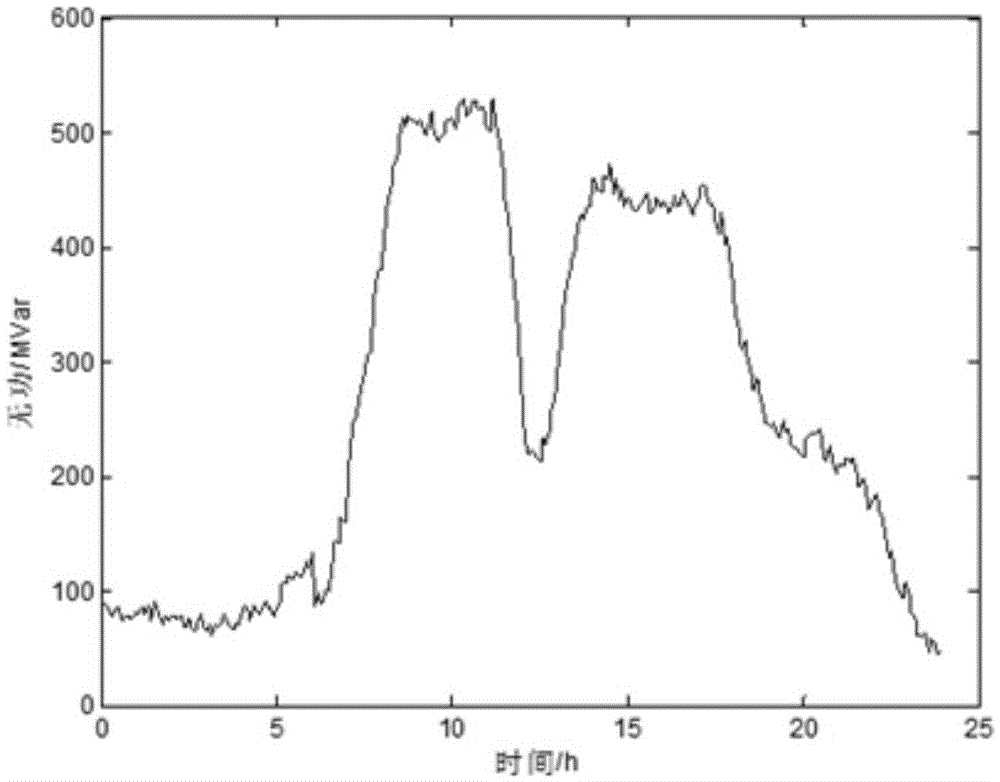

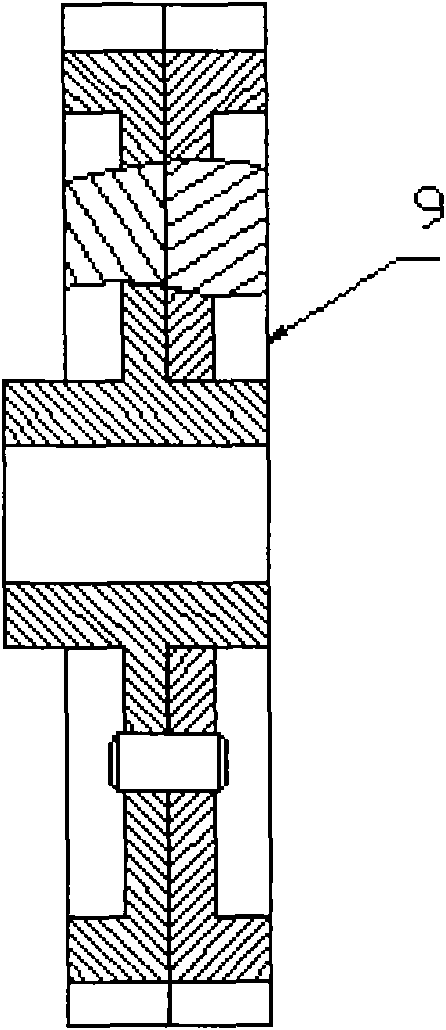

Harmonic suppression method for automatic voltage control system

ActiveCN103825275AImprove voltage pass rateThe control strategy hasReactive power adjustment/elimination/compensationReactive power compensationAutomatic controlHarmonic

The invention discloses a harmonic suppression method for an automatic voltage control system. A hierarchical partitioning control strategy is additionally arranged on the conventional automatic voltage control (AVC) system, and a charge prediction process and an electrical control property diagnosis process for considering the current state of equipment are added, so that the control strategy is predictable; meanwhile, advanced control is realized according to a running state of the equipment, and operation time delay of the equipment is reduced. An experiment result shows that the system has better effects of improving the voltage qualified rate of a power grid and optimizing the reactive power. The novel system optimizes the equipment operation frequency in the whole time sequence, so that the equipment damage accidents caused by frequent operation of the equipment are obviously reduced, and the service life of the equipment is prolonged.

Owner:STATE GRID CORP OF CHINA +1

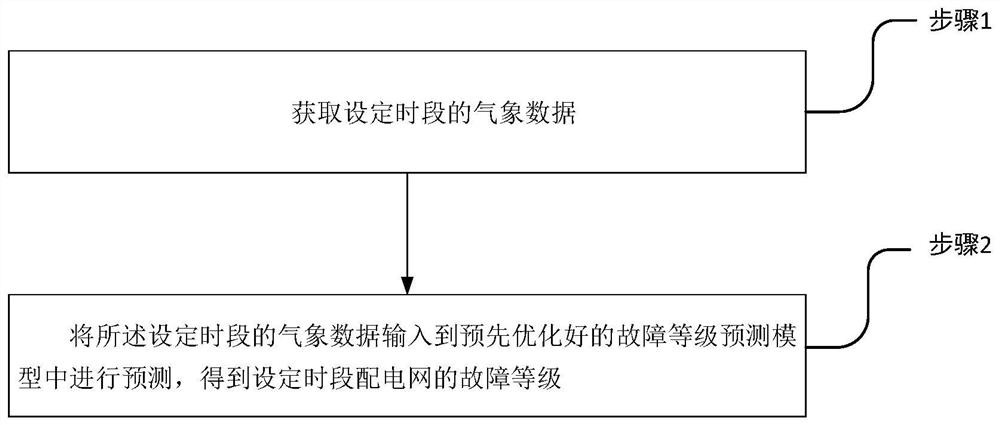

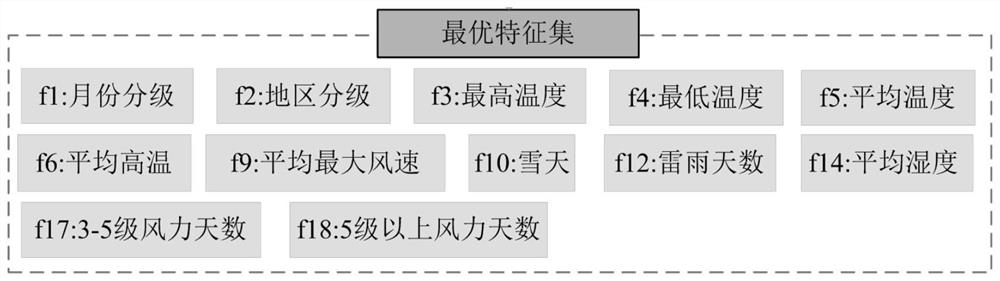

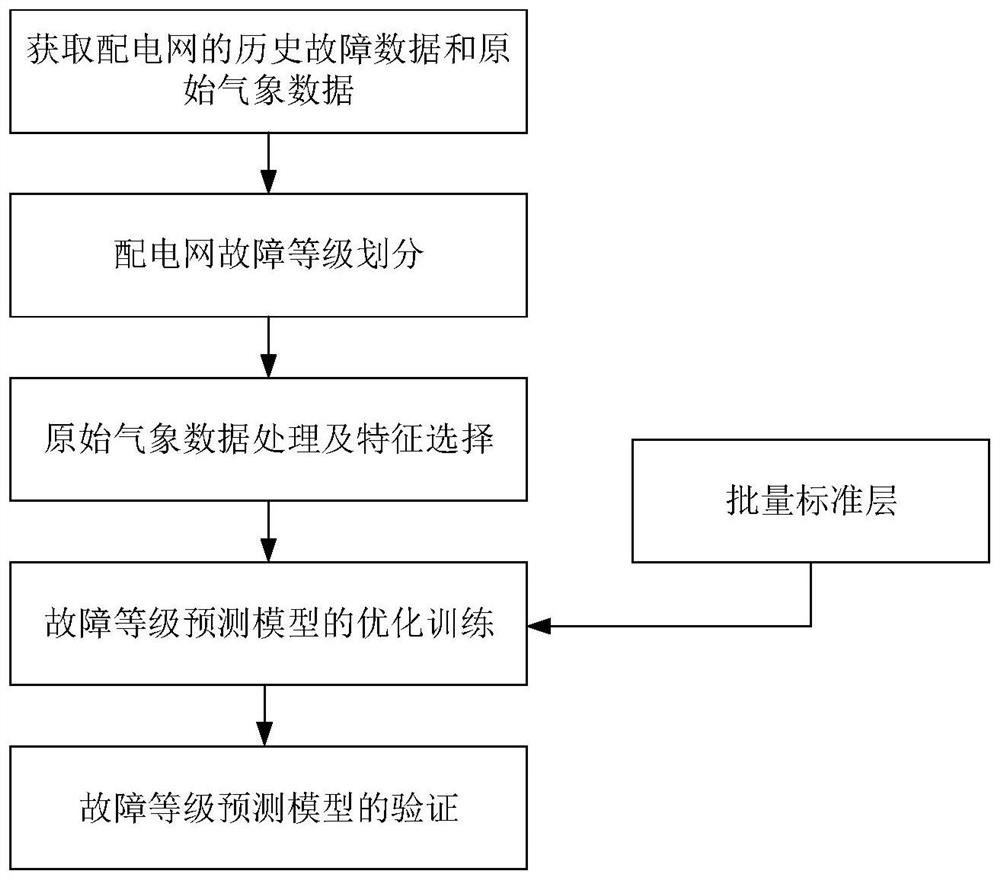

Power distribution network fault level prediction method and system considering weather factors

PendingCN113569462AImprove accuracyEarly warning is accurateDesign optimisation/simulationWeather factorSimulation

The invention provides a power distribution network fault level prediction method and system considering weather factors. The method comprises the following steps: acquiring meteorological data of a set time period; inputting the meteorological data of the set time period into a pre-optimized fault level prediction model for prediction to obtain a fault level of the power distribution network of the set time period, wherein the optimized fault level prediction model is obtained by performing optimization training on historical meteorological data obtained in advance and the historical fault level of the corresponding power distribution network based on a multi-support vector machine. Based on the multi-support vector machine model, the accuracy of fault level prediction of the power distribution network is improved, and accurate early warning can be effectively carried out on the fault which is about to occur in the power distribution network.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

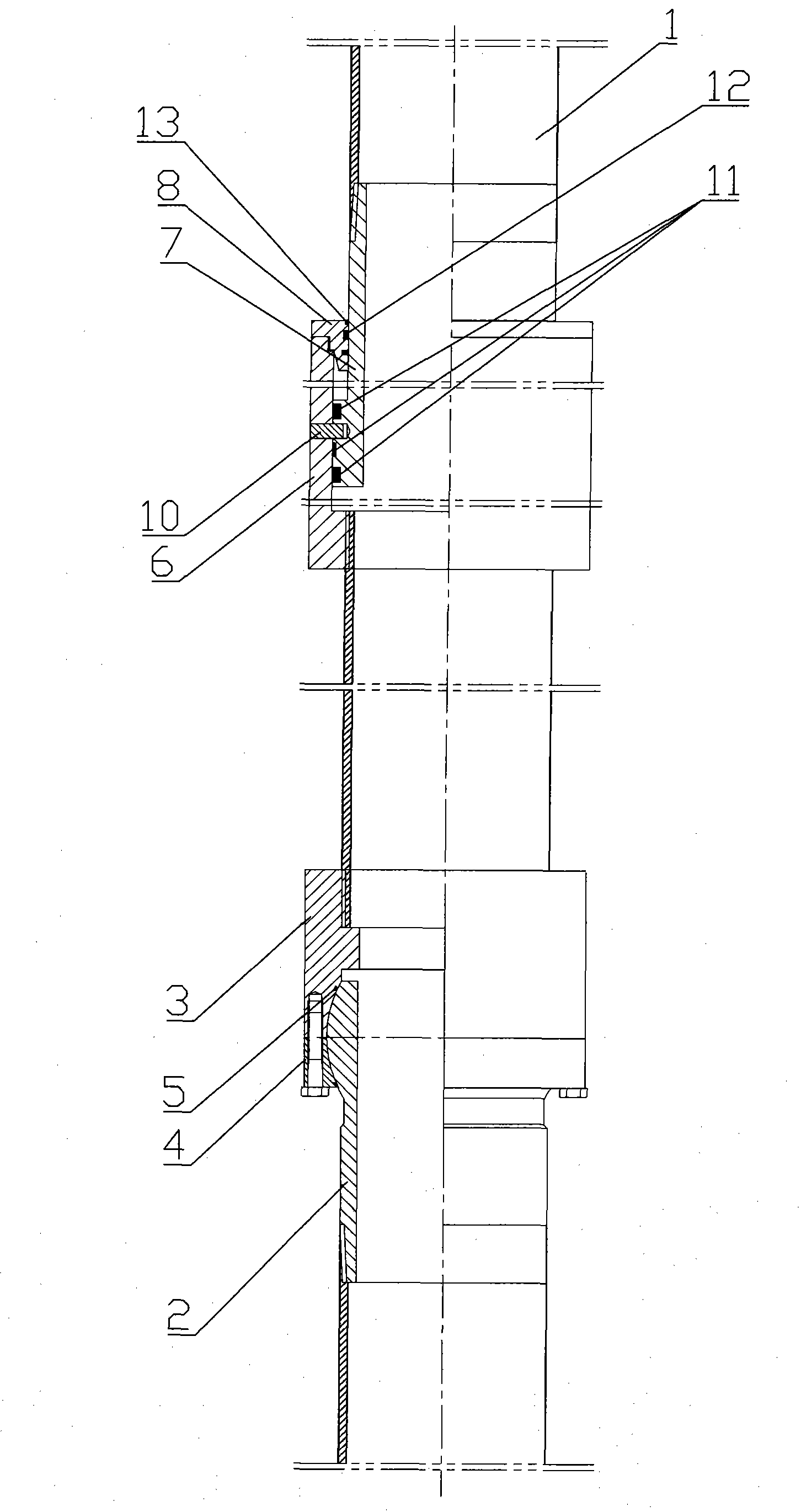

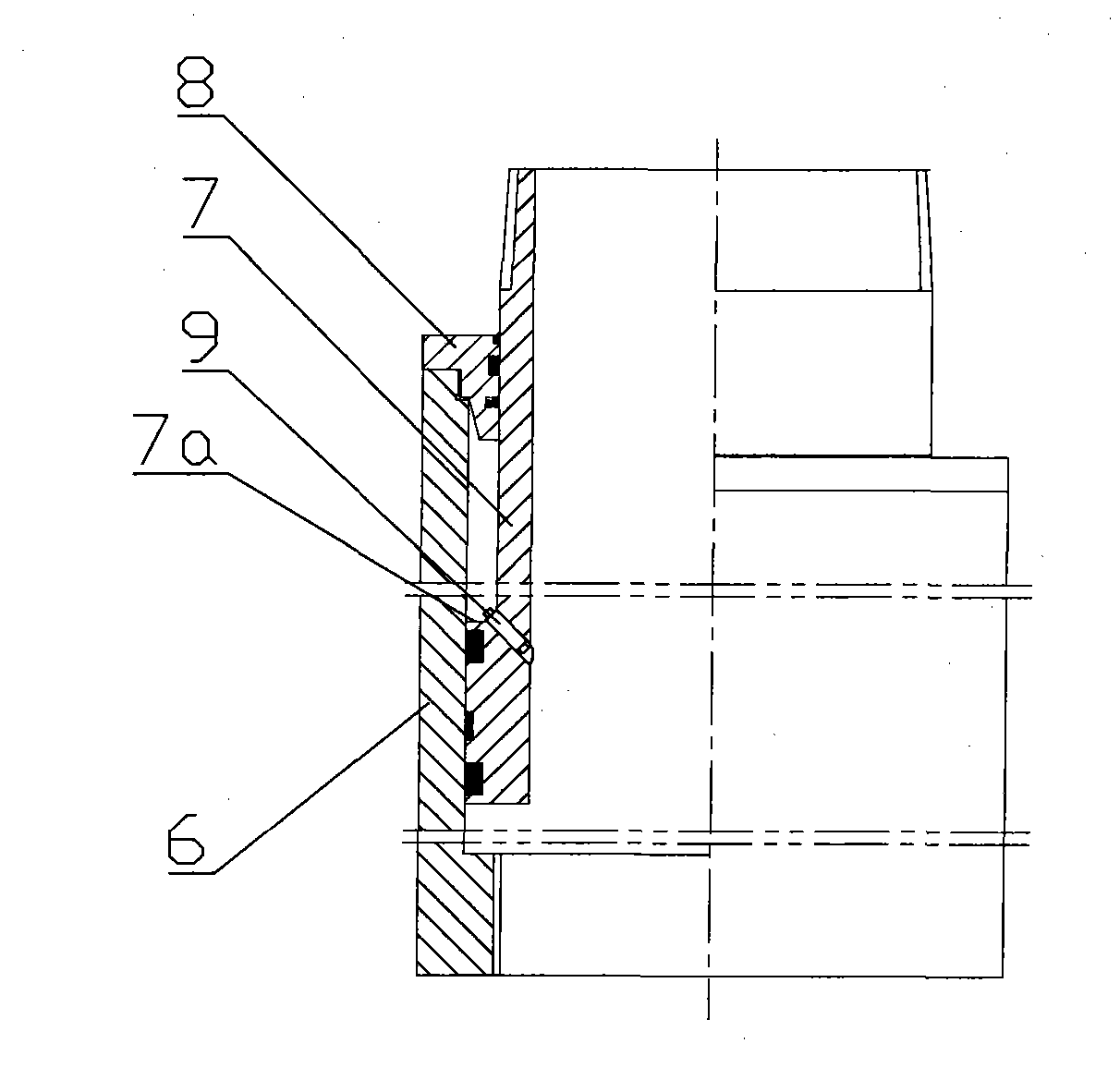

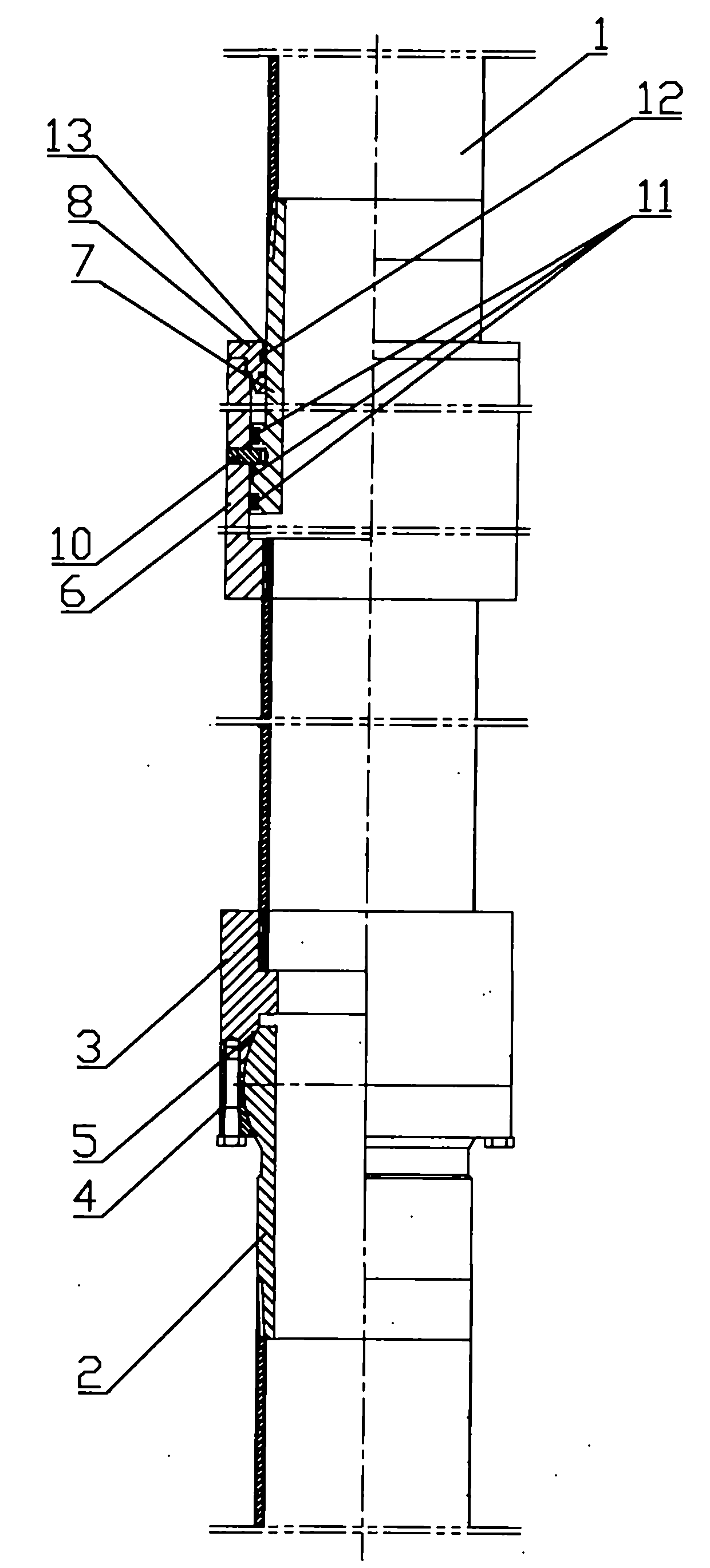

Ground well casing capable of preventing mining damage

ActiveCN101915063AReduce damage accidentsWell drawnDrilling rodsDrilling casingsExpansion jointGround level

The invention discloses a ground well casing capable of preventing mining damage, which comprises at least two casing bodies, a deflection joint and an expansion joint, adjacent casing bodies are connected by the deflection joint or the expansion joint, when in use, according to analysis results of strata displacement, the casing bodies are connected by the deflection joint in the depth corresponding to strata where the casing is easy to cut and twist, the casing bodies are connected by the expansion joint in the depth corresponding to strata where the casing is easy to pull and press, and the casing bodies are connected after the deflection joint and the expansion joint are connected in series in a small depth range corresponding to strata where the casing is easy to not only cut and twist but also pull and press, so that the casing can adapt to strata variation, thus reducing damage accidents of the well casing and guaranteeing smooth gas extraction through the ground well.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

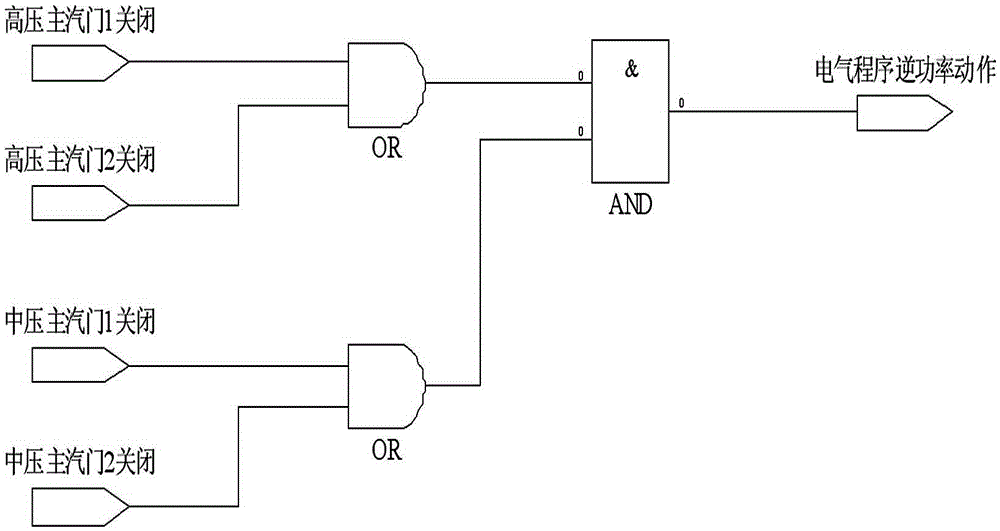

Checking method for preventing failure of thermal process protection system of thermal generator set

ActiveCN105332744ACoverage determinationVerification steps are concise and clearMachines/enginesSafety/regulatory devicesAutomatic controlEngineering

The invention belongs to the technical field of automatic control of thermal generator sets, and particularly relates to a checking method for preventing failure of a thermal process protection system of a thermal generator set. The thermal process protection system comprises the following elements: design of the logic of a main protection system of the set, design of an important auxiliary engine protection system of the set, measuring and sampling by an instrument, and allocation of DCS hardware addresses; the inspection method comprises the following steps: collecting the design data of the thermal process protection system, and knowing the composition condition, the operation mode and the operation parameters of the thermal process protection system of the thermal generator set; checking the thermal process protection system of the thermal generator set by referencing to the latest national electric power industry regulations and specifications, and finding design defects and potential safety hazards; proposing a regulating solution for on-site regulation, finishing a static test and a dynamic test, and putting the thermal generator set into safe operation; and if the requirements are not met, returning to the regulation and test steps till meeting the requirement. The checking method has the advantages that the checking steps are simple and clear, the safety and the reliability are realized, the on-site debugging process is simple, and the operation and the implementation are convenient.

Owner:STATE GRID CORP OF CHINA +1

Fixed alloy gas roasting device

The invention discloses a fixed alloy gas roasting device which comprises four roasting grids, two gas steam pockets and an air steam pocket, wherein the four roasting grids form an alloy storage bin; the two gas steam pockets are arranged in the alloy storage bin; a shared air steam pocket is arranged outside the alloy storage bin; each gas steam pocket is used by two roasting grids; three gas nozzles are arranged in each roasting grid; the outer side of a gas pipe in the gas steam pocket is coated with an air pipe of the air steam pocket; and special gas valves are arranged at the gas inlets and outlets of the gas steam pockets and air steam pocket. According to the device disclosed by the invention, four alloys can be simultaneously roasted, pressure of gas and air can be stabilized by the steam pockets, the amount of the roasted alloys is about 4-8tons, continuous production of lots of roasted alloys is met, the operation is simple, the flexibility is high, the gas energy can be saved, the smelting cost of tons of steel is reduced, and personal injury or equipment damage accidents are reduced.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

Temperature-sensitive indication nut

The invention discloses a temperature-sensitive indication nut, comprising a pedestal, a temperature-sensitive element and an induction column. The pedestal is provided with a cylindrical storage slot with an opening in the top. An inner wall of the storage slot is provided with clamp grooves. The induction column is mounted in the storage slot. An outer wall of the induction column is provided with clamp claws cooperated with the clamp grooves. The induction column has a hollow cylindrical structure which is open at the lower end and closed at the top. The induction column is internally provided with the temperature-sensitive element. The temperature-sensitive indication nut is reasonable in design and simple in structure. The temperature-sensitive indication nut is mounted at a position, in need of temperature detection, of power equipment. The shape memory effect of shape memory alloy is utilized to timely monitor the temperature of a power line joint, thereby helping inspection persons to timely find the power line joint, and further grasping change in temperature of the power line joint. Therefore, potential safety hazards of system operation are eliminated, and the normal operation of system equipment is ensured.

Owner:兰州西脉科立新材料有限公司

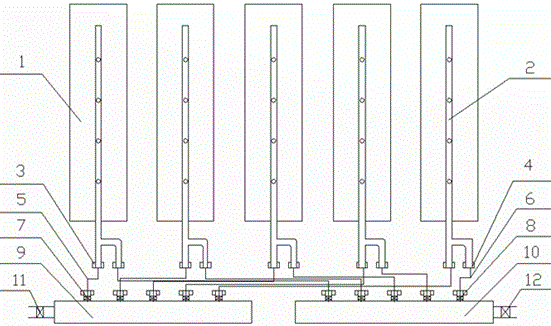

Detachable multi-hopper type alloy gas baking device

InactiveCN104152624AGuaranteed baking temperatureReduce waiting timeProcess efficiency improvementCouplingAlloy

The invention discloses a detachable multi-hopper type alloy gas baking device. The detachable multi-hopper type alloy gas baking device comprises scrap steel hoppers, oxygen blowing pipes, quick couplings A, quick couplings B, metal hoses A, metal hoses b, gas dedicated ball valves A, gas dedicated ball valves B, a gas steam pocket, an air compressing wind steaming pocket, a gas dedicated ball valve C and a gas dedicated ball valve D. According to the device, about 20 tons of alloy can be baked at one time, and small-tonnage multi-kind alloy baking can be achieved. The occupied space is small, the device can be suitable for multiple stations of a revolving furnace, an argon oxygen furnace, a high-steel refining furnace and the like, and it is ensured that the alloy baking temperature is larger than or equal to 200 DEG C. The aim that the alloy is added in the furnaces rapidly, safely and economically is achieved, in-furnace alloy baking meets the technological requirements, and therefore gas in in-furnace steel is controlled, molten steel waiting time is reduced, the tonnage steel smelting cost is reduced, and the personal injury or equipment damage accident is reduced.

Owner:XINXING DUCTILE IRON PIPES CO LTD

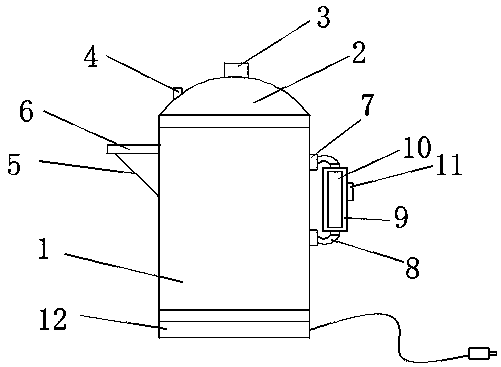

Anti-burning electric kettle

InactiveCN108937563AReduce damage accidentsReduce the temperatureBoiling over preventionWater-boiling vesselsClamp connectionWater vapor

The invention relates to the technical field of household appliances and discloses an anti-burning electric kettle. The kettle comprises a kettle body. The kettle body comprises a heat conduction sheet. The outer surface of the heat conduction sheet is fixedly connected with a heat radiation board. Two sides of the heat radiation board are in clamp connection with two sides of the heat radiation board. The top of the kettle body is movably connected with a kettle cover. The top of the kettle cover is fixedly connected with a lifting handle. The upper surface of the kettle cover is equipped with an air communicating pipe. One side of the kettle body is fixedly connected with a kettle spout. The upper surface of the kettle spout is movably connected with a kettle spout cover. The other sideof the kettle body is fixedly connected with two fixing blocks. One sides of the two fixing blocks are fixedly connected with connecting rods. A holding gap is fixedly connected between the two connecting rods. When water is boiled, water does not overflow because the kettle spout cover is added on the kettle spout and is converted into water vapor by the air communicating pipe and finally discharged. Damage to a plug seat is avoided because water is boiled and overflows. Additionally, the kettle is safer.

Owner:河南骐驭软件科技有限公司

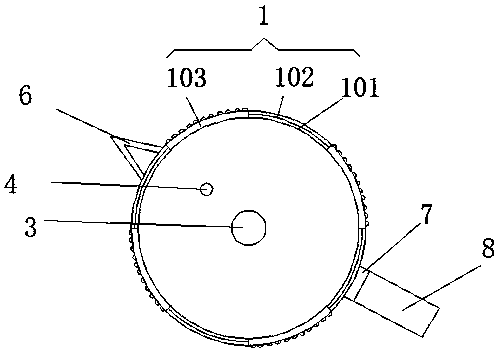

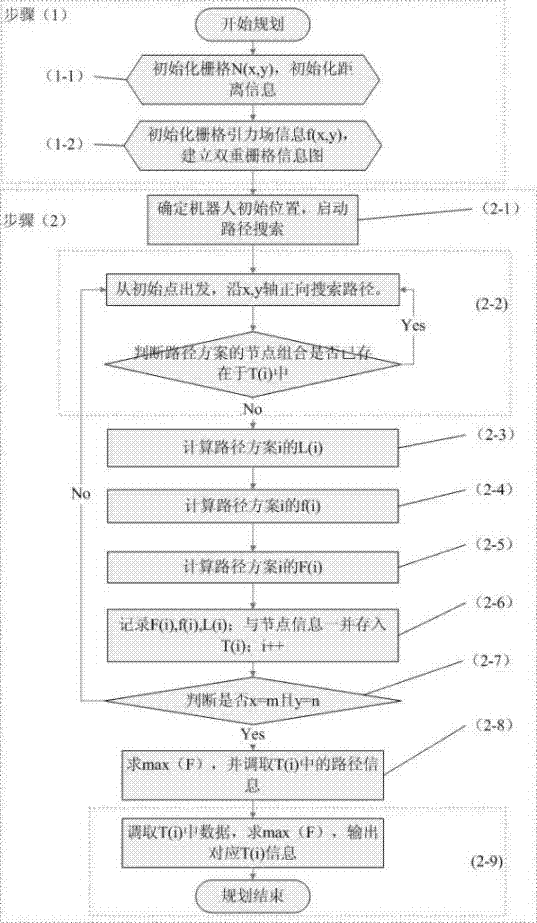

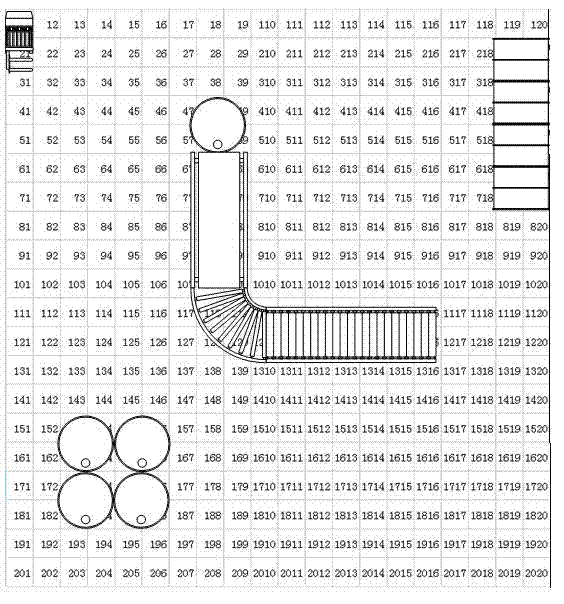

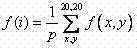

Physical modeling-based robot obstacle avoidance path planning method

InactiveCN102520718BImprove efficiencyOvercome the disadvantage of not considering geometric attributesPosition/course control in two dimensionsEngineeringObstacle avoidance

Owner:SHANGHAI UNIV

Anti-overflow mixing device for clothing dye proportioning

ActiveCN111992126APrevent splashReduce loadTransportation and packagingMixer accessoriesClothing dyeMaterials science

The invention relates to the technical field of dye mixing equipment, in particular to an anti-overflow mixing device for clothing dye proportioning. The device includes an equipment shell; an electric coil is fixedly connected to the interior of the equipment shell; a center shaft is inserted into the center of the interior of the equipment shell; an electric wire frame is sleeved outside the central shaft and inside the equipment shell; a wire is fixedly connected to the interior of the electric wire frame; and the lower end of the wire is fixedly connected with a connector. Speed control processing is carried out on the equipment; therefore, dyes in the equipment can be well prevented from splashing out, and the influence on the ratio of the pigment to the water, color difference of thedyed cloth and unnecessary dye loss are avoided, meanwhile, high-load work of the device is avoided, an extrusion plate extrudes an air bag on the right side, lubricating oil in the air bag is extruded out, a rotating shaft in the device is protected, and therefore the service life of the device can be well prolonged.

Owner:湖南亚瑞特运动用品有限公司

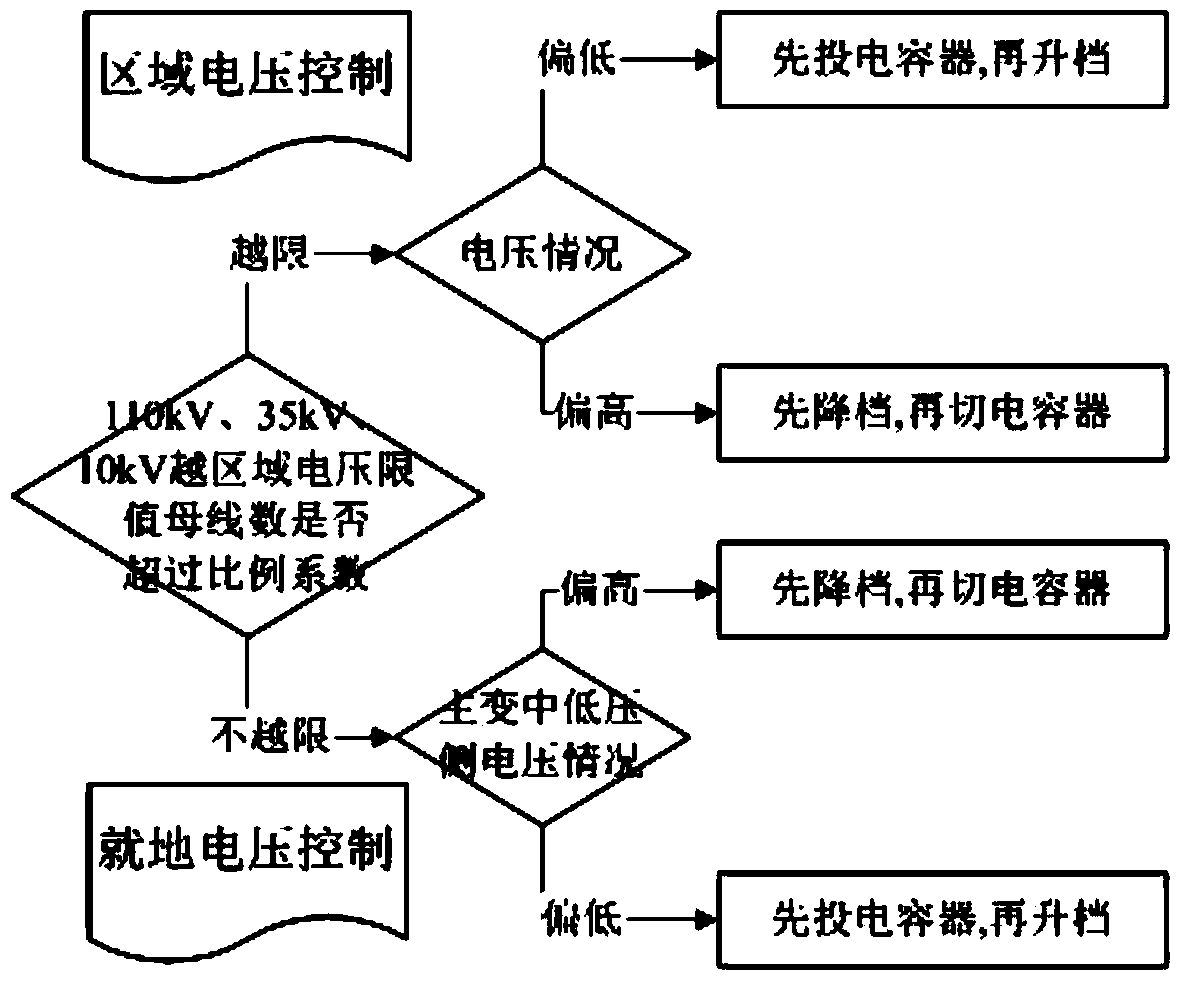

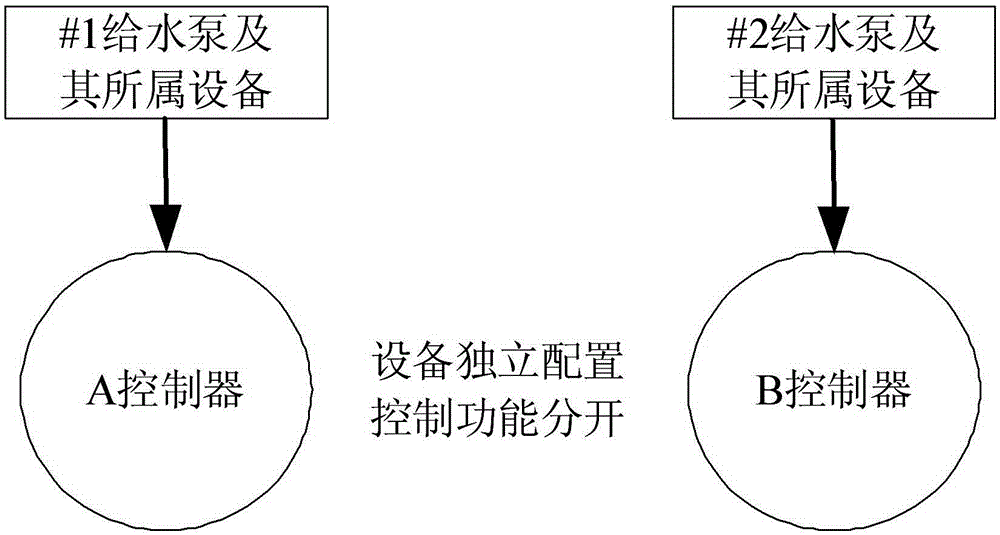

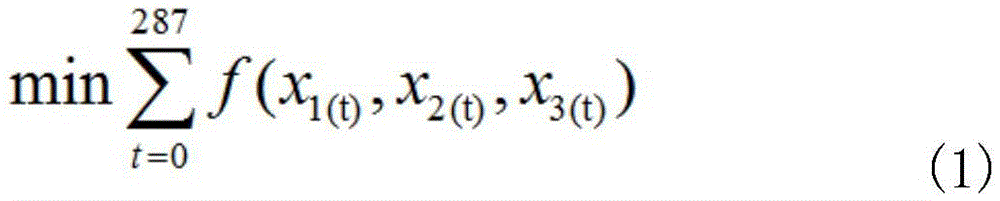

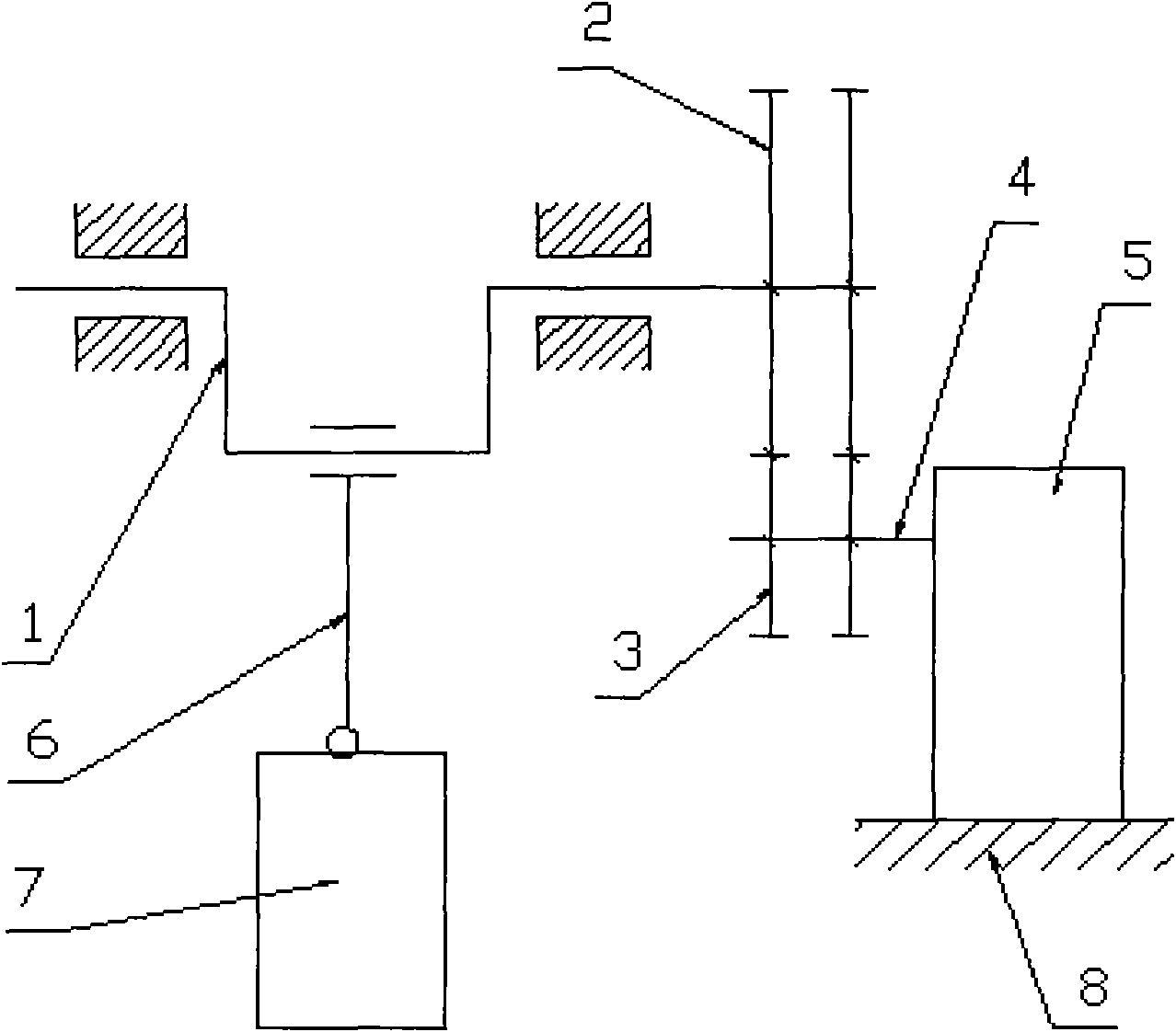

A kind of AVC control method of regional power grid

ActiveCN103812112BImprove voltage pass rateThe control strategy hasAc network voltage adjustmentReactive power compensationElectric power systemControl system

Owner:STATE GRID CORP OF CHINA +1

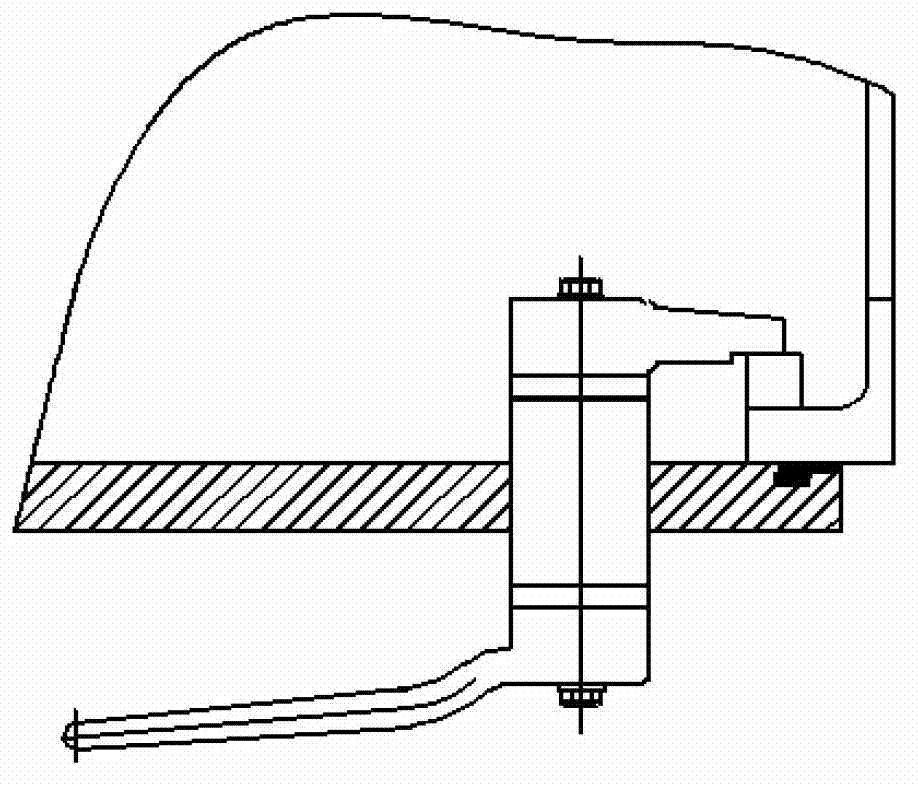

Crankshaft driving mechanism of press machine

InactiveCN101844409AAvoid damageReduce damage accidentsForging press drivesPress ramGear wheelEngineering

The invention relates to a crankshaft driving mechanism of a press machine. In the crankshaft driving mechanism, a duplex herringbone gear at a crankshaft end is correctly arranged on a crankshaft; a duplex herringbone gear at an output shaft end of a gear case is correctly arranged on the output shaft of the gear case; the gear case is arranged on a lathe bed of the press machine; and the duplex herringbone gear at the crankshaft end is ensured to be correctly engaged with the duplex herringbone gear at the output shaft end of the gear case. A connecting rod and the crankshaft are correctly arranged on the crankshaft driving mechanism; the connecting rod is correctly connected with a sliding block; and other delivery parts are correctly arranged on the crankshaft driving mechanism.

Owner:段巧荣

Method of Baking Newly Laid Ladle with Waste Heat of Steel Slag

The invention discloses a method of applying steel slag waste heat to bake a new-built ladle. The method comprises the steps that liquid state steel slag of a converter is splashed in the middle of a slag pond in a hot splashing way, and a certain amount of solidified red hot state steel slag after hot splashing is selected to be loaded into a slag tank; the red hot state steel slag is used for baking the ladle according to the baking curve of the ladle; the opening of the ladle is covered by a ladle cover, thermal energy is prevented from being lost, after baking for 8h, an infrared thermometry gun is used for measuring the baking temperature of a refractory matter, wherein the temperature of the refractory matter reaches 180+ / -50 DEG C, and new hot state slag is added to enter a next temperature baking phase; after baking for 16h, the baking temperature of the refractory matter in the ladle is measured to reach 300+ / -50 DEG C, the slag in the ladle is poured, the red hot state slag is added into the ladle to continue baking, the temperature is measured after 8h, if the temperature of the refractory matter in the ladle reaches 500+ / -50 DEG C, the slag in the ladle is poured, the ladle is sequentially baked to 900 DEG C by using fuel gas or fuel oil, and the ladle can be used according to a normal technology.

Owner:XINJIANG BAYI IRON & STEEL

A profile hot rolling finishing mill rolling piece position tracking device and tracking method

ActiveCN103499946BImprove location tracking accuracyReduce the number of manual interventionsNumerical controlFailure rateMan machine

The invention discloses a rolled piece position tracking device for a sectional material hot rolling finishing mill. The rolled piece position tracking device comprises a machine frame, a tracking region, a zero current sampling section, a tension adjustment section, a hot metal detector, a frequency converter, a man-machine interface local area network, a high-performance controller, a man-machine interface server and a local control panel, wherein the zero current sampling section and the tension adjustment section are arranged in the tracking region, and a rolled piece position tracking control module is arranged in the high-performance controller. A rolled piece position tracking method for a sectional material hot rolling finishing mill comprises the following steps that 1, the rolled piece position tracking control module is started; 2, the position of a rolled piece in the tracking region is calculated and is compared with the position values of the tension adjustment section and the zero current sampling section; 3, the rolled piece position tracking control module finishes the tracking procedure of the current tracking region according to cascade signals and steel occluding current change signals. The rolled piece position tracking device and the rolled piece position tracking method have the characteristics that the rolled piece tracking precision is high, the manual intervention is little, the yield of hot rolling sectional materials is high, the failure rate is low, and the labor cost is low. The rolled piece position tracking device and the rolled piece position tracking method can be widely applied to the technical field of sectional material hot rolling automation control.

Owner:通用电气(武汉)自动化有限公司

Mixed atomizer cooling protection system for entrained-flow reactor

ActiveCN101735858BGuaranteed continuous supplySupply is no longer limited by timeHydrogenGranular/pulverulent flues gasificationWater bathsEngineering

The invention discloses a mixed atomizer cooling protection system for an entrained-flow reactor. The cooling protection system comprises twelve subsystems such as a cooling water pump self-starting subsystem, a cooling water batch liquid level control subsystem, a cooling water header pressure indicating and alarming subsystem, an emergency cooling water bath protection subsystem, a mixed atomizer cooling water inlet flow protection subsystem, a mixed atomizer cooling water outlet flow indicating and alarming subsystem, a mixed atomizer cooling water outlet temperature indicating and alarming subsystem, etc. The mixed atomizer cooling protection system can effectively protect equipment of the mixed atomizer and the mixed atomizer cooling protection system, prolong the total service life of the mixed atomizer, improve the on-stream availability of the entrained-flow reactor, and ensure the safety of personnel and equipment.

Owner:XIAN ORIGIN CHEM TECH

A magnetic handle for assembling ferromagnetic precision workpieces

InactiveCN104900391BEasy and reliable extractionEasy and reliable installationInductances/transformers/magnets manufactureMetal-working hand toolsActuatorControl theory

The invention discloses a magnetic handle, which comprises two magnetic actuators and a rotation adjustment mechanism connected between the two magnetic actuators; the magnetic actuator includes a magnetic seat, a middle connecting plate, a bearing arm, an elastic positioning mechanism and handle; the upper end surface of the magnetic base is fixedly connected to the load-bearing arm through the intermediate connecting plate; a through hole is opened on the intermediate connecting plate, and an elastic positioning mechanism connecting the upper end surface of the magnetic force base is arranged in the through hole; one end of the bearing arm is connected to the handle On one side, the other side of the handle is provided with a connecting arm for connecting the rotating adjustment mechanism; the rotating adjusting mechanism includes a ratchet, a pawl, a rotating shaft and a spring, the ratchet is fixed on the connecting arm of a magnetic actuator, and the rotating end of the ratchet The connection arm of another magnetic actuator is connected through the rotating shaft, and the big end of the ratchet is connected with the handle of another magnetic actuator through a spring. The invention has the advantages of simple structure, convenient use, stability and reliability, and can realize non-scratch and non-stain assembly of precision ferromagnetic workpieces.

Owner:CHINA ELECTRIC POWER RES INST +1

Ground well casing capable of preventing mining damage

ActiveCN101915063BReduce damage accidentsWell drawnDrilling rodsDrilling casingsExpansion jointPetroleum engineering

The invention discloses a ground well casing capable of preventing mining damage, which comprises at least two casing bodies, a deflection joint and an expansion joint, adjacent casing bodies are connected by the deflection joint or the expansion joint, when in use, according to analysis results of strata displacement, the casing bodies are connected by the deflection joint in the depth corresponding to strata where the casing is easy to cut and twist, the casing bodies are connected by the expansion joint in the depth corresponding to strata where the casing is easy to pull and press, and the casing bodies are connected after the deflection joint and the expansion joint are connected in series in a small depth range corresponding to strata where the casing is easy to not only cut and twist but also pull and press, so that the casing can adapt to strata variation, thus reducing damage accidents of the well casing and guaranteeing smooth gas extraction through the ground well.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Overheated alarm for electrical equipment heating

InactiveCN102054332BReduce consumptionReduce power outagesVisible signalling systemsAlarmsHeat conductingElectrical devices

Owner:STATE GRID CORP OF CHINA +1

System for measuring outer surface temperature of metal shell of air-flow bed reactor

InactiveCN102042881BLow running costReduce maintenance costsThermometers using electric/magnetic elementsUsing electrical meansLower limitAcousto-optics

The invention discloses a system for measuring the outer surface temperature of a metal shell of an air-flow bed reactor. The system comprises an armored cable type thermocouple, a thermocouple compensating lead, a temperature display alarm instrument and the like. The system can effectively detect and display the outer surface temperature of the metal shell of the air-flow bed reactor in real time, sends an acousto-optic alarm signal when the outer surface temperature of the metal shell is lower than the lower limit of the normal temperature range or higher than the upper limit of the normaltemperature range so as to timely prompt operating personnel to take measures, and can effectively reduce the accident occurrence probability of the air-flow bed reactor and the labor intensity of the operating personnel, improve the operation safety and the operating rate of the air-flow bed reactor and guarantee the safety of the operating personnel and a gasification device. The system has thecharacteristics of simple structure, low cost, high alarm display accuracy and high reliability and is easy to industrialize and popularize.

Owner:THE NORTHWEST RES INST OF CHEM IND

A temperature-sensitive indicator nut

The invention discloses a temperature-sensing indicating nut, which comprises a base, a temperature-sensing element and an indicating column; the base is provided with a cylindrical accommodating groove with an open top; the inner wall of the accommodating groove is provided with a card slot, The indicating column is installed in the accommodating groove, and the outer wall of the indicating column is provided with a claw that cooperates with the slot; the indicating column is a hollow cylindrical structure with an open lower end and a closed top. The temperature sensing element is installed inside the indicating column. The invention is reasonable in design and simple in structure. It is installed at the place where the electric equipment needs to detect the temperature, and the temperature of the contact point of the transmission line can be monitored in real time by using the shape memory effect of the shape memory alloy. , Eliminate the hidden dangers of system operation and ensure the normal operation of system equipment.

Owner:兰州西脉科立新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com