Method of Baking Newly Laid Ladle with Waste Heat of Steel Slag

A ladle and slag technology, applied in metal processing equipment, manufacturing tools, casting melt containers, etc., can solve the problems of cracking of refractory materials, difficult to peel off, scrapping of ladle, etc., to reduce gas explosion and leakage, reduce collapse and Damage, significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Implementation of the present invention illustrates with specific embodiment:

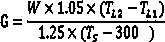

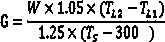

[0021] Taking a 3×120 ton converter production line as an example, the volume of the production line is 11m 3 The steel casting slag tank holds the converter liquid steel slag, and the converter steel slag is processed by the hot stuffy slag process. The weight of the newly built ladle refractory material is 58 tons, and the temperature before baking is 5°C.

[0022] 1) According to the normal process flow, use 11m 3 The steel casting slag tank holds the liquid steel slag of the converter;

[0023] 2) After filling the converter liquid steel slag, when the external temperature of the slag tank cast steel body reaches above 250°C, it can be measured with an infrared temperature measuring gun, command the crane to lift the slag tank, and pour the high-temperature steel slag in the slag tank into the slag pool , when the liquid steel slag is solidified;

[0024] 3) After the liquid steel sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com