Automatic pressing and packaging machine for aluminum sheets

An automatic, aluminum sheet technology, applied in the direction of packaging, rotating wrapping of items, etc., can solve the problems of time-consuming, labor-intensive, damage to the surface smoothness of the aluminum sheet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

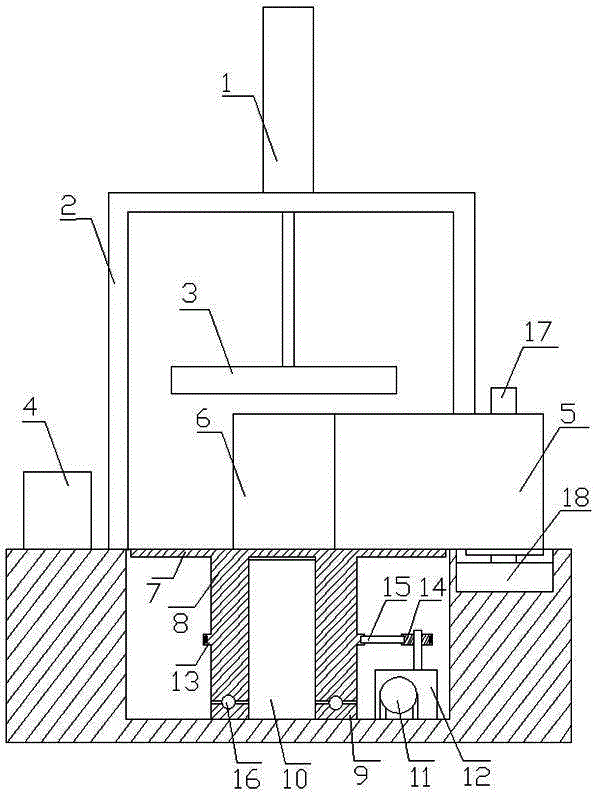

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

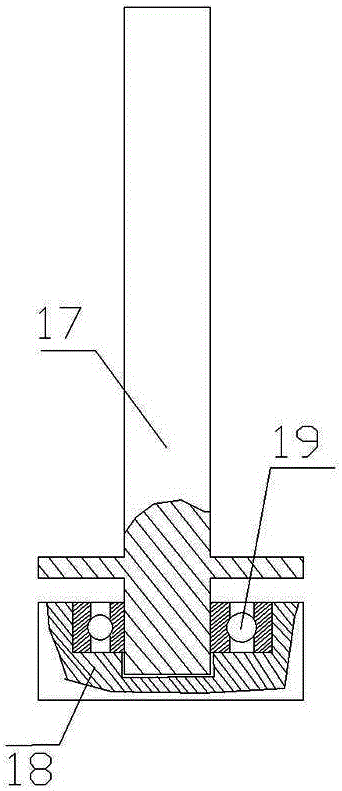

[0013] like Figure 1 to Figure 2 As shown, an aluminum sheet automatic compression packing machine is characterized in that: it includes a compression device, a rotating device, a film fixing device and a control box 4; the control box 4 controls the compression device and the rotation device; the compression device includes a cylinder 1 , cylinder frame 2 and pressure plate 3, cylinder frame 2 fixes cylinder 1, and cylinder 1 ejector rod fixes pressure plate 3; the rotating device includes turntable 7, swivel body 8, swivel body seat 9, top column 10, motor 11, reducer 12. The large pulley 13, the small pulley 14, the belt 15 and the elastic ball 16, the turntable 7 is located under the pressure plate 3, the turntable 7 is integrally connected with the swivel 8, and the swivel 8 rolls on the swivel seat 9 through the elastic ball 16 , the top colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com