High-temperature reactor inner wall corrosion damage prewarning method

A high-temperature reactor and inner wall corrosion technology, which is applied to furnaces, inspection devices, lighting and heating equipment, etc., can solve the problems of high cost of infrared thermal imaging cameras and inability to use high-temperature reactors, so as to reduce maintenance workload and reflect The effect of quickly and quickly solving online security monitoring problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

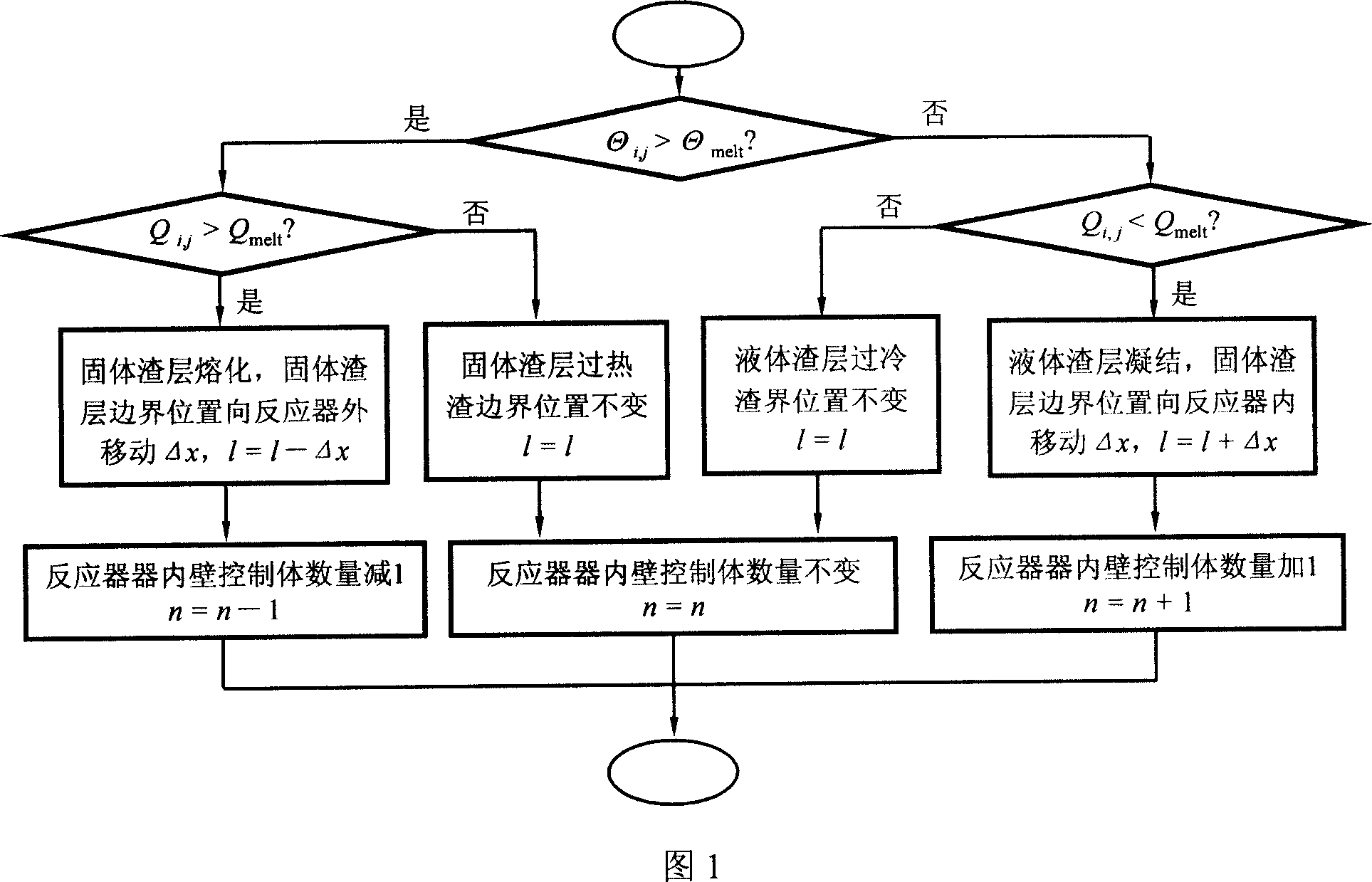

[0020] The high temperature reactor inner wall corrosion damage early warning method of the present invention comprises the following steps:

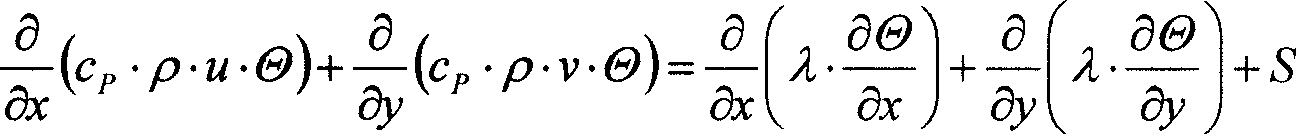

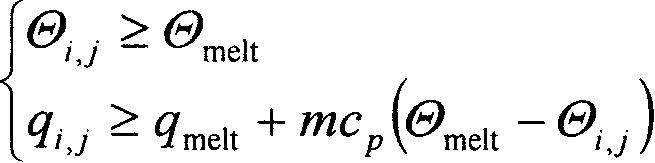

[0021] 1) According to the high-temperature medium in the reactor and the type of liquid mixture at the bottom of the reactor, the composition of reaction slag and matte, material composition and consumption, etc., the conversion of the phase composition of the material in the reactor and the inference of the average flue gas temperature in the reactor are completed. The conversion process of the phase composition of the material in the reactor is based on the assumed molecular composition of the material, and the corresponding phase composition of each material is reasonably calculated from the chemical element composition of the material. According to the principle of mass conservation and energy conservation, separate material balance calculation and energy balance calculation are carried out, that is, comply with:

[0022] All eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com